Under-pressure well repairing working device and method of oil-gas field

A kind of operating device and oil and gas field technology, which is applied in the direction of wellbore/well valve device, earthwork drilling and production, wellbore/well components, etc., which can solve the problems of lowering the pressure level, having to shut down the well for maintenance, and low safety factor, so as to reduce the Pressure level, reducing workover energy consumption, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

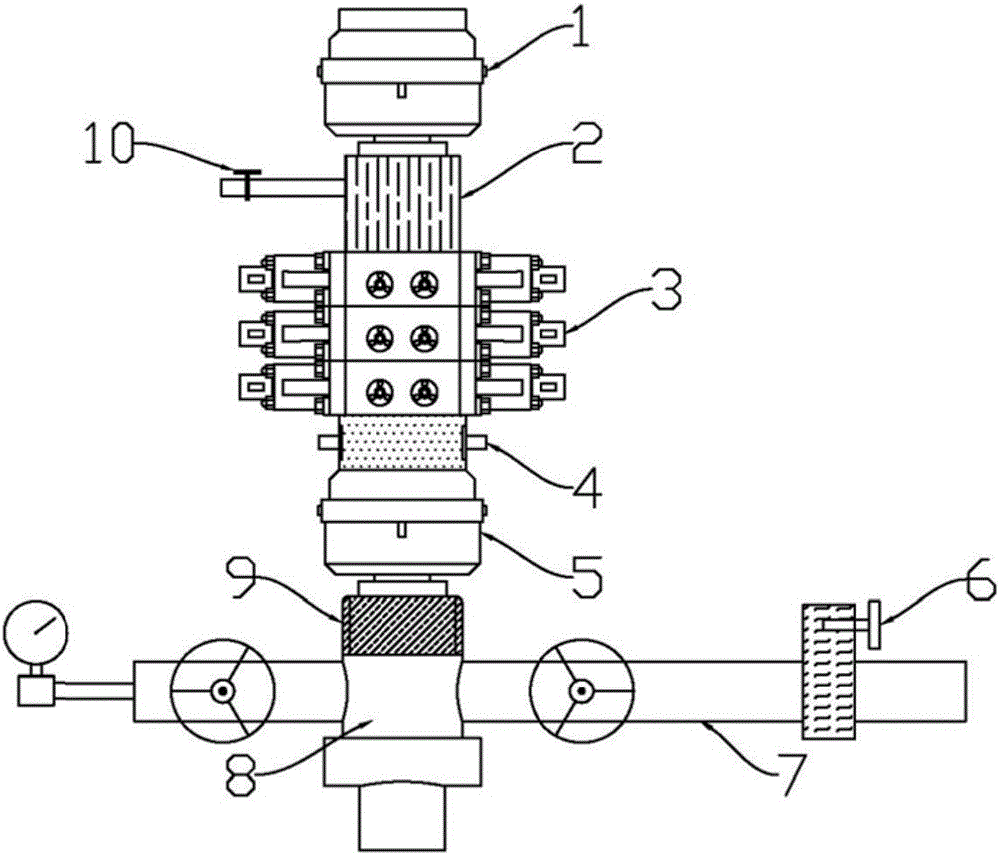

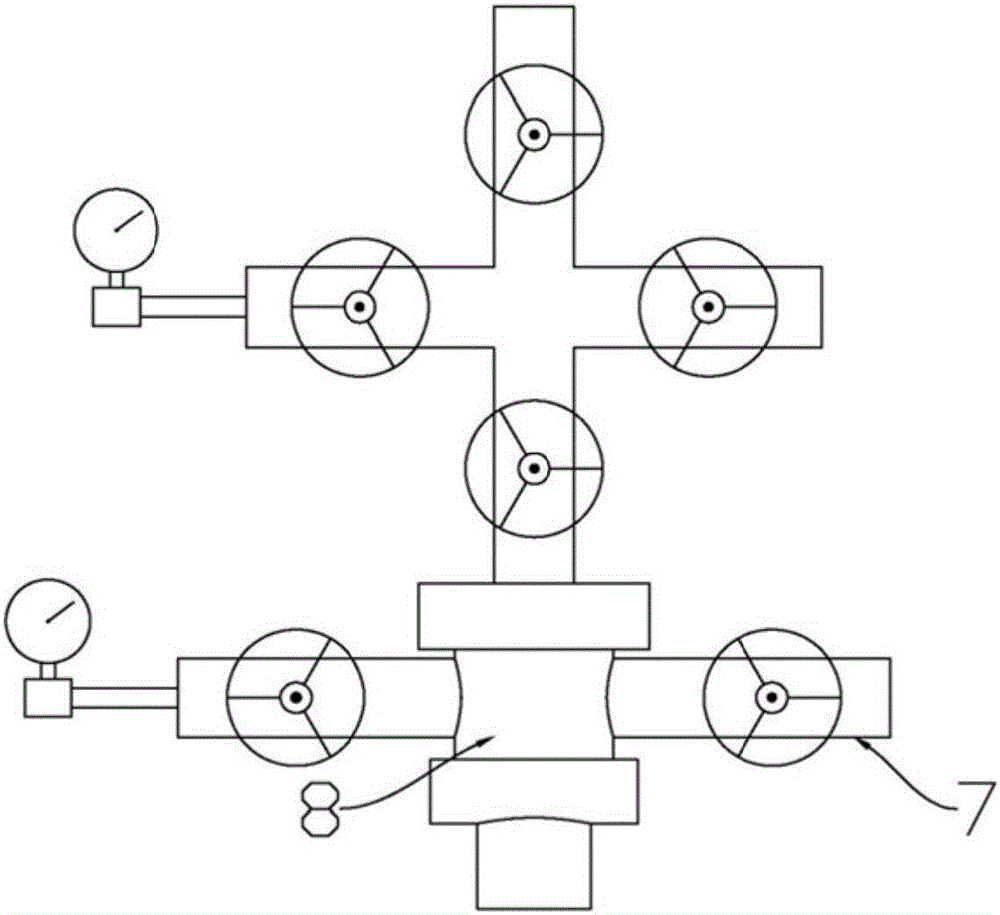

[0049] like figure 1 As shown, the present invention discloses a pressurized workover operation device for oil and gas fields, including a constant pressure valve 6 installed on the original production pipeline 7 of the station, and the pressure setting value of the constant pressure valve 6 is within the original production pipeline 7 of the station. pressure. During the workover process, when the pressure in the well is higher than this pressure, the oil, gas and water will be sent into the production pipeline 7 by the automatic pressure relief of the constant pressure valve 6 . The upper part of the four-way 8 is sequentially installed with a coupling detector 9, a lower annular blowout preventer 5, a built-in hydraulic elevator 4, a three-ram blowout preventer 3, a casing nipple 2, and an upper annular blowout preventer 1. The upper annular blowout preventer 1 and the lower annular blowout preventer 5 all have a rubber inner core, and the upper annular blowout preventer 1...

Embodiment 2

