Coal low temperature dry distillation method

A low-temperature, dry distillation technology, applied in the field of coal dry distillation, can solve the problems of high energy consumption and difficult processing, and achieve the effects of improving dry distillation efficiency, reducing the amount of fine powder and preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

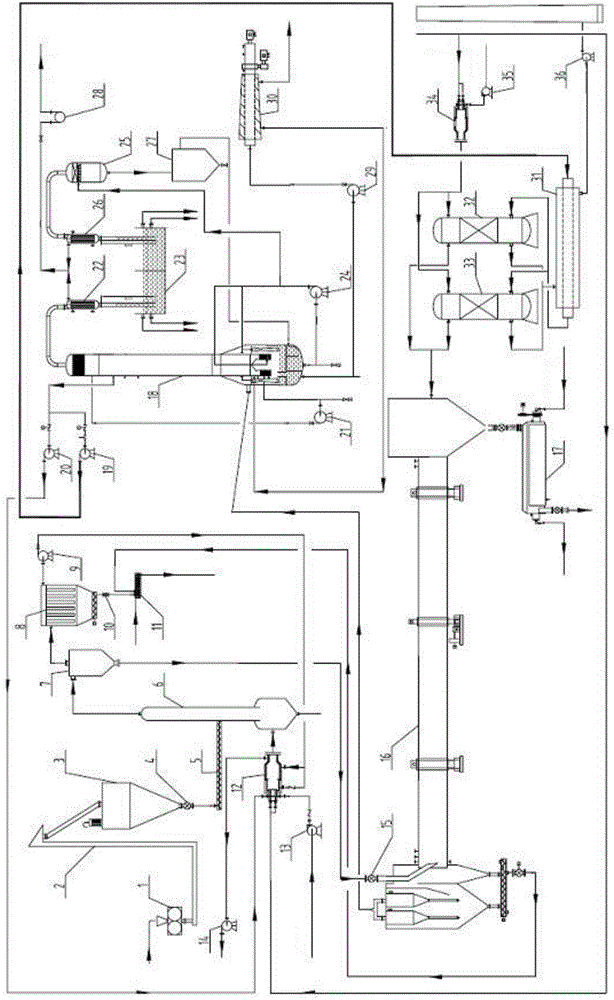

[0027] Specific Embodiment 1: In this embodiment, the coal low-temperature carbonization method includes a coal preparation unit, a carbonization unit, a carbonization tail gas recovery unit, and a carbonization heat source generation unit. The coal low-temperature carbonization method is as follows:

[0028] 1. Coal preparation unit:

[0029] The coal is crushed into coal powder with a particle size of less than 10mm, and sent to the airflow dryer 6, and the coal powder enters the classifier 7 along with the hot flue gas for particle size classification, so that the coal powder larger than 0.5mm after classification is sent through the rotary valve 15. Enter the retort furnace 16, the coal powder with particle size less than 0.5mm enters the bag type dust collector 8 for dust removal along with the dry tail gas, and the heat source required by the airflow dryer 6 is provided by the incinerator 12;

[0030] 2. Dry distillation unit:

[0031] In step 1, the pulverized coal sen...

specific Embodiment approach 2

[0036] Specific embodiment two: the difference between this embodiment and specific embodiment one is that a part of the tail gas after the bag filter 8 dedusts in step one is sent into the chimney by the induced draft fan 14 through the incinerator 12, and a part is sent back to incineration by the circulating fan 9 The hot flue gas outlet of the furnace 12 is used as dry mixed temperature air, and the dust collected by the bag filter 8 is merged by the dust collector conveyor and sent to the mixing humidifier 11 through the rotary valve 10 for processing. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0037] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the retort furnace 16 in step 1 is a lined internal heat rotary cylinder furnace. Others are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com