Patents

Literature

73results about How to "Disposal method is environmentally friendly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing method of cold plasma modified cellulolytic enzyme lignin/plant fiber composite material

ActiveCN101712179AHigh strengthImprove controllabilityWood working apparatusDomestic articlesFiberDry weight

The invention discloses a manufacturing method of a cold plasma modified cellulolytic enzyme lignin / plant fiber composite material. The manufacturing method comprises the following steps of: firstly dehydrating and drying the cellulolytic enzyme lignin to be with a moisture content of 6-10 percent; after processing the cellulolytic enzyme lignin into pulverulent bodies with grain diameters of 200-300 mesh by high-energy ball-milling, placing the pulverulent bodies into a sample chamber of cold plasma modified equipment; vacuumizing the sample chamber to 2-4 Pa; introducing oxygen or nitrogen; controlling a vacuum degree to be 10-30 Pa; starting a radio frequency power supply and adjusting treating power to 100-300 W; modifying the cellulolytic enzyme lignin for 30-150 s; uniformly mixing the modified cellulolytic enzyme lignin with the plant fiber, wherein the oven dry weight of the modified cellulolytic enzyme lignin accounts for 5-25 percent of the oven dry weight of the plant fiber; and spreading the mixed modified cellulolytic enzyme lignin and the plant fiber in a plate blank form for thermo-compression, wherein thermo-compression temperature is 160-210 DEG C, and thermo-compression pressure is 3.0-4.0 MPa, and thermo-compression time is 20-40 s / mm. The material contains no free formaldehyde, and can be widely applied to industries, such as architectural decoration, furniture manufacturing, packaging, children toy manufacturing, and the like.

Owner:NANJING FORESTRY UNIV

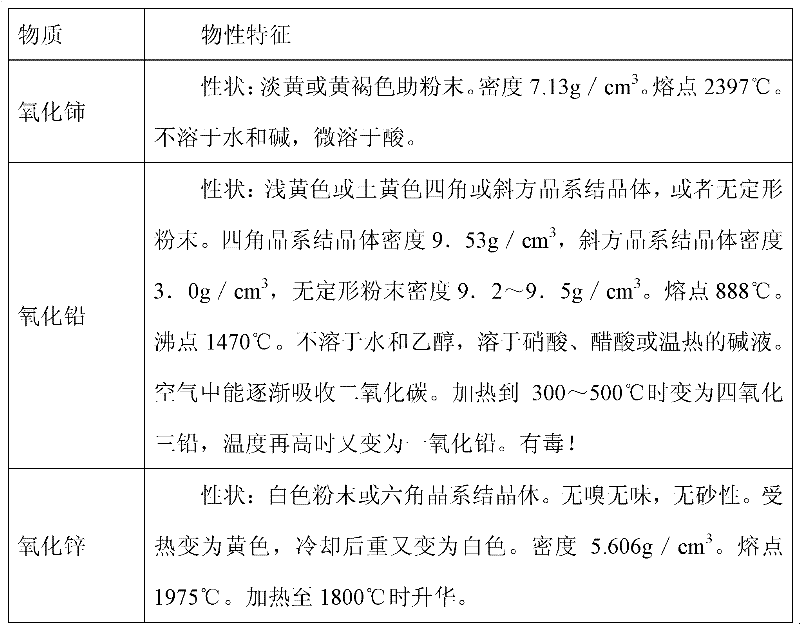

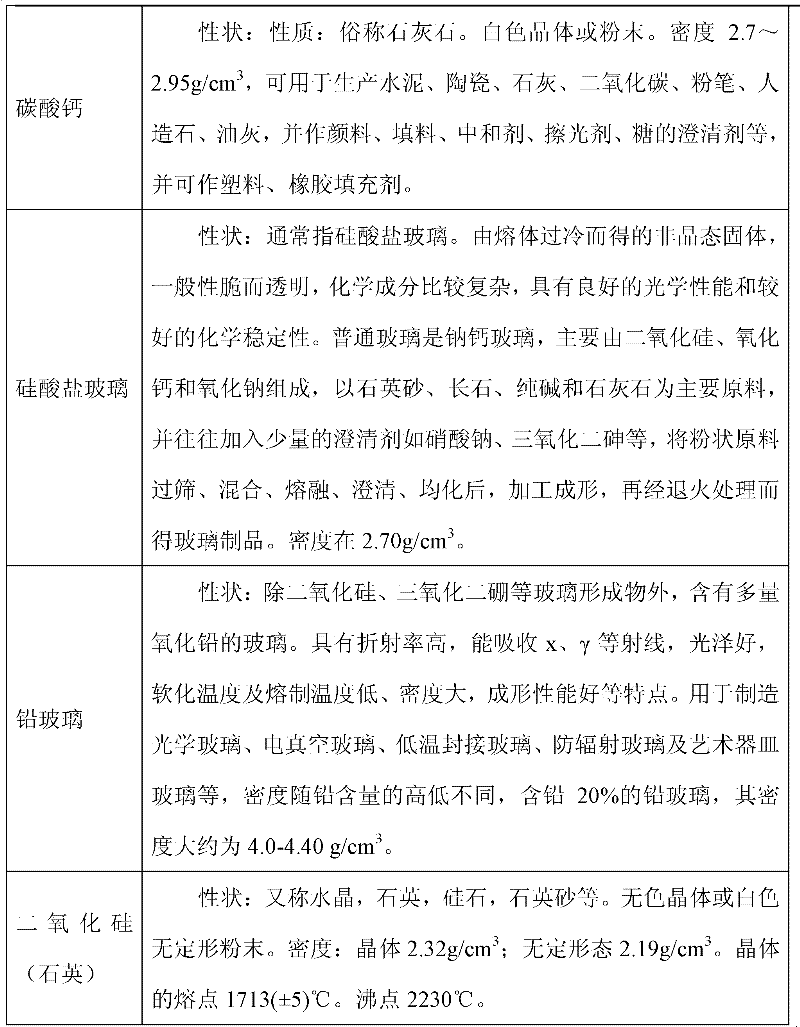

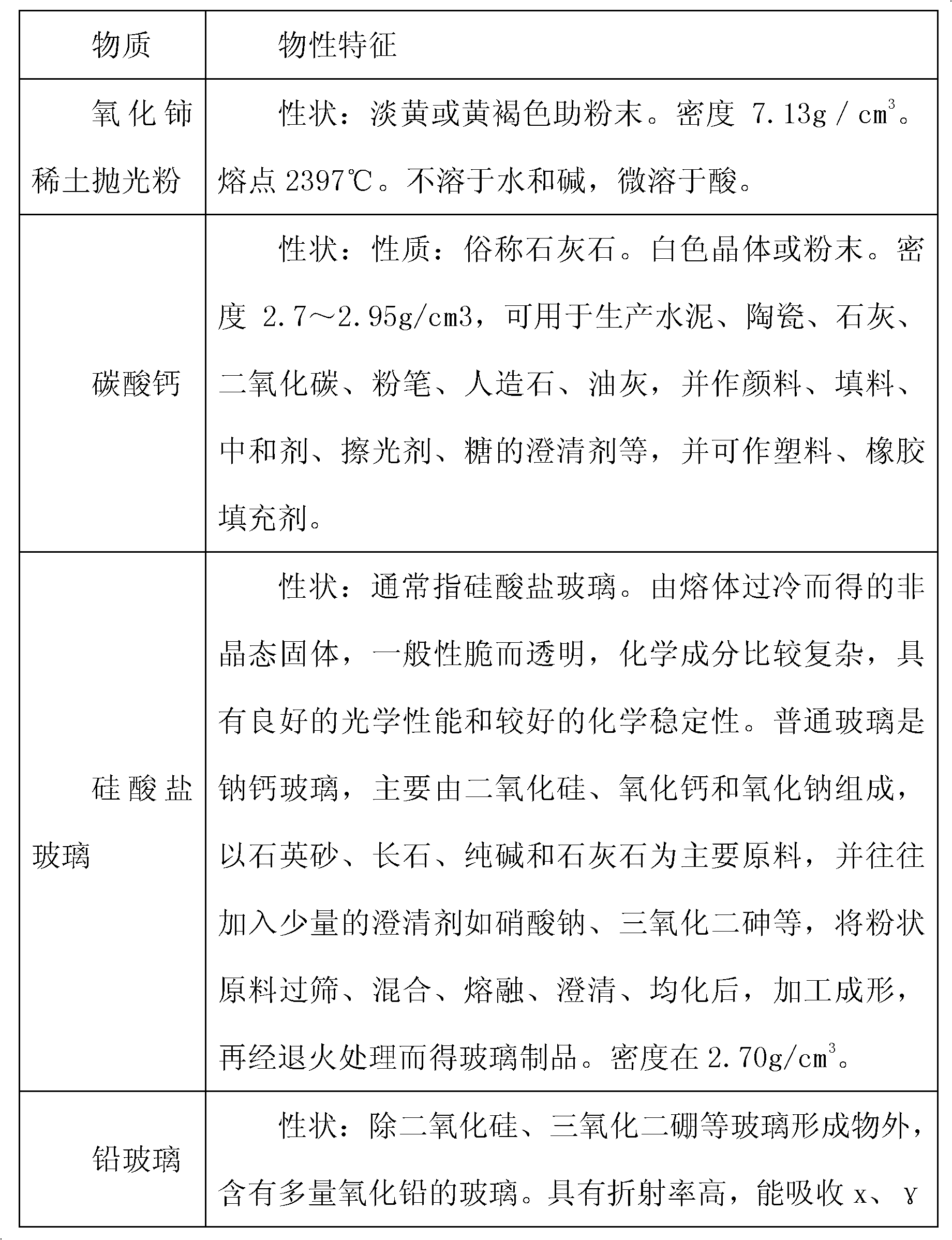

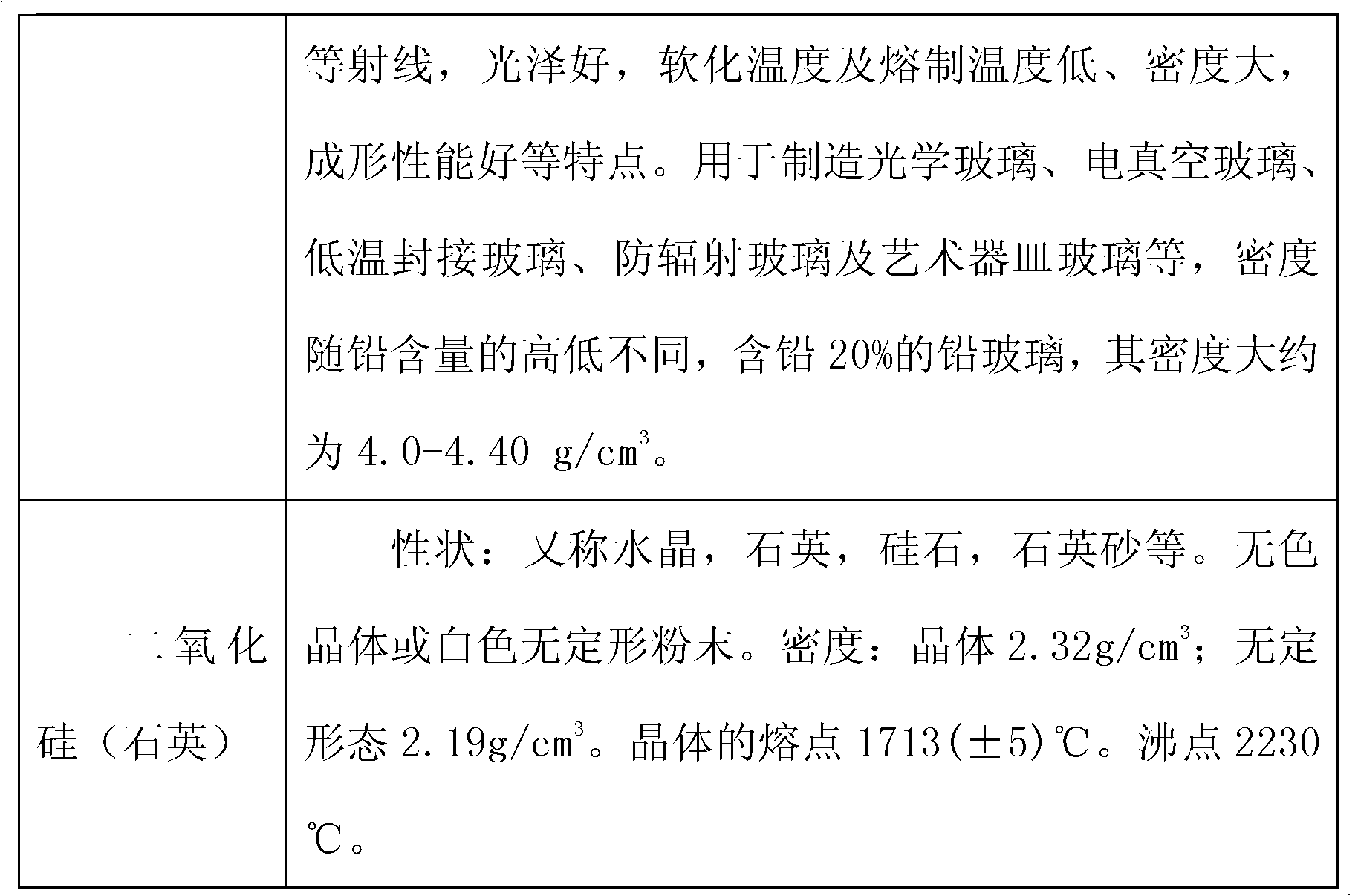

Method for recycling and applying discarded rare earth polishing powder into crystal glass

InactiveCN102391833ALow costDisposal method is environmentally friendlyOther chemical processesPolishing compositions with abrasivesGravity separationStrong acids

The invention discloses a method for recycling and applying discarded rare earth polishing powder into crystal glass, which includes the following process flow: (1) screening equipment is utilized to coarsely screen waste rare earth polishing powder residue in order to remove foreign matters and large particles; (2) the waste rare earth polishing powder residue is pulped, gravity concentration equipment is utilized to carry out gravity separation, and the separated heavy component is high-content rare earth polishing powder waste; (3) strong acid is then used for chemical treatment to dissolve soluble substances in the rare earth polishing powder waste; (4) the waste is roasted at high temperature being more than 800 DEG C in order to remove thermosetting resin and organic greasy dirt in the waste and increase the rigidity of the rare earth polishing powder; (5) after the temperature is decreased, the roasted material is levigated to reach such a grain size range that the roasted material can be reused as polishing powder. The separation method for extracting the rare earth component has the following advantages: the dosage of chemical substances is little, so that environment pollution is reduced; the method is easy to operate, and the treatment cost is low; the rare earth recovery rate is high, and the purity of the extracted rare earth is high.

Owner:JINHUA GUANHUA CRYSTAL +1

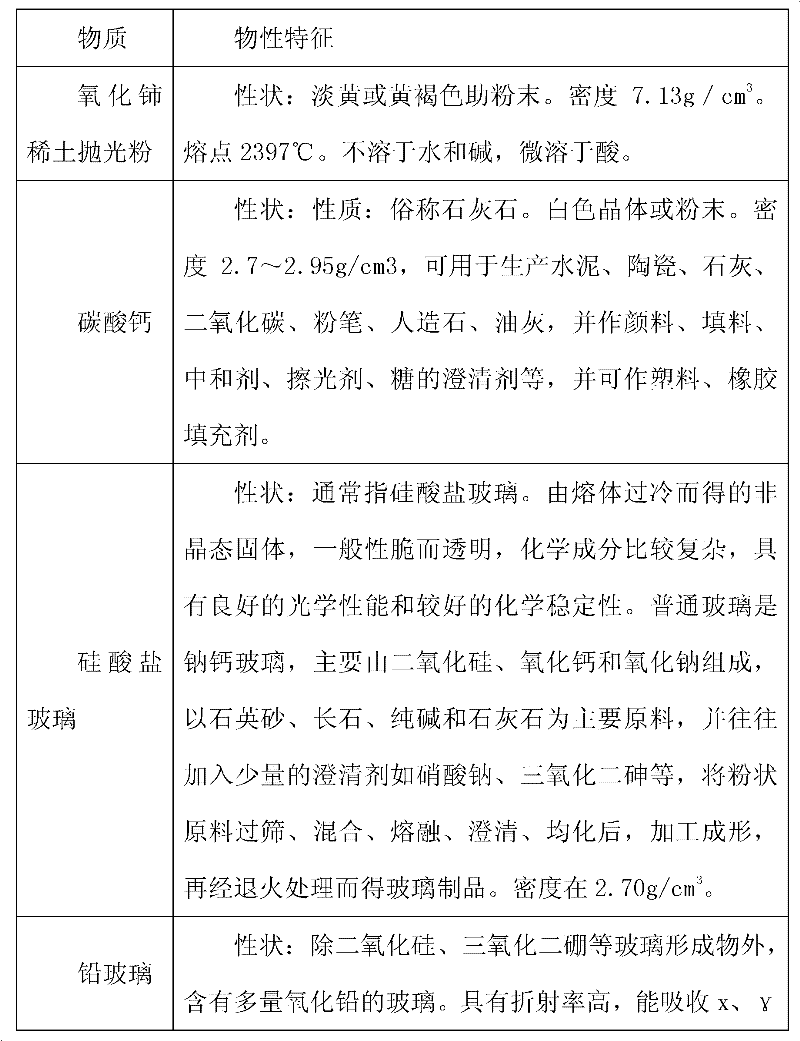

Circulation method for recovering organic acid from organic acid lithium waste water

ActiveCN105016415AHigh transparencyHigh whitenessWater/sewage treatment by extractionOrganic acidLithium

The invention discloses a circulation method for recovering organic acid from organic acid lithium waste water. The circulation method is characterized in that the waste water is generated by lithium deintercalation in a lithium system polymer glue solution through organic acid; solvent and acidifying agents used for polymerization reaction of generated lithium system polymers are added into the waste water for acidifying reaction with organic acid lithium in the waste water, and the pH value of an acidifying reaction endpoint is controlled to be within 3.0-6.9; the organic acid is extracted to be recovered through the solvent, and oil phases obtained after layering are returned into the process of lithium deintercalation of the organic acid. The method can be used for using the original organic acid in a lithium system polymer glue solution lithium deintercalation unit in a circulating mode after the organic acid lithium waste water is treated and restored, meanwhile, COD in the waste water can be effectively reduced, and corrosion to equipment in the treatment process is greatly reduced; the lithium deintercalation cost in the lithium system polymer technology is effectively lowered.