[0080] This embodiment is a workover operation under pressure in the case of a gas lift production string. The method is similar to the method in Example 1. Install a constant pressure valve 6 on the pipeline entering the station or into the gathering and transportation system, and set the original entering station pressure as the working pressure of the constant pressure valve 6. When the wellbore pressure exceeds this pressure, the pressure will be automatically released into the gathering and transportation system.

[0081] S1, the steps of starting the tube:

[0082] S11, install the constant pressure valve 6 on the inbound pipeline, install the blowout prevention standpipe on the uppermost gate, open each gate in turn so that the tool can pass through the gate and the wellhead device and go down the oil pipe to the upper part of the first gas lift valve; wire work Plug the oil pipe plug under the equipment to the upper part of the first gas lift valve, and block the uppe...

Embodiment 3

[0094] This implementation is somewhat similar to the second embodiment, the difference is that in this embodiment, a gas lift string with a smaller diameter is lowered into the original production string.

[0095] S1, remove the devices above the main gate of the oil and gas production tree, and install the small cross, the lower annular BOP 5, the three-ram BOP 3, the casing nipple 2, and the upper annular BOP 1 above the main gate in sequence , Oil pipe injection head; connect the constant pressure valve to the incoming pipeline and set the original incoming pressure as the working pressure of the constant pressure valve;

[0096] S2. Use the injection head to lower the gas lift string with liner plug. When the weight of the tubing can overcome the upward force and sealing friction resistance generated by the pressure in the well on the sealing part of the tubing, use the workover rig to lower the tubing and tools. A special check valve is arranged on the upper part of each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com