Oil pipe online cleaning and flaw detection device

A technology of flaw detection device and cleaning device, which is applied in the direction of cleaning equipment, flushing wellbore, measurement, etc., can solve the problems of affecting the operation of connecting a single piece of tubing, high labor intensity, and many procedures, so as to improve the efficiency of workover operations and avoid surrounding Environmental pollution and the effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

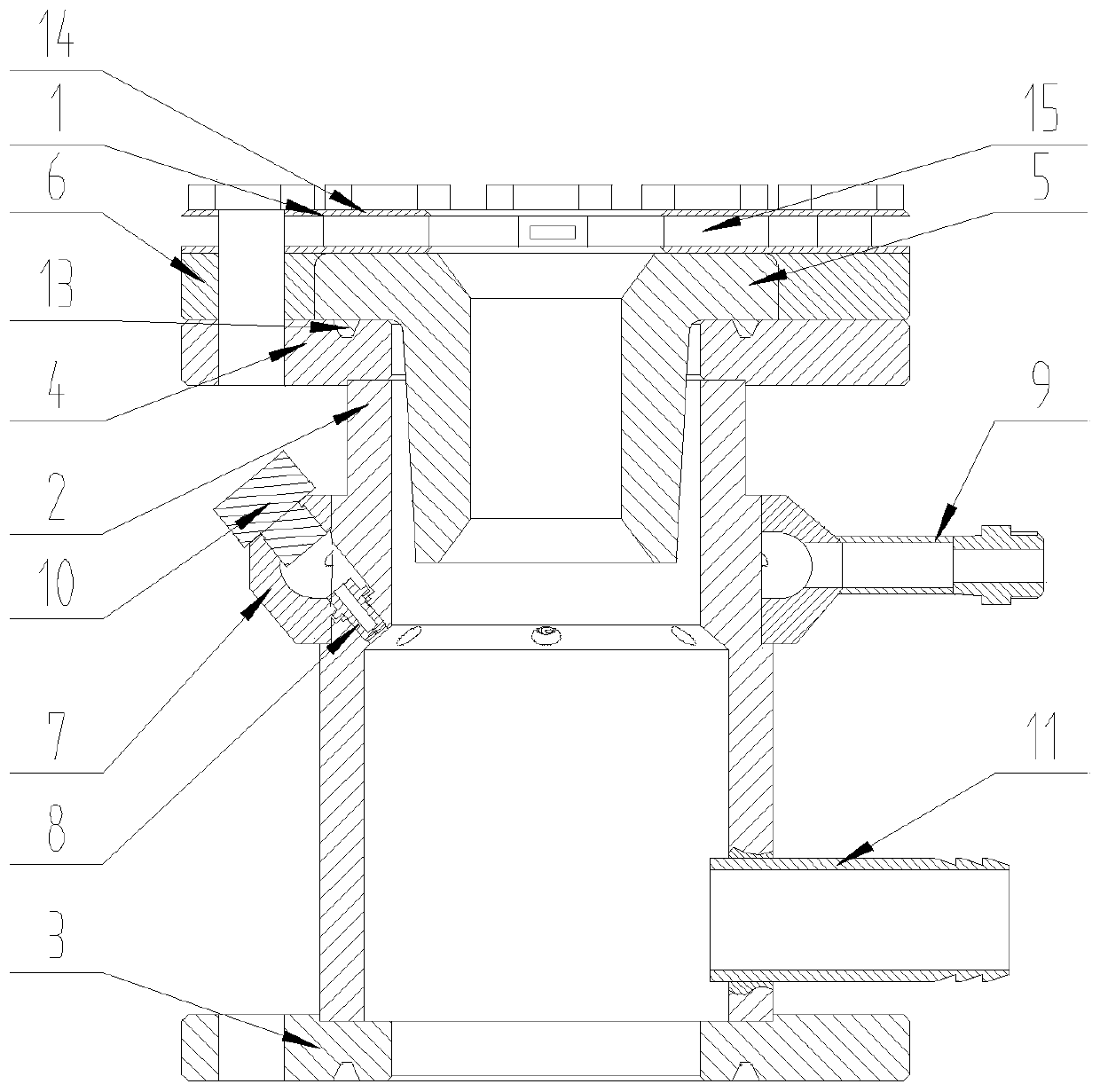

[0023] refer to Figure 1~2 , is a structural schematic diagram of Embodiment 1 of the present invention, an online cleaning flaw detection device for oil pipes, which is characterized in that it includes a probe 1, a lower flange 2, a housing 3, a cleaning device, an upper flange 4, and a self-sealing rubber core 5. The housing 3 is a cylindrical hollow structure, the upper flange 4 and the lower flange 2 are respectively fixed on the top and the bottom of the housing 3, and the upper flange 4 and the lower flange 2 are coaxial with the housing 3, so The cleaning device is fixed on the outer peripheral surface of the housing 3, the inner peripheral surface of the housing 3 is provided with a nozzle through hole communicating with the cleaning device, the execution end of the cleaning device is located in the nozzle through hole, and the top end of the upper flange 4 The gasket 6 is detachably connected, the self-sealing rubber core 5 is detachably connected between the gasket...