Owner:CHINA PETROLEUM & CHEM CORP

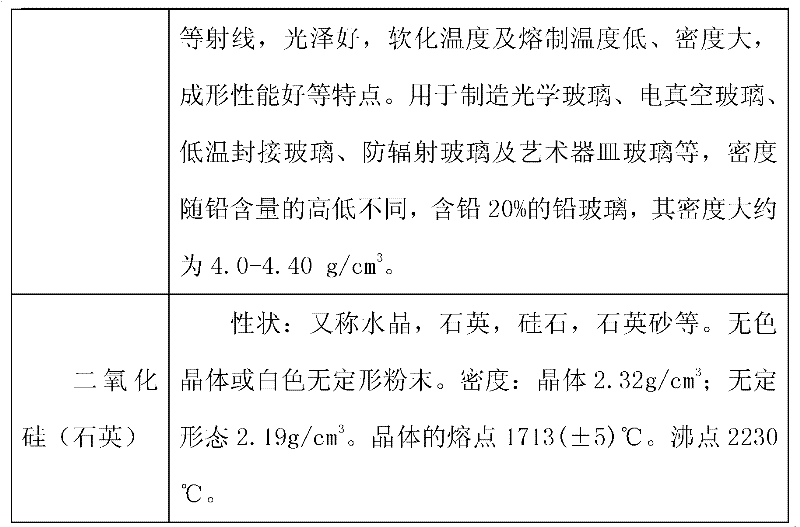

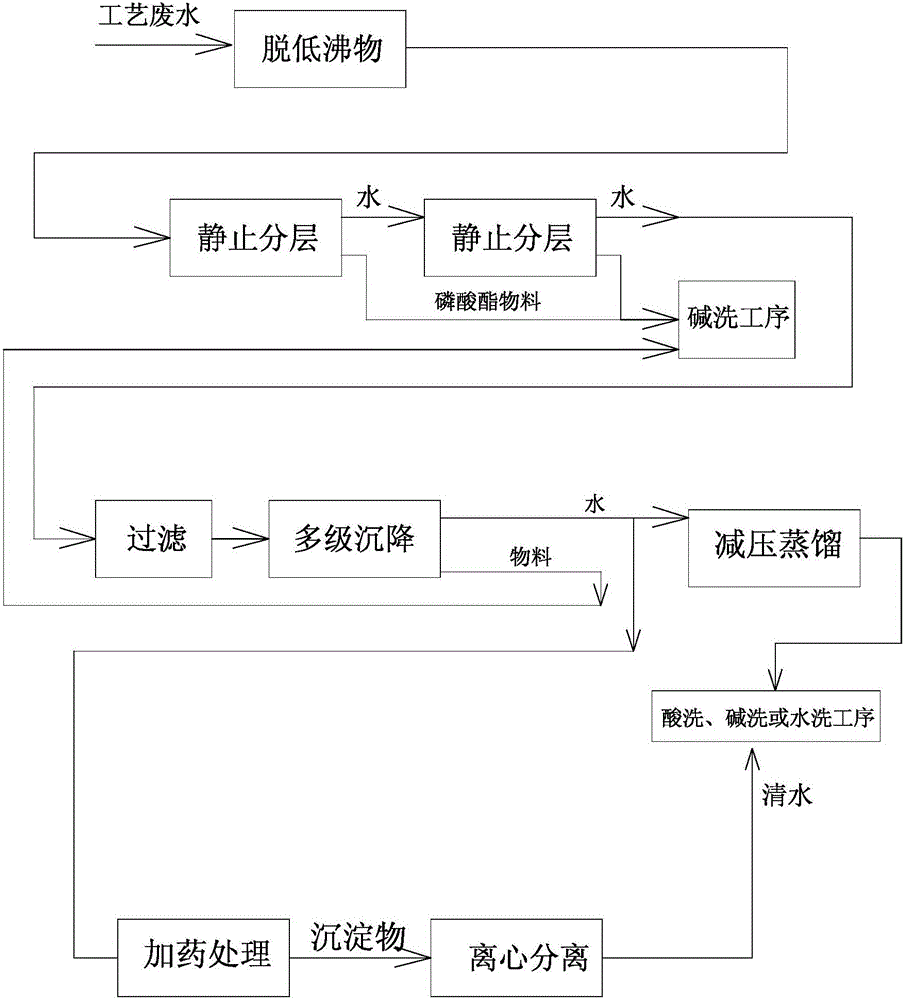

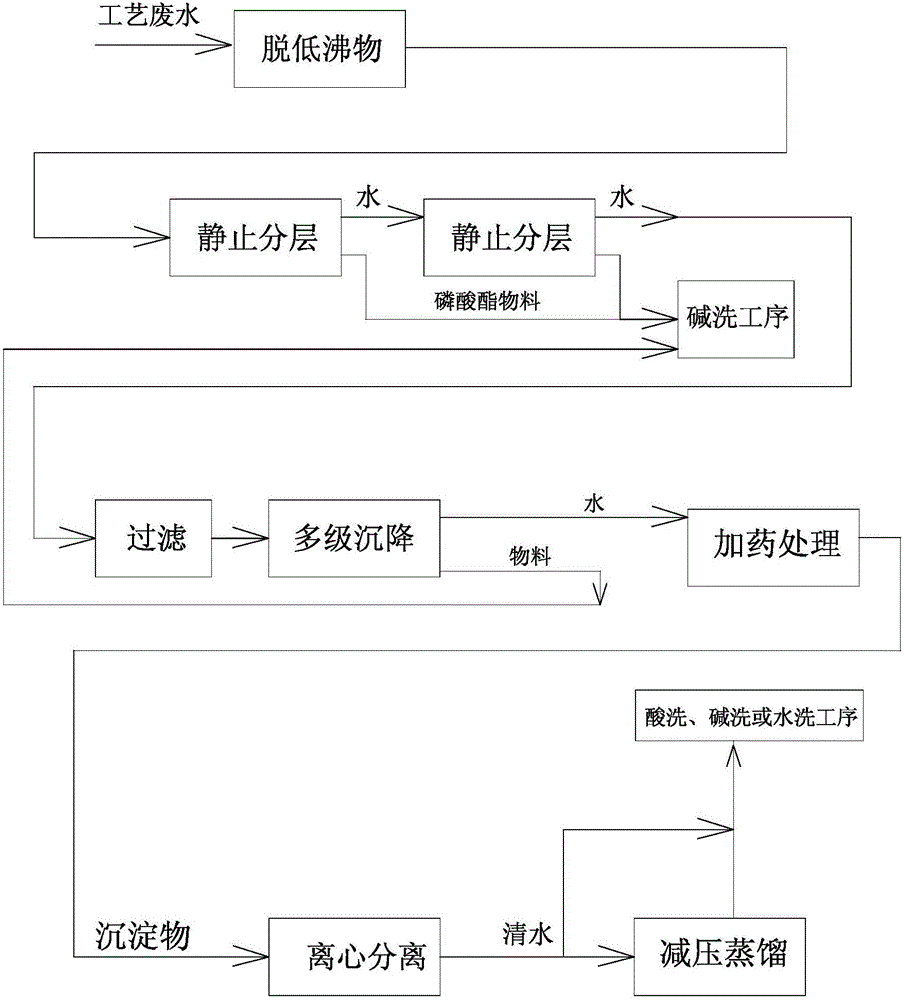

Method for treating wastewater of phosphate fire retardant production process

ActiveCN106336059AReduce contentHigh yieldWater/sewage treatment by centrifugal separationTreatment involving filtrationHigh concentrationEnvironmental resistance

The invention discloses a method for treating wastewater of a phosphate fire retardant production process. The wastewater of the phosphate fire retardant production process is high-concentration salt-containing organic phosphorus wastewater, wastewater treatment is always a difficult problem in the industry, and at present there is no feasible method. The method includes the following steps that 1, process wastewater produced in the phosphate fire retardant preparation process is subjected to low-boiling-point substance removal treatment; 2, the wastewater is fed into a wastewater layering box for static layering; 3, the wastewater is fed into a multistage sedimentation pool for sedimentation, the lower-layer material of the multistage sedimentation pool is recycled, and the upper-portion wastewater is subjected to subsequent treatment; 4, dosing treatment is performed, and organic phosphorus and inorganic phosphorus in the wastewater precipitate in the form of solid; 5, centrifugal separation or filtering is performed. The various impurities in the wastewater of the phosphate fire retardant production process are effectively removed through low-boiling-point substance removal, static layering, multistage sedimentation and dosing treatment, process wastewater reuse is achieved, and the method is economic and environmentally friendly.

Owner:福建新安科技有限责任公司

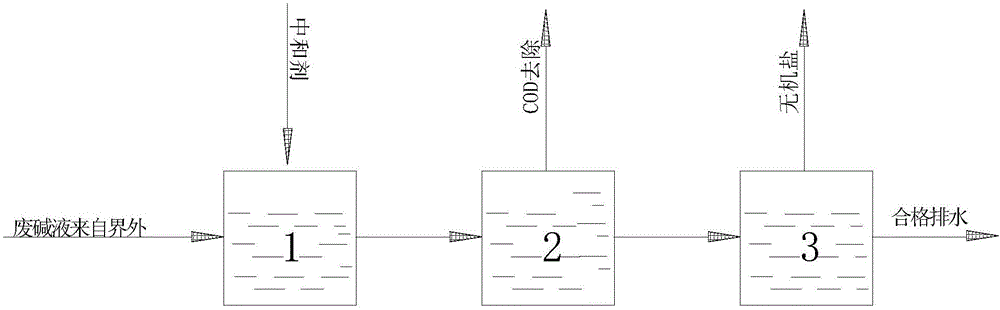

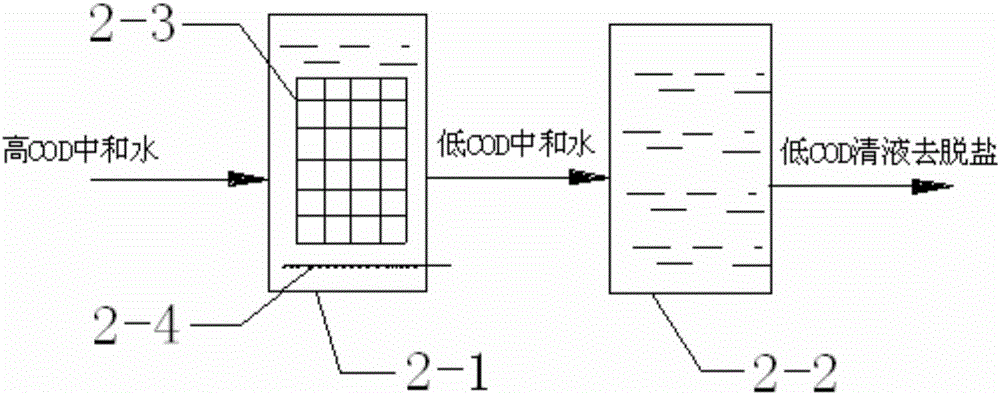

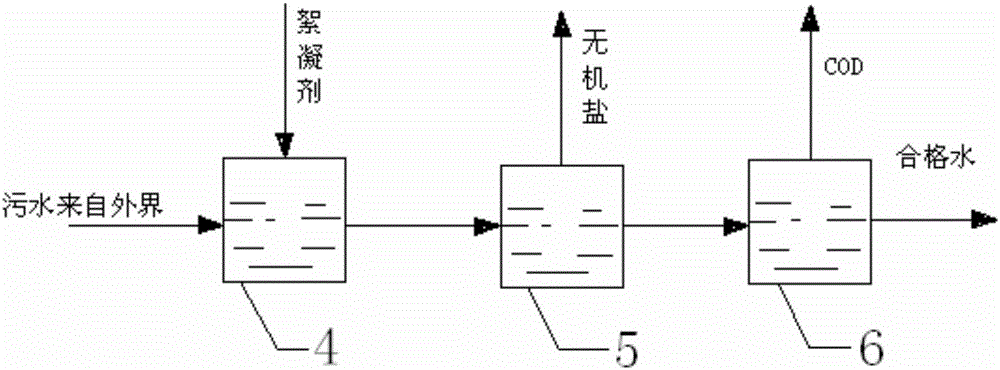

Method and process system for innocuous treatment of high-salt and high-COD waste alkali liquid

InactiveCN106587470ALower quality requirementsEasy to handleMultistage water/sewage treatmentWater/sewage treatment by neutralisationInorganic saltsProcess systems

The invention discloses a method and a process system for innocuous treatment of high-salt and high-COD waste alkali liquid. The method includes the steps of: adding a neutralizer to pre-treat the high-salt and high-COD waste alkali liquid, wherein the pH of the treated waste alkali liquid is 2-8; adding a catalyst to perform a catalytic reaction under an aeration or a stirring condition to remove COD in the waste alkali liquid; and performing evaporating desalination to the waste alkali liquid to complete the treatment. The method has lower requirement on the quality of the waste alkali liquid and can be used for treating the waste alkali liquid well even inorganic salt content reaches 20% and COD content reaches 10%. The method has more environment-friendly treatment process and is free of addition of microorganisms. The treated liquid is not more than 45 ppm in COD content and is not more than 200 ppm in inorganic salt content.

