Patents

Literature

52results about How to "The processing method is scientific and reasonable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Processing method of Dendrobium officinale golden bar or sheet

ActiveCN103404862AKeep active ingredientsGolden skin colorFood shapingFood preparationSurface moistureCooking & baking

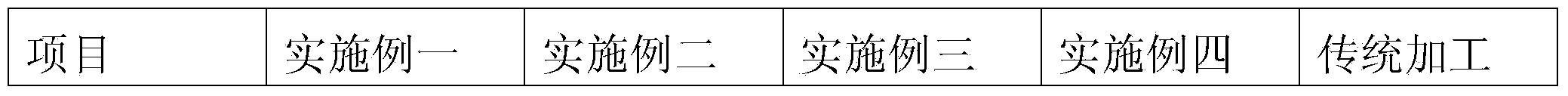

The invention relates to a processing method of a Dendrobium officinale golden bar or sheet, which comprises the following steps: a. taking Dendrobium officinale fresh strips, cleaning to remove sand, and airing to remove surface moisture, thereby obtaining clean Dendrobium officinale; b. baking at 100-105 DEG C for 3-6 minutes, taking out and kneading while the Dendrobium officinale is hot, and repeating the operation until the surface of the clean Dendrobium officinale becomes golden; and c. cutting into sections or sheets, freezing at -70 to -90 DEG C, and carrying out freeze-drying to obtain the golden Dendrobium officinale golden bar finished product or golden Dendrobium officinale golden sheet finished product. The Dendrobium officinale product is golden, beautiful and crisp, is convenient to eat, and can effectively reserve the original active components in the Dendrobium officinale.

Owner:YUNNAN DENDROBIUM OFFICINALE TECH DEV CO LTD

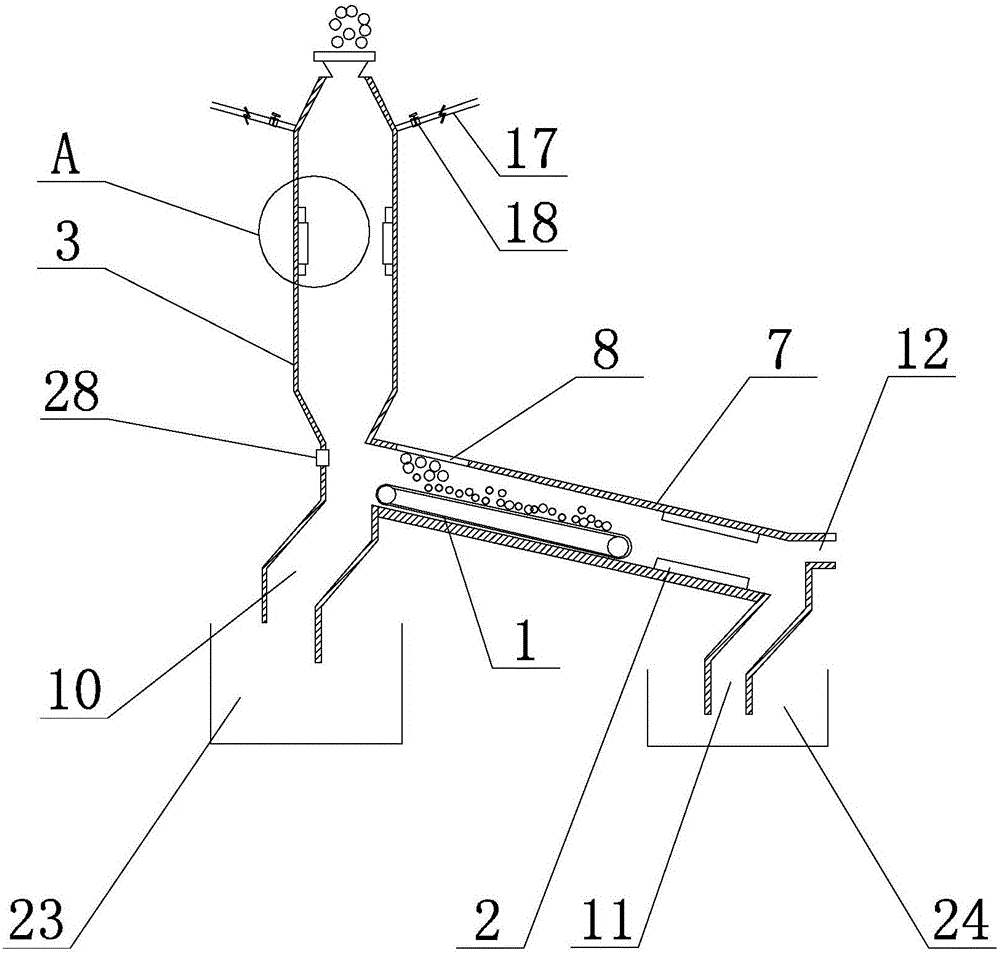

Method for continuously processing degradation-resistant wastewater by means of microwave catalysis

InactiveCN103420445AImprove use reliabilityImprove processing efficiencyWater/sewage treatment by irradiationAutomatic controlMicrowave

