Patents

Literature

74results about How to "There will be no sticking phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

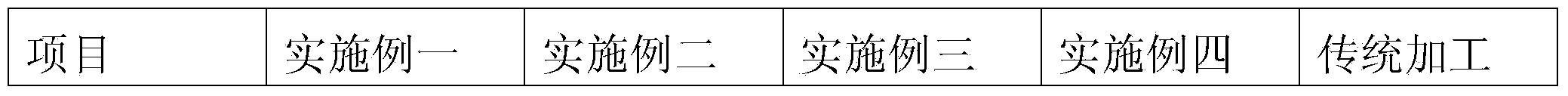

Processing method of Dendrobium officinale golden bar or sheet

ActiveCN103404862AKeep active ingredientsGolden skin colorFood shapingFood preparationSurface moistureCooking & baking

The invention relates to a processing method of a Dendrobium officinale golden bar or sheet, which comprises the following steps: a. taking Dendrobium officinale fresh strips, cleaning to remove sand, and airing to remove surface moisture, thereby obtaining clean Dendrobium officinale; b. baking at 100-105 DEG C for 3-6 minutes, taking out and kneading while the Dendrobium officinale is hot, and repeating the operation until the surface of the clean Dendrobium officinale becomes golden; and c. cutting into sections or sheets, freezing at -70 to -90 DEG C, and carrying out freeze-drying to obtain the golden Dendrobium officinale golden bar finished product or golden Dendrobium officinale golden sheet finished product. The Dendrobium officinale product is golden, beautiful and crisp, is convenient to eat, and can effectively reserve the original active components in the Dendrobium officinale.

Owner:YUNNAN DENDROBIUM OFFICINALE TECH DEV CO LTD

Medical soup for treating soup, preparing method and use of the same

InactiveCN101129618AEasy to makeLow costDermatological disorderAluminium/calcium/magnesium active ingredientsEmulsionSlag

The invention discloses a soup to treat burn, such as boiling water, molten steel slag, high-temperature steel board and flame, which comprises the following steps: dispensing the soup with camellia oil, calcium hydrate and water; adding 35-45g water into the container with 10-15g calcium hydrate; stirring until the water becomes clarified; fetching clear water in another container with 50-60g camellia oil; stirring evenly; obtaining light yellow emulsion-soup; using long feather on the duck wing to dip the dispensed soup to coat the burn everyday with good treating effect and short treating period without scar.