Owner:SHANDONG DONGYUE FLUO SILICON MATERIALS CO LTD

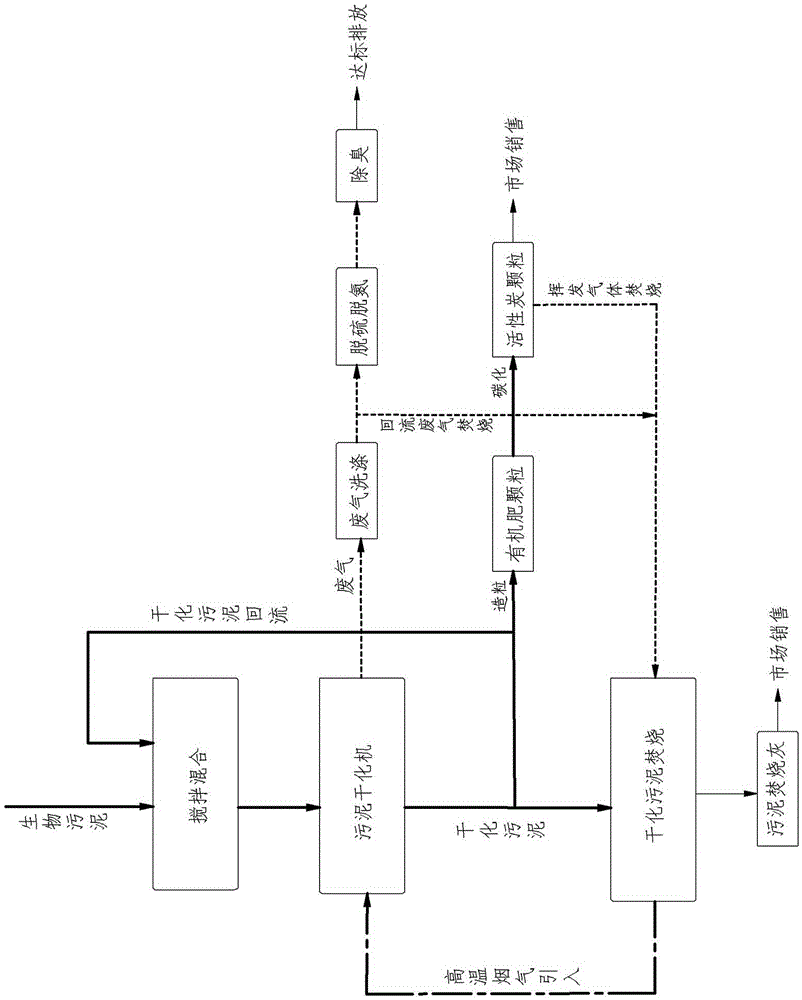

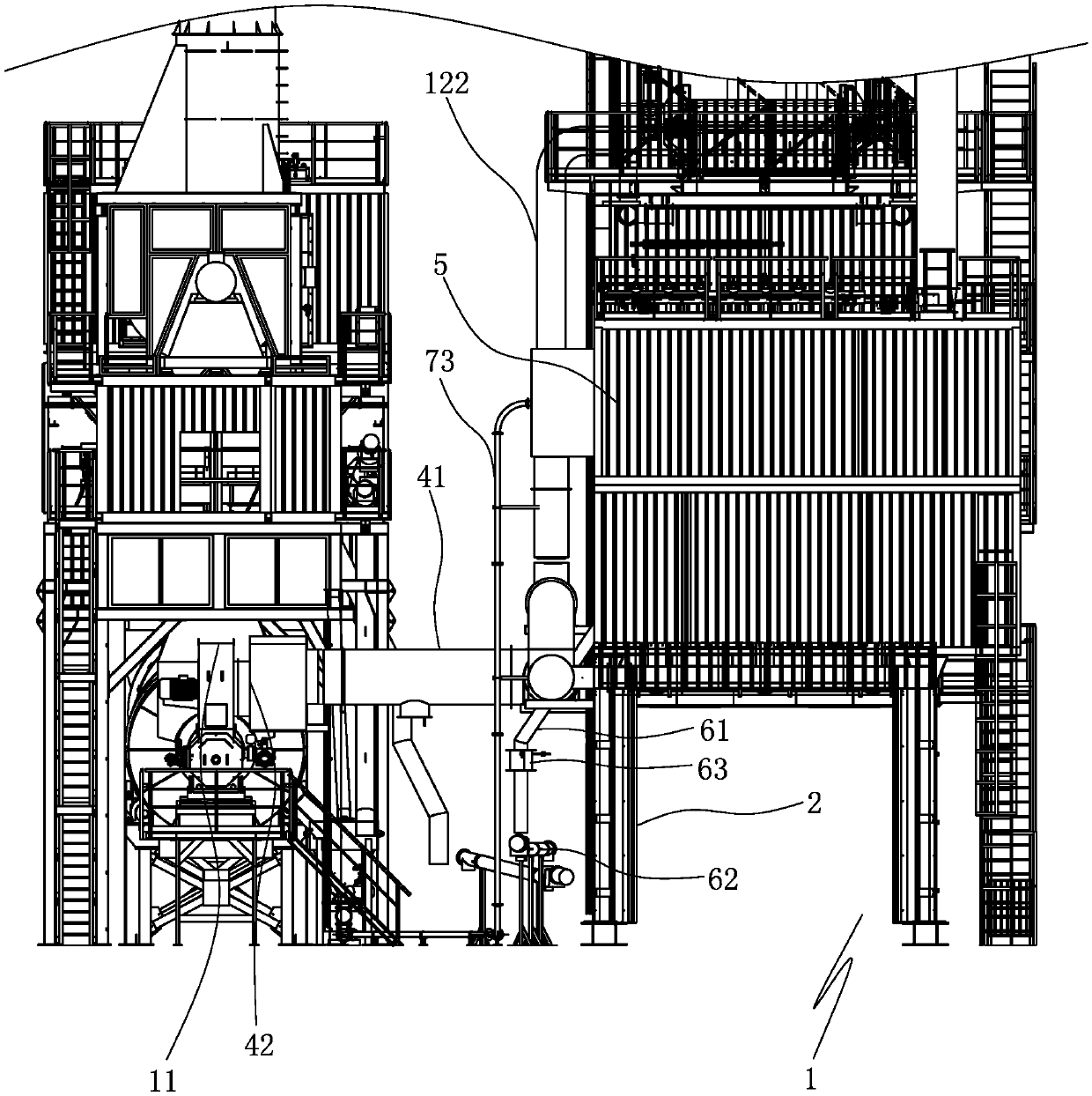

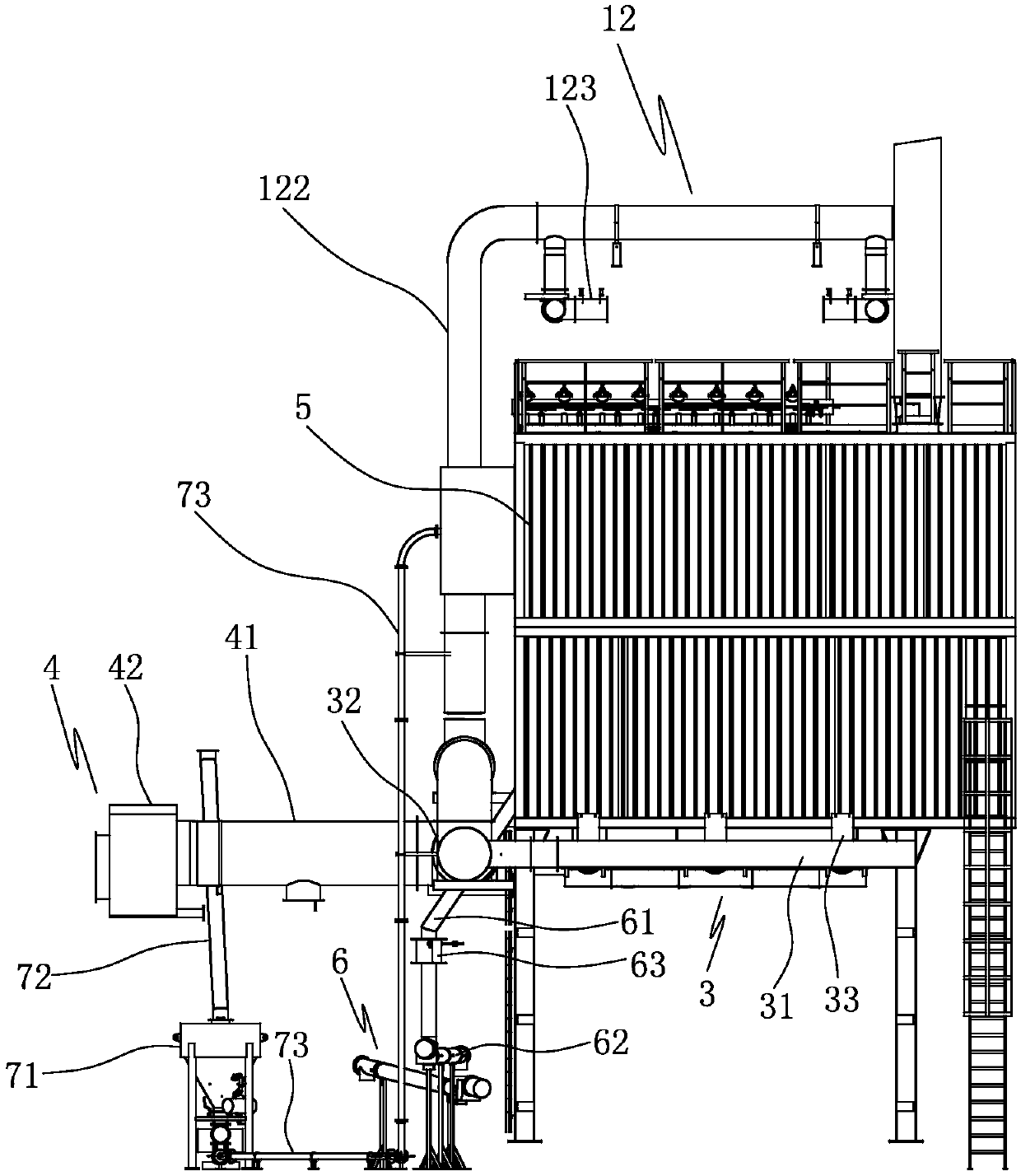

Biological sludge drying and incineration cycle-treatment method and complete equipment

ActiveCN105399304AThorough treatmentImprove environmental safetySludge treatment by de-watering/drying/thickeningRunoff/storm water treatmentExhaust gasTreatment completed

The invention relates to a biological sludge harmless and resourceful treatment method. A biological sludge drying and incineration cycle-treatment method comprises the following steps: 1) sludge drying treatment process: adding backflow drying sludge into biological sludge, fully stirring and drying by sending the sludge into a rotary sludge drier; 2) dried sludge incineration treatment process: sieving part of dried sludge after the drying treatment, incinerating the sludge by sending the sludge into a boiling-type sludge incinerator, directly introducing high temperature flue gas generated by the incineration into the rotary sludge drier so as to dry mixed sludge; introducing exhaust gas generated by drying and incineration of sludge into an exhaust gas washing tower, introducing exhaust gas which has undergone washing treatment back into the boiling-type sludge incinerator to be incinerated, and carrying out harmless treatment on residual exhaust gas; and 3) simultaneously carrying out the above biological sludge drying treatment process and dried sludge incineration treatment process and ceaselessly cycling the processes. Biological sludge drying and incineration cycle-treatment complete equipment comprises the rotary sludge drier and the boiling-type sludge incinerator.