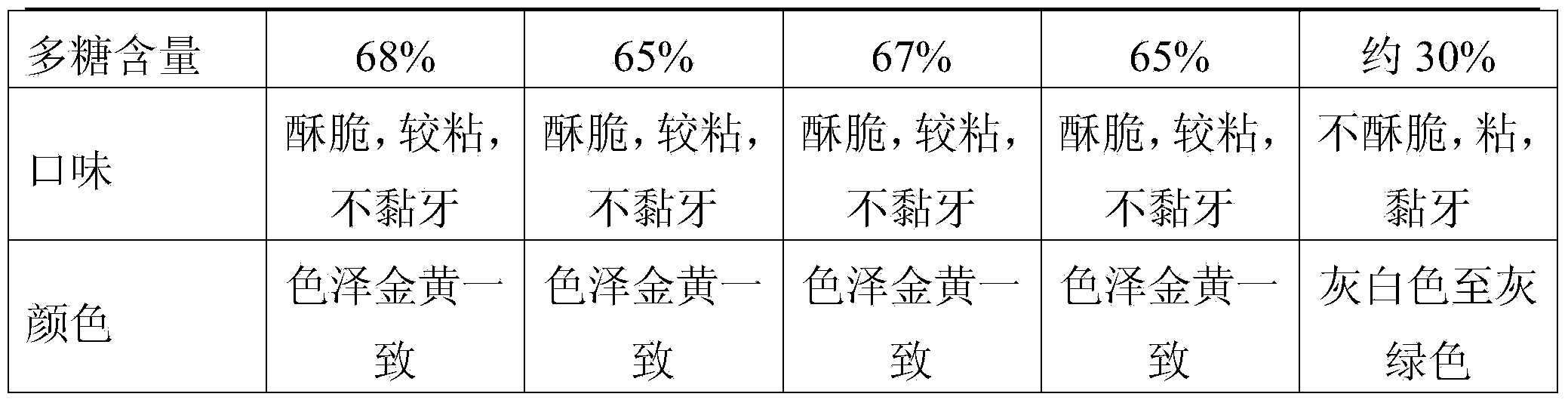

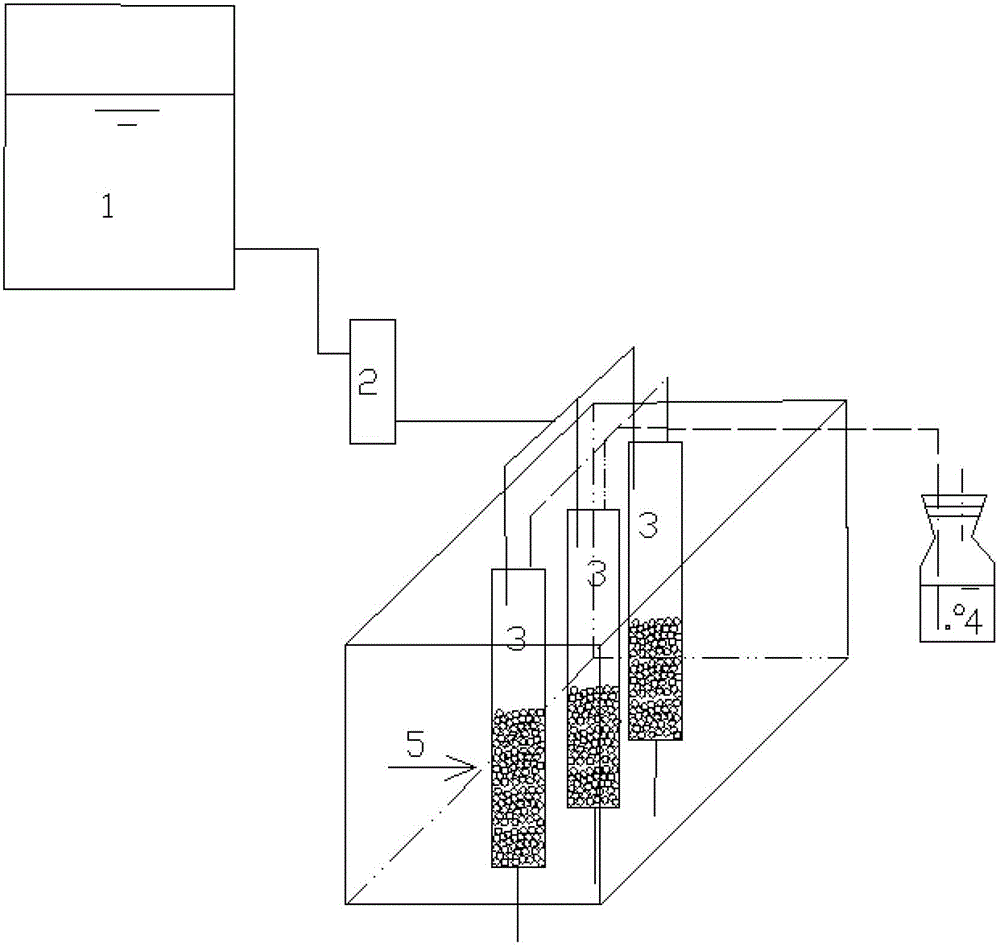

The invention discloses a method for continuously processing degradation-resistant wastewater by means of microwave catalysis and an implementation device thereof. Granular catalyst is filled into quartz tubes to form quartz tube catalyst columns; the quartz tube catalyst columns are placed into a microwave field to form catalyst fixing beds, wherein the intersection angle of the axial direction of the quartz tube catalyst columns and the direction of the irradiation microwave is not less than 45 degrees; wastewater to be processed continuously flows through the catalyst fixing beds, so that pollutants in the wastewater can be removed under the combined action of the microwave and the granular catalyst; processed water and gas produced during wastewater treatment are discharged; the granular catalyst is husk-like granular activated carbon prepared through carbonization, smashing, bonding formation and carbon dioxide activating treatment. With adoption of the method, continuous industrialized degradation of degradation-resistant wastewater can be realized, the operation is simple, the automatic control is facilitated, the application to different wastewater processing amounts can be realized by means of increasing or decreasing the number of the quartz tube catalyst columns, the investment and the operation cost are low, and the removal efficiency is high.

Owner:SICHUAN UNIV

Surface treatment method for magnesium alloy

The invention discloses a surface treatment method for magnesium alloy. The method includes the following steps of (1) primary washing, (2) ungrease treatment, (3) secondary washing, (4) primary acid pickling, (5) secondary acid pickling, (6) alkali washing, (7) anodic oxidation, (8) third-time washing and (9) drying and heat preservation. All the steps of the processing method are scientific, reasonable and ingenious in process. The structure of surface oxidation films of a magnesium alloy material is effectively improved, the strong acid resistance, strong base resistance and organic solvent corrosion resistance are improved obviously, the surface strength is improved by 30%-35%, and the brittleness is well improved. A special cellular structure is achieved, the deep processing technique like dyeing is facilitated, and the use value is good.

Owner:刘洪建

Processing equipment for low heat value wastes and processing method

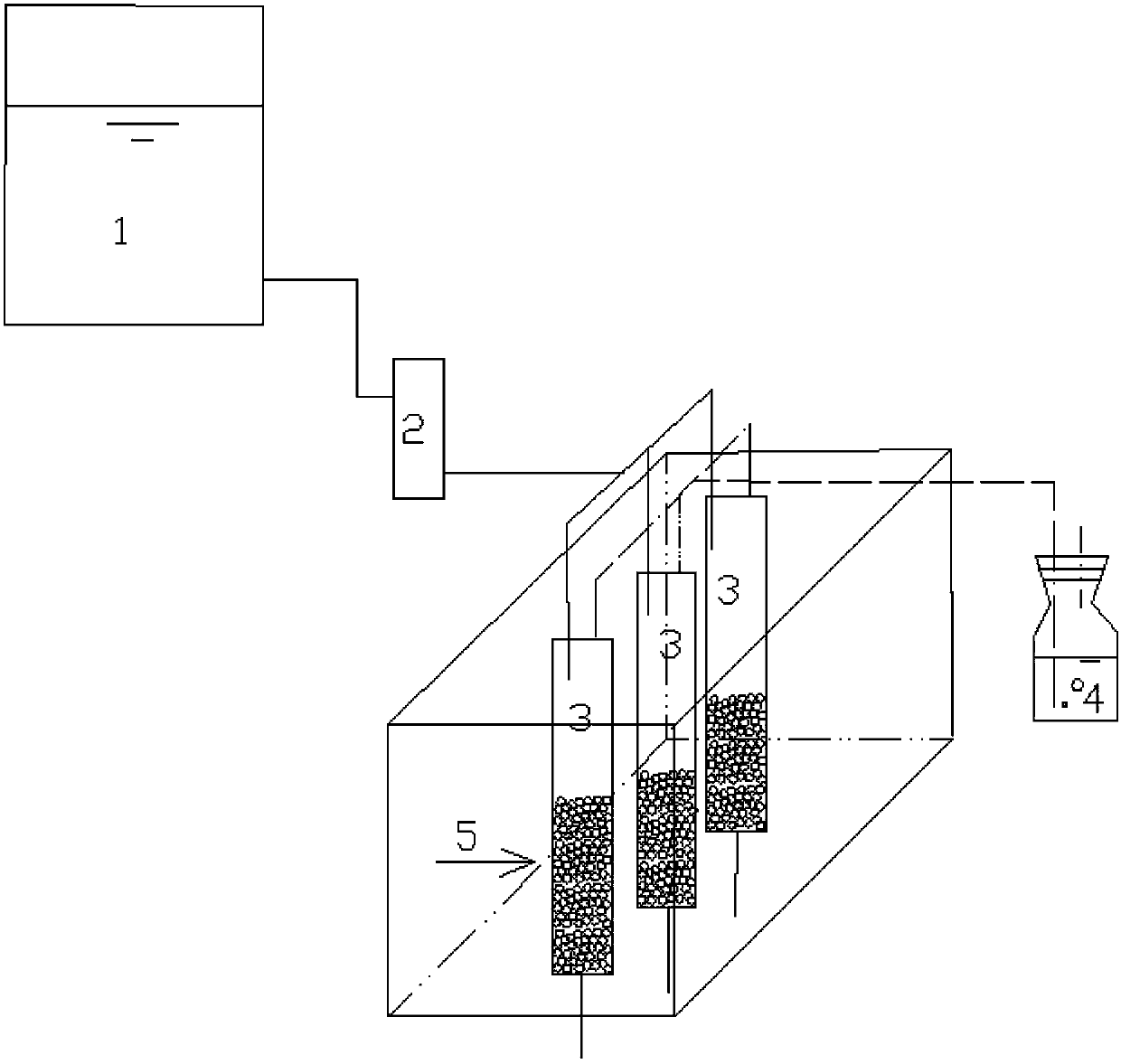

InactiveCN101457935AMeet the temperature requirementsSave fuelIncinerator apparatusTemperature controlProcess equipment

The invention relates to processing equipment for the low calorific value waste and a processing method thereof. When the waste is incinerated in an incinerator, part of generated high-temperature gas is transmitted into a rotary kiln for conducting heating, drying and incinerating treatment to the low calorific value waste; the volume of the high-temperature gas entering the rotary kiln is controlled by controlling the air supply volume of a high-temperature fan, so the temperature requirement of the rotary kiln is achieved; by temperature control, various components of the low calorific value waste are respectively treated such as drying, recycling, incineration, etc. As a pipeline and a high-temperature fan are arranged, the invention can transmit the heat in the incinerator to the rotary kiln, the fuel in the rotary kiln is not needed to be heated, and the energy is saved, thereby being quite environmental-protection to the recycle and use of a plurality of materials.

Owner:沈福昌

Processing method capable of improving surface strength of aluminum and aluminum alloy

The invention discloses a processing method capable of improving the surface strength of aluminum and aluminum alloy. The processing method includes the following steps of (1) primary washing, (2) ungrease treatment, (3) secondary washing, (4) primary acid pickling, (5) secondary acid pickling, (6) alkali washing, (7) anodic oxidation, (8) third-time washing and (9) drying and heat preservation. All the steps of the processing method are scientific, reasonable and ingenious in process. The structure of surface oxidation films of an aluminum or aluminum alloy material is effectively improved, the strong acid resistance, strong base resistance and organic solvent corrosion resistance are improved obviously, and the surface strength is improved by 20%-25%. Furthermore, a special cellular structure is achieved, the deep processing technique like dyeing is facilitated, and the use value is good.

Owner:刘洪建

Health fruit jelly containing snow lotus pulp and preparation process thereof

The invention relates to a jelly and process for preparing same, wherein the jelly is prepared from (by weight portions) saussurea involucrate fruit grout 90-110 parts, composite glue solution 90-110 parts, xylitol 15-25 parts, and lemon acid 0.3-0.5 part. The jelly is prepared into stramineus gelatin with sufficient nourishing ingredients.

Owner:贵州明美进出口贸易有限责任公司

Processing method of siberian solomonseal rhizome pickle

InactiveCN1907113APromote prosperityThe processing method is scientific and reasonableFood preparationPickled vegetablesRaw material

The invention relates to a process for preparing pickled vegetable containing Siberian solomonseal rhizome, wherein the raw materials include vegetable 100 weight parts, cooking wine 0.40 weight part, pricklyash peel 0.40 weight part, ginger powder 0.20 weight part, pimiento 1 weight part and common salt 19 weight parts.

