Gas guide system and method

A technology of air guide and air guide device, applied in the field of air guide system, can solve the problems of too dense coal seam, large gas resistance, uneven distribution of air, etc., and achieve the effects of reducing resistance, uniform air distribution, and reducing dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

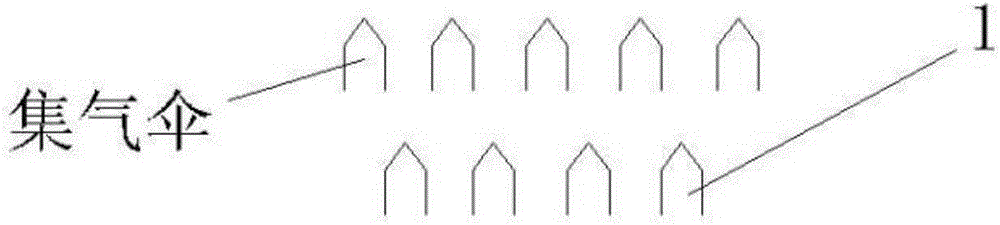

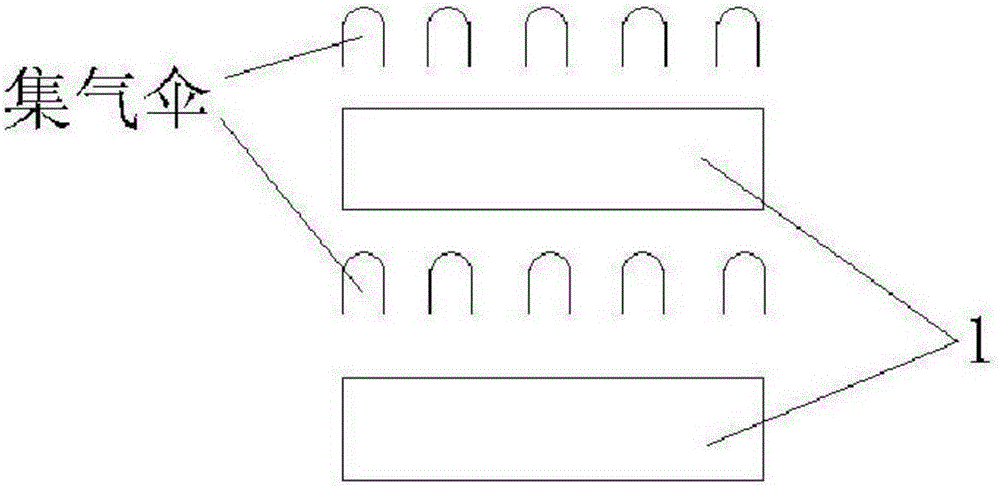

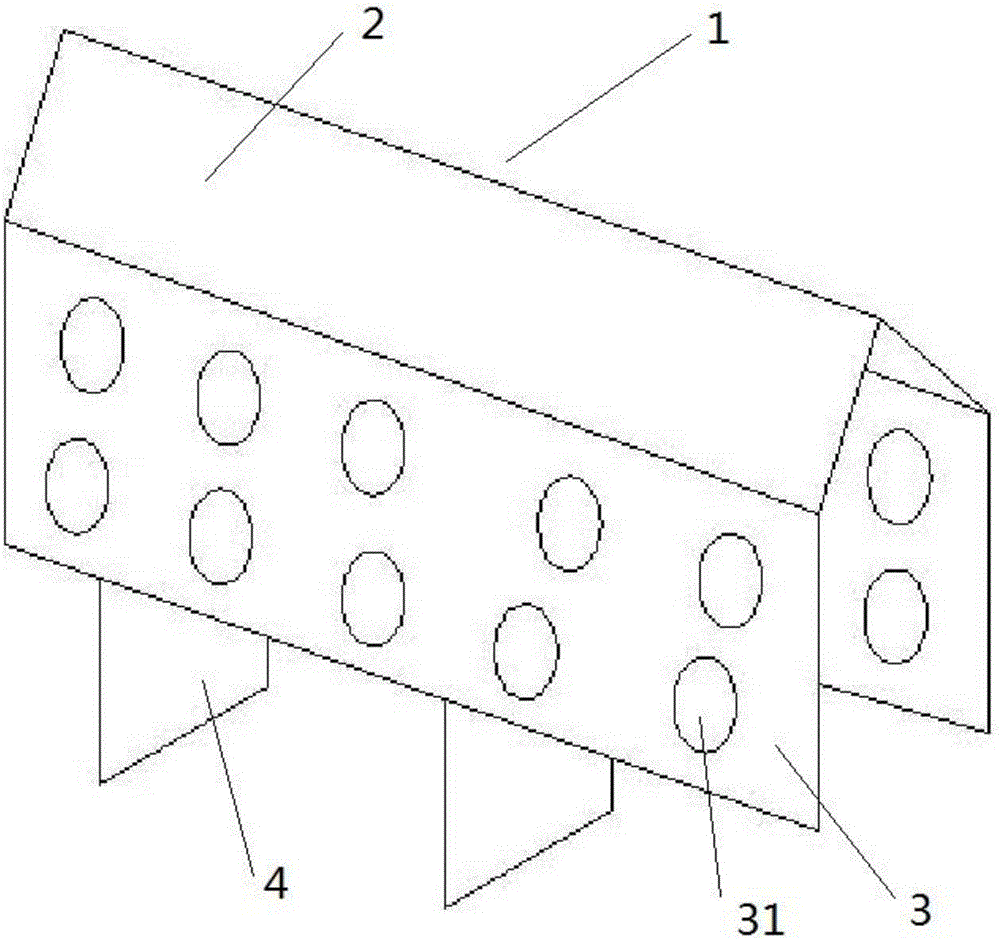

[0028] Such as figure 2 As shown, the gas guiding device 1 is only arranged on one horizontal plane; the gas guiding device 1 is arranged under the gas collecting umbrella in the semi-coke low-temperature carbonization furnace. The air collecting umbrella and the air guiding device 1 are arranged parallel to each other. The top 2 of the device is in the shape of an inverted "V".

[0029] The present invention comprises the following steps when in use:

[0030] (1) When the semi-coke low-temperature carbonization furnace is in use, the raw coal enters the carbonization section after entering, and finally falls on the gas guiding device 1; due to the shape of the top 1 of the gas guiding device 1, the raw coal is more evenly dispersed and falls on the carbonization inside the furnace.

[0031] (2) When starting dry distillation, the air is passed in from the outside of the semi-coke low-temperature dry distillation furnace, enters by the gas injection port 31 of the air guid...

Embodiment 2

[0035] The gas guiding device 1 is only arranged on one horizontal plane; the gas guiding device 1 is arranged under the gas collecting umbrella in the semi-coke low-temperature carbonization furnace. The air collecting umbrella and the air guiding device 1 are arranged parallel to each other. The top 2 of the device is circular.