Owner:戴吉文

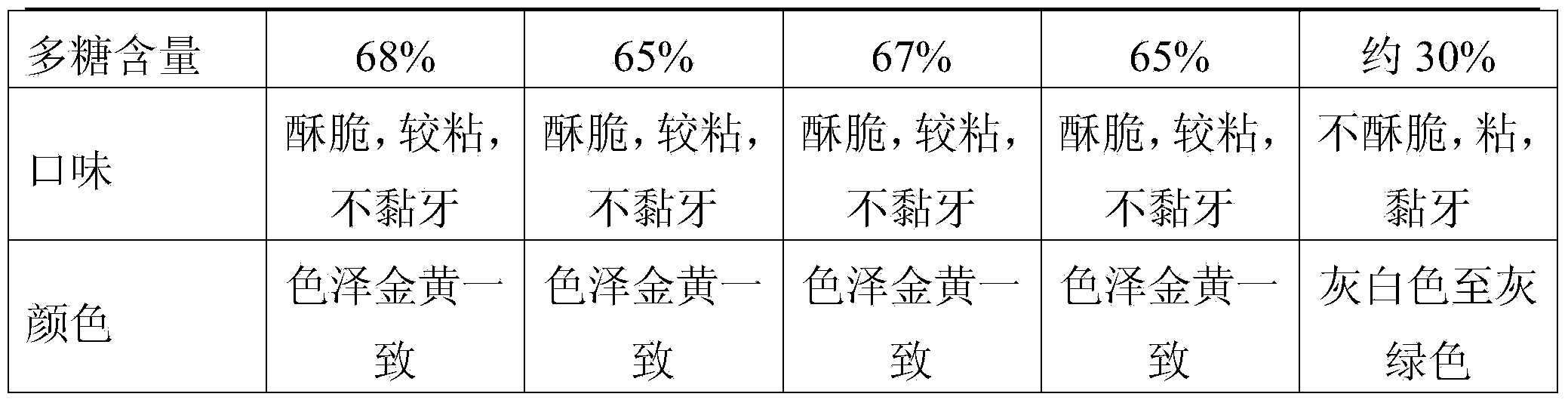

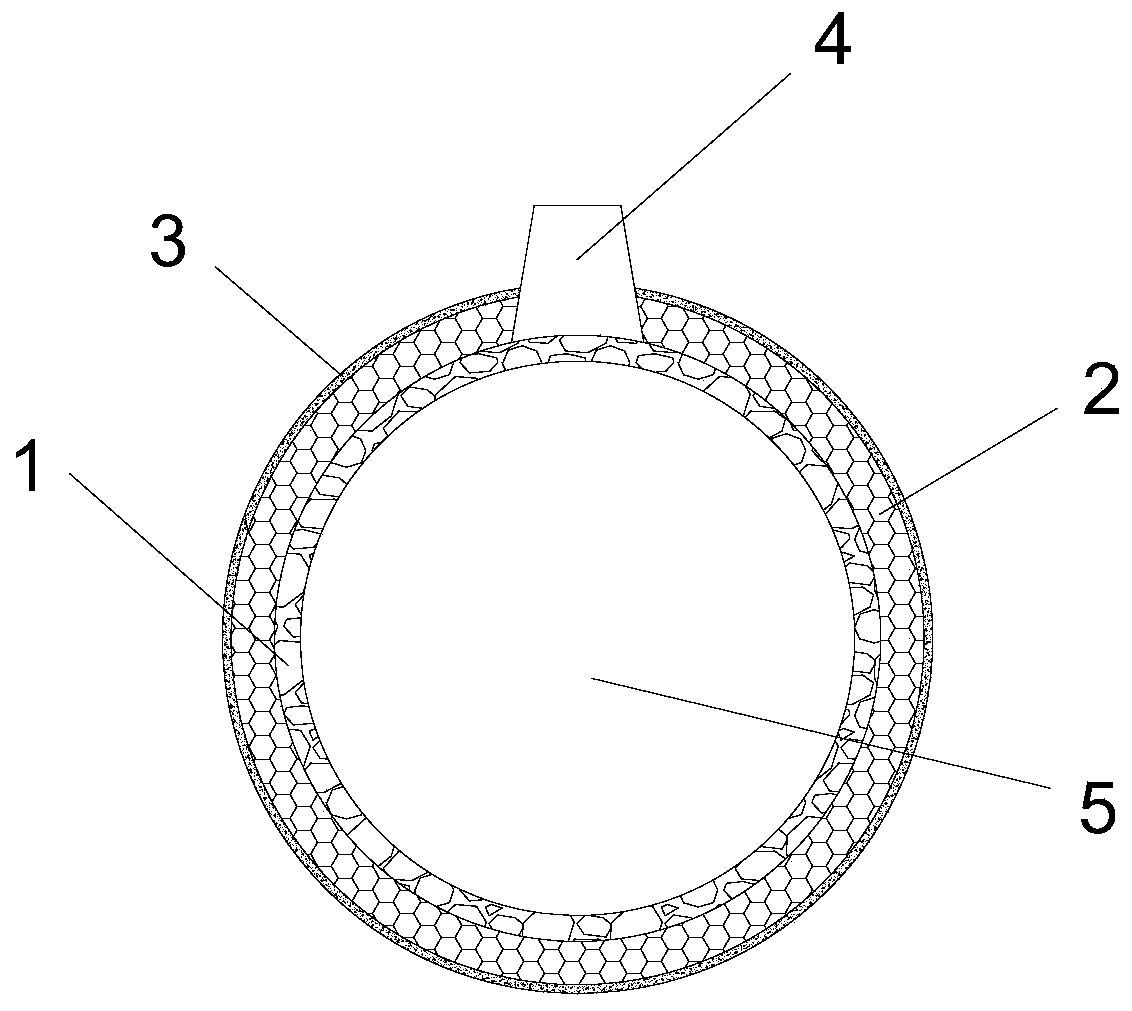

Ramming material for ladle lining and preparation method thereof

The invention relates to a ramming material for a ladle lining and a preparation method thereof. The ramming material comprises the following raw materials: 52 to 57 percent of silica, 20 to 23 percent of high-alumina bauxite, 5 to 10 percent of clay, 5 to 15 percent of graphite, 0.1 to 5 percent of fly ash, 0.2 to 5 percent of silicon carbide power, 0.1 to 3 percent of chromium slag powder, 0.1 to 1 percent of sodium silicate and 0.1 to 1 percent of aluminum polyphosphate. Advantages of the invention are as follow: as that structure strength is high in the use process, it will not cause ladleleakage accidents due to loosening, peeling and other damages in the use process, thus ensuring the safety of people and equipment around the ladle during lifting and transporting, preventing molteniron from sticking to the ladle, preventing wrapping of molten iron in slag, improving the recovery rate of molten iron, and greatly improving the safety and economy.

Owner:鄂尔多斯市瀚博科技有限公司

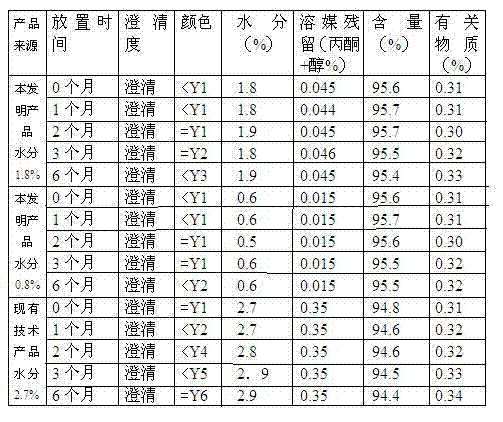

Preparation method of low-moisture and high-stability sterile cefuroxime sodium

The invention discloses a preparation method of low-moisture and high-stability sterile cefuroxime sodium, which comprises the steps of (a) dissolving cefuroxime acid in an anhydrous mixed solvent, decolorizing, conducting sterile filtration, collecting filter liquor to a crystallizing tank, (b) dissolving soda in an organic solvent, decolorizing, conducting the sterile filtration, collecting filter liquor to a sodium solution metering tank, (c) controlling temperature for 10-50min, adding a soda solution into the crystallizing tank dropwise, controlling a stirring rate at 20-60r / min, crystallizing, adding acetone after the sterile filtration to ensure full crystallizing; (d) pressing crystallized liquid in a three-in-one multifunctional tank for filtration, washing with the mixed solvent, drying at 30-60 DEG C, obtaining the sterile cefuroxime sodium, and (e) transferring materials in a sterile bicone at 30-70 DEG C, continuing to dry under reduced pressure for 2-5h, and obtaining the sterile cefuroxime sodium with better stability and the moisture less than 1%. The preparation method is short in drying time and simple and practicable, the sterile cefuroxime sodium is easy to smash, low in moisture, less in solvent residual and stable in quality, the color, clarity and color points of the sterile cefuroxime sodium are not affected, and the production cost is lowered.