Owner:HENAN UNIV OF SCI & TECH

Processing method of starters using pepper

InactiveCN101491320AHas the function of hangover appetizerThe processing method is scientific and reasonableFood preparationSucroseHot peppers

The invention relates to a processing method for preparing a cocktail with hot peppers, which belongs to a food processing technique, in particular to a processing method for preparing the cocktail with the hot peppers. The processing method uses the hot peppers as the main material which is mixed with certain proportion of seasoning water prepared from auxiliary materials of cane sugar, white vinegar, honey and sweetener, and comprises the following steps sequentially: selecting and cleaning materials, removing pedicels and seeds, deepfrying the materials, cooling and peeling the materials, soaking the materials in the seasoning water, and packaging the product. With the implementation of the proposal, the processing method thereof is scientific and reasonable and easy to master rightly, and has lower processing cost; and the product has brilliant color, clear and translucent appearance, fresh and tender taste and crispness, does not get stuck between teeth, is suitable for both the young and old, and has the functions of anti-inebriation and appetite stimulation.

Owner:柳洪儒

Processing method of Huoshan dendrobium officinale

InactiveCN104587213AKeep active ingredientsPromote dissolutionTea substituesFood preparationAdditive ingredientCuticle

The invention discloses a processing method of Huoshan dendrobium officinale. The method comprises the following steps: picking up fresh stems of three-year Huoshan dendrobium officinale with good shapes from a base, storing the picked stems in a warehouse at a constant temperature of 15 DEG C for 1-2 days till the moisture of the stems is evaporated by 20%, and processing through the processing steps. The dendrobium officinale prepared by the invention is golden in surface color and luster and fragrant in smell, and is capable of effectively reserving original active ingredients of the dendrobium officinale. The processing method disclosed by the invention is scientific and reasonable; compared with traditional process for processing the endrobium officinale, the processing method has the advantage that the internal active ingredients are easy to dissolve out; in addition, the endrobium officinale does not need to be decocted for a long period of time and the active ingredients in the endrobium officinale can be dissolved out, so that absorption by a human body is facilitated. The dendrobium officinale prepared by the method is wide in application range, is sanitary and safe, and is easy to digest and absorb by a human body, can be directly eaten in a chewing manner, and can be used for making tea and cooking soup or can be added to porridge.

Owner:安徽中升生物科技有限公司

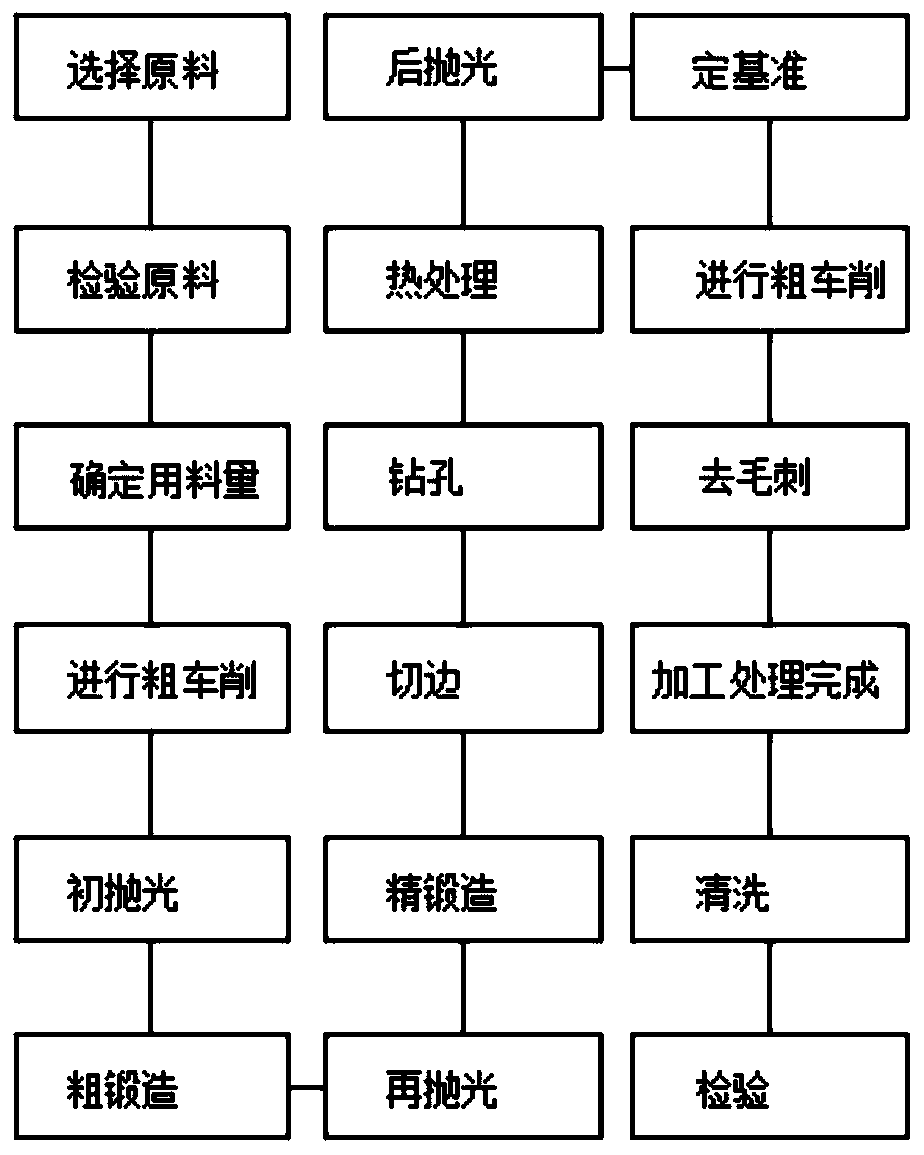

Processing method of large diameter connection flange plate

InactiveCN109848654AReduce processing stepsAvoid processing method influencePolishingProcess engineering

The invention discloses a processing method of a large diameter connection flange plate. The processing method comprises the following steps of S1: the raw material selection; S2: the raw material inspection, namely, the 45 steel material raw material selection; S3: the material amount determination; S4: the rough turning; S5: the initial polishing; S6: the rough forging; S7: the re-polishing; S8:fine-forging; S9: the edge cutting, namely, the forged fly edge cutting; S10: the drilling, namely, the drilling on the material through a drilling mold; S11: the heat treatment, namely, the heatingmodulation; S12: post-polishing; S13: the benchmark determination, namely, the benchmark center determination of the flange plate; S14: the fine turning; S15: the deburring; S16: the processing completing; S17: the washing; and S18: the inspection, namely, the processed flange plate inspection according to the drawings. The processing method is more scientific and reasonable, and can reduce the production cost, the processing method steps of the processing method are simple, the automated batch processing of the flange plates can be achieved, and the processing accuracy, the product pass rateand production efficiency can be improved.

Owner:无锡市星达石化配件有限公司

Process of making cooked pig's head meat

InactiveCN1383749AThe processing method is scientific and reasonableRich varietyFood preparationFood flavorSpring onion

In the process of making cooked pig's head meat. pig's head after being washed and roasted is re-washed, cut according to different regions, soaked and cooked in soy sauce to make eight different dishes in different flavor. During its making process the seasoning oil is made with vegetable oil, scallion, ginger, garlic, caraway and celery.

Owner:曲铁栋

Processing method of burdock pickles and its product

InactiveCN1409993APromote prosperityThe processing method is scientific and reasonableFood preparationPreservativeArctium Lappa Root

Owner:郑武一

Soft pear fruit vinegar beverage and production method thereof

ActiveCN103535810AFruity aromaFruityNatural extract food ingredientsVinegar preparationPEARFood flavor

The invention relates to a soft pear fruit vinegar beverage and a production method thereof. The soft pear fruit vinegar beverage takes soft pears as a raw material and is produced with processes of fruit sorting, storing, juicing, instant high-temperature sterilization, enzyme treatment, primary fermentation, secondary fermentation, preparation, filtering, desaeration, encapsulation and sterilization. The soft pear fruit vinegar beverage is simple in production method and low in cost, and the soft pear fruit vinegar in the beverage has prominent fruit fragrance, strong vinegar fragrance and distinct flavor.

Owner:青海兴农实业有限公司

Fusion device capable of simultaneously treating polymorphic hazardous wastes

ActiveCN105716093AEfficient dischargeEffective secondary meltingIncinerator apparatusCombustorCombustion chamber

The invention discloses a fusion device capable of simultaneously treating polymorphic hazardous wastes, and relates to a fusion device. The existing solid or liquid hazardous wastes need classified treatment, and the treatment process is complicated, difficult to realize the effects of effective fusion and non-toxic discharge, low in ignition stability and bad in heat energy utilization rate. The top end of a vertical combustion chamber is an inlet end for thin-particle size hazardous wastes; the interior of the vertical combustion chamber is a vertical combustion hearth; a horizontal combustion chamber is arranged below the vertical combustion chamber in an inclined manner; the high end of the horizontal combustion chamber is communicated with the bottom end of the vertical combustion chamber; a first discharging channel and a second discharging channel are formed in the horizontal combustion chamber in sequence; the interior of the horizontal combustion chamber is a horizontal combustion hearth; the interior of the horizontal combustion chamber is divided into a preliminary fusion chamber and a thermal insulation warming chamber in sequence; a reciprocating grate is arranged in the preliminary fusion chamber; and a plurality of warming combustor are arranged in the thermal insulation warming chamber. The fusion device disclosed in the invention is used for treating hazardous wastes.

