Method for treating electroplating mixed wastewater

A technology of mixed wastewater and treatment method, applied in the treatment of electroplating mixed wastewater and electroplating industrial production wastewater treatment field, can solve the problems of small amount of treated water, complicated management, difficult to achieve, etc., and achieves less construction investment and reduction of electroplating wastewater. , easy-to-manage effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

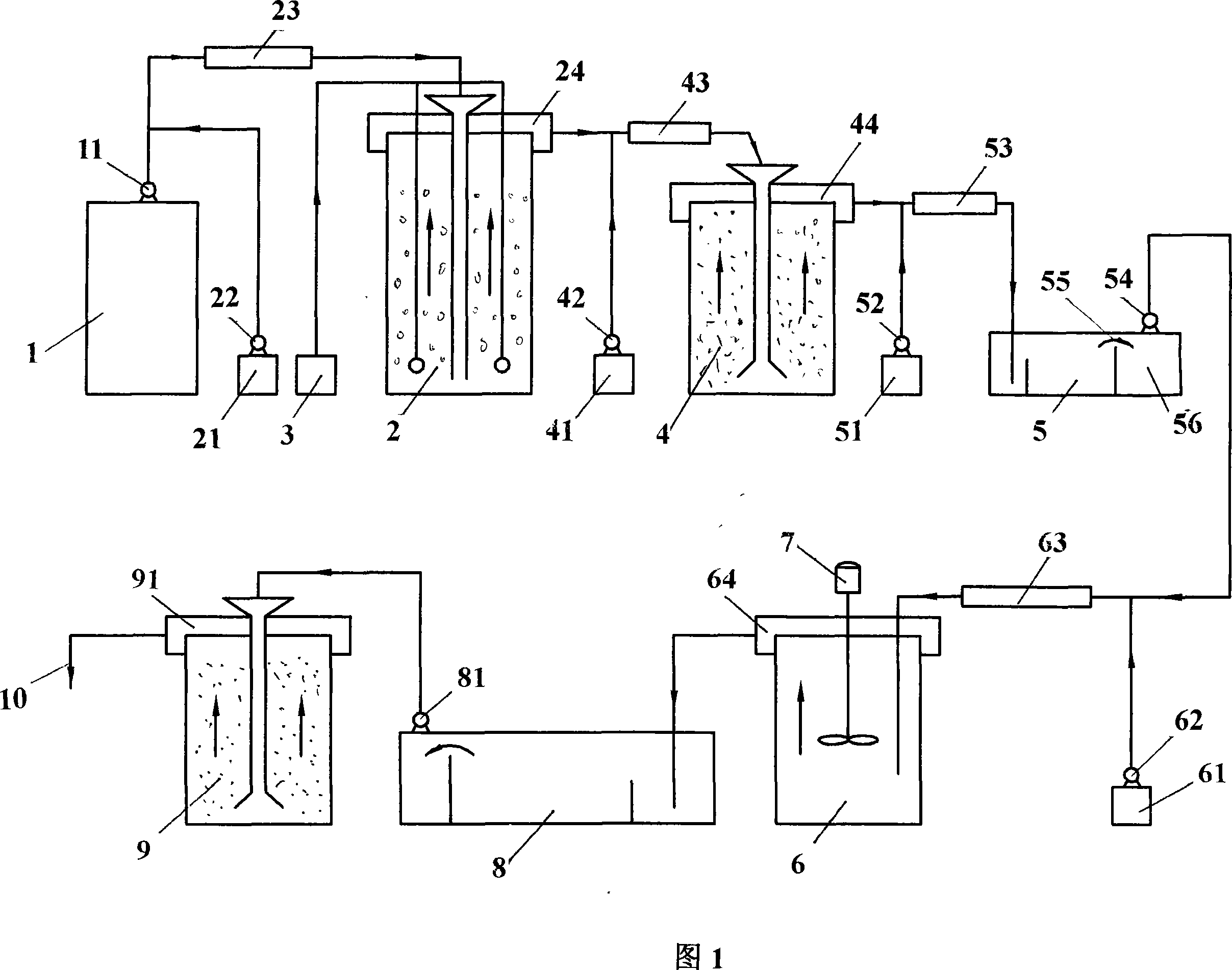

Method used

Image

Examples

Embodiment 1

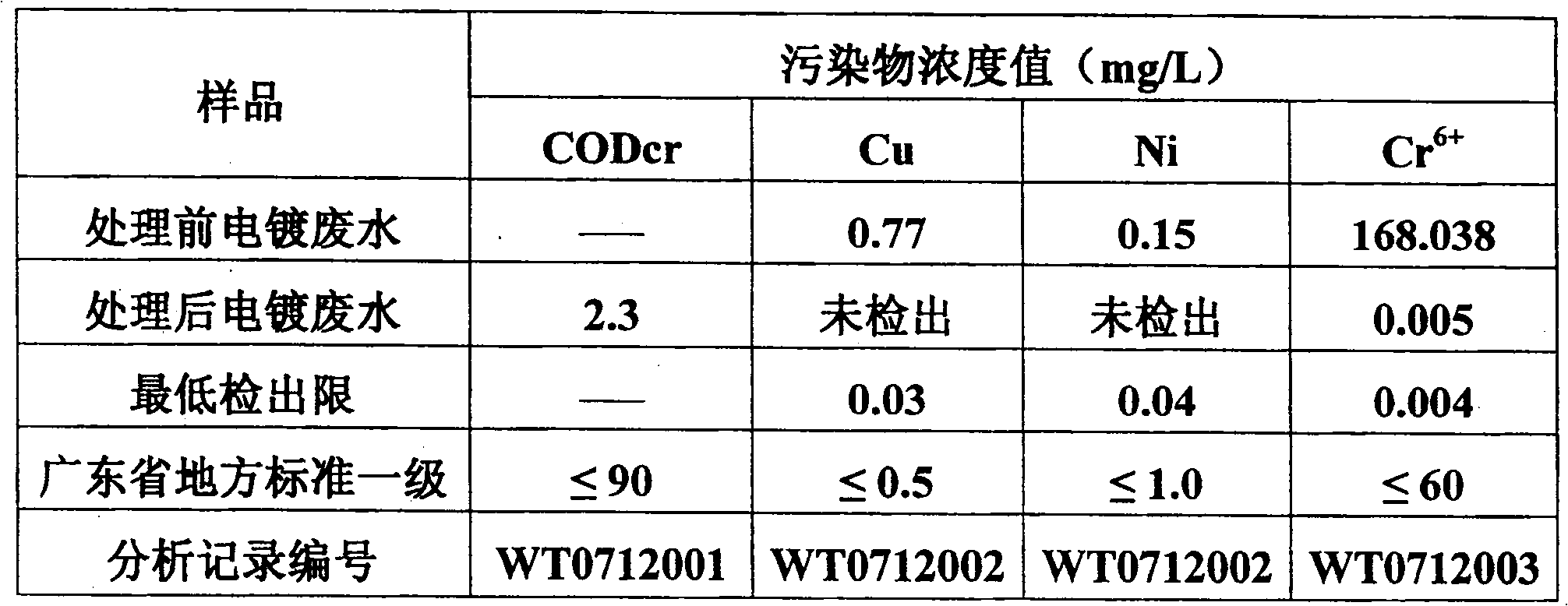

[0065] Embodiment 1: Laboratory treatment of electroplating mixed wastewater

[0066] 1. Electroplating mixed wastewater sample

[0067] Shenzhen ×× Environmental Protection Technology Co., Ltd. provided 1520ml of electroplating mixed wastewater samples, including: 400ml of cyanide-containing wastewater, 1100ml of chromium-containing wastewater, and 20ml of electroplating pre-treatment wastewater.

[0068] Tested by the Environmental Protection Monitoring Station of Jilin City, the electroplating mixed wastewater sample: Contains Cr 6+ 168.038mg / L; containing Cu 0.77mg / L; containing Ni 0.15mg / L; due to Cr 6+ High content interferes with CODcr detection, and CODcr cannot be detected.

[0069] 2. Preparatory work before the test

[0070] Appliances: 2000ml glass cup for decomposition and reduction tank; small air pump; 1000ml plastic cup for internal electrolytic reduction tank, filling: 0.5L of cast iron chips with a particle size of 1-10mm, 0.5L of metallurgical coke with ...

