Coal carbonization technology

A technology of coal dry distillation and process, applied in the field of coal dry distillation process, can solve the problem that the cold flue gas is not fully utilized, achieve high dry distillation efficiency, and improve the effect of dry distillation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

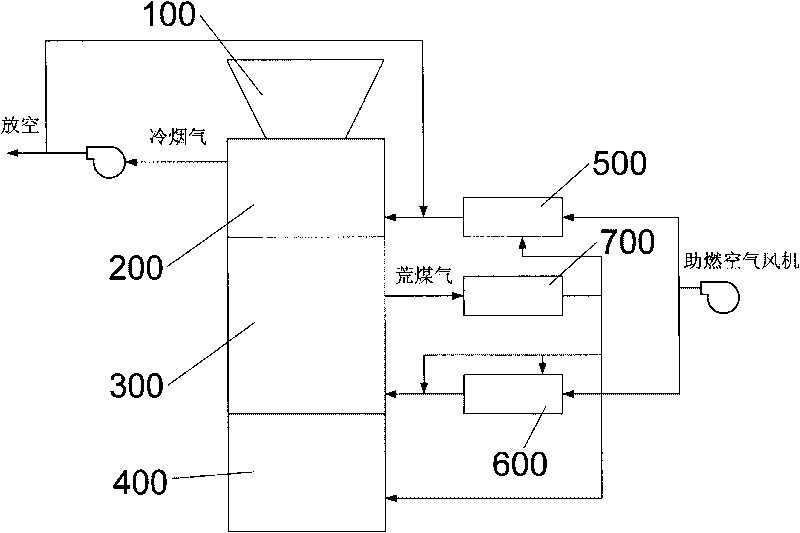

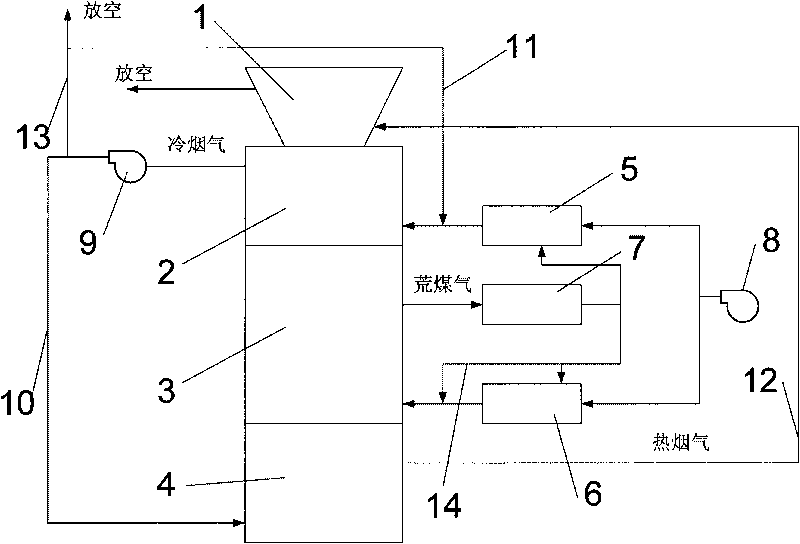

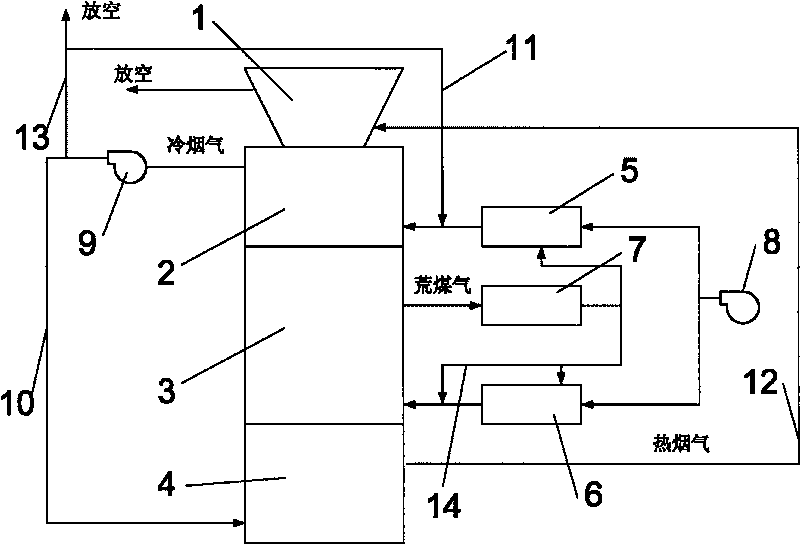

[0032] figure 2 Shows a specific implementation of the coal carbonization process of the present invention, an external combustion internal heating coal carbonization furnace applying the coal carbonization process of the present invention, which is sequentially from top to bottom: preheating section 1, drying section 2 , dry distillation section 3 and cooling section 4. The preheating section is arranged above the drying section, communicates with the drying section, and is used for preheating the raw coal; the drying section is used for drying the raw coal and obtaining cold flue gas at the same time; The dry distillation section 3 is used to carry out dry distillation treatment on the dried raw coal, which forms semi-coke after the dry distillation treatment; the cooling section 4 is used to cool the semi-coke produced therein by introducing the cold flue gas. Cooling treatment is carried out, and hot flue gas is obtained at the same time. The coal pyrolysis furnace is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com