[0036] The present invention comprises the following steps when in use:

[0037] (1) When the semi-coke low-temperature carbonization furnace is in use, the raw coal enters the carbonization section after entering, and finally falls on the gas guiding device 1; due to the shape of the top 1 of the gas guiding device 1, the raw coal is more evenly dispersed and falls on the carbonization furnace;

[0038] (2) When starting dry distillation, the air is passed in from the outside of the semi-coke low-temperature dry distillation furnace, enters by the gas injection port 31 of the air guide device 1, and is ejected from between the two connecting baff...

Embodiment 3

[0042] The gas guiding device 1 is only arranged on one horizontal plane; the gas guiding device 1 is arranged under the gas collecting umbrella in the semi-coke low-temperature carbonization furnace. The air-collecting umbrella and the air-guiding device 1 are arranged perpendicularly to each other. The top 2 of the device is circular.

[0043] The present invention comprises the following steps when in use:

[0044] (1) When the semi-coke low-temperature carbonization furnace is in use, the raw coal enters the carbonization section after entering, and finally falls on the gas guiding device 1; due to the shape of the top 1 of the gas guiding device 1, the raw coal is more evenly dispersed and falls on the carbonization furnace;

[0045] (2) When starting dry distillation, the air is passed in from the outside of the semi-coke low-temperature dry distillation furnace, enters by the gas injection port 31 of the air guide device 1, and is ejected from between the two connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com