Owner:潘行远

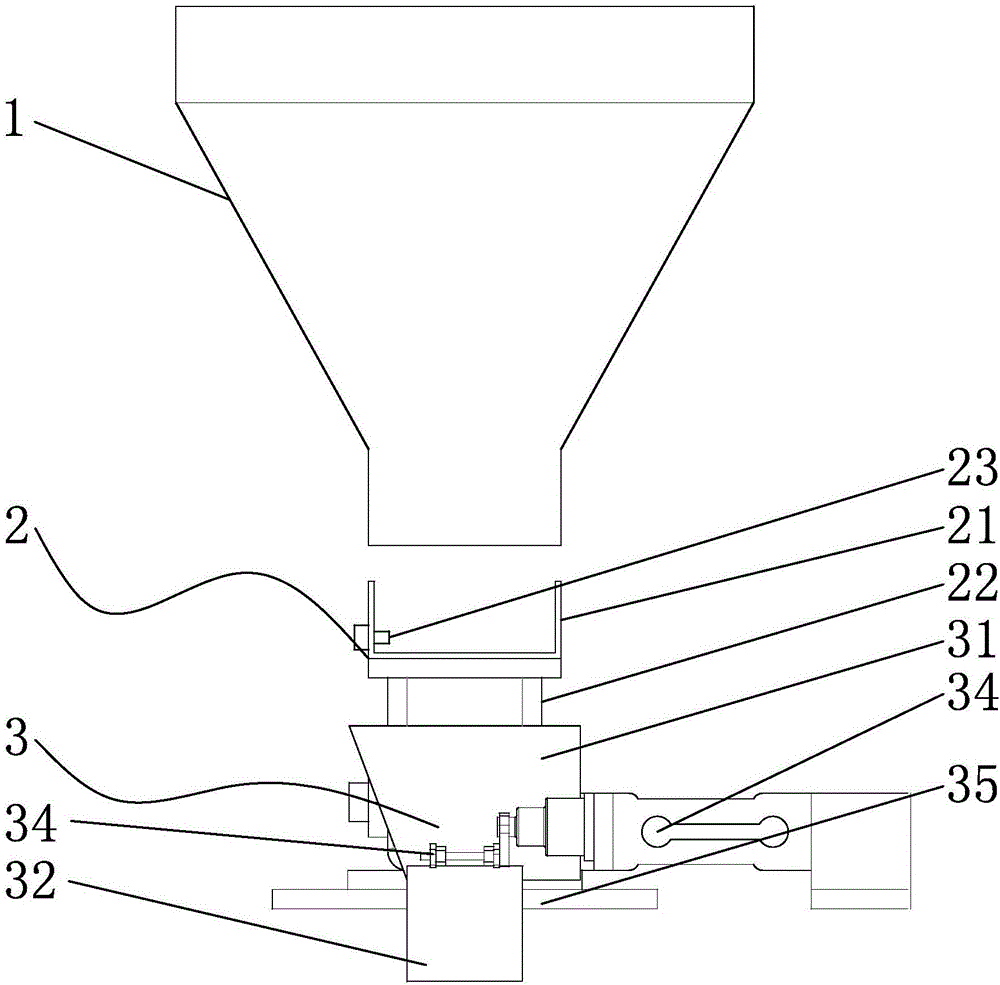

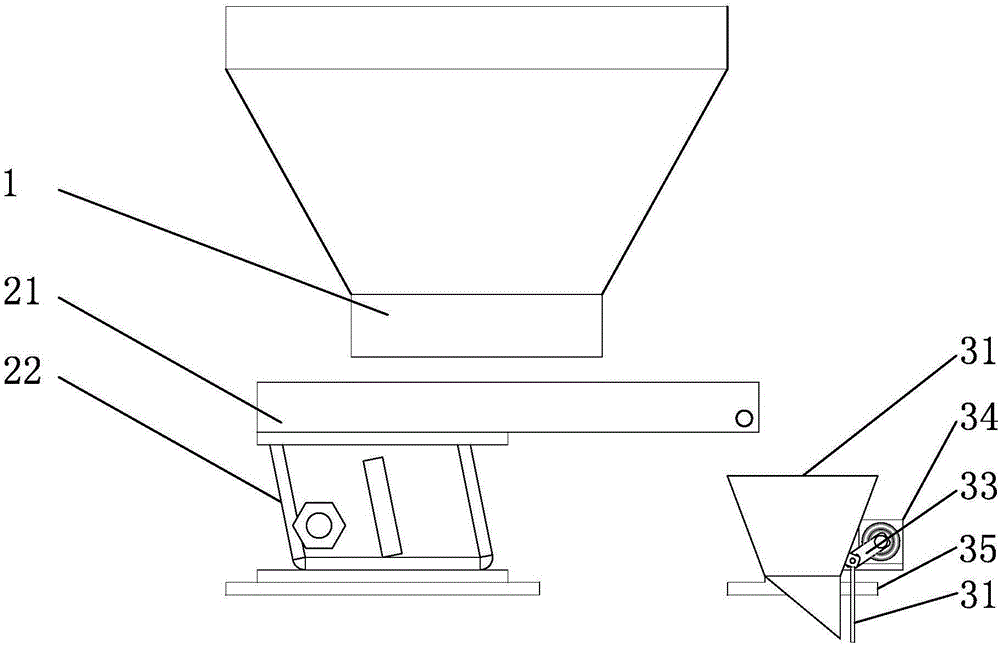

