Open hole packer, acid fracturing tubular column and open hole acid fracturing method

A packer and open hole technology, which is used in sealing/packing, earth-moving drilling, wellbore/well components, etc., can solve the problems of high workover costs, limited treatment methods, and large workover workload in the later stage. Improve operation safety, improve work status, and ensure the effect of effective unsealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereby.

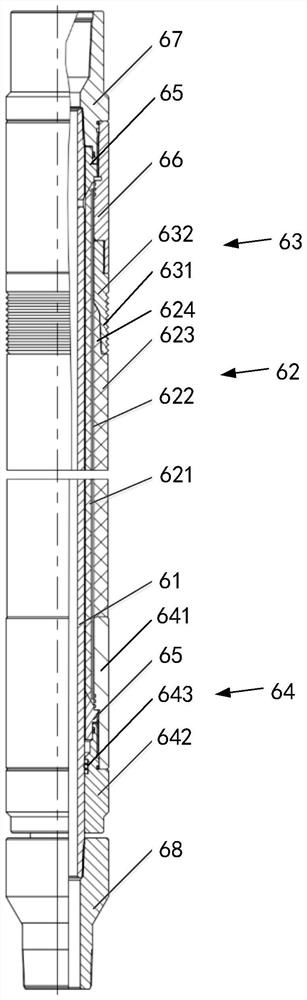

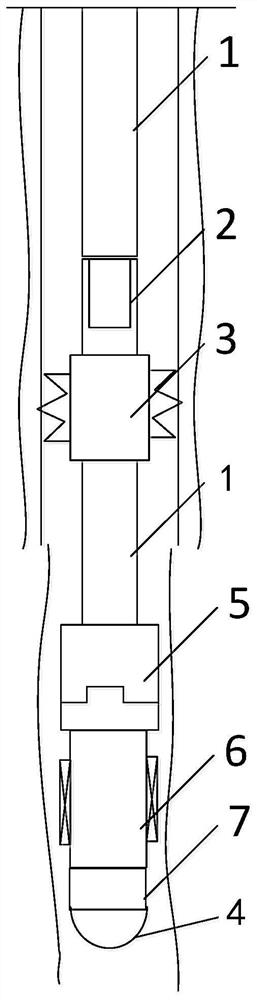

[0033] Such as figure 1 As shown, the open hole packer of this embodiment includes a central pipe 61 , a sealing rubber cylinder 62 , an anchoring component 63 and an unsealing component 64 . The sealing rubber cylinder 62 includes an inner rubber cylinder 621, a rigid support sleeve 622 and an outer rubber cylinder 623 which are sequentially connected from the inside to the outside, wherein the inner rubber cylinder 621 and the central tube 61 surround and form an injection annular space for the injection liquid to enter. The inner rubber sleeve 621 expands under the action of the injected liquid; the rigid support sleeve 622 is vulcanized and connected between the inner rubber sleeve 621 and the outer rubber sleeve 623 to improve the support strength and ancho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com