A method for controlling the retort of brewing and distillation process by using images

A technology of image pairing and process, applied in the direction of sequence/logic controller program control, electrical program control, etc., can solve the problems of increasing wine making cost, unrealized continuous mechanization, and unsatisfactory effect, so as to improve the efficiency of retort and the effect of wine yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings.

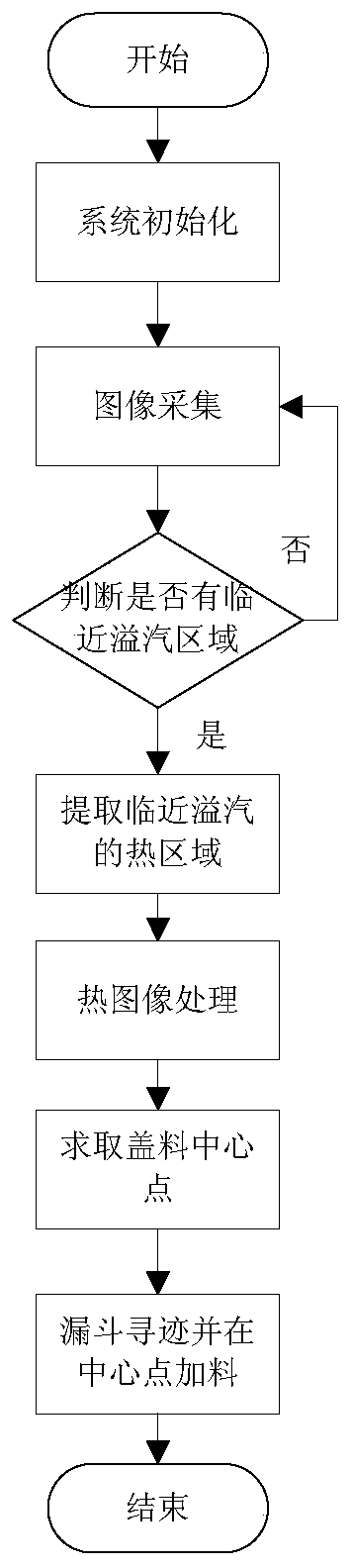

[0037] Such as figure 1 As shown, a method for controlling the retort of brewing distillation process by using image comprises the following steps:

[0038] Step 1: System initialization, which is used to self-check the system to determine whether the system is working normally;

[0039] Step 2: Image collection, the invisible infrared radiation energy distribution pattern on the surface of the screening material is reflected on the photosensitive element of the infrared detector through the infrared detector of the infrared thermal imager and the optical imaging objective lens to obtain an infrared thermal image;

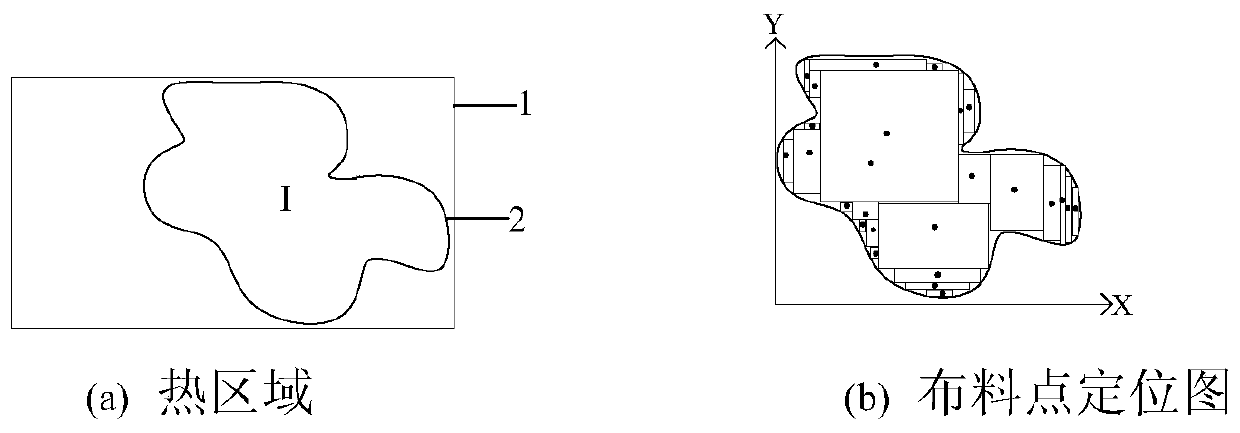

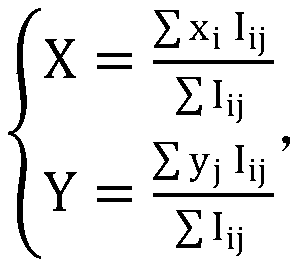

[0040] Step 3: Enter the cyclic test of the infrared thermal image; set the surface temperature VT of the raw material in the retort, the threshold temperature Vt, and the coefficient α 1 and alpha 2 , 01 2 1 VT,α 2 VT] interval, it shows that the surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com