Owner:国泥工程中心(哈尔滨)有限公司

Processing method for slightly baking hemirhamphidae in three-sectional manner

InactiveCN103535774AUniform colorFiber integrityFood thermal treatmentFood preparationProcess engineeringColor changes

The invention belongs to the technical field of food processing. The invention aims at providing a processing method for slightly baking hemirhamphidae in a three-sectional manner and can guarantee the appearance and the taste of a slightly-baken hemirhamphidae product. The processing method comprises the steps of slicing and removing the bones of the hemirhamphidae, washing, salting so as to be tasty, baking, pressing, shaping, cooling and packing, and the processing method is characterized in that the baking step is the three-sectional baking manner, the three-sectional baking manner comprises a color changing step, a color determining step and a baking step. The processing method for slightly baking the hemirhamphidae is scientific and reasonable and strict in procedures and can be widely applied to the mass production of the slightly-baken hemirhamphidae.

Owner:RONGCHENG HONGYE IND

Anti-cracking treatment method for salix integra

InactiveCN108858564AAvoid crackingAvoid deformationWood treatment detailsReed/straw treatmentSodium azideMicrowave power

The invention belongs to the technical field of processing of salix integra, and particularly relates to an anti-cracking treatment method for salix integra. The anti-cracking treatment method comprises the following steps of peeling the salix integra, cleaning, and disinfecting; soaking by a sodium azide water solution with mass concentration of 0.6 to 1.2%, soaking for 20 to 30min, and drying byhot air at the temperature of 55 to 65 DEG C until the surface is free from water; coating the treated salix integra by a treatment agent, treating for 20 to 30min at the temperature of 50 to 60 DEGC and microwave power of 600 to 800w in a warehouse with temperature of 34 to 36 DEG C and humidity of 65 to 70%, and then weaving. Compared with the prior art, the anti-cracking treatment method hasthe advantages that the treatment method is scientific and reasonable, the treatment time is effectively shortened to one day or less, the cracking or deformation of the salix integra is effectively avoided, the weaving efficiency and finished rate are improved, and the commercial property of the salix integra product is improved.

Owner:ANHUI HUAYU CRAFTS GRP

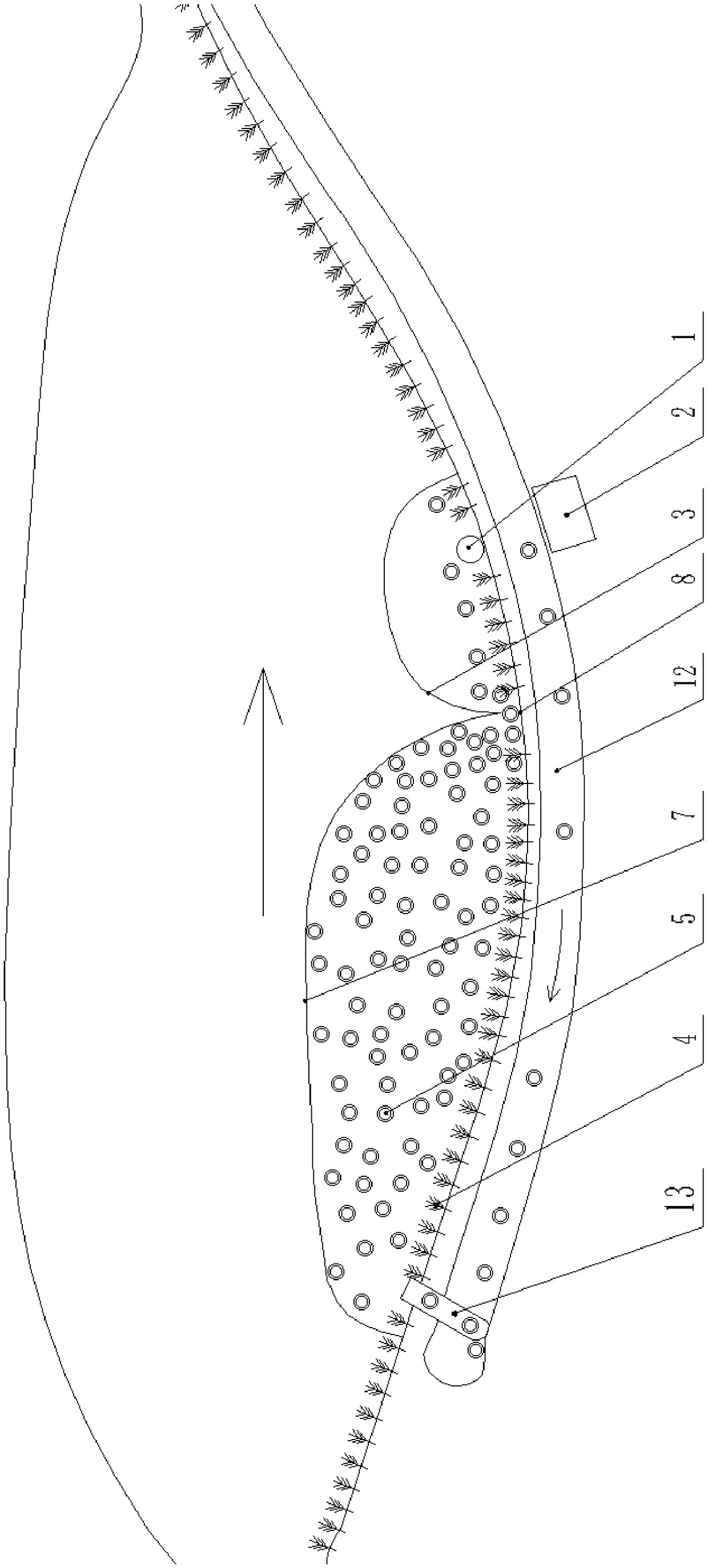

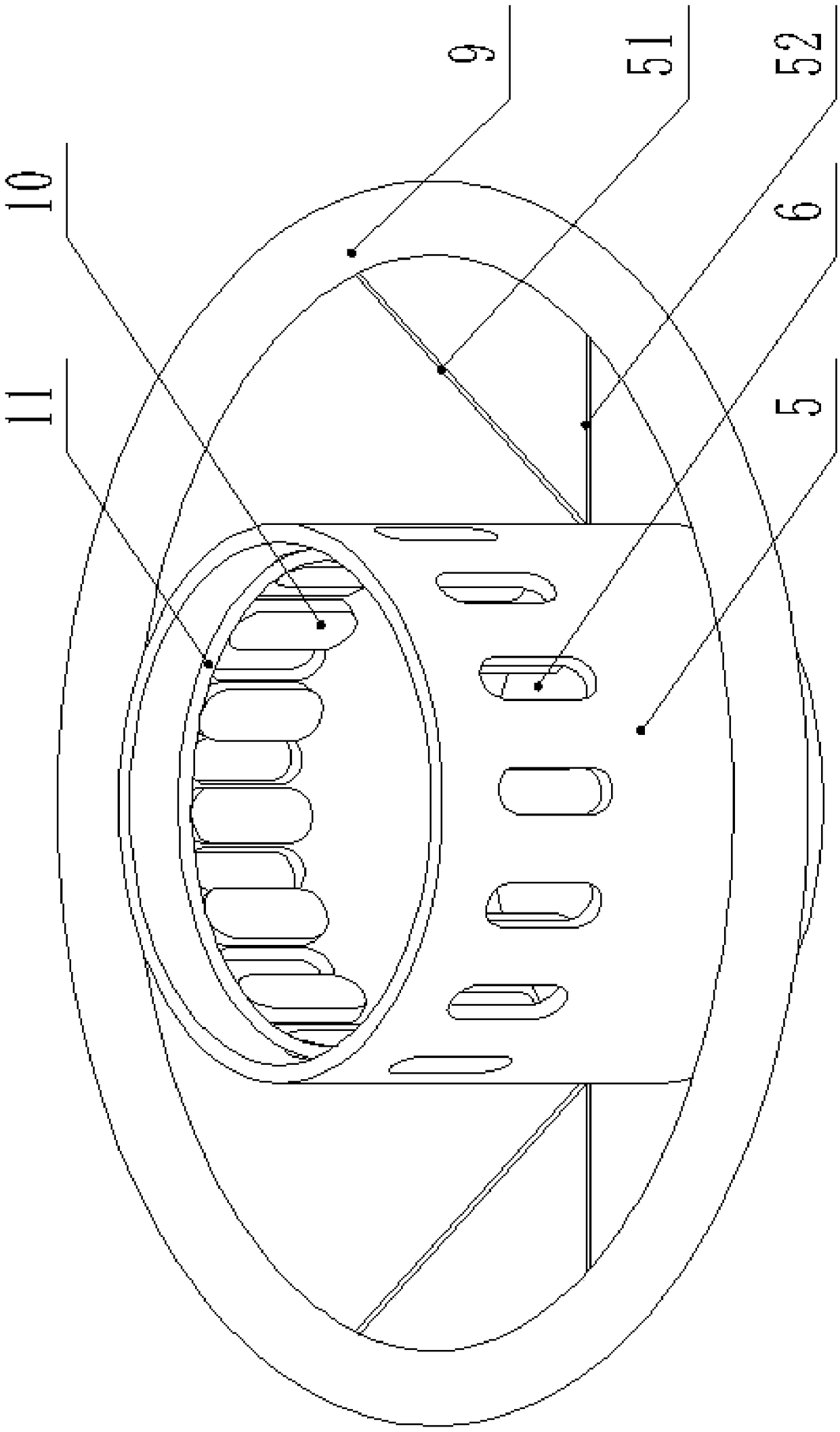

Water area blue-green algae treatment method based on biological competition principle and device used therefor