Embodiment 2

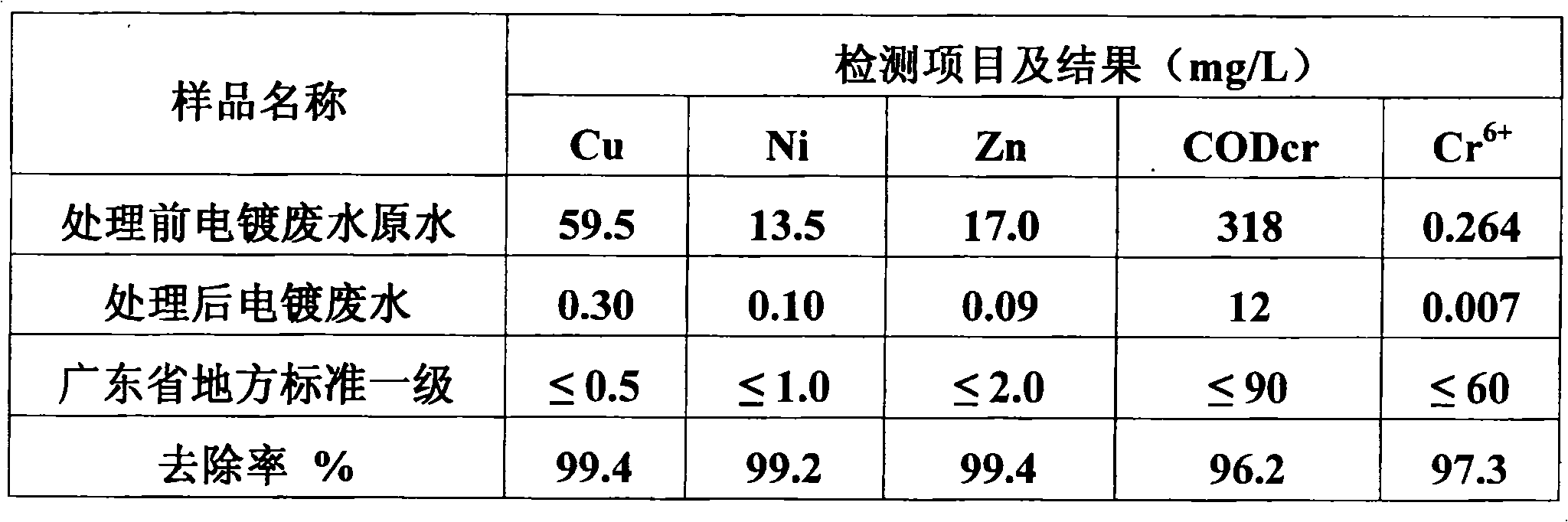

[0086] Example 2: Simulated treatment of electroplating mixed wastewater

[0087] This embodiment is a simulated treatment test for the continuous treatment process of electroplating mixed wastewater.

[0088] 1. Electroplating mixed wastewater sample

[0089] From the sewage station of Shenzhen ××× Metal Products Factory, about 500M of electroplating mixed wastewater samples were taken out from the 14 electroplating production lines of the factory. 3 . Among them: comprehensive wastewater 300M 3 (containing copper, nickel, zinc, chromium), cyanide-containing wastewater 50M 3 , chromium-containing wastewater 80M 3 , aluminum oxidation wastewater 70M 3 .

[0090]Tested by Shenzhen XX Huanke Testing Technology Co., Ltd., the electroplating mixed wastewater sample: contains Cu59.5mg / L; contains Ni 13.5mg / L; contains Zn 17.0mg / L; CODcr 318mg / L; contains Cr 6+ 0.264mg / L.

[0091] 2. Preparatory work before the test

[0092] Appliances: 2000ml measuring cylinder for decompo...

Embodiment 3

[0104] Embodiment 3: Dynamic continuous treatment of electroplating mixed wastewater

[0105] 1. Sample source of electroplating mixed wastewater:

[0106] The electroplating mixed wastewater sample is provided by the wastewater station of Shenzhen ××× Products Factory, of which: comprehensive wastewater: 300M per day 3 , accounting for 60% of the total wastewater discharge, 120L samples were taken; chromium-containing wastewater: 80M per day 3 , accounting for 16% of the total amount of discharged wastewater, pumping 32L; cyanide-containing wastewater: 50M per day 3 , accounting for 10% of the total amount of wastewater discharged, pumping 20L; aluminum oxidation wastewater: 70M per day 3 , accounting for 14% of the total amount of wastewater discharged, pumping 28L. A total of 200L was packed in barrels and shipped to Jilin City, and then made into a 180L electroplating mixed wastewater sample according to the original wastewater discharge ratio.

[0107] Tested by the E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com