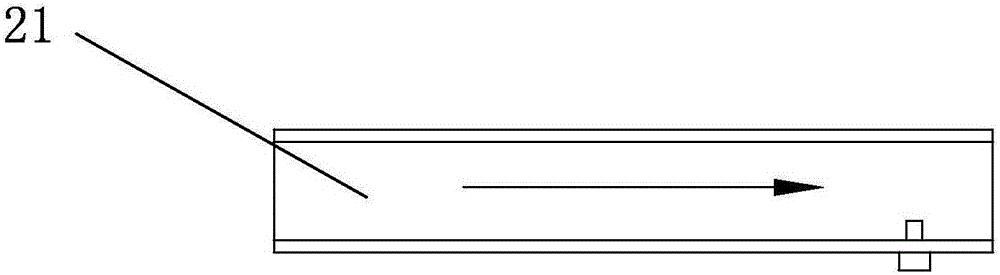

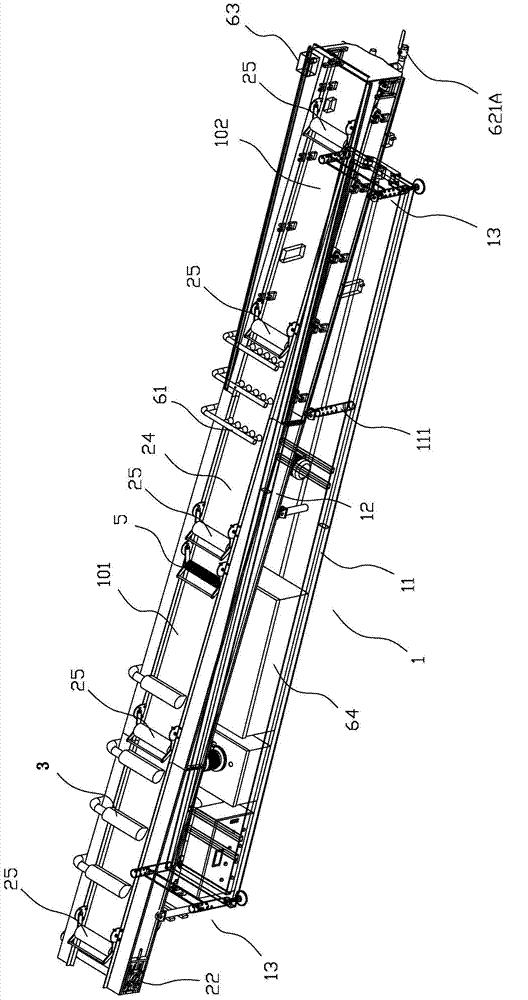

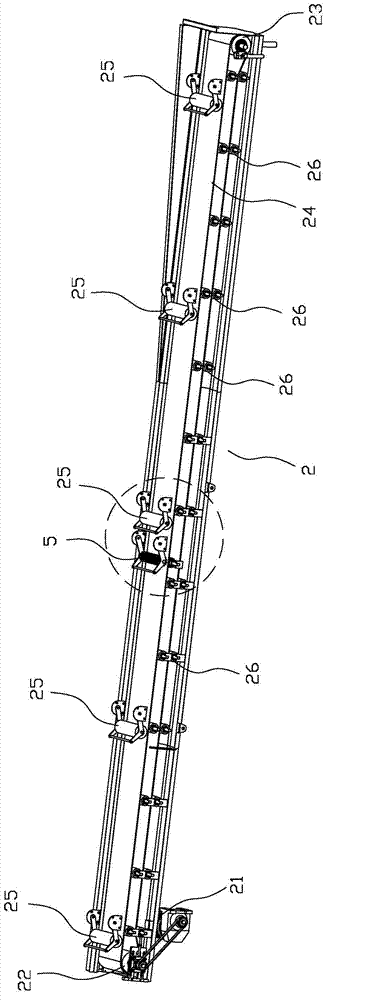