ActiveCN109205929AReal-time cleaningEasy to cleanBarrages/weirsWater cleaningWater qualityBlue green algae

The invention discloses a water area blue-green algae treatment method based on biological competition principle and a device used therefor, the method comprises the following steps: firstly finding amost easily-enriched area of blue-green algae, namely a concave bank of a water area, arranging an algae blocking net around the most easily-enriched area of the blue-green algae, fast removing a large amount of the blue-green algae in a manual or mechanical fishing mode, planting emergent aquatic plants on the shore of the water area so as to fundamentally improve water quality, arranging treatment tanks in a larger area and in the water area, gradually killing the blue-green algae through the intensively-arranged treatment tanks, collecting dead blue-green algae to prevent the dead blue-green algae from continuously polluting the water area, and collecting and treating the treatment tanks according to a preset rule so as to facilitate the recycling of the treatment tanks.

Owner:FUDAN UNIV

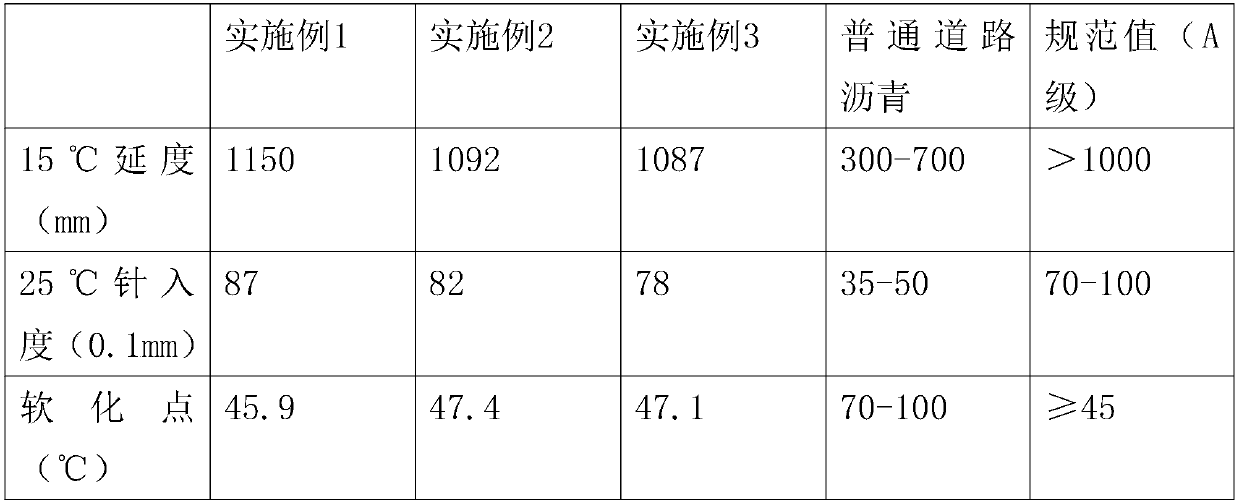

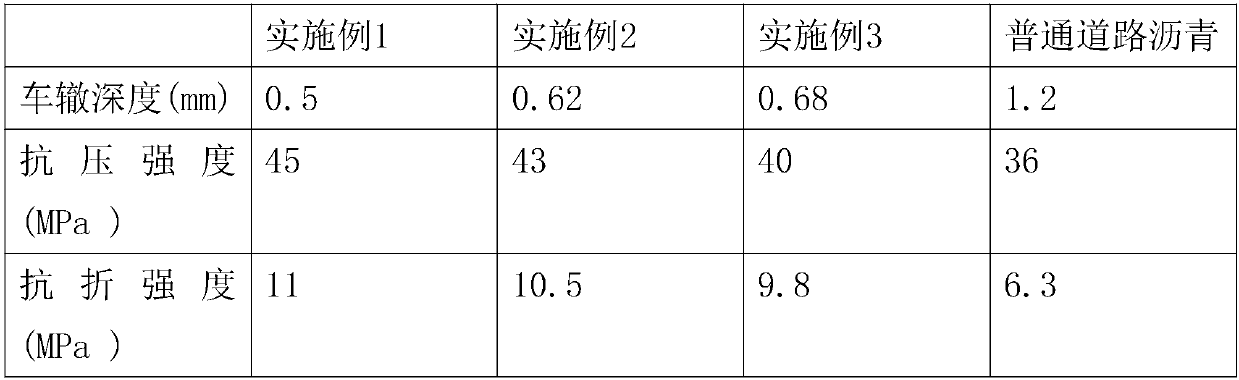

Preparation method of high-temperature-resistant asphalt concrete

InactiveCN107628775AImprove high temperature resistanceImprove aging resistanceKeroseneAcrylonitrile

The invention discloses a preparation method of high-temperature-resistant asphalt concrete. The preparation method comprises the following steps: 1. pouring matrix asphalt into a reactor, heating thereactor to 300-320DEG C, then adding perfluoroelastomer rubber, hydrogenated acrylonitrile butadiene rubber, boron-silicon rubber, gum-based ester rubber and SBS thermoplastic elastomer, and stirringand reacting; 2. cooling the interior of the reactor to 200-220DEG C, adding furfural, asbestos powder, zinc oxide, silicon nitride, chromium carbide, aluminum-plated glass beads, calcium sulphate whisker powder and chlorinated paraffin, and stirring and reacting; 3. pouring the mixture, obtained in the step 2, into an ultrasonic dispersing machine, then adding composite resin, xylene, zinc naphthenate, Barium petroleum sulfonate, kerosene, lauroyl diethanolamine and promoter, and performing ultrasonic dispersion; and 4. shearing and dispersing the mixture, obtained in the step 3, stopping and then stirring for 30-50minutes at 150-160DEG C to obtain the high-temperature-resistant asphalt concrete.

Owner:HEFEI UNIV

Recycling method for plastic films

InactiveCN106466890AThe processing method is scientific and reasonableImprove processing efficiencyPlastic recyclingEnvironmentally friendlyPlastic film

The invention belongs to the technical field of plastic recycling and discloses a recycling method for plastic films to ensure the purpose of treating the plastic films in an economical and environment-friendly manner. According to the technical scheme, the recycling method mainly comprises the steps of precipitating, washing, filter pressing and smashing. By means of the steps, impurity and oil contamination removing and the like are completed for the plastic films; by means of smashing, the plastic films are made into plastic particles, and due to the fact that the plastic films contain a large number of high molecular materials, the plastic films can be used in a degradation manner, can serve as padding of other rubber or plastic products and can be recycled. The treatment method is scientific, reasonable, environmentally friendly and high in treatment efficiency and utilization rate and has excellent social and economic benefits and popularization value.

Owner:邹贝尔

Processing method of instant flour

InactiveCN102125068AMuscle strengtheningImprove quality characteristicsDough treatmentFood preparationMonosodium glutamatePhosphate

The invention relates to a processing method of instant flour, belonging to a flour processing technique. In the processing method of the instant flour, based on the total weight of new Matt I flour, auxiliary materials added into the new Matt I flour comprise the following components in percentage by weight: 0.1-0.3% of monosodium glutamate, 1-2% of edible salt, 0.3-0.5% of nutrient agar, 0.1-0.4% of composite phosphate, 0.001-0.004% of potassium chlorate and 0.1-0.5% of dietary alkali; and the high-quality instant flour can be prepared through the following steps: mixing raw materials, stirring and packaging. The processing method is scientific, reasonable, simple in operation, low in processing cost and beneficial to industrialized and standard production of the instant flour on a large scale.

Owner:HENAN UNIV OF SCI & TECH

Plastic recovery method

InactiveCN106608002AImprove processing efficiencyIncrease profitPlastic recyclingMechanical material recoveryEnvironmentally friendlyEngineering

The invention provides a plastic recovery method, and belongs to the technical field of plastic recovery. The purpose of treating plastic economically in an environmental-friendly mode can be achieved. According to the technical scheme, the plastic recovery method mainly includes the steps of sedimentation, washing, filter pressing and smashing. Through the steps, impurities, oil stains and the like of plastic are removed, plastic particles are obtained after smashing, since a large quantity of high-molecular materials are contained in the plastic particles, the plastic particles can be used after degradation, and the plastic particles can be used as padding of other rubber or plastic products so as to be recycled. The plastic recovery method is scientific, reasonable, environmentally friendly and high in treating efficiency, the utilization rate is high, and the method has great social and economic benefits and popularization value.