Embodiment 2

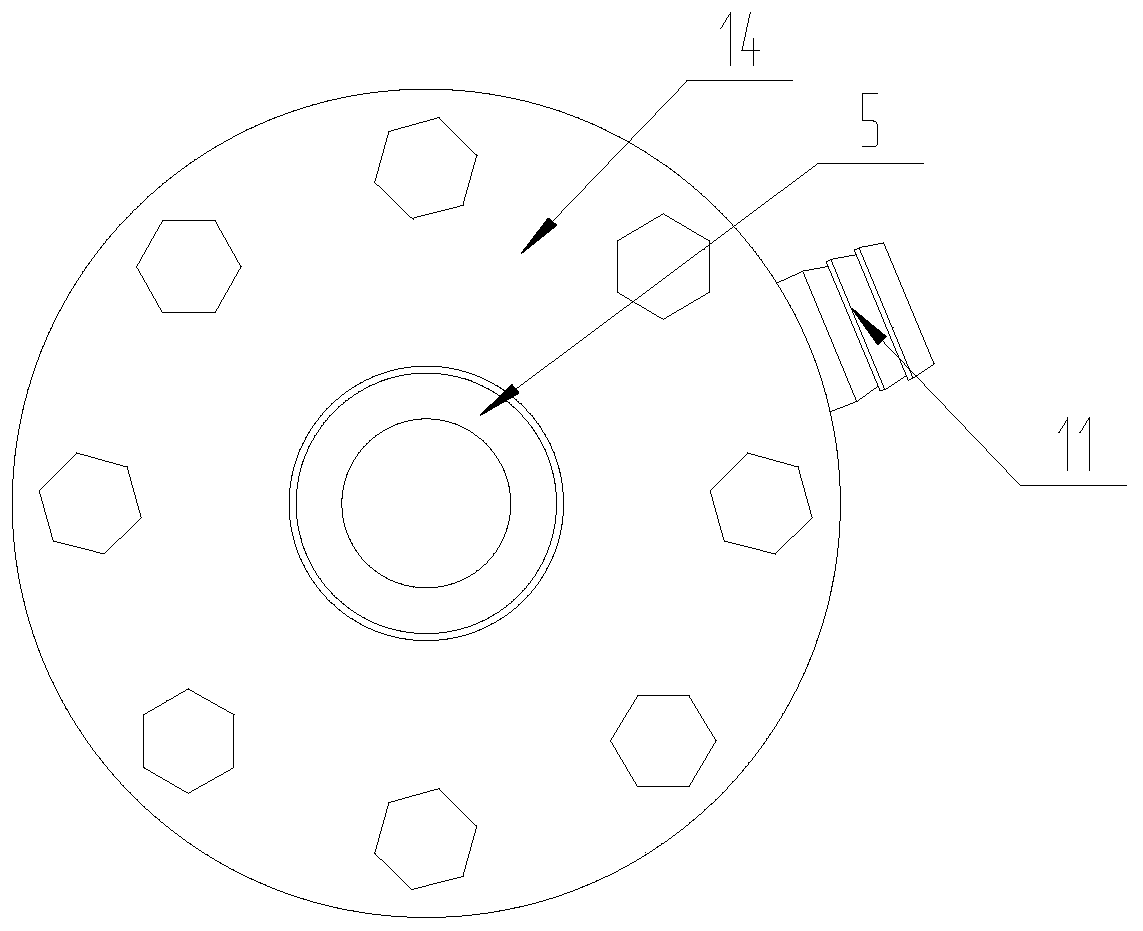

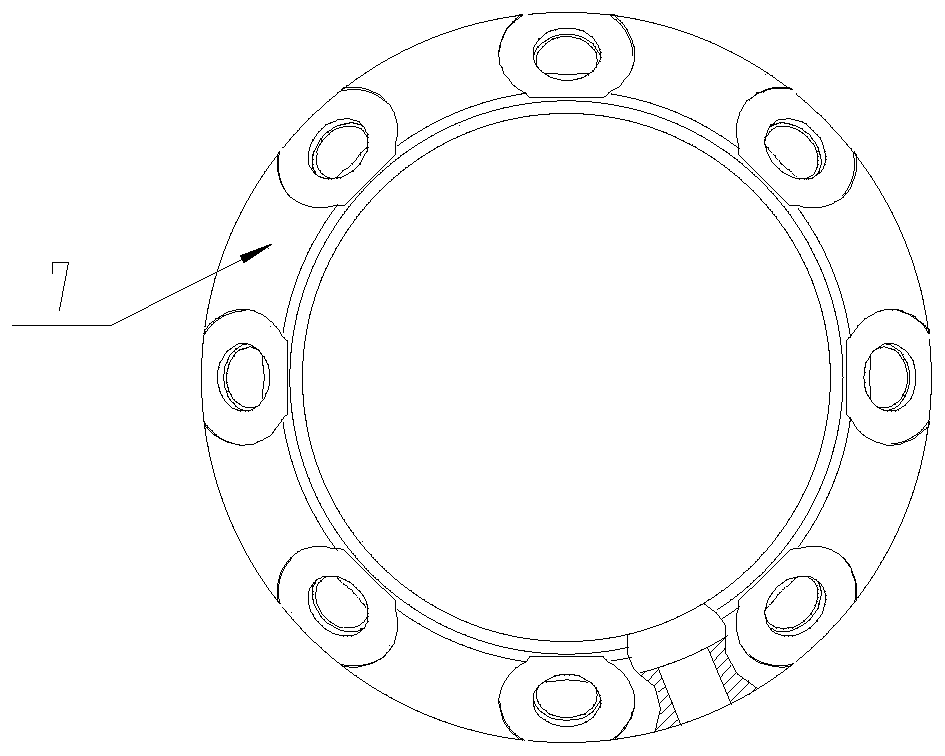

[0026] On the basis of embodiment 1, with reference to Figure 1-4 , the cleaning device is composed of a water channel 7, a nozzle 8 and a water inlet pipe 9, the water channel 7 is an annular hollow structure, and the inner peripheral surface of the water channel 7 has an opening, and the two sides of the opening of the inner peripheral surface of the water channel 7 are fixed on the shell The outer peripheral surface of the body 3, and the water channel 7 is horizontal to the upper flange 4, the nozzle 8 is detachably connected in the nozzle through hole of the housing 3, the outer peripheral surface of the water channel 7 is fixed with a water inlet pipe 9, and the water inlet pipe 9 It communicates with the waterway 7.

[0027] In actual use: first connect the water inlet pipe 9 to the water outlet of the water pump, then start the water pump, the water pump injects water into the water channel 7 through the water inlet pipe 9, and then sprays it out through the nozzle 9,...

Embodiment 3

[0029] On the basis of embodiment 2, with reference to figure 1 , there are at least two nozzle through holes, and the nozzle through holes are equidistantly located in the housing 3 , and each nozzle through hole can be detachably connected to a nozzle 8 , and the nozzle of the nozzle 8 is located in the inner cavity of the housing 3 .

[0030] In actual use: multiple nozzles 8 can clean the circumferential surface of the oil pipe at the same level without any gaps, so that the cleaning effect of the oil pipe is better and prominent. In this embodiment, 8 nozzles are used. Between the threaded connection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com