Owner:宁波高新区纯丽节能技术有限公司

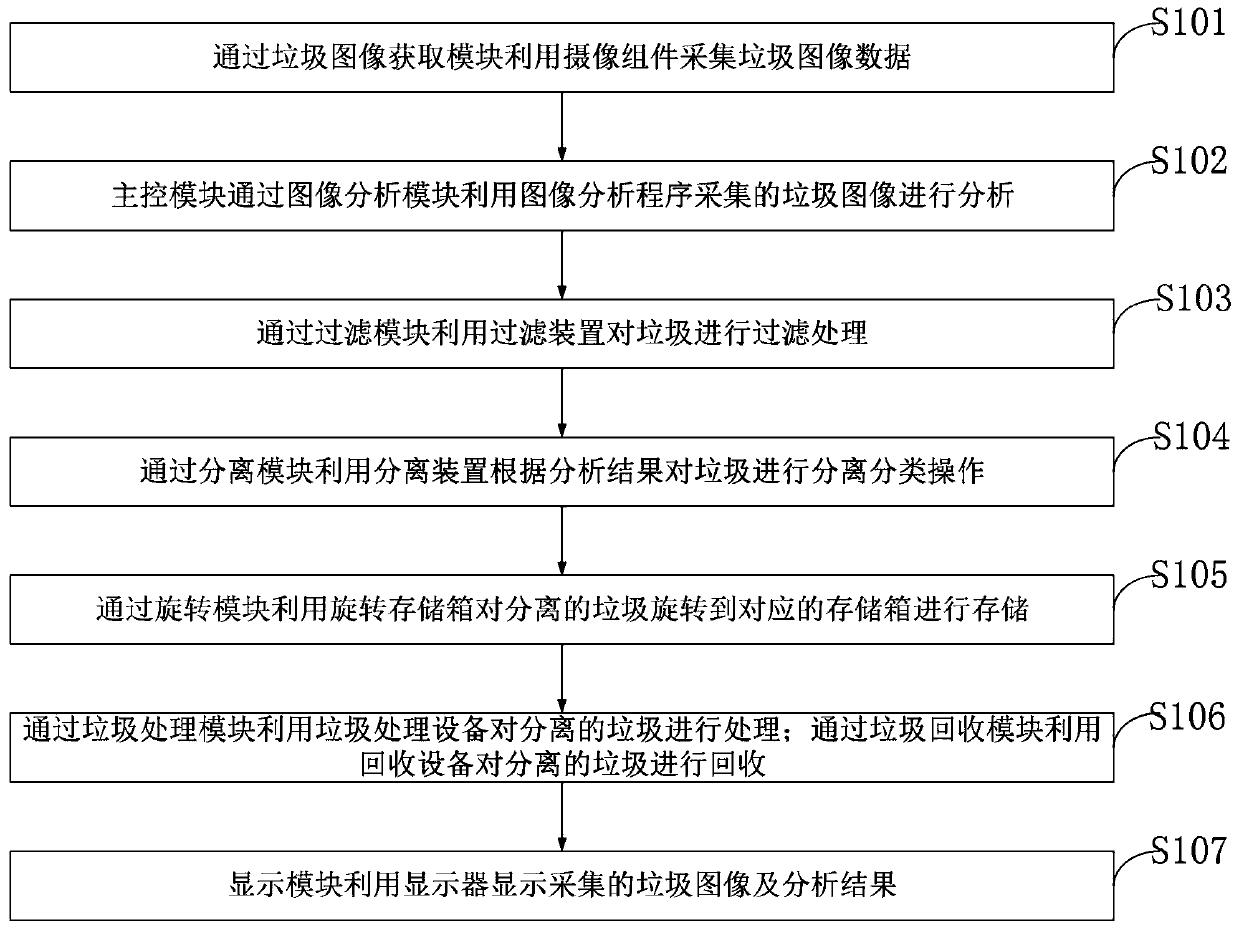

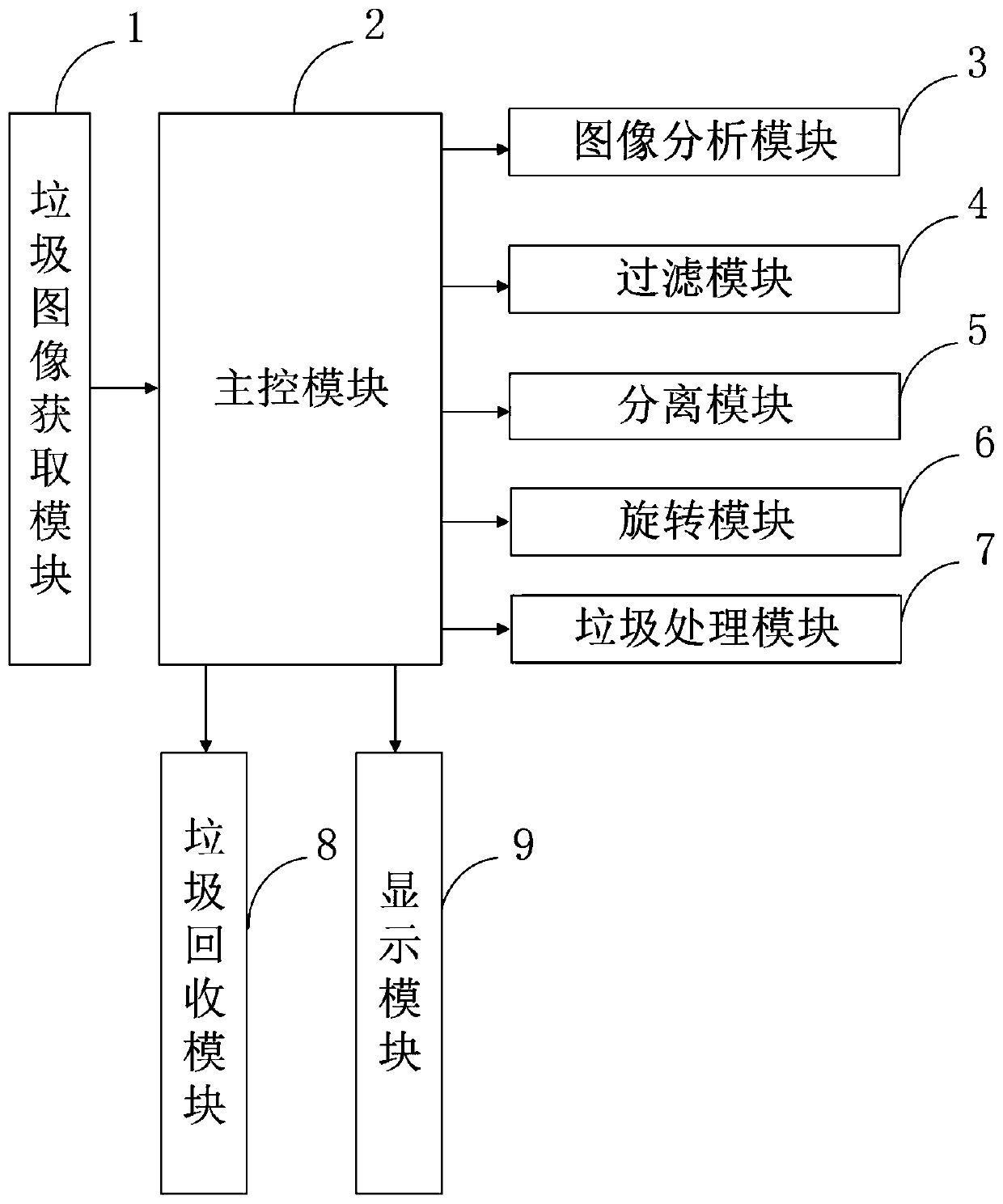

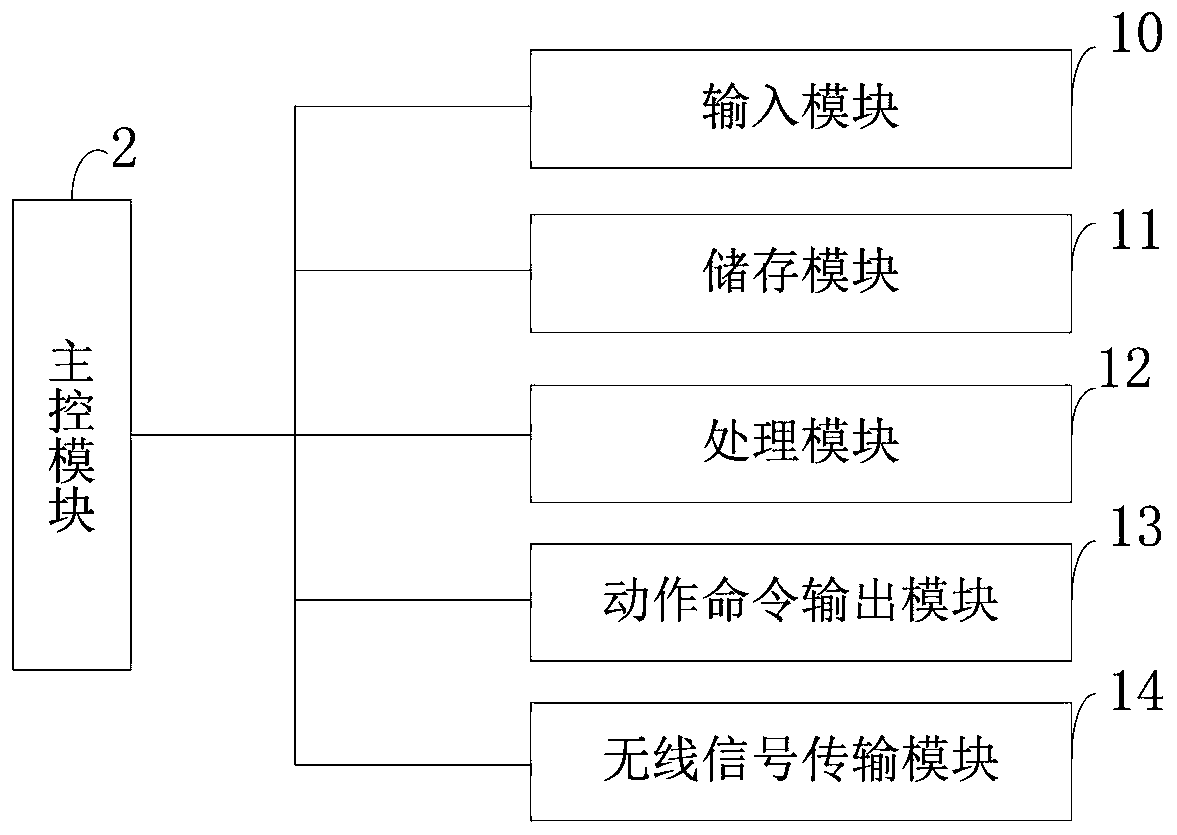

Cloud-based garbage sorting system and method, information processing terminal and storage medium

PendingCN111027639AImprove retort efficiencyImprove energy utilizationCharacter and pattern recognitionMagnetic separationInformation processingRefuse Disposals

The invention belongs to the technical field of garbage sorting, and discloses a cloud-based garbage sorting system and method, an information processing terminal and a storage medium. The cloud-basedgarbage sorting system comprises a garbage image acquisition module, a main control module, an image analysis module, a filtering module, a separation module, a rotating module, a garbage processingmodule, a garbage recycling module and a display module; the garbage image acquisition module acquires garbage image data; the main control module controls each module to work normally; the image analysis module analyzes the collected garbage images; and the separation module separates and classifies the garbage. A complex oil-gas separation system in a traditional garbage pyrolysis process is omitted through the garbage treatment module, and the garbage treatment method is simple, low in cost and easy to operate; and through the garbage recycling module, the garbage treatment and recycling efficiency is improved, resource waste is reduced, the garbage harmless treatment difficulty is reduced, and the influence on the environment is weakened.

Owner:BEIHUA UNIV

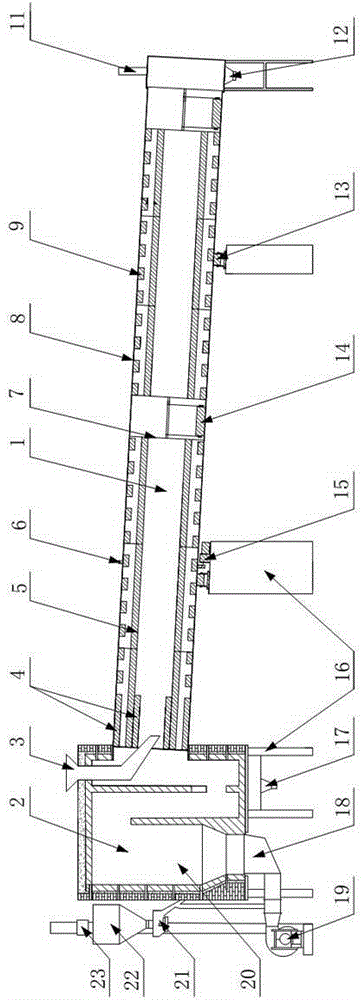

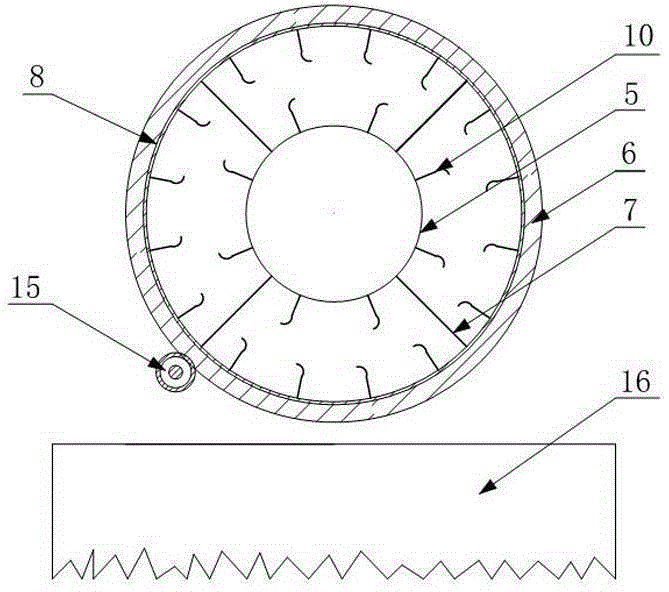

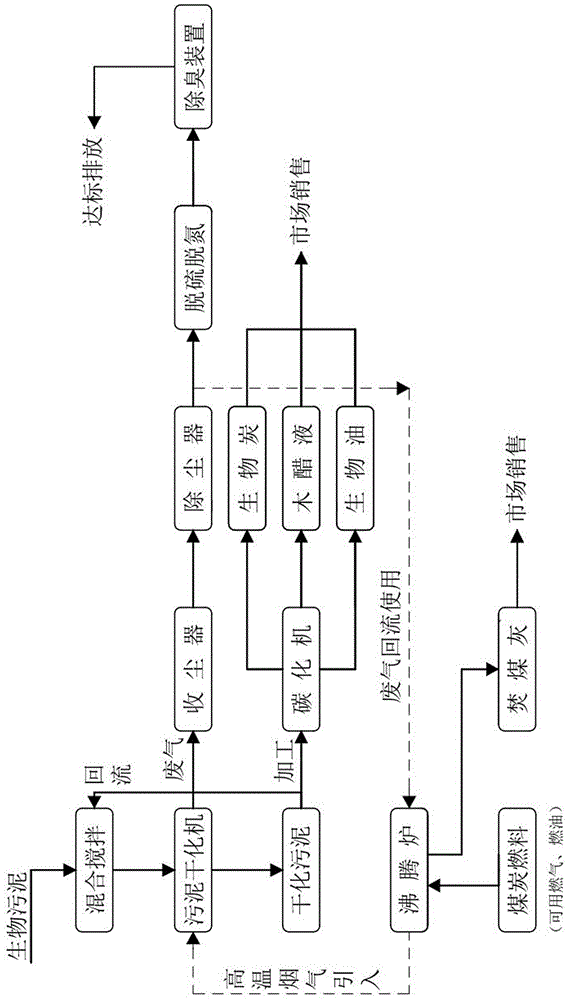

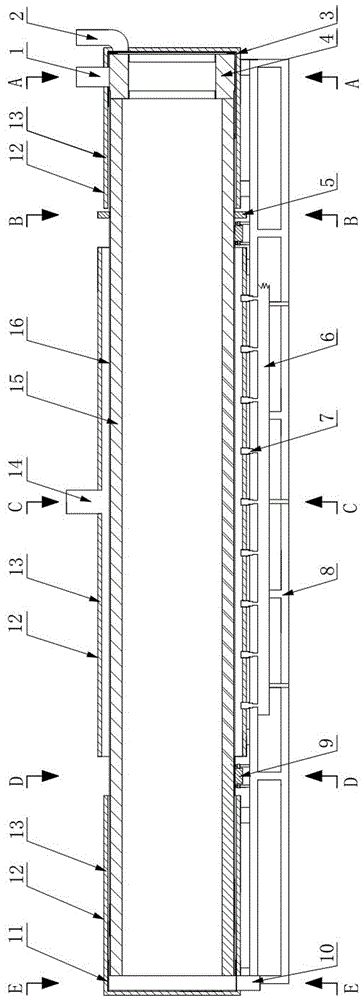

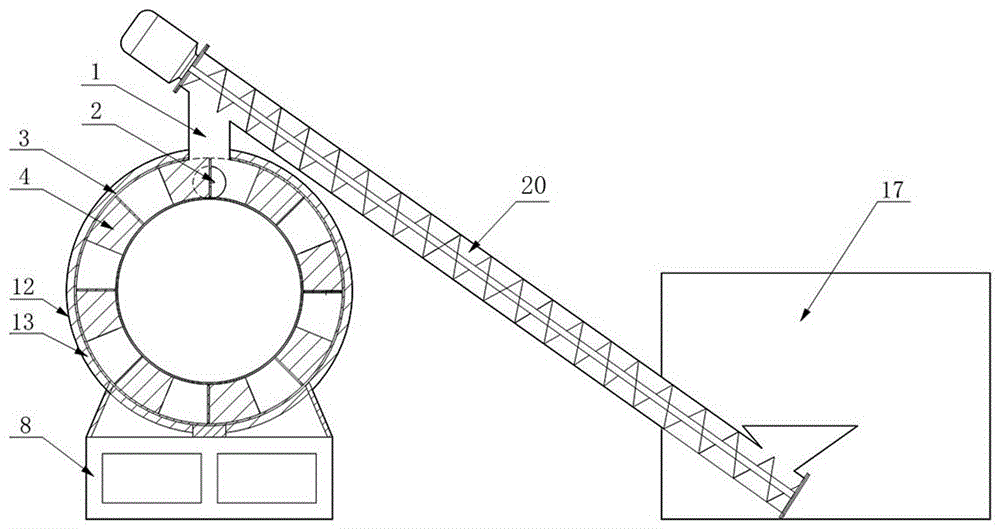

Commercial treatment method and system for biological sludge and rotary sludge carbonizing machine

ActiveCN105753281AImprove environmental safetyReduce processing costsSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisSludgeCarbonization

The invention relates to resourceful treatment on biological sludge.A commercial treatment method for biological sludge includes the steps that the biological sludge is dried, the dried sludge with the water content being 7-10% is carbonized and generates biochar, pyroligneous liquor and biological tar through high-temperature pyrolysis, and biochar, pyroligneous liquor and biological tar are packaged for sale; methane gas generated in the treatment process is recovered and used for carbonization treatment on the dried sludge.According to a rotary sludge carbonizing machine, a handpiece component and a tail component are fixed to the two ends of a rack, the two ends of a rotary cylinder are inserted into the handpiece component and the tail component and matched with the handpiece component and the tail component in a sealed mode, and a supporting and driving mechanism matched with the rotary cylinder is arranged on the rack; a guiding plate is arranged on the front portion of the rotary cylinder, a lifting plate is arranged on the inner wall of the rotary cylinder, and a combustor is arranged in a heat preservation outer cover below the rotary cylinder.A commercial treatment system for the biological sludge comprises biological sludge drying treatment complete equipment and dried sludge carbonizing treatment complete equipment.The harmful biological sludge is turned into wealth, and the commercial treatment method and system for the biological sludge have high socioeconomic performance and can create huge wealth for enterprises and the society.

Owner:四川泰翱农业科技有限公司

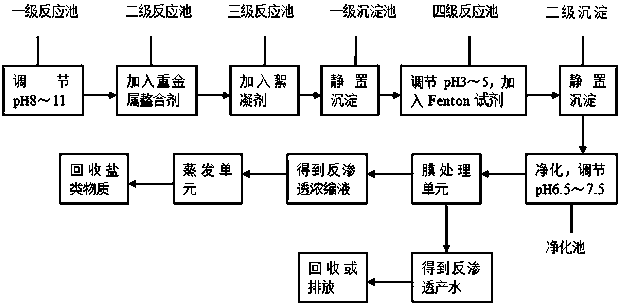

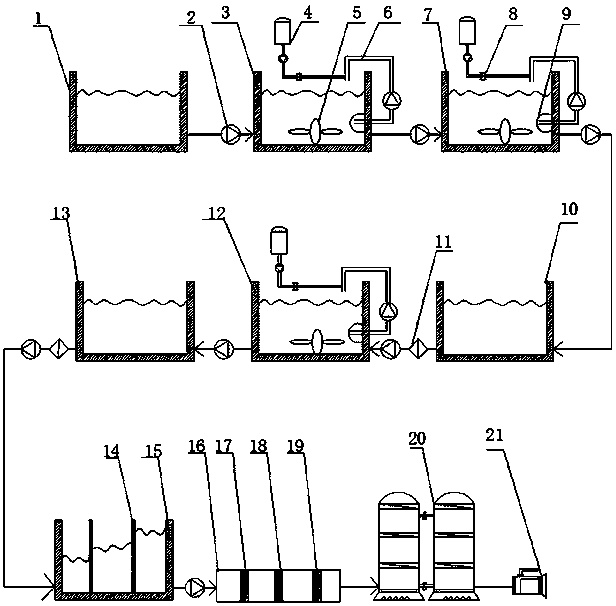

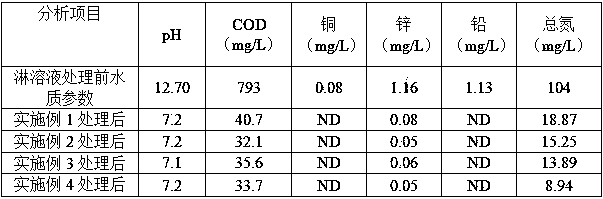

Fly ash leaching solution treatment method and system

PendingCN109264916AGood water qualityLow energy consumptionWater contaminantsTreatment involving filtrationZero emissionEnvironmental resistance

The invention discloses a fly ash leaching solution treatment method and system. The fly ash leaching solution treatment method comprises the following steps: adjusting the pH of a leaching solution to be 8 to 11 in a primary reaction tank, then feeding the leaching solution in various reaction tanks, separately adding a heavy metal chelating agent and a flocculating agent, generating alumen ustumparticles, standing, precipitating, adjusting the pH to 3 to 5, adding a Fenton reagent, standing, precipitating, introducing supernatant into a purification tank, purifying the supernatant, treatingby using a membrane treatment unit, thus obtaining reverse osmosis production water and a reverse osmosis concentrated solution, wherein the produced water is good in quality, the produced water is recyclable, evaporating and crystallizing the reverse osmosis concentrated solution by virtue of an evaporation unit, recycling salt substances, wherein the recycled salt substances can be used for producing industrial salt. The treated solution can be recycled, so that the zero emission of waste water can be realized; the crystal salt can be produced; the fly ash leaching solution treatment methodis an environment-friendly, safe and efficient treatment method, the environment pollution problem caused by the fly ash leaching solution produced after the garbage is incinerated can be solved, thesystem operation is simple, the equipment requirement is simple, and the system operation is reliable.