Owner:邹贝尔

Plastic product processing method

InactiveCN109747069AThe processing method is scientific and reasonableDisposal method is environmentally friendlyPlastic recyclingEconomic benefitsEngineering

The invention provides a plastic product processing method, belongs to the technical field of plastics, and aims to achieve the environment-friendly purpose. The technical scheme mainly comprises thesteps of freezing, breaking, separating and crushing, so that the plastic products can be effectively processed. At low temperature, the plastic product is easy to generate cracking phenomenon, the structure of the plastic product is damaged by low-temperature freezing, so that the plastic product is easy to crush, and the structural member in the product can be taken out to use as a filling material for other plastic products by crushing and can be degraded and used. The processing method has advantages of being scientific and reasonable, environmentally-friendly, high in processing efficiency, high in utilization rate, excellent in social and economic benefits, and good in popularization value.

Owner:杨润

Printing and dyeing sewage treatment method

InactiveCN106608704AEfficient separationNo impuritiesSpecific water treatment objectivesTreatment involving filtrationDecompositionLitter

The invention relates to a printing and dyeing sewage treatment method, belongs to the field of environmental protection, and aims to reach the purpose of effective treatment of garbage. The printing and dyeing sewage treatment method mainly comprises the steps of decomposition, classification, press filtration, disinfection and filtration, and the garbage can be effectively treated. Chemical materials which cannot be fermented and decomposed are effectively separated for reuse; treated water has no impurities and no peculiar smell, can be used as special water for flushing toilets, as well as special water for irrigating flowers, grass and trees. The treatment method is scientific and reasonable, the processing efficiency is high, the comprehensive benefit is good, the method is simple, and the utilization rate is high.

Owner:吴越涵

Treatment method for pomegranate cuttings

InactiveCN109041842AImprove survival ratePromotes nutrient absorptionVegetative propogationShootUltraviolet

The invention discloses a treatment method for pomegranate cuttings and belongs to the technical field of pomegranate planting. The treatment method comprises the following steps of (1) selection of the cuttings; (2) pre-treatment of the cuttings; (3) primary treatment of the cuttings; (4) irradiation treatment; (5) secondary treatment of the cuttings; (6) ultraviolet curing. According to the provided treatment method for the pomegranate cuttings, the nutrient absorption capacity of the cuttings is improved, the germination of new shoots and roots is promoted, the survival rate of the cuttingsis increased, the content of nutrients in pomegranates is increased, the treatment method is scientific and reasonable, the bioavailability degree of raw materials is high, and a great market popularization value is achieved.

Owner:蚌埠市涂山村富民石榴专业合作社

Method for continuously processing degradation-resistant wastewater by means of microwave catalysis and device therefor

InactiveCN103420445BImprove processing efficiencyGreatly improve processing efficiencyWater/sewage treatment by irradiationPtru catalystCarbonization

The invention discloses a method for continuously processing degradation-resistant wastewater by means of microwave catalysis and an implementation device thereof. Granular catalyst is filled into quartz tubes to form quartz tube catalyst columns; the quartz tube catalyst columns are placed into a microwave field to form catalyst fixing beds, wherein the intersection angle of the axial direction of the quartz tube catalyst columns and the direction of the irradiation microwave is not less than 45 degrees; wastewater to be processed continuously flows through the catalyst fixing beds, so that pollutants in the wastewater can be removed under the combined action of the microwave and the granular catalyst; processed water and gas produced during wastewater treatment are discharged; the granular catalyst is husk-like granular activated carbon prepared through carbonization, smashing, bonding formation and carbon dioxide activating treatment. With adoption of the method, continuous industrialized degradation of degradation-resistant wastewater can be realized, the operation is simple, the automatic control is facilitated, the application to different wastewater processing amounts can be realized by means of increasing or decreasing the number of the quartz tube catalyst columns, the investment and the operation cost are low, and the removal efficiency is high.

Owner:SICHUAN UNIV

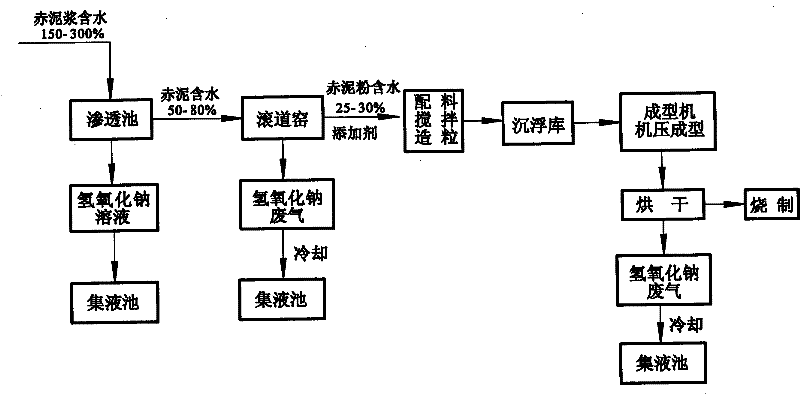

Treatment method for recycling waste red mud residues

InactiveCN101773925BSolve processing problemsThe processing method is scientific and reasonableAluminium compoundsConstruction materialTunnel kilnRed mud

