Hydraulic hoisting device for replacing pipe column and wellhead part and method thereof

A technology of hydraulic lifting device and wellhead device, which is applied in wellbore/well components, earthwork drilling and other directions, can solve the problems of lagging production efficiency, needing many personnel, and low work efficiency, shortening the construction period, improving economic benefits, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

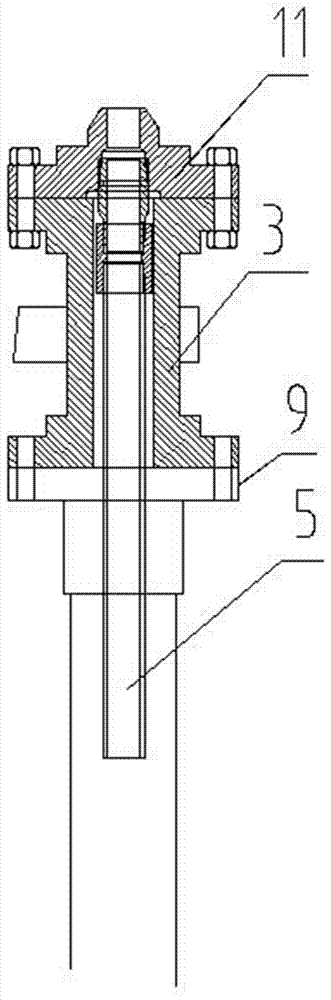

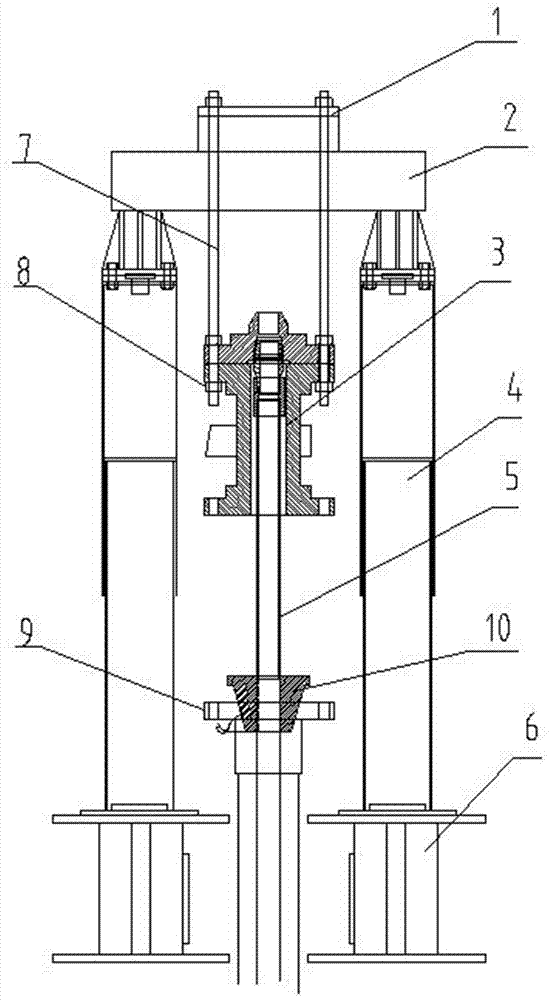

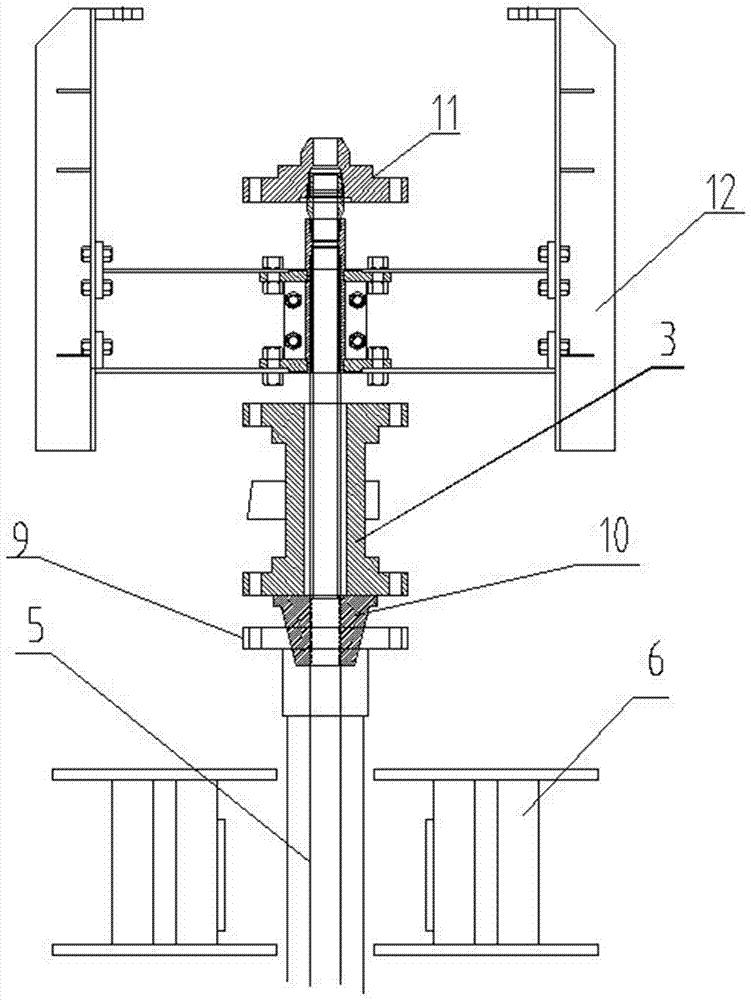

[0059] The invention proposes a hydraulic lifting device for replacing pipe strings and wellhead parts. Through the cooperation of the lifting system, the connecting mechanism and the pipe string locking device, the replacement of the wellhead can be completed without removing the entire pipe string in the well. , the time-consuming for replacement is only within 25% of the prior art. Greatly improve work efficiency, such as Figure 2-Figure 6 As shown, the following arrangement structure is adopted in particular: a lifting system and a connecting mechanism are provided, and the lifting system is connected with the wellhead device 3 to be replaced through the connecting mechanism; A string locking device 10 for locking the column 5.

[0060] When in use, when the existing wellhead (such as figure 1 When replacing the wellhead device 3 to be replaced as shown), the lifting system is arranged above the existing wellhead, and the lifting system is connected with the wellhead de...

Embodiment 2