Owner:深圳能源资源综合开发有限公司

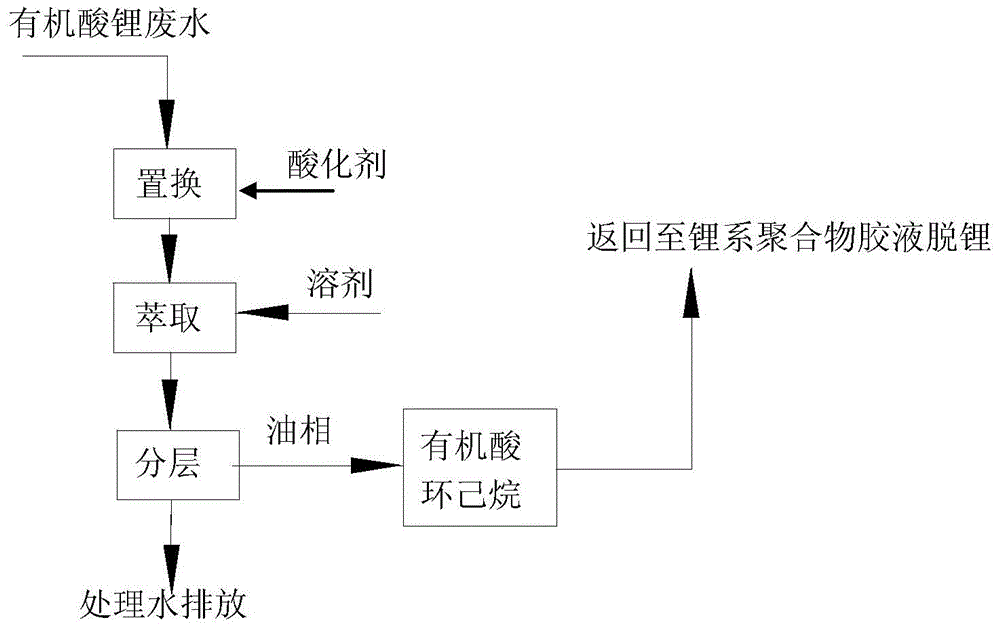

Method for separating each component in waste residue in crystal industry

InactiveCN102357398AHigh separation purityCreate pollutionPolishing compositionsWet separationInorganic compositionRare earth

The invention discloses a method for separating each component in waste residue in the crystal industry, and relates to a method for separating rare earth polishing powder, lead-containing crystal glass and other light components. The method is characterized in that the components are separated by a sorting technology in the mineral separation industrial according to the characteristic that the density of each component is larger in difference. The method comprises the following technical processes of milling crystal waste residue by milling equipment, so that the grain diameter of the waste residue reaches a certain size; mixing the milled waste residue; and repeatedly reelecting and sorting by reselection equipment. Higher-purity components within different density ranges are obtained after separation, so that the heavy component is the high-content rare earth polishing powder component, the intermediate component is the lead-containing crystal glass component, the light component is the inorganic composition which mainly contains the crystal glass, and the separated high-content component can be subsequently and cyclically utilized at a high added value. The method belongs to a physical separation method which is an environment-friendly, high-efficiency and low-cost processing method.

Owner:JINHUA GUANHUA CRYSTAL +1

Anti-shrinkage silk cotton fiber fabric finishing method

The invention relates to the field of silk cotton products. In the prior, tangles and adhesions can be generated between silk cotton fibers of a silk quilt processed through the traditional process after use for a plurality of years so as to reduce elasticity and warm keeping property, such that cotton batting is required to be frequently turned, split and loosened. In order to solve the problem in the prior, the present invention provides an anti-shrinkage silk cotton fiber fabric finishing method, wherein a commercially available ordinary silk cotton fabric is subjected to two dipping and two rolling in a finishing solution, and then is subjected to drying, acid washing, water washing and drying to obtain an anti-shrinkage silk cotton fiber fabric. With the present invention, the silk cotton can be bulk and smooth, elasticity can be increased, silk cotton adhesion can be prevented, resilience and flatness of the silk cotton can be increased, warm keeping property and health care property can be enhanced, wearability of the silk cotton can be improved, and occurrence of tangles and adhesions of the silk cotton after use can be reduced, such that the silk quilt has a free-turning-splitting function, and performances of the silk quilt can be improved.

Owner:CHUNAN QIANDAO LAKE SANGYUAN SILK

Method for recycling and applying discarded rare earth polishing powder into crystal glass

InactiveCN102391833BLow costDisposal method is environmentally friendlyOther chemical processesPolishing compositions with abrasivesChemical treatmentForeign matter

The invention discloses a method for recycling and applying discarded rare earth polishing powder into crystal glass, which includes the following process flow: (1) screening equipment is utilized to coarsely screen waste rare earth polishing powder residue in order to remove foreign matters and large particles; (2) the waste rare earth polishing powder residue is pulped, gravity concentration equipment is utilized to carry out gravity separation, and the separated heavy component is high-content rare earth polishing powder waste; (3) strong acid is then used for chemical treatment to dissolve soluble substances in the rare earth polishing powder waste; (4) the waste is roasted at high temperature being more than 800 DEG C in order to remove thermosetting resin and organic greasy dirt in the waste and increase the rigidity of the rare earth polishing powder; (5) after the temperature is decreased, the roasted material is levigated to reach such a grain size range that the roasted material can be reused as polishing powder. The separation method for extracting the rare earth component has the following advantages: the dosage of chemical substances is little, so that environment pollution is reduced; the method is easy to operate, and the treatment cost is low; the rare earth recovery rate is high, and the purity of the extracted rare earth is high.

Owner:JINHUA GUANHUA CRYSTAL +1

3-chloropropyltrichlorosilane synthesis tail gas treatment mechanism and treatment method thereof

PendingCN108525487AReduce sticky residueAvoid equipment jamsSequential/parallel process reactionsGas treatmentEthanol absorptionDistillation

The invention discloses a harmless treatment mechanism of 3-chloropropyltrichlorosilane synthesis tail gas. The harmless treatment mechanism comprises a reaction chamber, a synthesis chamber, a distillation machine and a neutralization chamber. A treatment method of the 3-chloropropyltrichlorosilane synthesis tail gas comprises the following steps: dissolving and reacting non-condensable gases including trichlorosilane, silicon tetrachloride and propyltrichlorosilane in the 3-chloropropyltrichlorosilane synthesis tail gas by using excess absolute ethyl alcohol absorption liquid under a freezing condition with micro-positive pressure, wherein the non-condensable gases in the 3-chloropropyltrichlorosilane synthesis tail gas after being treated by the process only include hydrogen chloride and purified propylene; adding the non-condensable gases only including hydrogen chloride and purified propylene into the synthesis chamber and carrying out chloride-free treatment; carrying out alcoholysis and hydrolysis of an incompletely-esterified crude product which is the ethyl alcohol absorption liquid after absorbing the non-condensable gases including trichlorosilane, silicon tetrachlorideand propyltrichlorosilane to prepare a polysiloxane product with an additional value. The harmless treatment mechanism is novel in structure; the treatment method is environmentally friendly; the waste can be used and changed into wealth; the economic benefit is improved.

