Petroleum workover operation robot

A technology for operating robots and well repairing, which is applied to manipulators, drilling equipment, earthwork drilling and production, etc. It can solve problems such as complex workflow, long time for lifting and unloading pipes, and large floor space, and achieves high automation, improved efficiency, and small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

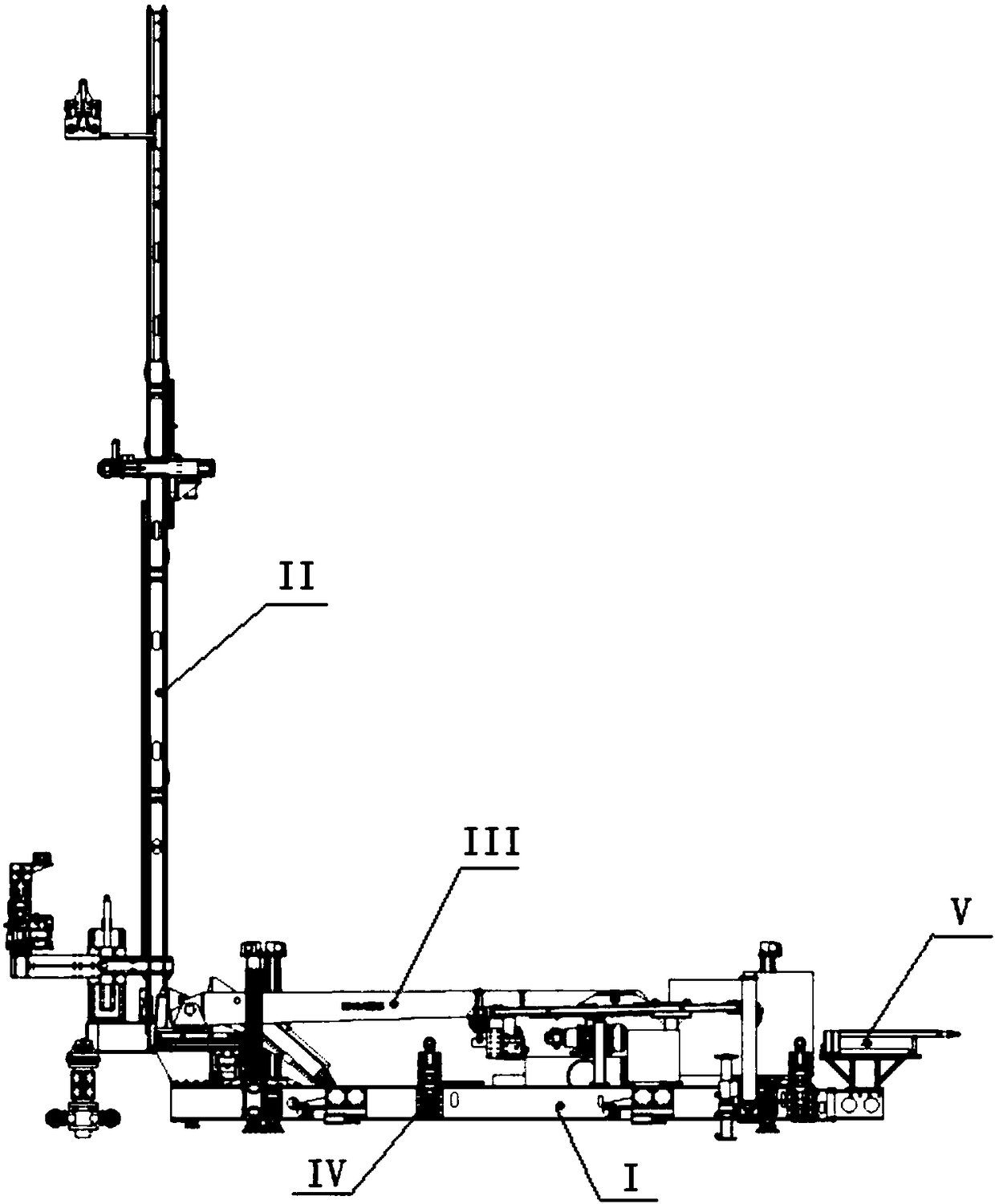

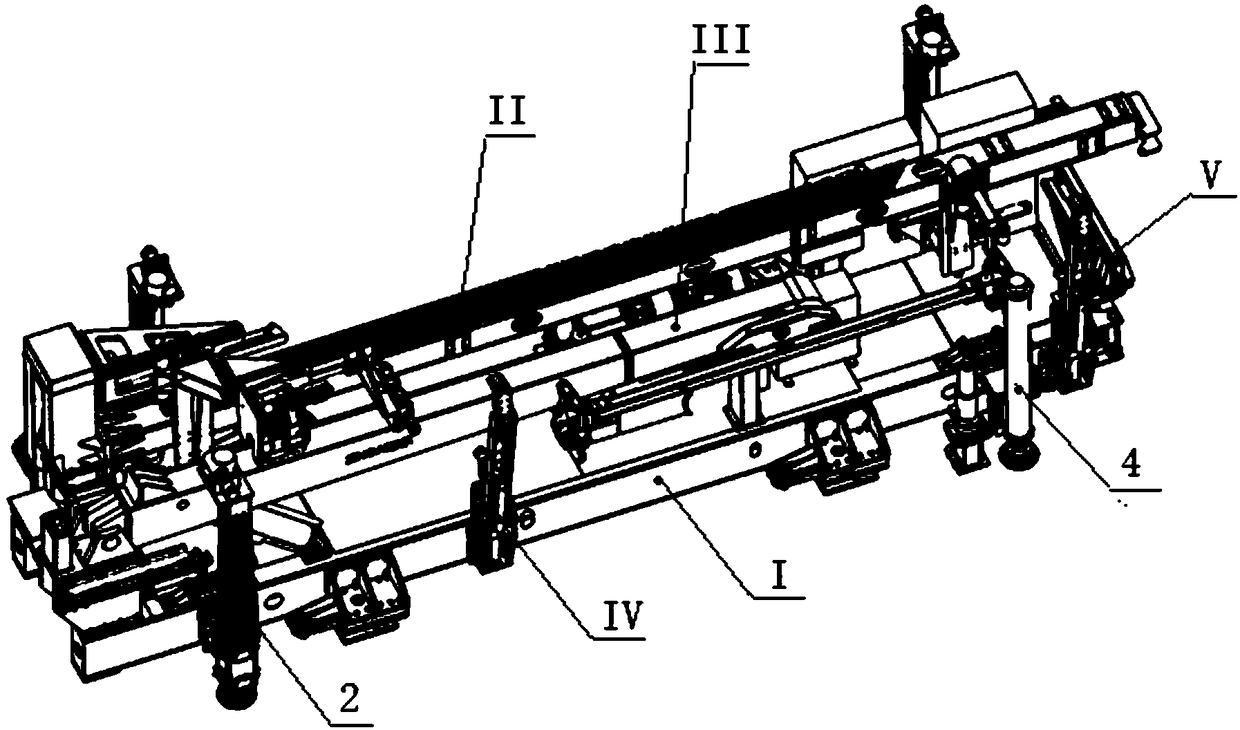

[0036] figure 1 Shown is the structural representation of the present invention.

[0037] The invention provides a petroleum workover operation robot, which includes a base device I, a guiding device II, a boom device III, a swing seat transmission device IV, a length measuring device V and a hydraulic control system.

