Method for processing plant-derived food additives

A technology of food additives and processing methods, applied in food preservation, food preparation, food science, etc., can solve problems such as unstable quality, easy evaporation or change of taste, high moisture content of finished products, and achieve scientific and reasonable processing methods, easy operation and Monitoring, the effect of low moisture content in finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

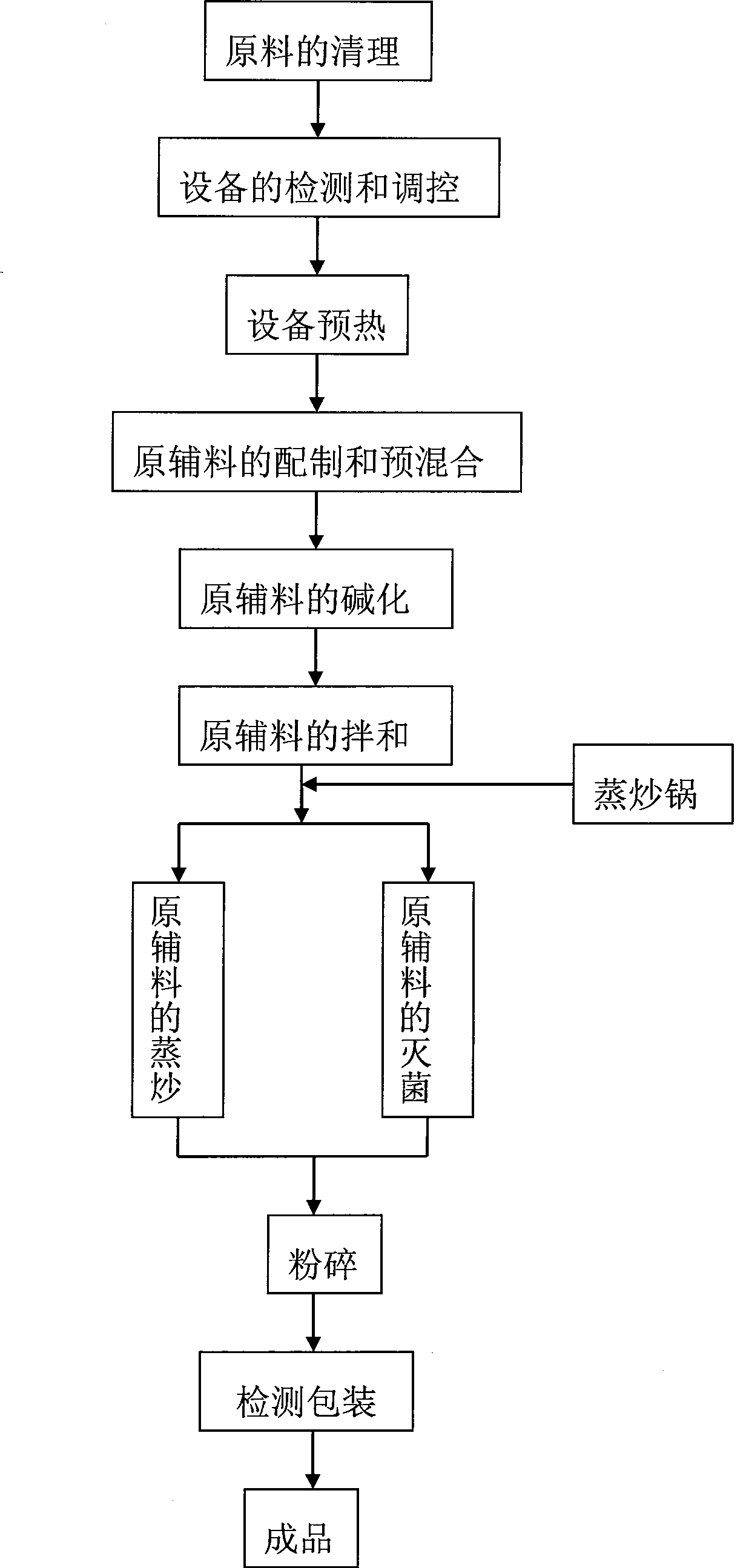

Method used

Image

Examples

Embodiment 1

[0025] Calculated by making 1t of pepper as raw material:

[0026] (1) Cleaning of pepper: Before selecting the feed material, first screen 1 ton of the pepper raw material that has passed the inspection and remove impurities such as metal objects; After the abnormal noise, pepper was started.

[0027] (2) Inspection and regulation of equipment: Check the normal operation of each production equipment before starting up, then discharge the condensed water in the steam supply bin, and supply steam to the coarse powder processing equipment after discharge.

[0028] (3) Equipment preheating: heat the water tank for production, the temperature is controlled at about 95°C, and the mixer is heated, the temperature is controlled at about 100°C-120°C, and the steaming and frying pan is heated at the same time.

[0029] (4) Preparation and pre-mixing of raw and auxiliary materials: In the mixer, add the required auxiliary materials and pepper and mix thoroughly, and adjust the pH value...

Embodiment 2

[0036] Calculated by making 1t of cocoa as raw material:

[0037] (1) Cleaning of cocoa: before feeding, screen 1 ton of cocoa that has passed the inspection and remove impurities such as metal objects; check that there is no foreign matter near the transmission chain and then start the buried scraper to check that there is no abnormality in the buried scraper After the sound, start to put in cocoa.

[0038] (2) Inspection and control of equipment: Before starting up, first check the normal operation of each production equipment, then discharge the condensed water in the steam supply chamber, and supply steam to the coarse powder processing equipment after discharge.

[0039] (3) Equipment preheating: heat the production water tank at about 100°C, heat the mixer at about 100°C to 120°C, and heat the steamer at the same time.

[0040] (4) Preparation and pre-mixing of raw and auxiliary materials: In the mixer, add the required auxiliary materials and cocoa and mix fully, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com