Operation driving device of oil-electricity hybrid power workover rig

A technology of hybrid electric drive and driving device, which is applied in the direction of electromechanical devices, electric components, machines/engines, etc., and can solve problems such as cumbersome operation, serious noise, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

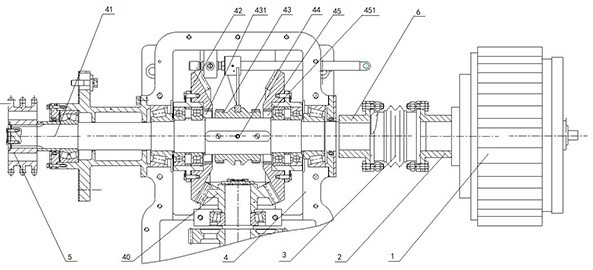

[0012] refer to figure 1 , a kind of oil-electric hybrid workover rig driving device, comprising a permanent magnet synchronous motor 1 and an angle transmission box 4, a sprocket 5 is arranged at the power output end of the power shaft 41 of the angle transmission box 4, and the power shaft 41 It is rotationally connected with bevel teeth I 43 and bevel teeth II 45, and is fixedly connected with the reversing shift fork 44 in the radial direction. Connected, engaged with the bevel gear III 40, the input flange 6 is set at the power input end of the power shaft 41 of the angle transmission box 4, and the input flange 6 is connected with the coupling 3, the output flange 2 and the permanent magnet in turn. The synchronous motor 1 is fixedly connected. When performing workover operations, the vehicle-mounted power system drives the workover rig to the exact position on the well site, operates the transfer case to switch the chassis travel branch to the drive operation drum branc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com