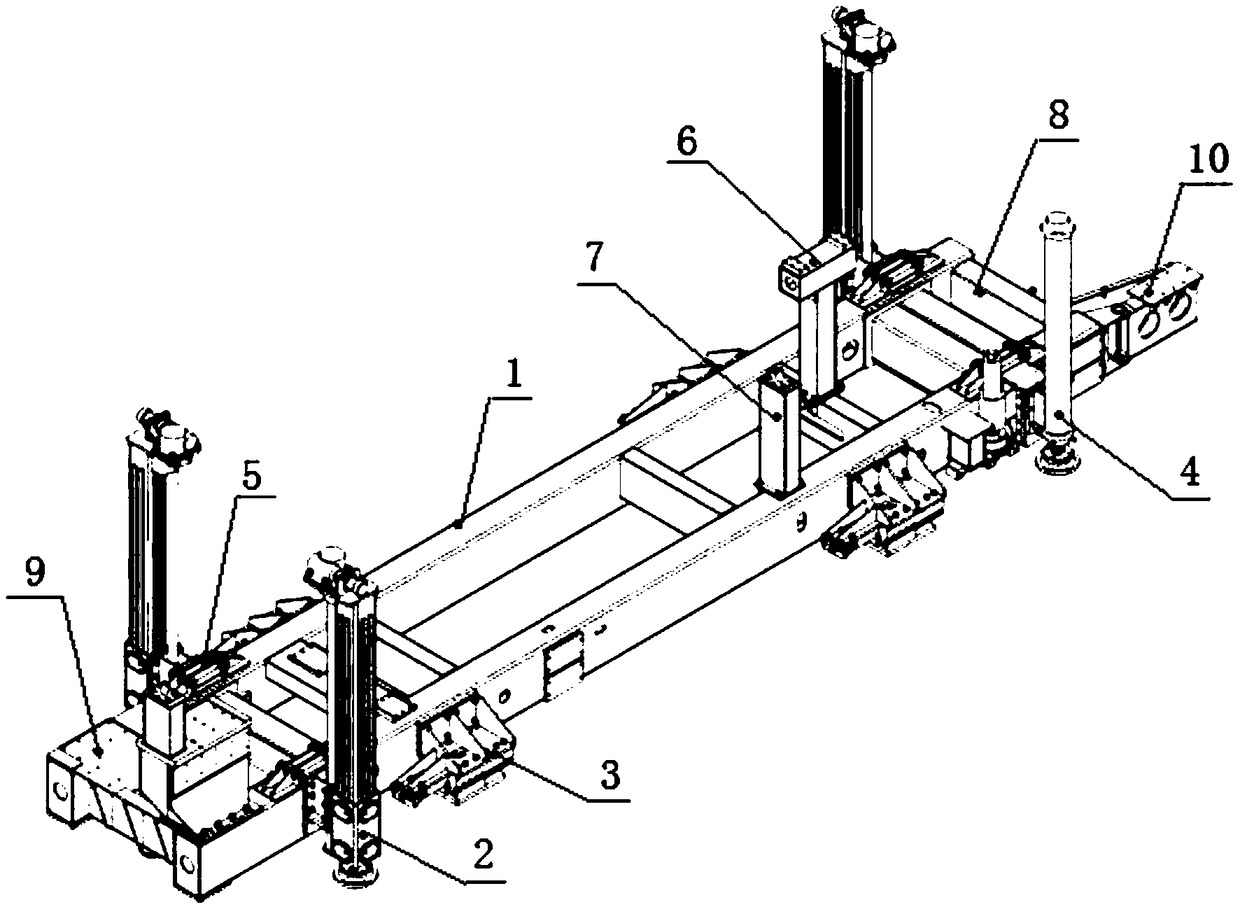

[0038] image 3 Shown is a schematic structural view of the base device of the present invention.

[0039] The base device 1 includes a base 1, a hydraulic support leg 2, a walking mechanism 3, a rotating hydraulic support leg 4, a large arm mounting seat 5, a guiding support 6, a large arm support 7, a supporting rotating disk 8, and a guiding device installation base. Seat 9 and length measuring device mounting bracket 10, base 1 is a rectangular frame structure, a boom mounting seat 5 and a boom support 7 are arranged at the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com