[0062] This embodiment is further optimized on the basis of the above-mentioned embodiments, further to better realize the present invention, such as Figure 2-Figure 6 As shown, the following arrangement structure is adopted in particular: the lifting system includes a door-shaped lifting device and a pipe string lifting device 1, and the pipe string lifting device 1 is arranged on the top of the door-shaped lifting device; the door-shaped lifting device It includes two lifters 4, two support bases 6 and a lifting beam 2, and the two lifters 4 are respectively arranged on the two support bases 6, the lifting beam 2 is overlapped on the two lifters 4, and the pipe string is lifted The device 1 is arranged on the top of the lifting beam 2, and the pipe string lifting device 1 is connected with the wellhead device 3 to be replaced through a connecting mechanism.

[0063] When setting and using, a supporting base 6 is respectively set at a suitable position on both sides of the e...

Embodiment 3

[0065] This embodiment is further optimized on the basis of any of the above embodiments, further to better realize the present invention, such as Figure 2-Figure 6 As shown, the following arrangement structure is adopted in particular: the lifter 4 adopts a hydraulic lifter, and the lifter 4 is detachably arranged on the support base 6, and the lifting beam 2 is detachably arranged on the lifter 4. When setting, the lifting The lifter 4 adopts a hydraulic lifter, and the lifter 4 is detachably arranged on the support base 6, so as to facilitate the separation and adjustment of the lifter 4 and the support base 6, and also to facilitate the transfer; the support base 6 is preferably detachably arranged on the Replacement of the existing wellhead; the lifting beam 2 is also installed on the top of the two lifters 4 in a detachable manner, so that the lifter 4, the support seat 6 and the lifting beam 2 just form a gate-shaped structure, so that the effective While ensuring the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com