Owner:李志奇

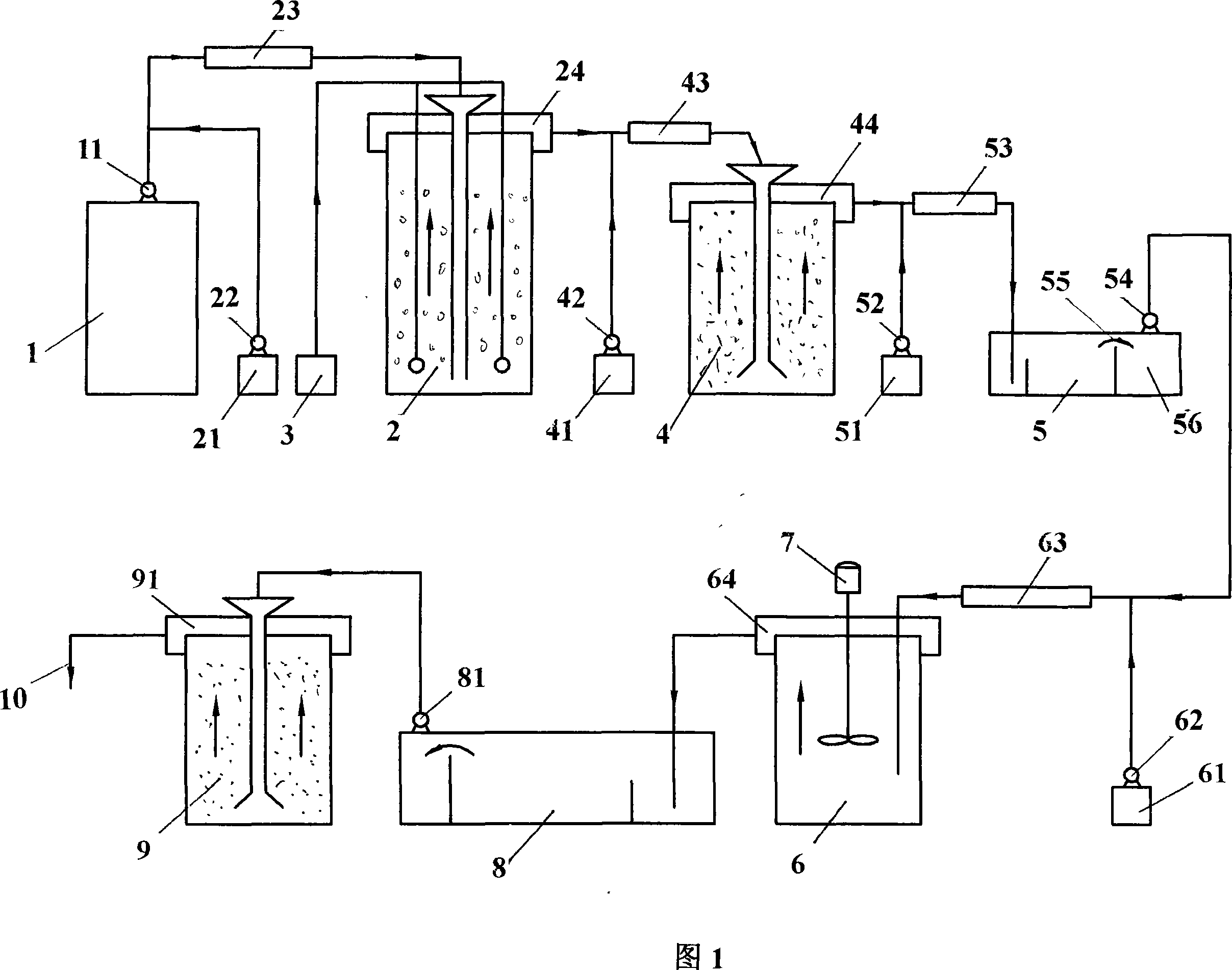

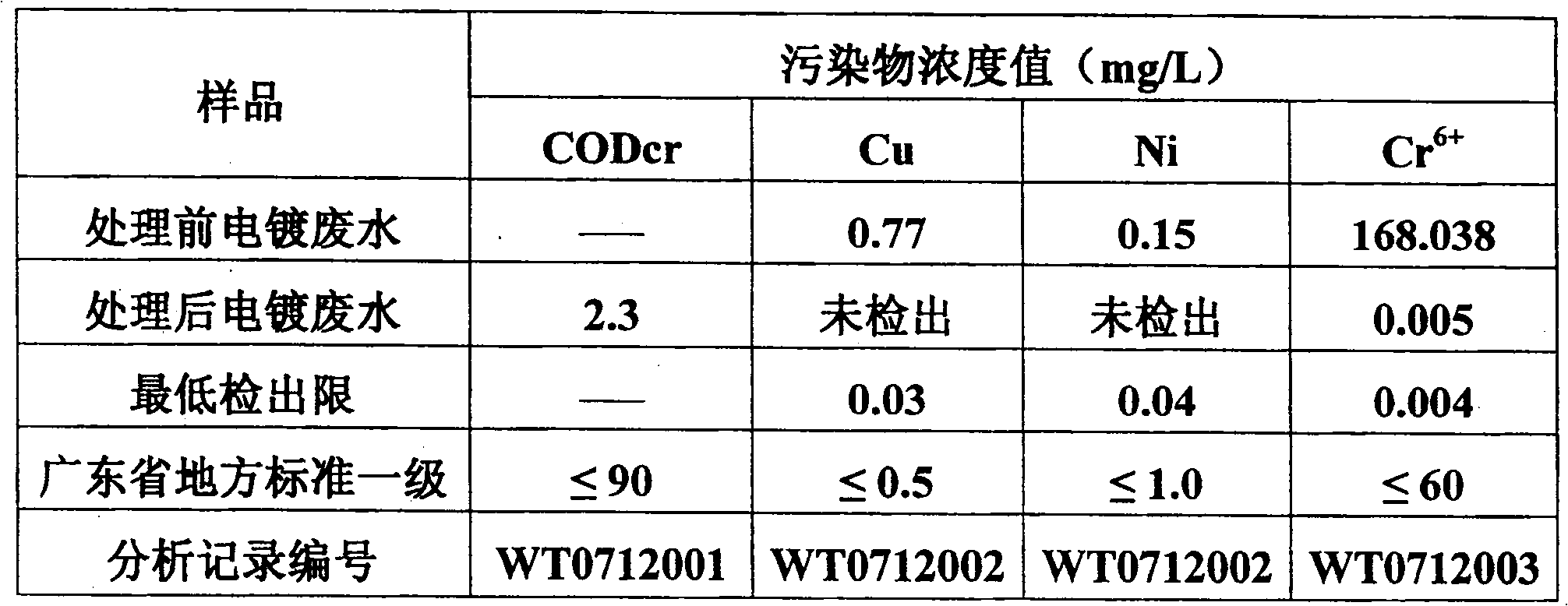

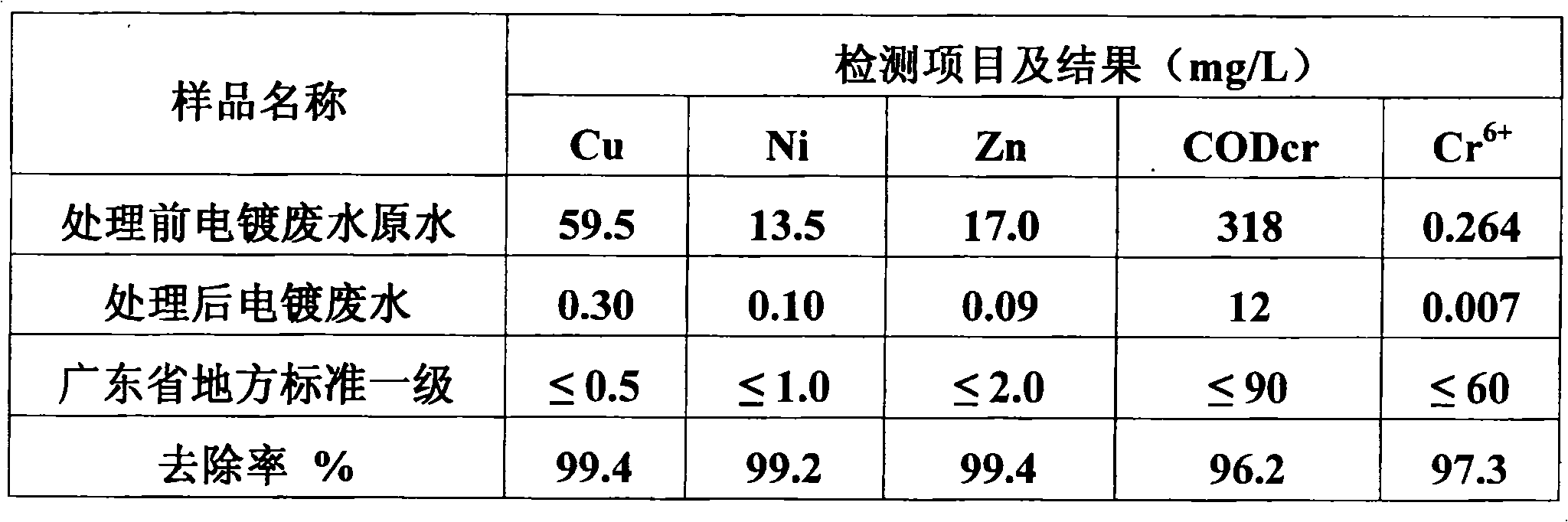

Method for treating electroplating mixed wastewater

InactiveCN101186419BThe processing method is scientific and reasonableEasy to handleDispersed particle separationWaste water treatment from metallurgical processDecompositionIon exchange

The invention relates to a treatment method of mixed electroplating wastewater, and is characterized in that: organic compounds in the mixed electroplating wastewater are decomposed for a plurality of times through decomposition and reduction reaction, internal electrolytic reduction reaction, neutralization and precipitation, compound absorption, etc., and the decomposition process comprises intensified demulsification, electric field flocculation, hydroxyl group decomposition, molecular absorption and ion exchange; heavy metals are reduced for a plurality of times: ferrous ion reduction, hydrogen reduction and neutralized and precipitated. The treatment devices of the method of the invention are simple and can be easily obtained, the operation is simple and convenient, the land occupancy is small and the construction investment is small. The treatment agent is prepared from normal materials and devices, and the treatment expense can be saved by 30 to 50 percent compared with traditional methods. The invention can be used for treating mixed electroplating wastewater with coexisted copper, nickel, zinc, chromium and COD Cr, with a removal rate generally higher than 96 percent. Thetreatment method of the invention has the advantages of simplicity, short process, small investment, low running expense, high removal efficiency, good treatment effect, and wide popularization value, being bound to have remarkable social and economic benefits.