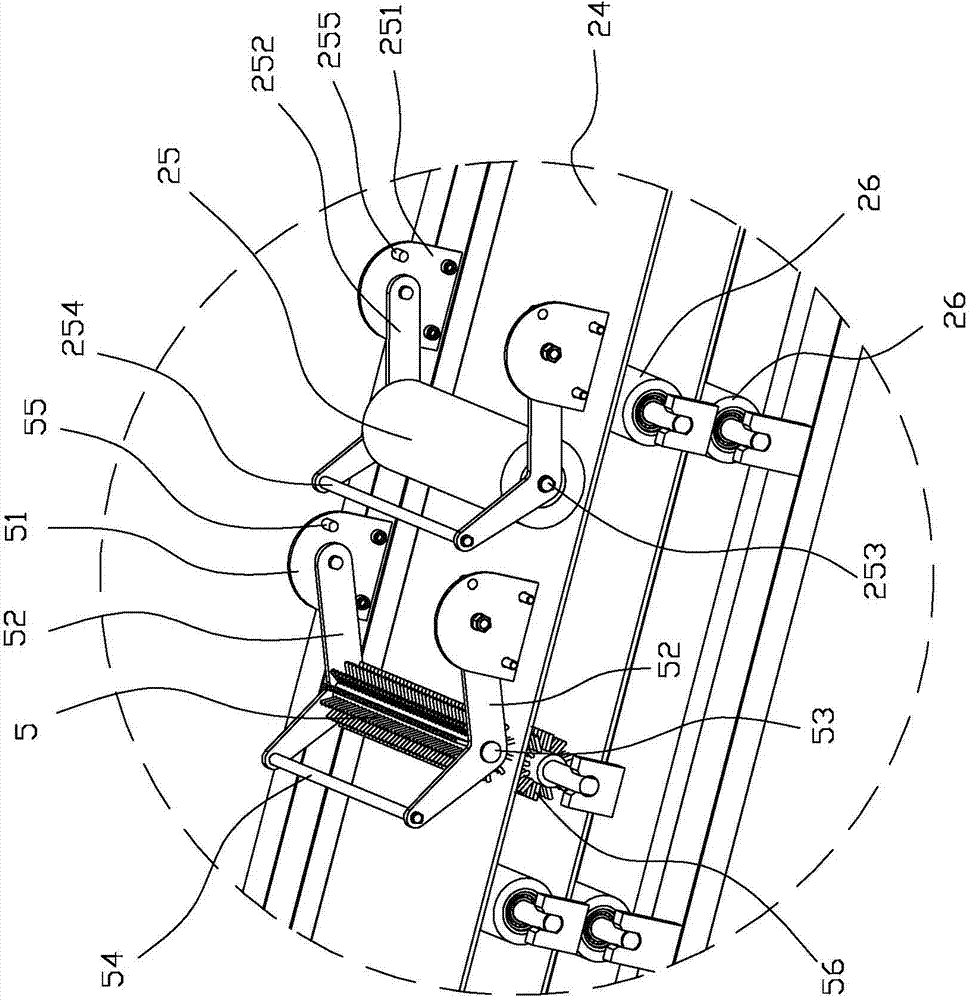

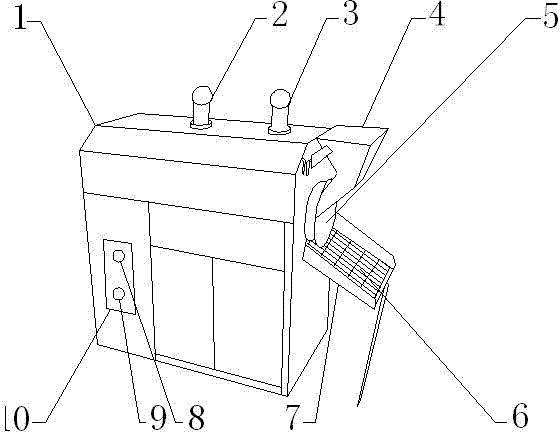