Owner:南京曙光精细化工有限公司

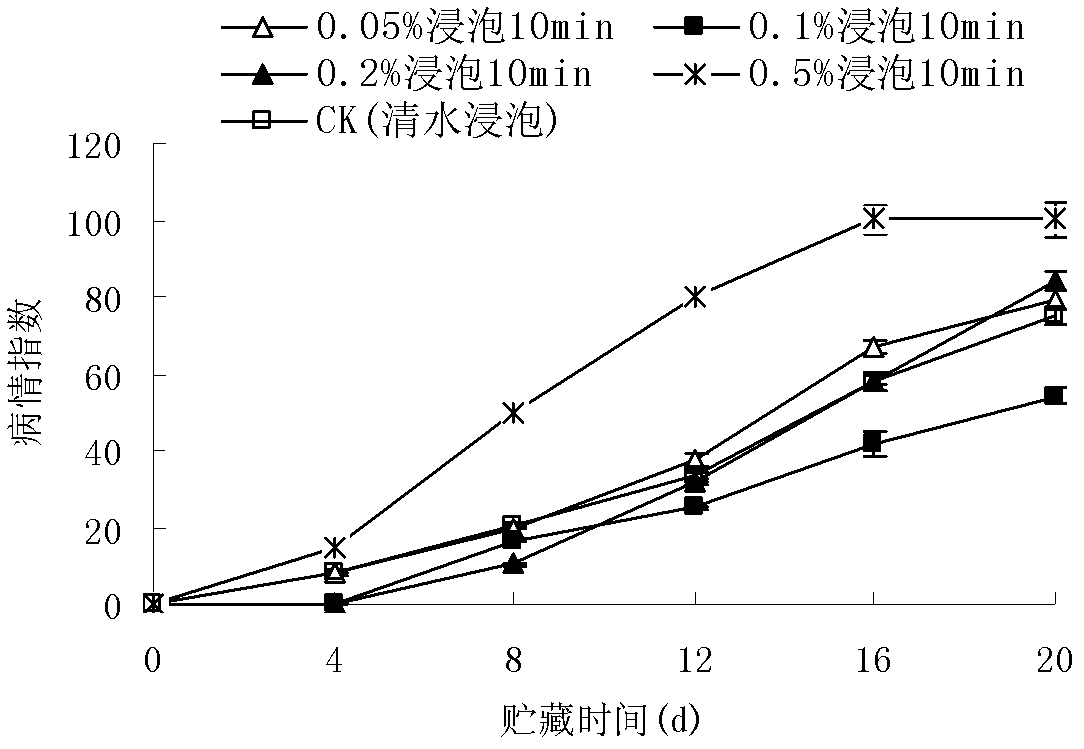

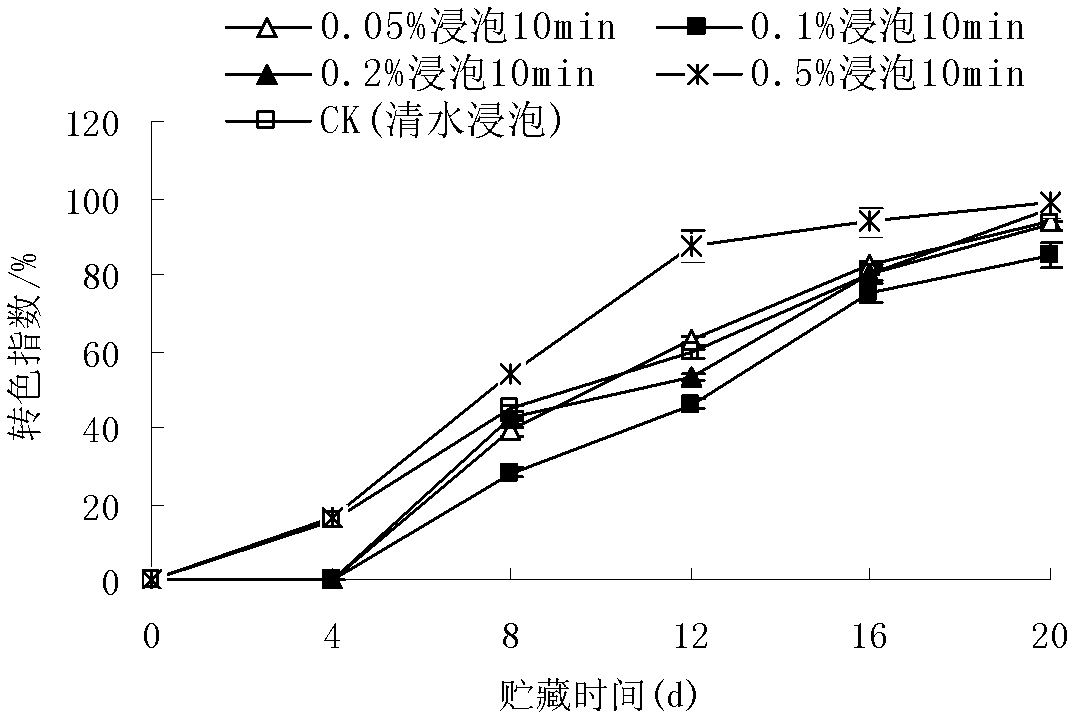

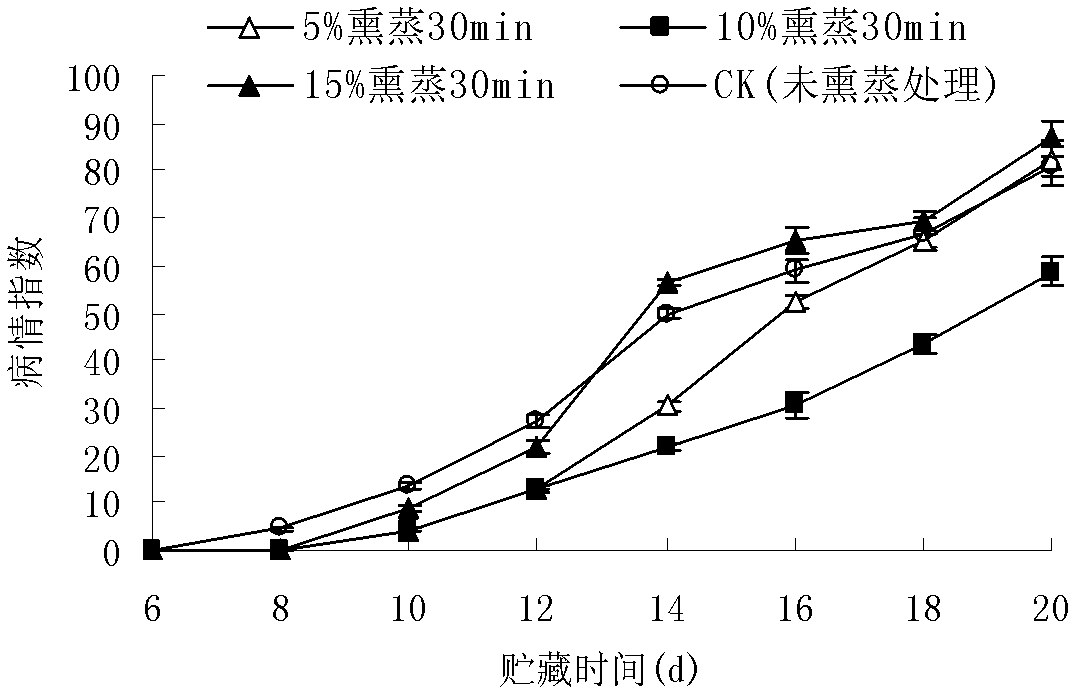

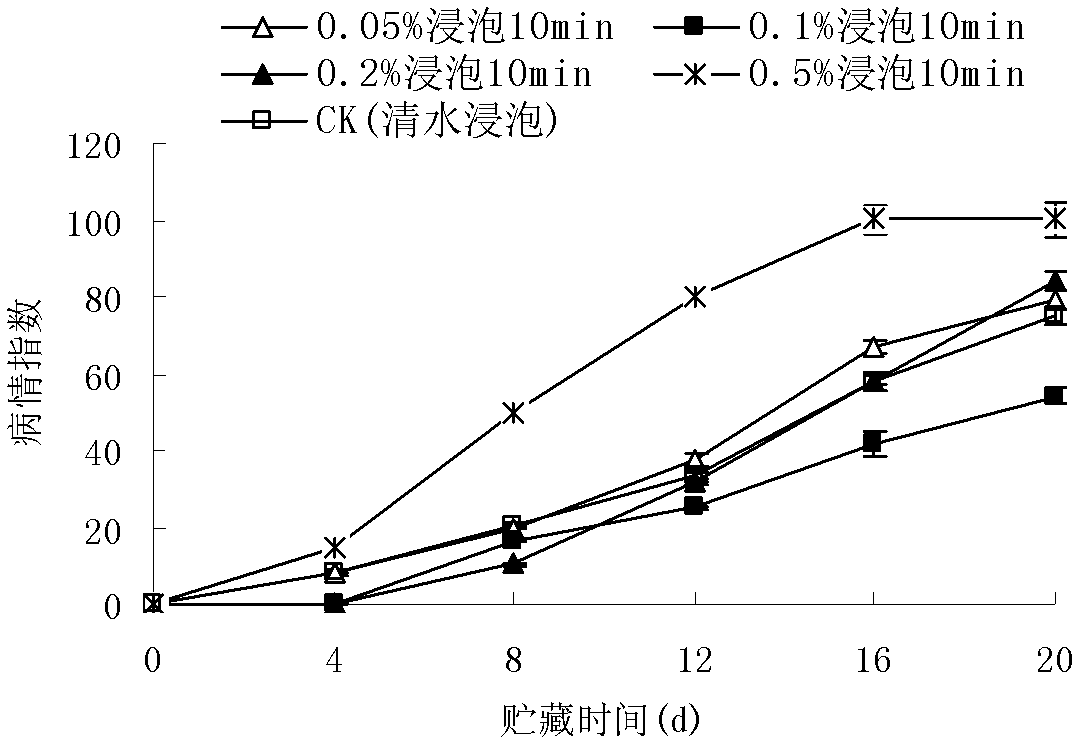

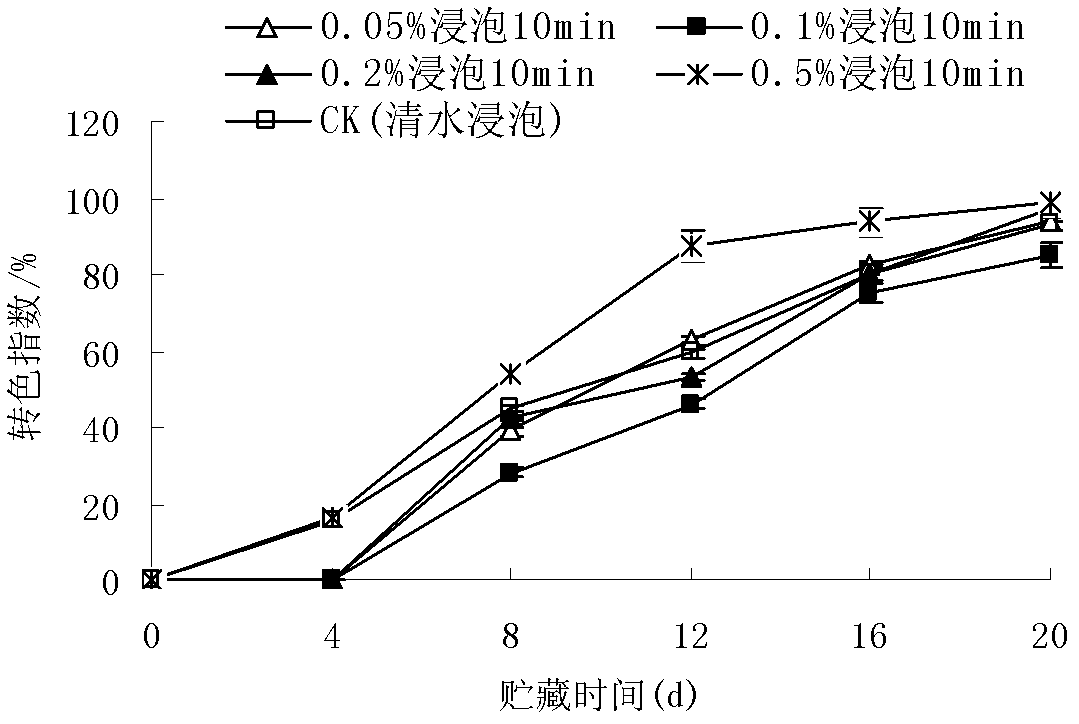

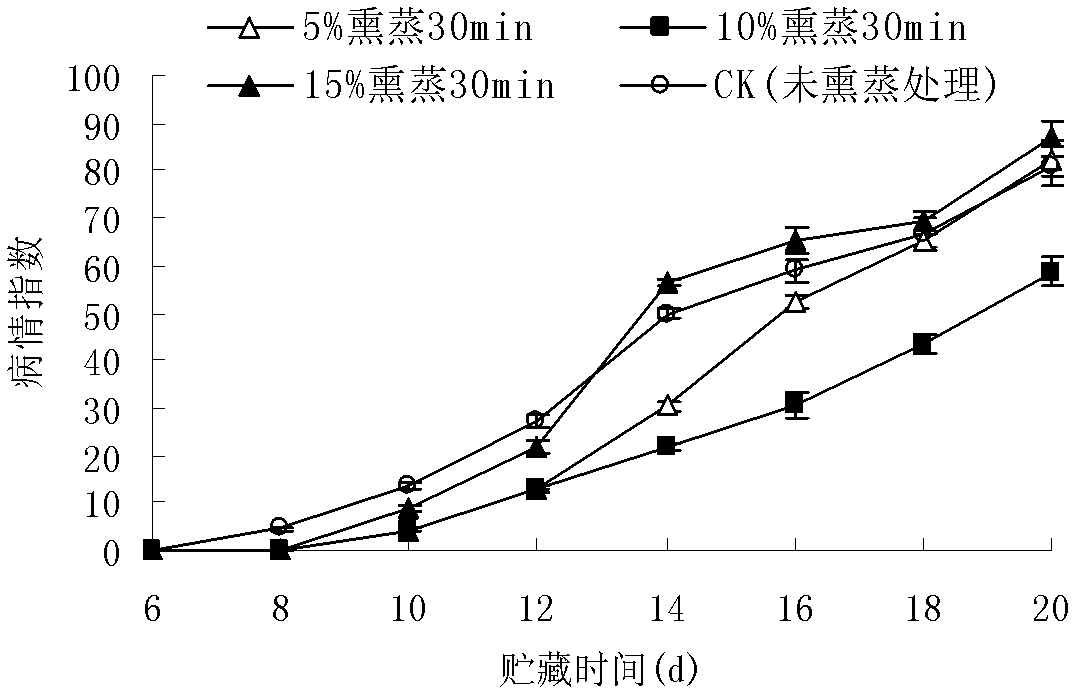

Application of glacial acetic acid in fresh keeping of hot pepper fruit and hot pepper fresh-keeping method

InactiveCN102578219AReduce the disease indexReduce color transfer indexFruit and vegetables preservationChemistryProper treatment

The invention discloses application of glacial acetic acid in fresh keeping of hot pepper fruits and a hot pepper fresh-keeping method. The hot pepper fresh-keeping method comprises the following step: preparing a glacial acetic acid water solution with the concentration of 0.09-0.11 percent (V / V) by using the glacial acetic acid to soak the hot pepper fruits, or preparing a glacial acetic acid water solution with the concentration of 9-11 percent (V / V) by using the glacial acetic acid to fumigate the hot pepper fruits. Aiming at hot pepper, the invention provides glacial acetic acid with proper concentration as well as a proper treatment method and proper treatment conditions, and the hot pepper fruits are successfully kept fresh and sterilized; after the hot pepper fruits treated by the method of the invention are stored for 20 days at 22 DEG C, diseases are reduced obviously, the disease index of the soaked hot pepper fruits is reduced by 20.8 percent compared with a contrast, the disease index of the fumigated hot pepper fruits is reduced by 22.1 percent compared with a contrast, and the hot pepper skin color change is delayed obviously. The treatment method is environment-friendly, simple and convenient to operate and easy to popularize and use, and is low in cost.

Owner:SOUTH SUBTROPICAL CROPS RES INST CHINESE ACAD OF TROPICAL AGRI SCI +1

Resource utilization method of residual kettle tar in phenylenediamine production

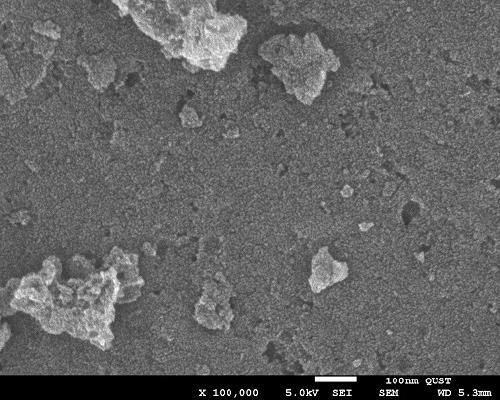

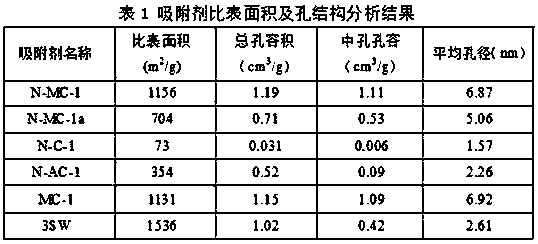

ActiveCN109174073AReasonable structureHigh porosityAmino compound purification/separationCatalyst activation/preparationSorbentResource utilization

The invention relates to the technical field of phenylenediamine production, and particularly discloses a resource utilization method of residual kettle tar in phenylenediamine production. The resource utilization method uses the residual tar in the rectification kettle in phenylenediamine production as a carbon source and a nitrogen source, and is characterized in that the residual tar in the kettle, an auxiliary agent and a templating agent precursor are added to an autoclave, a stabilization pre-treatment is performed under a microwave condition in a heating manner to obtain a carbon precursor / templating agent precursor mixture, the obtained mixture is transferred to a tubular atmosphere furnace, carbonization is performed, the obtained product is added to an acid solution to remove thetemplate, washing is performed to achieve a neutral pH value, drying is performed to obtain mesoporous carbon, the aniline in the water generated by a mixed dinitrobenzene hydrogenation reaction is subjected to adsorption removal by using the mesoporous carbon as an adsorbent, and the mesoporous carbon achieving the saturated adsorption is treated so as to recycled. According to the present invention, the prepared mesoporous carbon has characteristics of reasonable pore channel structure, high mesoporosity, rich acidic oxygen-containing groups on the carbon surface, and excellent adsorption effect on aniline-based weakly-basic aromatic ring organic substances; and the treatment method is environmentally friendly, and no additional pollutants are discharged.

Owner:QINGDAO UNIV OF SCI & TECH

Xylose mother liquid processing method

ActiveCN104892689AHigh yieldSimple processSugar derivativesSugar derivatives preparationCooling downSeed crystal

The invention provides a xylose mother liquid processing method. The method includes the steps of a), concentrating xylose mother liquid to 80-92% of total sugar concentration to obtain the concentrated xylose mother liquid; b), raising the temperature of the concentrated xylose mother liquid to 70-80 DEGC, then starting to cool down to 60-70 DEG C, adding seed crystal, and crystallizing when the temperature drops to 20-25 DEG C to obtain a crystallized product and first mixed sugar liquid; c), performing recrystallization on the crystallized product obtained in the step b) to obtain xylose and the mixed sugar liquid. The xylose mother liquid can be directly crystallized by the process of controlling first time crystallization, the process is concise and high in operability, and yield of the xylose is high; experiment result shows that purity of the xylose is 99% and the yield ranges from 40% to 50%.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

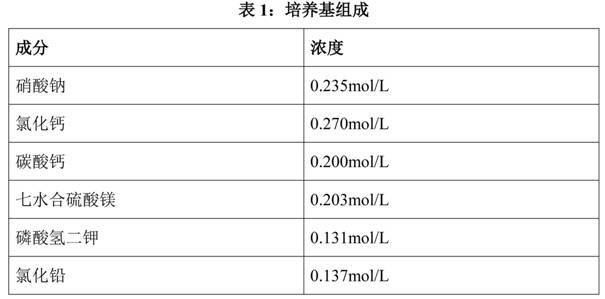

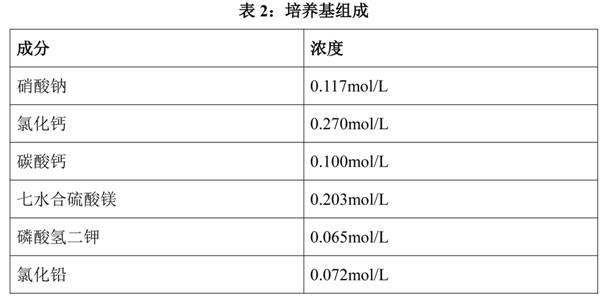

Culture medium of single-cell microalgae and method for treating lead-containing wastewater by using single-cell microalgae

ActiveCN102586117AReduce lead pollutionThe treatment method is green and environmentally friendlyUnicellular algaeWater contaminantsChemistryCarbon source

The invention discloses a culture medium of single-cell microalgae. The culture medium comprises a carbon source, a nitrogen source, a phosphor source and inorganic salts. A method for treating lead-containing wastewater by using the single-cell microalgae comprises the following steps of: firstly, feeding the single-cell microalgae into the culture medium for closed culture; secondly, after the culture is finished, condensing to obtain a concentrated solution of the single-cell microalgae; thirdly, uniformly mixing the concentrated solution with 0.2-0.7 percent agar semisolid suspension and then adding the lead-containing wastewater; fourthly, automatically treating the wastewater by using the single-cell microalgae and placing zooplankton into the wastewater for feeding the single-cell microalgae; and fifthly, collecting the zooplankton and separating water. According to the method for treating the lead-containing wastewater, lead pollution in a water body can be greatly reduced; and meanwhile, the treatment method is environment-friendly, low in price and feasible.

Owner:GUANGZHOU EP ENVIROMENTAL ENG

Curing method of soluble semi-solid waste salt

InactiveCN111744926ASolve curing problemsSolve the use problemSolid waste disposalTransportation and packagingPhysical chemistryEnvironmental engineering

The invention discloses a curing method of soluble semi-solid waste salt. The curing method comprises the following steps of: step 01. draining the soluble semi-solid waste salt, to be specific, draining the saturated soluble semi-solid waste salt to reduce the moisture content of the semi-solid waste salt; step 02. curing the soluble semi-solid waste salt, to be specific, adding the drained semi-solid waste salt, incineration fly ash, and a curing agent in proportion to a container, uniformly mixing the drained semi-solid waste salt, the incineration fly ash, and the curing agent, and fully chelating, wherein the mass ration of the soluble semi-solid waste salt to the incineration fly ash to the curing agent is 79.36 to 87.72: 7.94 to 8.77: 3.51 to 12.70, and the curing agent is one or more of cement, lime and asphalt; and step 03. putting the uniformly mixed chelated waste salt in a mold and maintaining for 1 to 7 days to obtain the chelated waste salt solidified body. By chelating and curing the soluble semi-solid waste salt, the curing agent and the incineration fly ash in proportion, the problem of solidification of the semi-solid waste salt is solved, and the problem of comprehensive utilization of the incineration fly ash is also solved; the treatment method is relatively environmentally-friendly; and the resource integration utilization rate is relatively high.

Owner:中节能(连云港)清洁技术发展有限公司

Sludge processing method

InactiveCN106467351ADisposal method is environmentally friendlyNo adverse side effectsSludge treatment by de-watering/drying/thickeningChemistrySide effect

A sludge processing method belongs to the field of environmental protection and is provided to achieve the purpose of environmental protection. According to the technical scheme, the method mainly comprises steps of screening, sedimentation, dehydration, press filtration and disinfection, etc., and can be adopted for effective treatment of sludge. Solids obtained after the treatment can be used as excellent organic fertilizers to be used in farmland and parterre, etc., are safe and environment friendly, and have no adverse side effect. The processing method is scientific and reasonable and environment friendly, has high treatment efficiency and high utilization rate, has excellent social and economic benefits, and has promotion value.

Owner:邹贝尔

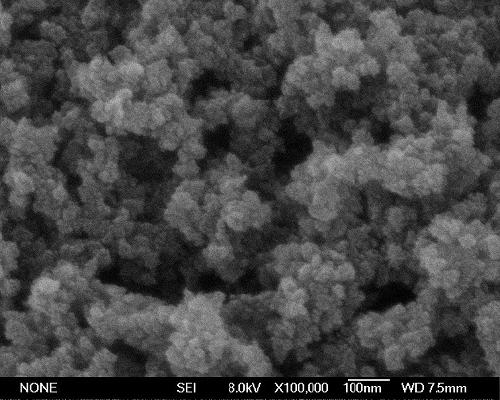

A method for improving the waterproof and corrosion resistance of wooden doors

ActiveCN110774395BIncrease water and corrosion resistanceLow water absorptionWood treatment detailsWood heatingCarbon layerPolymer science

The invention relates to the technical field of wood processing and discloses a method for improving the waterproof and corrosion resistance of wooden doors. During the processing of wooden doors, the prepared wood treatment agent is sprayed and adsorbed on the surface of wood, and further solidified and deposited to form a stable structure. The protective film layer, by bonding with the hydrophilic groups on the wood surface, greatly avoids the contact between the wood surface and moisture, and hinders the formation of hydrogen bonds between the hydroxyl groups of the cell wall polymers in the wood and water molecules, and has super Hydrophobic and anti-aging properties, reduce the water absorption and water absorption expansion rate of wood, solve the problem of poor effect and easy decay and aging of wooden doors in waterproof and corrosion-resistant treatment, can improve the waterproofness of wooden doors, and enhance the dimensional stability of wood At the same time, the nanoparticles in the film layer can use the synergistic effect to promote the rapid performance carbon layer on the surface of the wood, improve the fire resistance of the wooden door, and reduce the degree of harm caused by fire.

Owner:东莞市德俊家具有限公司

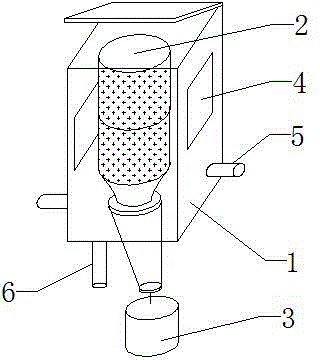

Method and device for removing fragments in electrode material

ActiveCN103000897ARealize batch processingEffective in removing debrisCell electrodesStationary filtering element filtersWater usePhysical chemistry

The invention provides a method and a device for removing fragments in an electrode material, which fills the blank of a special device and method for washing electrode materials in the prior art. The method comprises the following steps of: suspending the electrode material in a water tank; supplying circulating water to the water tank; and filtering the fragments in the circulating water by a filter. The device comprises a water tank, a suspension device and a circulating pump, wherein at least one water inlet is formed in the wall of the water tank or a water tank cover, and at least one water outlet is formed in the bottom of the water tank; the suspension device is arranged in the water tank and is used for suspending the electrode material in the water tank; and the circulating pump is used for circulating washing water. The method and the device have an obvious fragment removing effect, do not cause damages to the electrode material, can be used for processing electrode materials with different sizes synchronously so as to achieve mass processing, and are simple to operate.