Owner:赵青海 +1

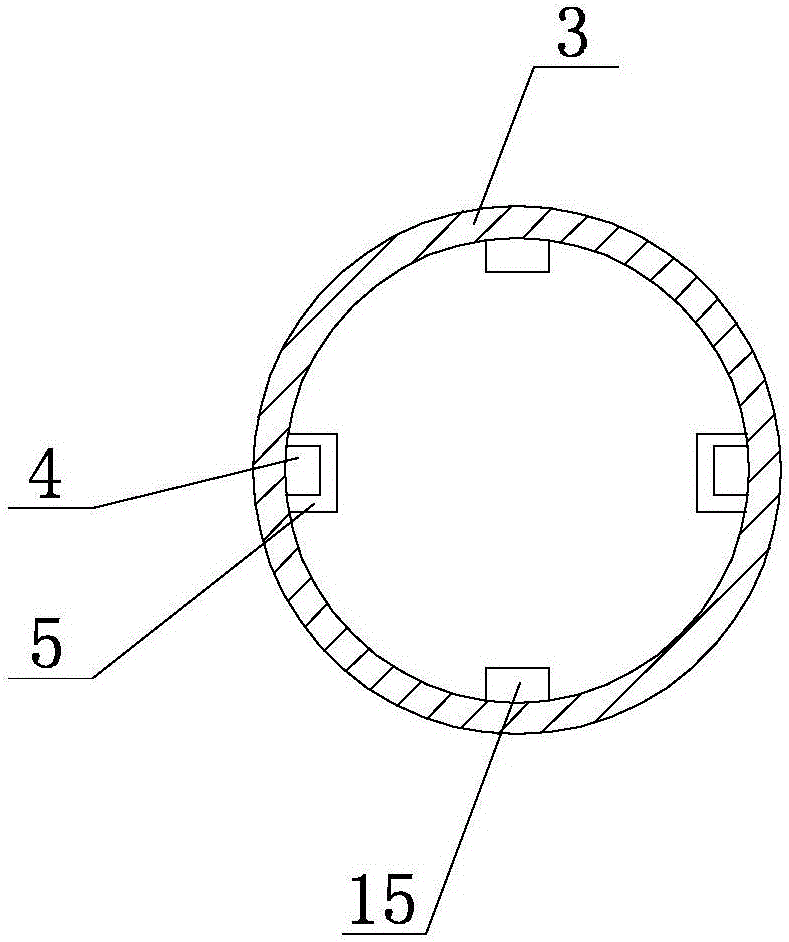

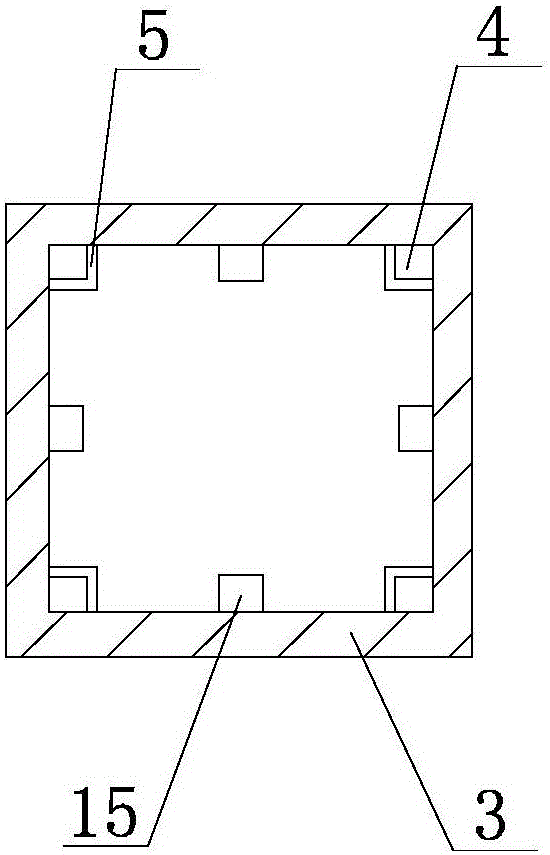

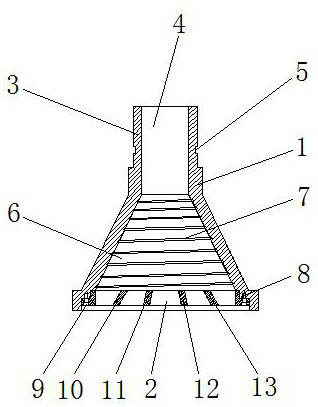

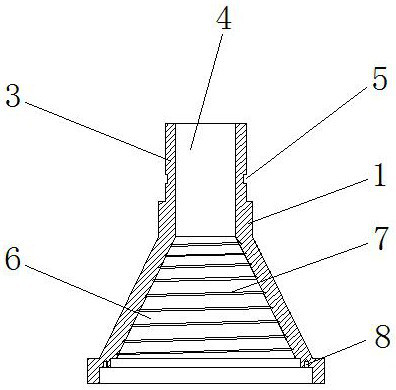

A combined cleaning and sweeping car noise reduction suction port, processing mold and using method of processing mold

ActiveCN111749178BEasy to disassembleEasy to installFoundry mouldsRoad cleaningMechanical engineering technologyCar noise

A method for using parts and parts processing molds and accessories for washing and sweeping vehicles belongs to the technical field of mechanical engineering. A noise reduction suction port is composed of a suction port base, a suction port cover plate and a spoiler; The mold, the upper mold core, the lower mold core and the guide rod are connected; the suction cover processing mold is composed of an upper mold and a lower mold; the noise reduction suction port adopts a combined design, which is easy to disassemble and install. It is processed by casting molding, the processing method is scientific and reasonable, the manufacturing speed is fast, and large-scale processing can be realized in the same process. When the invention works, the suction cover has 4 spoilers with different angles to divide the inhaled airflow and pass it through. The sound waves coming in from different angles will cancel each other out, dissipate part of the sound waves through the crests or troughs of the spiral groove, and conduct through the spiral groove, so as to achieve the purpose of noise reduction, which can effectively reduce the noise of the air flow of the cleaning vehicle fan.

Owner:YANGZHOU UNIV

Soft pear fruit vinegar beverage and production method thereof

ActiveCN103535810BFruity aromaFruityNatural extract food ingredientsVinegar preparationPEARFood flavor

The invention relates to a soft pear fruit vinegar beverage and a production method thereof. The soft pear fruit vinegar beverage takes soft pears as a raw material and is produced with processes of fruit sorting, storing, juicing, instant high-temperature sterilization, enzyme treatment, primary fermentation, secondary fermentation, preparation, filtering, desaeration, encapsulation and sterilization. The soft pear fruit vinegar beverage is simple in production method and low in cost, and the soft pear fruit vinegar in the beverage has prominent fruit fragrance, strong vinegar fragrance and distinct flavor.

Owner:青海兴农实业有限公司

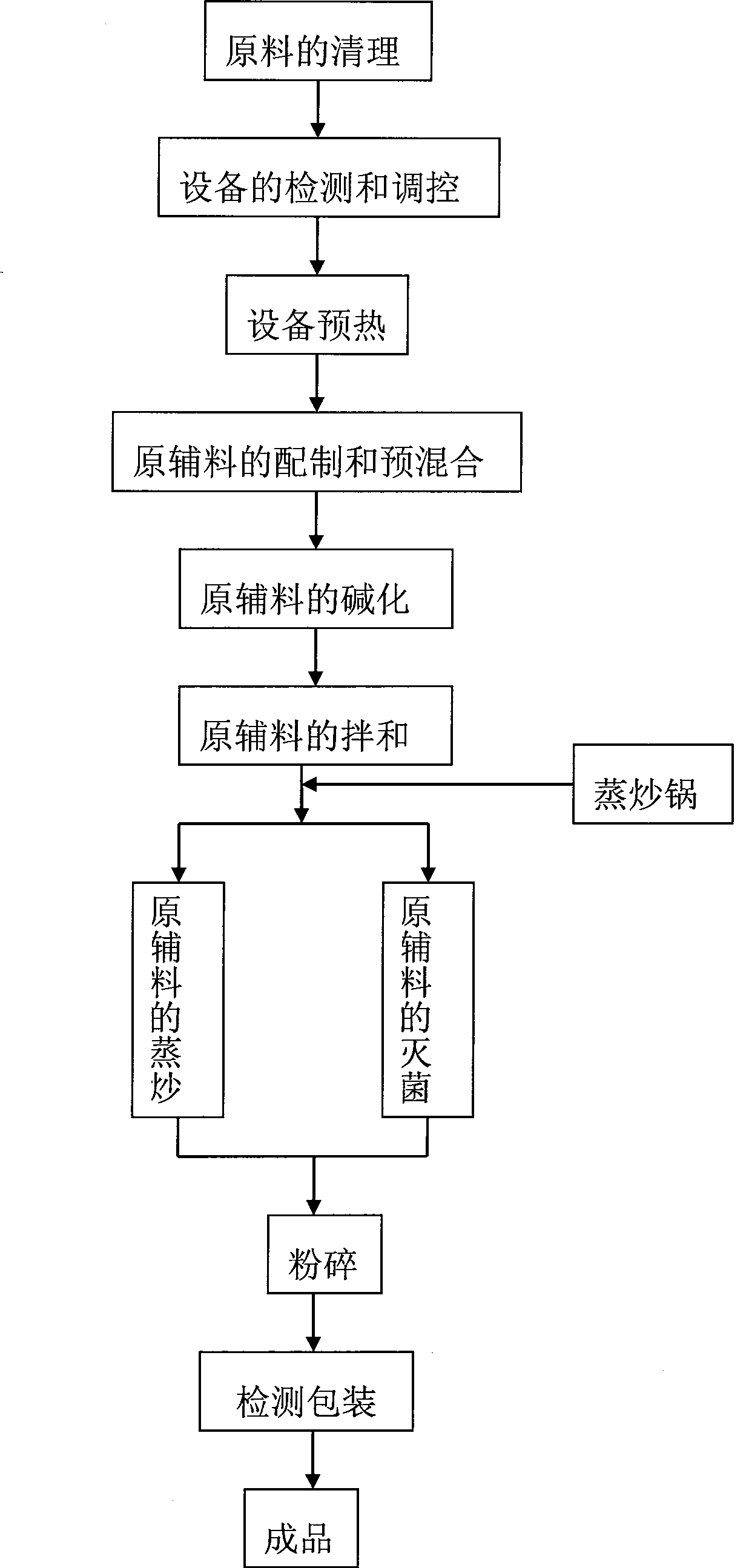

Method for processing plant-derived food additives

InactiveCN101502311AThe processing method is scientific and reasonableImprove securityFood preservationFood preparationFood additiveColony number

The present invention provides a processing method of plant food additive, comprising the following steps: cleaning the raw material, detecting and adjusting the device, preheating the device, preparing and pre-mixing the supplementary materials, alkalizing, mixing, cooking and crushing the supplementary materials and finally detecting, packaging and producing the finished products. The colony number of the finished products is below 20000 and the mold is in 200 / g or less, fully in accordance with the national food hygiene and safety standards. The processing method of plant food additive has features of scientific and reasonable process, high safety performance, easy operation and monitoring and is suitable for industrialization batch production. The food additive produced by the said processing method is thoroughly sterilized and the water content of the finished product is low and the finished product is easily stored and used with more safety.

Owner:邢海明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com