Deformed casing repairing device

A casing and core pipe technology, applied in the field of deformed casing repairing devices, can solve the problems of low repair efficiency, casing damage, long construction period, etc., so as to achieve the improvement of workover efficiency, reduction of repair cost, and controllable repair purpose. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

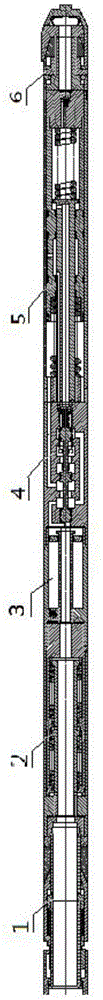

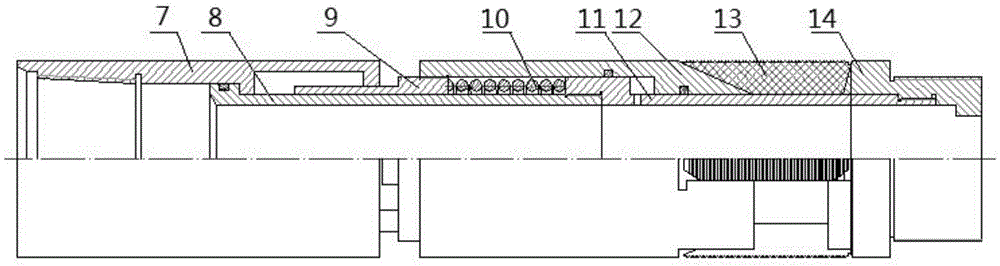

[0028] A kind of structure of deformed casing repairing device, see figure 1 , the repair device is composed of an anti-jamming hydraulic anchor 1, a travel booster 2, a hydraulic accumulator 3, an intelligent commutator 4, a hydraulic impactor 5 and a split pipe expansion head 6.

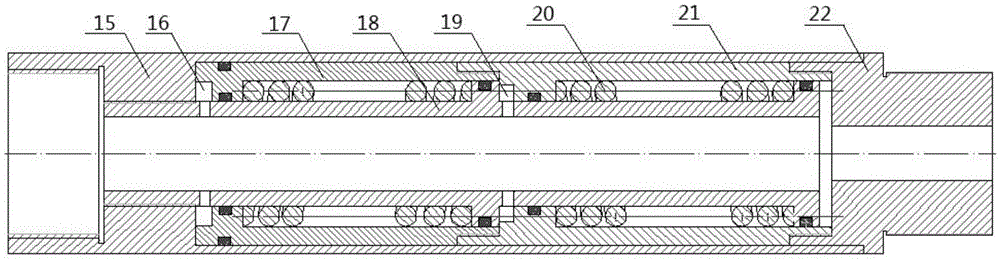

[0029]The first lower joint 14 of the anti-jamming hydraulic anchor 1 is seamlessly connected with the second upper joint 15 of the stroke booster 2, and the lower end of the stroke booster outer tube of the stroke booster 2 and the hydraulic energy storage of the hydraulic accumulator 3 The upper end of the external connecting pipe 26 is seamlessly connected, and the upper end of the hydraulic accumulator core tube 25 of the hydraulic accumulator 3 is seamlessly connected with the lower end of the stroke booster core tube of the stroke booster 2; the hydraulic en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com