Owner:大力储能技术湖北有限责任公司

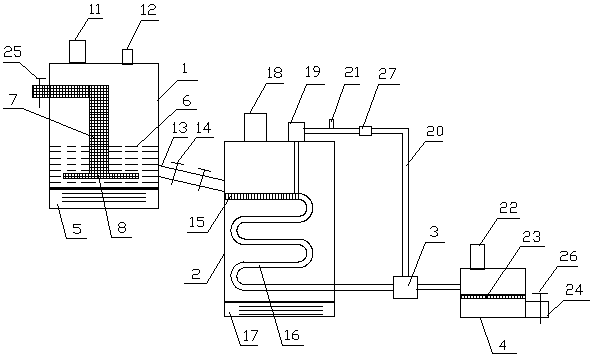

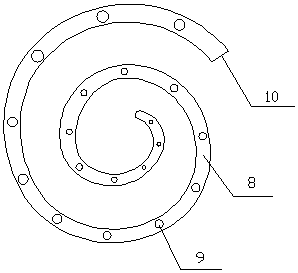

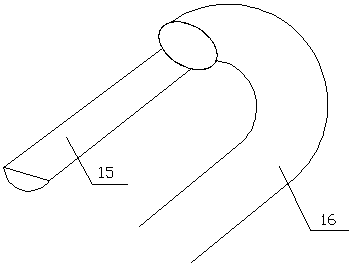

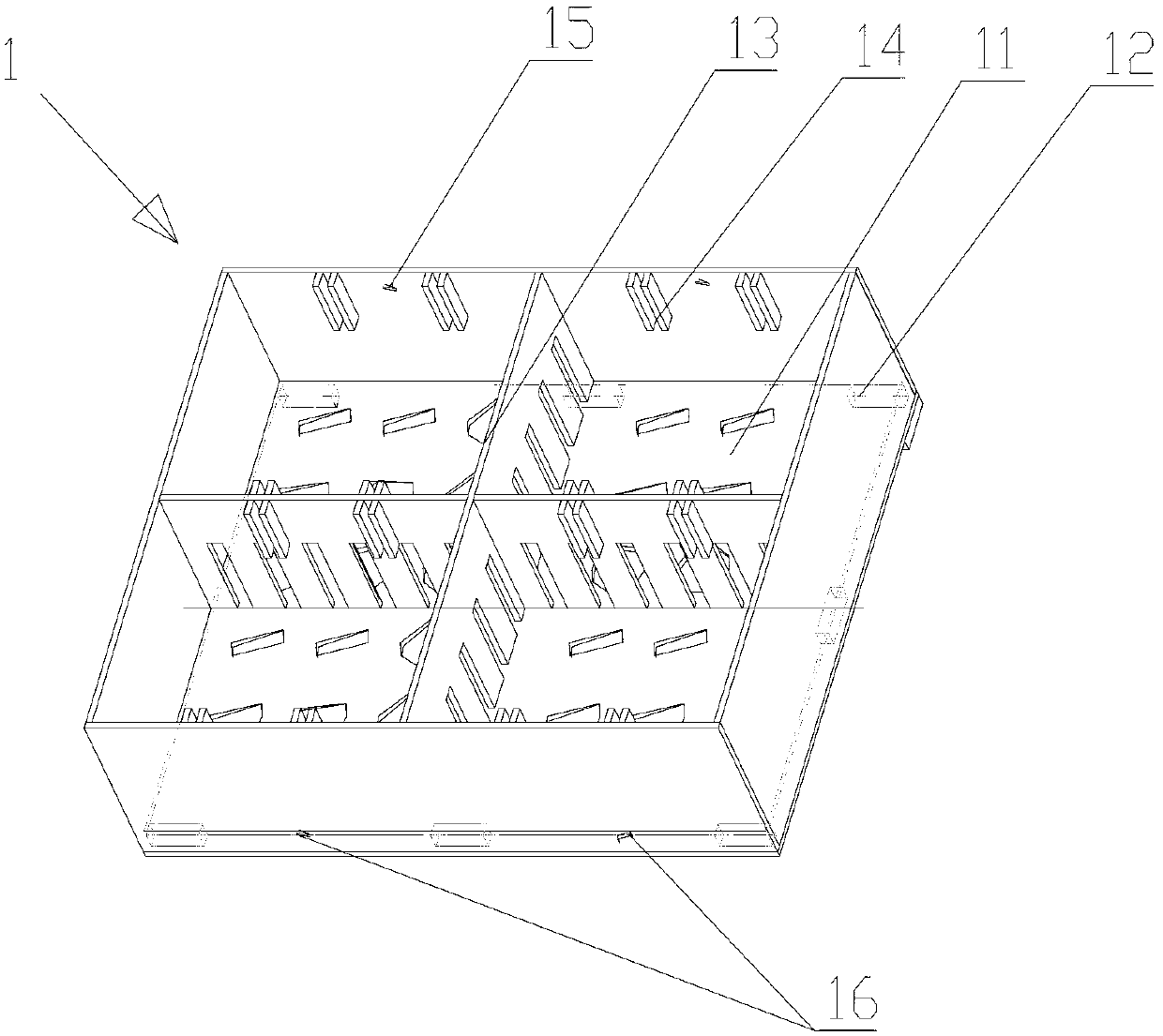

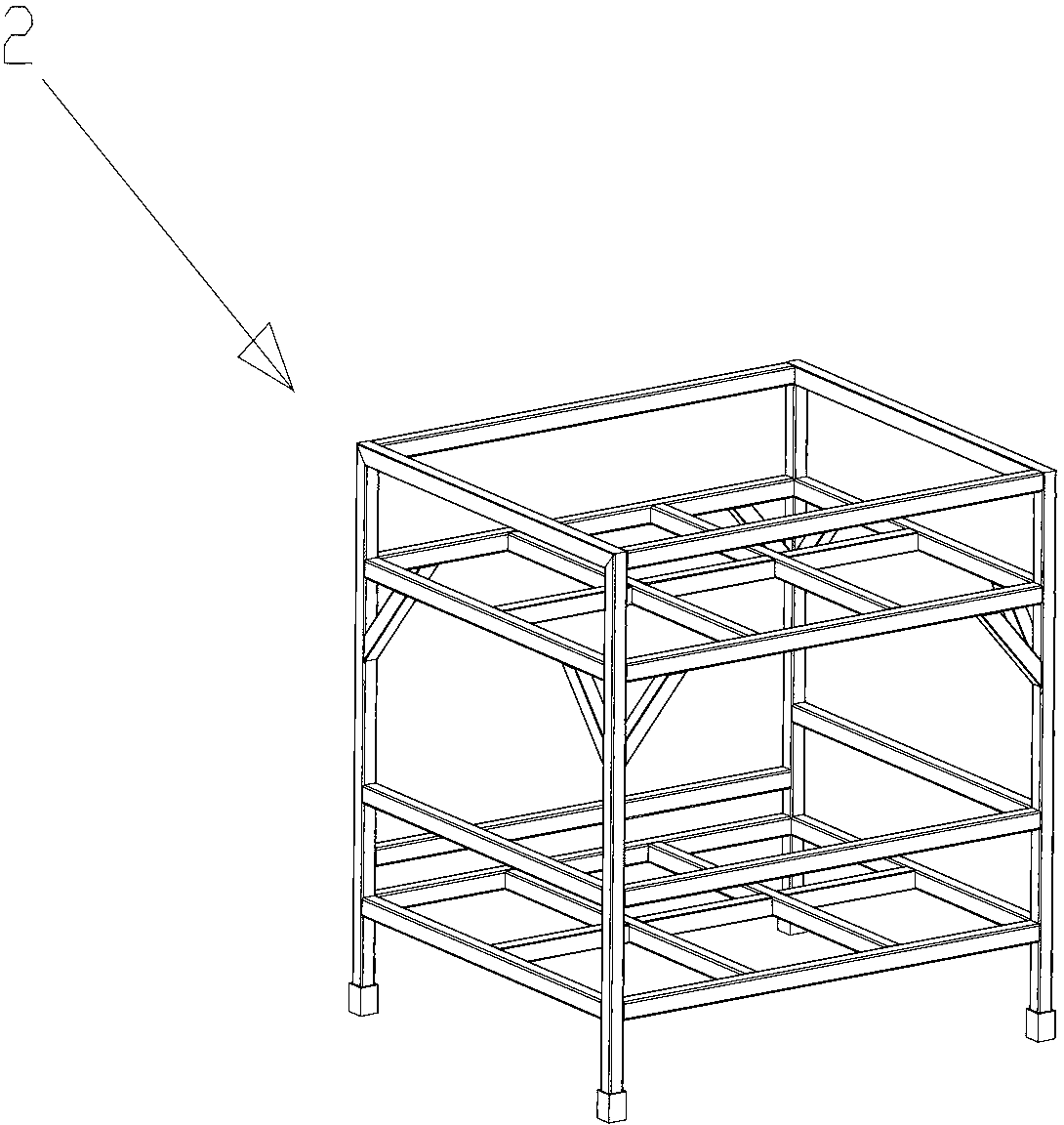

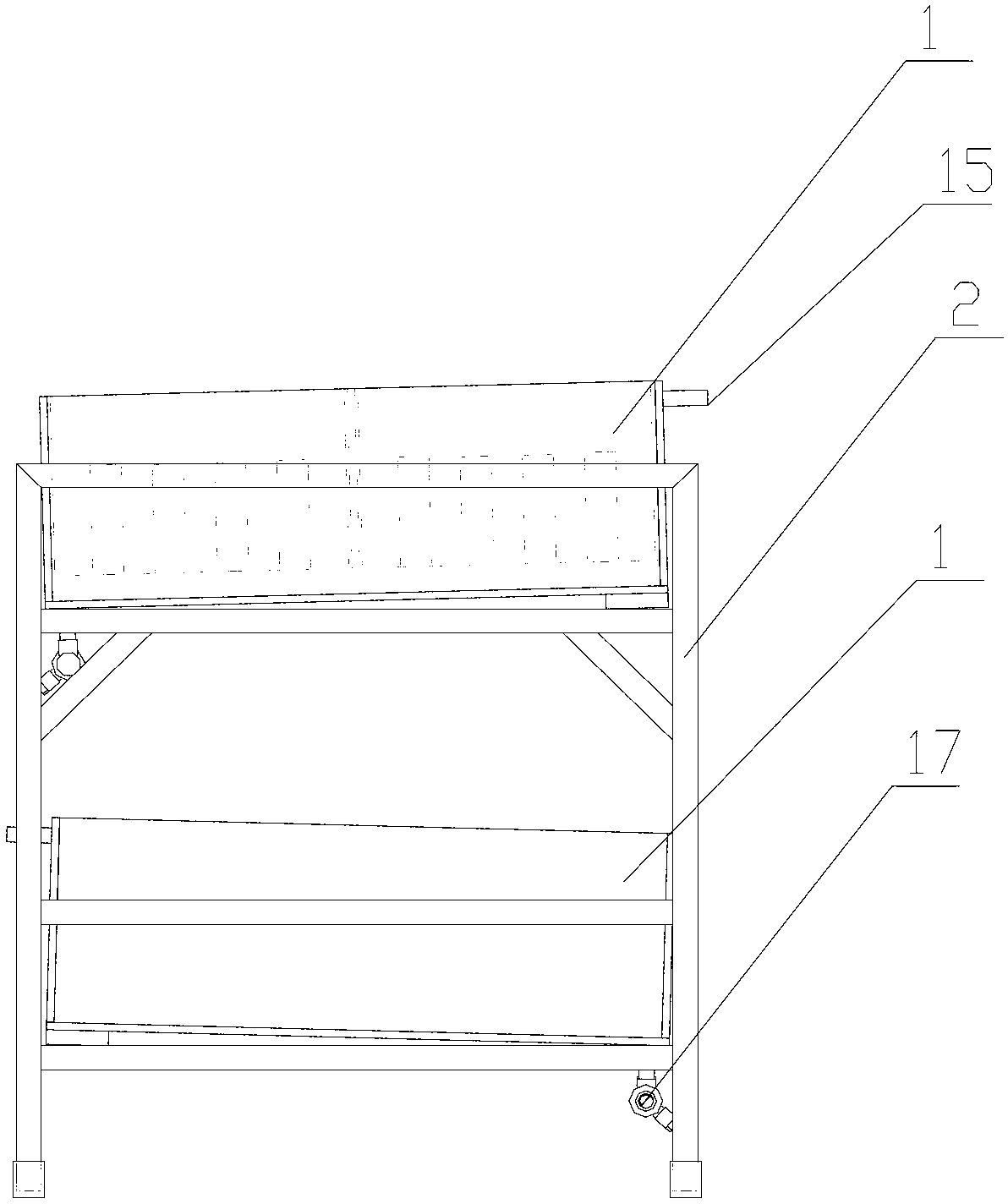

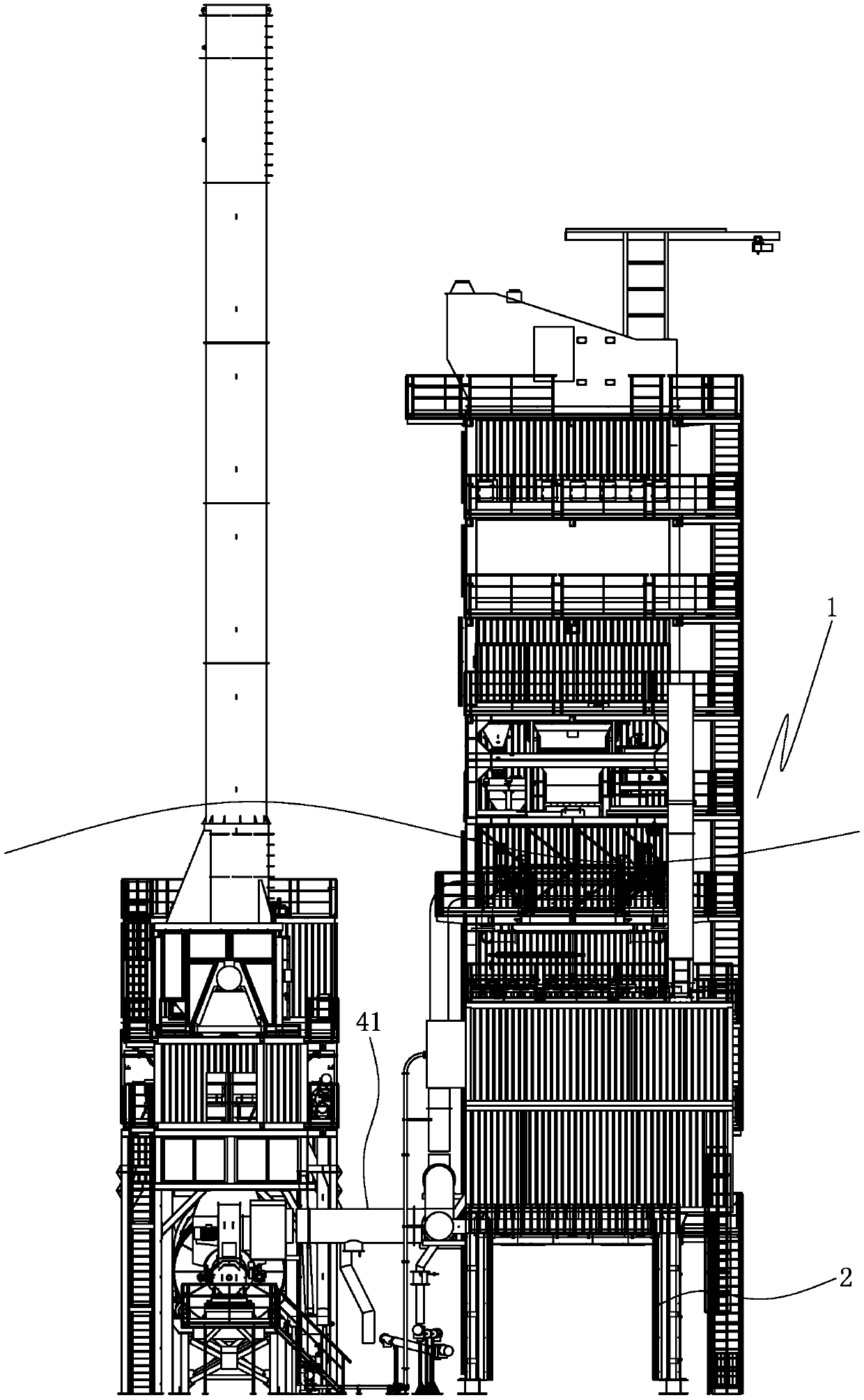

Asphalt smoke treatment system for loading area of asphalt stirring station

PendingCN109513301AReduce wasteRealize secondary useCombination devicesGas treatmentCombustorEnvironmental engineering

The invention discloses an asphalt smoke treatment system for a loading area of an asphalt stirring station. The asphalt stirring station comprises a combustor, a stirring cylinder and a waste gas treatment device, the waste gas treatment device treats waste gas generated by the asphalt stirring station, and the asphalt smoke treatment system comprises a loading workshop, a workshop dust-collection device, a combustor gas inlet device, a smoke powder treatment device, a reclaimed powder conveying device and a smoke powder conveying device. The smoke powder treatment device is arranged, reclaimed powder treated and reclaimed by the waste gas treatment device is fed into the smoke powder treatment device to adsorb asphalt smoke and then fed into the stirring cylinder to be utilized secondarily, thus the treatment mode is environmentally friendly, the asphalt smoke and the reclaimed powder can be simultaneously utilized secondarily, and resource waste is reduced.

