Intelligent large hook for mechanical workover operation

An intelligent, hook-body technology, applied in the field of hooks, can solve the problems of biting fingers, affecting the overall efficiency of mechanized workover operations, and high labor intensity, achieving the effects of preventing falling off, simple structure, and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

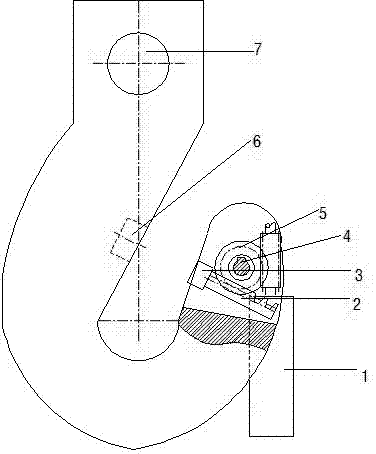

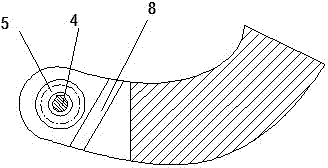

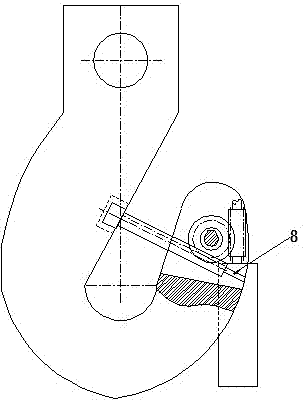

[0019] Further explanation is made below with reference to accompanying drawing:

[0020] Such as Figure 1-4 As shown, a smart hook for mechanized workover operation, the smart hook is connected with the traveling block of the ordinary workover rig through the pin shaft 7, a motor 1 is installed at the end of the smart hook, and a worm is installed on the output shaft of the motor, and the worm drives the worm gear 5 makes a circular motion, the worm wheel 5 is connected to the end of the smart hook through the mandrel 4, the rack 2 is installed under the worm wheel 5, and a rack movement track groove 8 is opened under the side of the worm wheel 5, and the rack movement track groove 8 forms a certain angle with the horizontal direction, and there are pin shafts on both sides of the rack 2, and the rack 2 is limited in the slot 8 of the rack movement track through the pin shafts on both sides, so that the rack 2 moves along the rack under the action of the worm wheel 5. The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com