Commercial treatment method and system for biological sludge and rotary sludge carbonizing machine

A technology of biological sludge and treatment method, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc. Sludge drying treatment, restricting the promotion of sludge incineration technology, etc., to achieve the effect of low processing cost, saving sludge treatment cost, and saving project investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

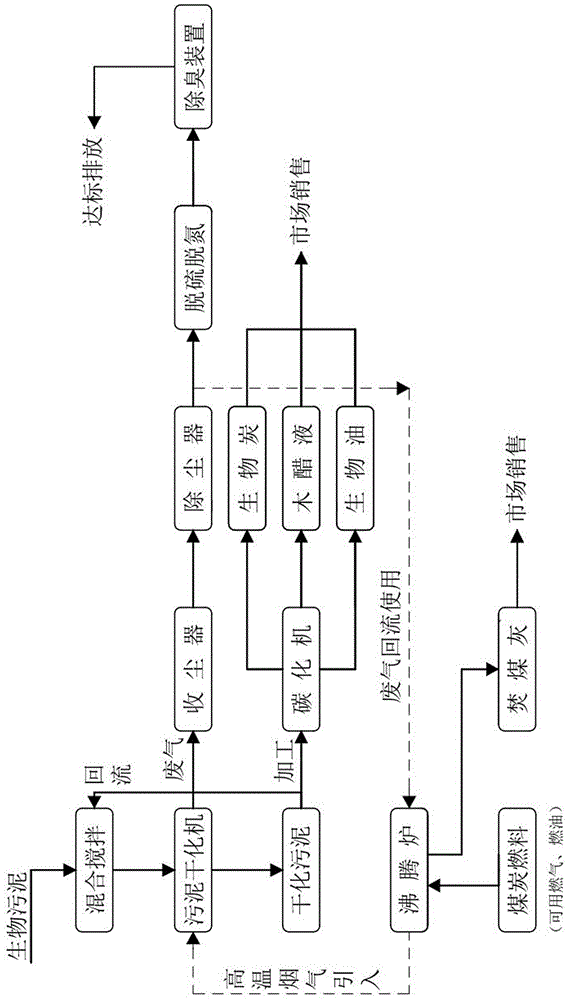

[0037] see figure 1 , the biological sludge commercialization treatment method of the present invention, its processing process that biological sludge adopts is as follows:

[0038] Firstly, the biological sludge is dried to obtain dried sludge with a moisture content of 7-10%;

[0039] Thirdly, carbonize the dried sludge with a water content of 7-10%. The carbonization process is completely in an anaerobic state. The dried sludge undergoes high-temperature pyrolysis and carbonization to generate biochar, methane gas, wood vinegar and biological tar;

[0040] Third, the methane gas generated during the carbonization treatment of dried sludge is recycled for carbonization treatment of dried sludge, and the remaining methane gas is used for biological sludge drying treatment;

[0041] Fourth, the biochar generated during the carbonization process of dried sludge is cooled and then put into woven bags or pumped into storage tanks for sale;

[0042] Fifth, the wood vinegar p...

Embodiment 2

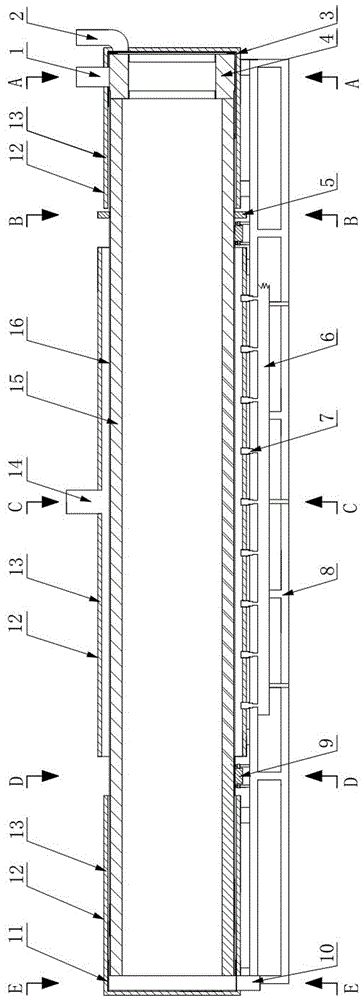

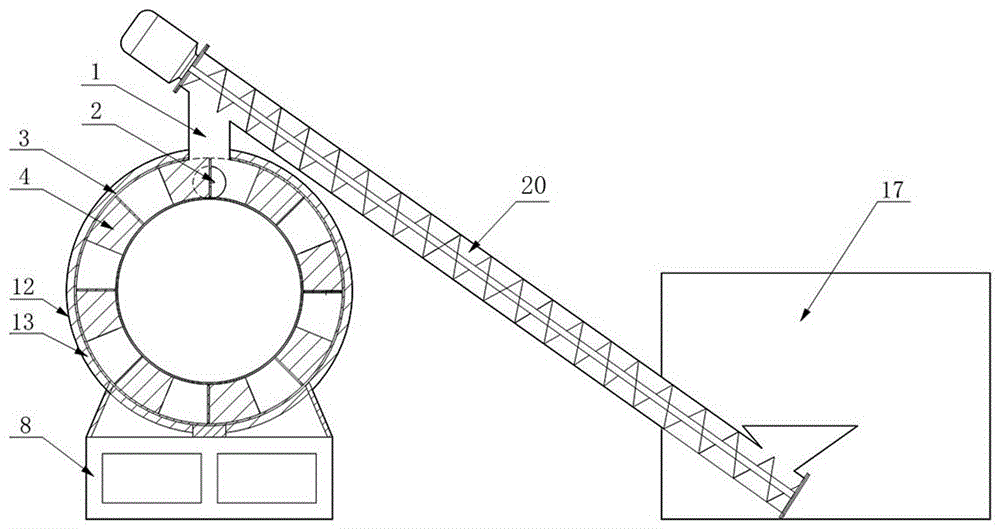

[0046] see figure 1 , the biological sludge commercialization treatment method of this embodiment differs from that of Example 1 in that: further, in the process of drying sludge carbonization, a rotary sludge carbonization machine is used, and by controlling the carbonization machine feed Speed, carbonization machine speed and methane gas burner intake, control carbonization temperature and carbonization efficiency. The high-temperature gas generated by peatization is cooled by the cooling tower, and methane gas, wood vinegar and bio-tar are separated.

[0047] A sludge carbonization machine is used to carbonize the dried sludge with a moisture content of 7-10%. The dried sludge is pyrolyzed at high temperature to generate biochar, methane gas, wood vinegar and bio-oil; the methane gas produced is used for heating in the sludge carbonization machine Carbonization and drying of sludge, carbonization, gas production, and heating cycle continuously, realizing the recycling o...

Embodiment 3

[0049] see figure 1 , the commercial treatment method of biological sludge in this embodiment differs from that of Example 1 or Example 2 in that: during the drying process of biological sludge, biological sludge with a moisture content of 78 to 82% is added to biological The sludge weight is 1.3-1.8 times the reflux drying sludge with a moisture content of 7-10%, fully stirred to obtain a mixed sludge with a moisture content of 35-40%, and then sent to a rotary sludge dryer for drying Treatment to obtain dried sludge with a moisture content of 7-10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com