Owner:FUJIAN TIETUO MACHINERY

Application of glacial acetic acid in fresh keeping of hot pepper fruit and hot pepper fresh-keeping method

InactiveCN102578219BReduce the disease indexReduce color transfer indexFruit and vegetables preservationAcetic acidProper treatment

The invention discloses application of glacial acetic acid in fresh keeping of hot pepper fruits and a hot pepper fresh-keeping method. The hot pepper fresh-keeping method comprises the following step: preparing a glacial acetic acid water solution with the concentration of 0.09-0.11 percent (V / V) by using the glacial acetic acid to soak the hot pepper fruits, or preparing a glacial acetic acid water solution with the concentration of 9-11 percent (V / V) by using the glacial acetic acid to fumigate the hot pepper fruits. Aiming at hot pepper, the invention provides glacial acetic acid with proper concentration as well as a proper treatment method and proper treatment conditions, and the hot pepper fruits are successfully kept fresh and sterilized; after the hot pepper fruits treated by the method of the invention are stored for 20 days at 22 DEG C, diseases are reduced obviously, the disease index of the soaked hot pepper fruits is reduced by 20.8 percent compared with a contrast, the disease index of the fumigated hot pepper fruits is reduced by 22.1 percent compared with a contrast, and the hot pepper skin color change is delayed obviously. The treatment method is environment-friendly, simple and convenient to operate and easy to popularize and use, and is low in cost.

Owner:SOUTH SUBTROPICAL CROPS RES INST CHINESE ACAD OF TROPICAL AGRI SCI +1

Simulated remediation system and method for underground water containing 1, 2-dichloroethane, nitrate and sulfate

ActiveCN111960552AImprove oxidation effectEfficient removalWater treatment parameter controlWater treatment compoundsPersulfateBioremediation

The invention provides a simulated remediation system and a method for underground water containing 1, 2-dichloroethane, nitrate and sulfate. According to the system, a rectangular tank-type shell with an opening in the top is sequentially divided into a pollution source section, a pollutant migration and transformation section and a pollutant remediation section from left to right; a sample spacelayer of the pollutant remediation section is filled with a denitrified material filling layer which is filled with a mixture of tourmaline, pyrite, quartz sand and sulfur autotrophic denitrifying bacteria, an oxide material filling layer which is filled with a mixture of persulfate, tourmaline, pyrite and quartz sand, and a desulfurized material filling layer which is filled with a mixture of tourmaline, quartz sand and sulfate reducing bacteria from left to right in sequence. The pH value and oxidation-reduction potential of the aquifer are optimized, the oxidability of a Fenton-like systemin underground water and the activity of denitrifying bacteria and sulfate reducing bacteria are integrally improved, and the effectiveness and practicability of a biological remediation system and achemical oxidation system in industrial polluted underground water remediation are obviously improved.

Owner:INST OF HYDROGEOLOGY & ENVIRONMENTAL GEOLOGY CHINESE ACAD OF GEOLOGICAL SCI

Preparation method of segment-shaped dendrobium stem brewing tea

InactiveCN107691712ADisposal method is environmentally friendlyTea substituesIonDendrobium sanguinolentum

The invention relates to the technical field of dendrobium stem deep processing, in particular to a preparation method of a segment-shaped dendrobium stem brewing tea. The method comprises the following steps: placing plucked fresh dendrobium stems in hot water for blanching, subjecting the dendrobium stems after the blanching to cold treatment at a temperature of 3-5 DEG C, placing the dendrobiumstems after the cold treatment in a soluble iron ion aqueous solution, conducting mechanical stirring, putting the finally obtained stirred dendrobium stems in a lyophilizer for drying, and subjecting the dried segment-shaped dendrobium stems to sterilization under ultrasonic ultraviolet rays, weighing and packaging. After the obtained segment-shaped dendrobium stem brewing tea is brewed with a conventional method, a dissolution rate of effective components is no less than the dissolution rate of the brewed dendrobium stem powder obtained by superfine grinding, and a treatment mode is green and environmentally friendly, and no toxic reagent is used.

Owner:霍山县长冲中药材开发有限公司

Plastic recovery method

InactiveCN106608002AImprove processing efficiencyIncrease profitPlastic recyclingMechanical material recoveryEnvironmentally friendlyEngineering

The invention provides a plastic recovery method, and belongs to the technical field of plastic recovery. The purpose of treating plastic economically in an environmental-friendly mode can be achieved. According to the technical scheme, the plastic recovery method mainly includes the steps of sedimentation, washing, filter pressing and smashing. Through the steps, impurities, oil stains and the like of plastic are removed, plastic particles are obtained after smashing, since a large quantity of high-molecular materials are contained in the plastic particles, the plastic particles can be used after degradation, and the plastic particles can be used as padding of other rubber or plastic products so as to be recycled. The plastic recovery method is scientific, reasonable, environmentally friendly and high in treating efficiency, the utilization rate is high, and the method has great social and economic benefits and popularization value.

Owner:邹贝尔

Fried rice with taste improved by reduced viscosity of soft rice, and stir-frying method thereof

PendingCN110122748AReduce viscosityDisposal method is environmentally friendlyFood scienceAdditive ingredientRice dishes

Disclosed are fried rice with taste improved by reduced viscosity of soft rice, and a stir-frying method thereof. The stir-frying method includes: 1) washing the soft rice with water; 2) pouring the washed soft rice into an electric cooker, and adding water to soak the soft rice; 3) powering on the electric cooker to steam the rice, and preserving the heat after steaming; 4) directly spreading thecooked rice on an utensil for cooling; 5) sealing and packaging the cooled rice, squeezing out residual air, leveling a bag, and directly putting the bag into a refrigerator for freezing; 6) thawingthe frozen rice; 7) unpacking the thawed rice, making the rice loose, blending the rice with ingredients and seasonings while stir-frying, and taking out the rice after uniform stirring of the rice, the ingredients and the seasonings. The method has the advantages that the viscosity of the soft rice is reduced, the rice does not stick to the cooker and a shovel during cooking, and smooth stir-frying is achieved; a rice treatment method before stir-frying is environmentally friendly, simple and easy to operate; the rice cooked by the method is moderately soft and crystal clear, and has high elasticity and good taste.

Owner:SHANDONG RICE RES INST

Tea dehydrating and drying method

InactiveCN104522202ASave drying process timeEnhanced Chestnut FlavorPre-extraction tea treatmentDrying timeMoisture

The invention discloses a tea dehydrating and drying method. Tea drying is assisted by adopting a centrifuge dehydration mode before a tea-making drying process or during the drying process. According to the tea dehydrating and drying method, the tea leaves are dried in an assisted mode by adopting a centrifugal force dehydration principle, the pectin and tea liquor contained in the moisture of the tea can be thrown out, the bitterness is removed, the drying time during the tea making is greatly saved, the taste and the quality of summer and autumn tea are improved, the tea making period is shortened, the method is a novel process for drying the summer and autumn tea, and due to the treatment mode, sanitary and environment-friendly effects are achieved.

Owner:贵州湄潭百道茶业有限公司

Plastic product processing method

InactiveCN109747069AThe processing method is scientific and reasonableDisposal method is environmentally friendlyPlastic recyclingEconomic benefitsEngineering

The invention provides a plastic product processing method, belongs to the technical field of plastics, and aims to achieve the environment-friendly purpose. The technical scheme mainly comprises thesteps of freezing, breaking, separating and crushing, so that the plastic products can be effectively processed. At low temperature, the plastic product is easy to generate cracking phenomenon, the structure of the plastic product is damaged by low-temperature freezing, so that the plastic product is easy to crush, and the structural member in the product can be taken out to use as a filling material for other plastic products by crushing and can be degraded and used. The processing method has advantages of being scientific and reasonable, environmentally-friendly, high in processing efficiency, high in utilization rate, excellent in social and economic benefits, and good in popularization value.

Owner:杨润

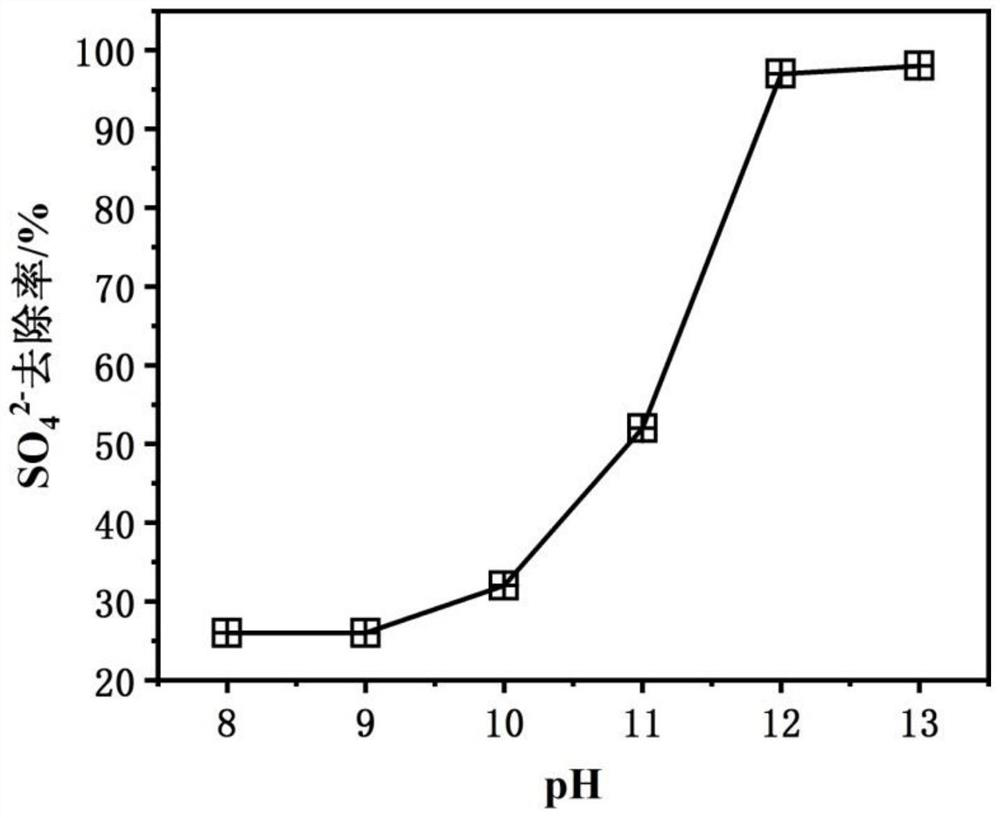

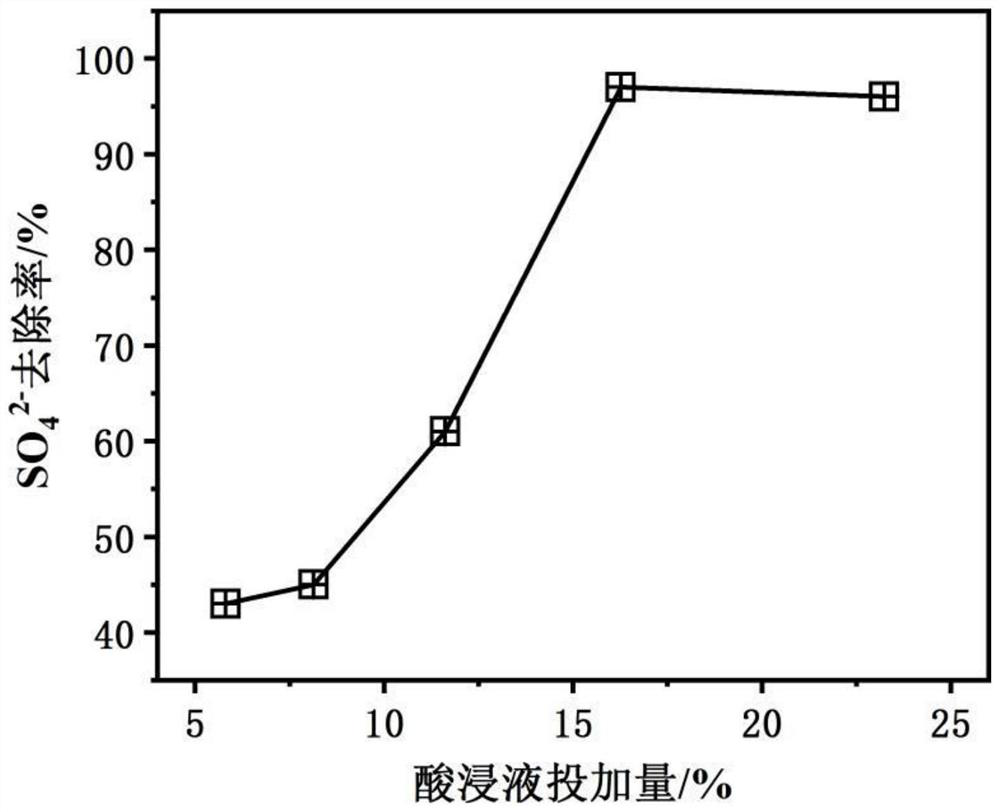

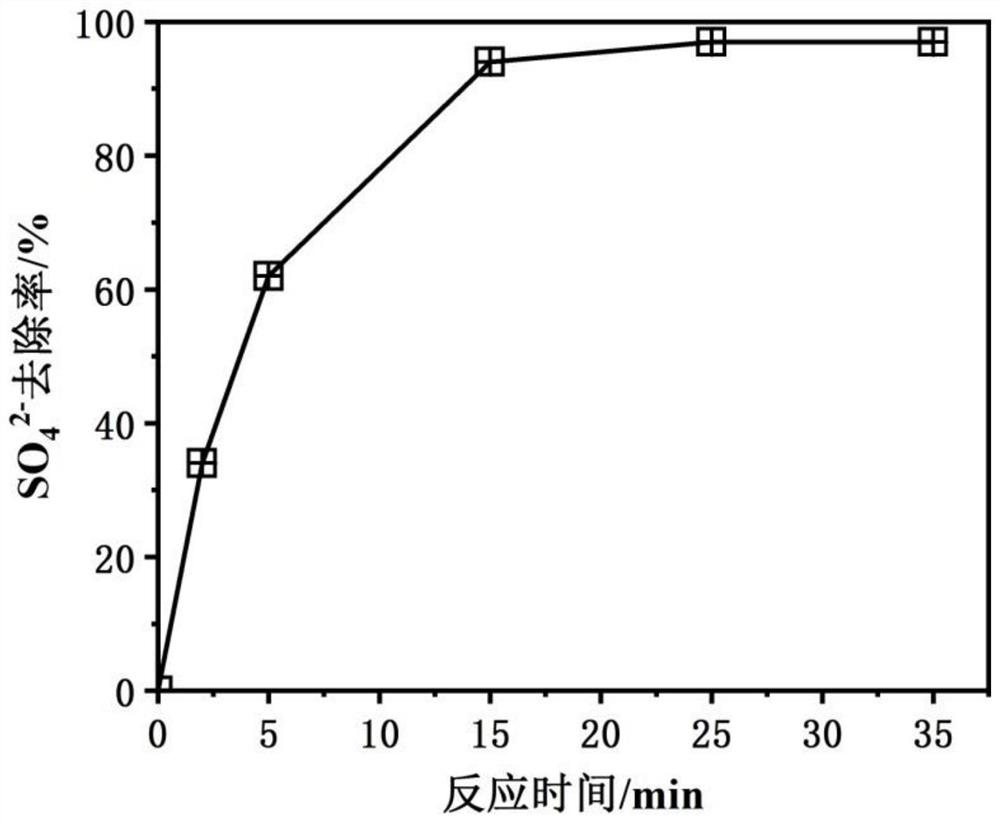

Method for treating sulfate in wastewater

PendingCN114163012ASimple processing methodProcessing method greenWater treatment parameter controlAluminium compoundsSulfateWastewater

The invention relates to a method for treating sulfate in wastewater, which comprises the following steps: crushing aluminum-containing oil shale waste residue, grinding into fine powder, and heating the oil shale waste residue for 3 hours; the method comprises the following steps: soaking heated oil shale waste residues in an HCl solution to dissolve the waste residues, filtering out solids, adding a Na2CO3 solution to adjust the pH value to 4.8-5.0 to remove Ca < 2 + > and Mg < 2 + >, filtering out the solids, adding a NaOH solution to adjust the pH value to be alkaline to remove Fe < 3 + >, filtering out the solids again, and adding an HCl solution to adjust the pH value to be acidic to obtain a liquid which is pickle liquor containing Al < 3 + >; the method comprises the following steps: mixing pickle liquor containing Al < 3 + > with wastewater to obtain first mixed liquor, adding quick lime or slaked lime into the first mixed liquor to adjust the pH value to be alkaline to obtain second mixed liquor, reacting the second mixed liquor in a constant-temperature environment, and after the reaction is finished, standing, precipitating and filtering to remove sulfate in the wastewater. The method disclosed by the invention is simple to operate, low in cost, environment-friendly, green and good in removal effect, and the problem of environmental pollution caused by accumulation of a large amount of oil shale waste residues is solved while sulfate pollution is removed.

Owner:CHINA COMM SOUTH ROAD & BRIDGE CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com