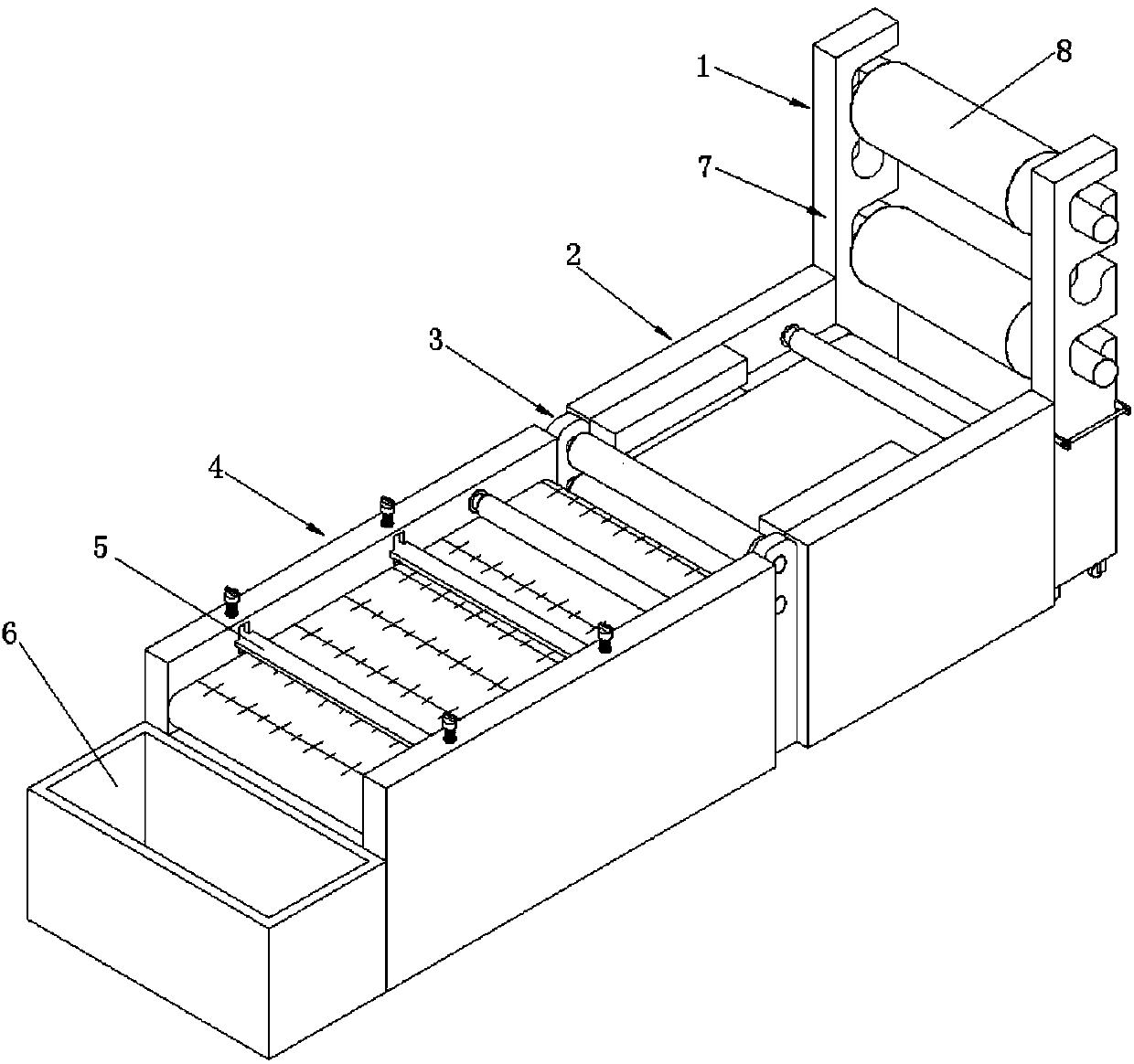

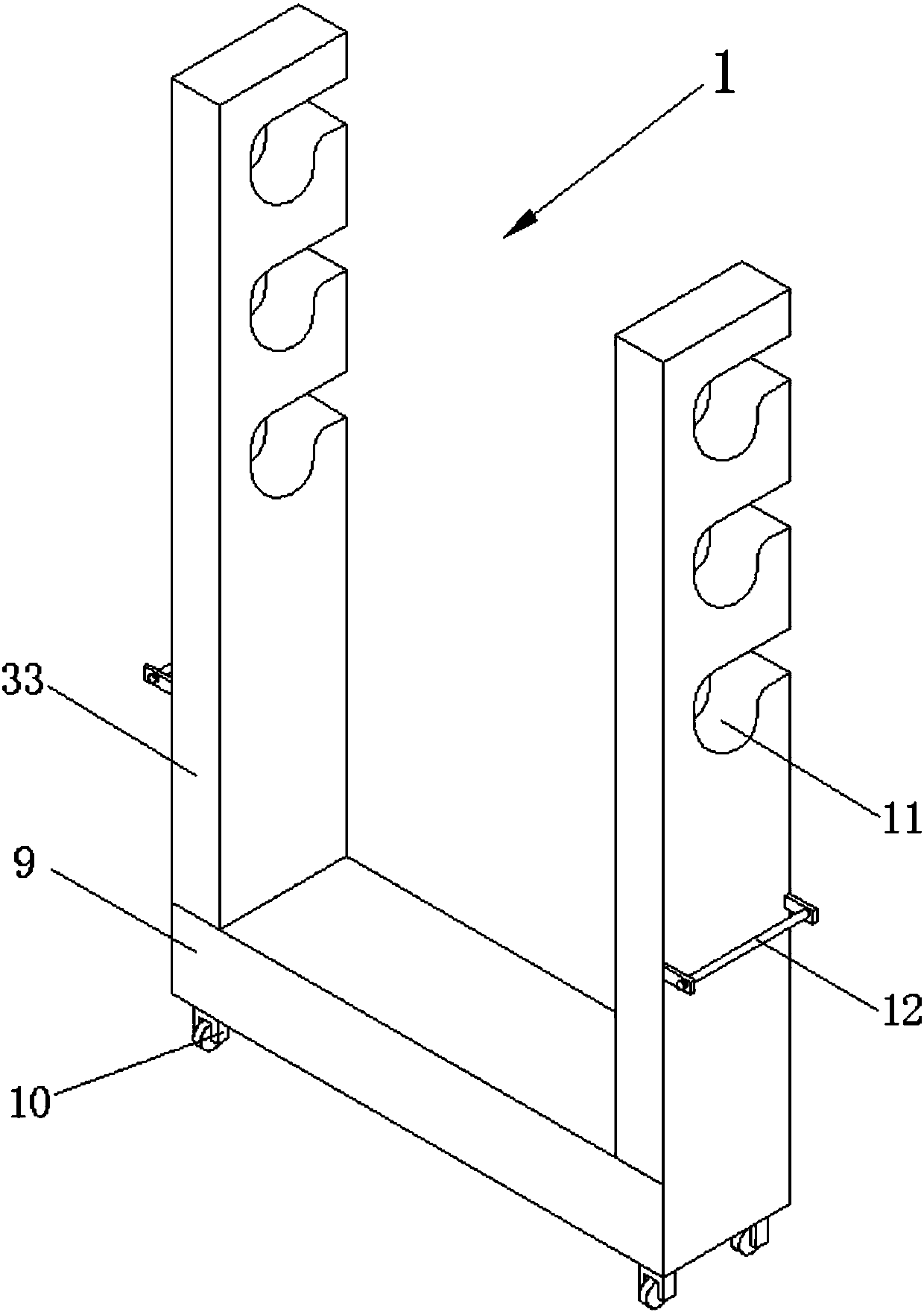

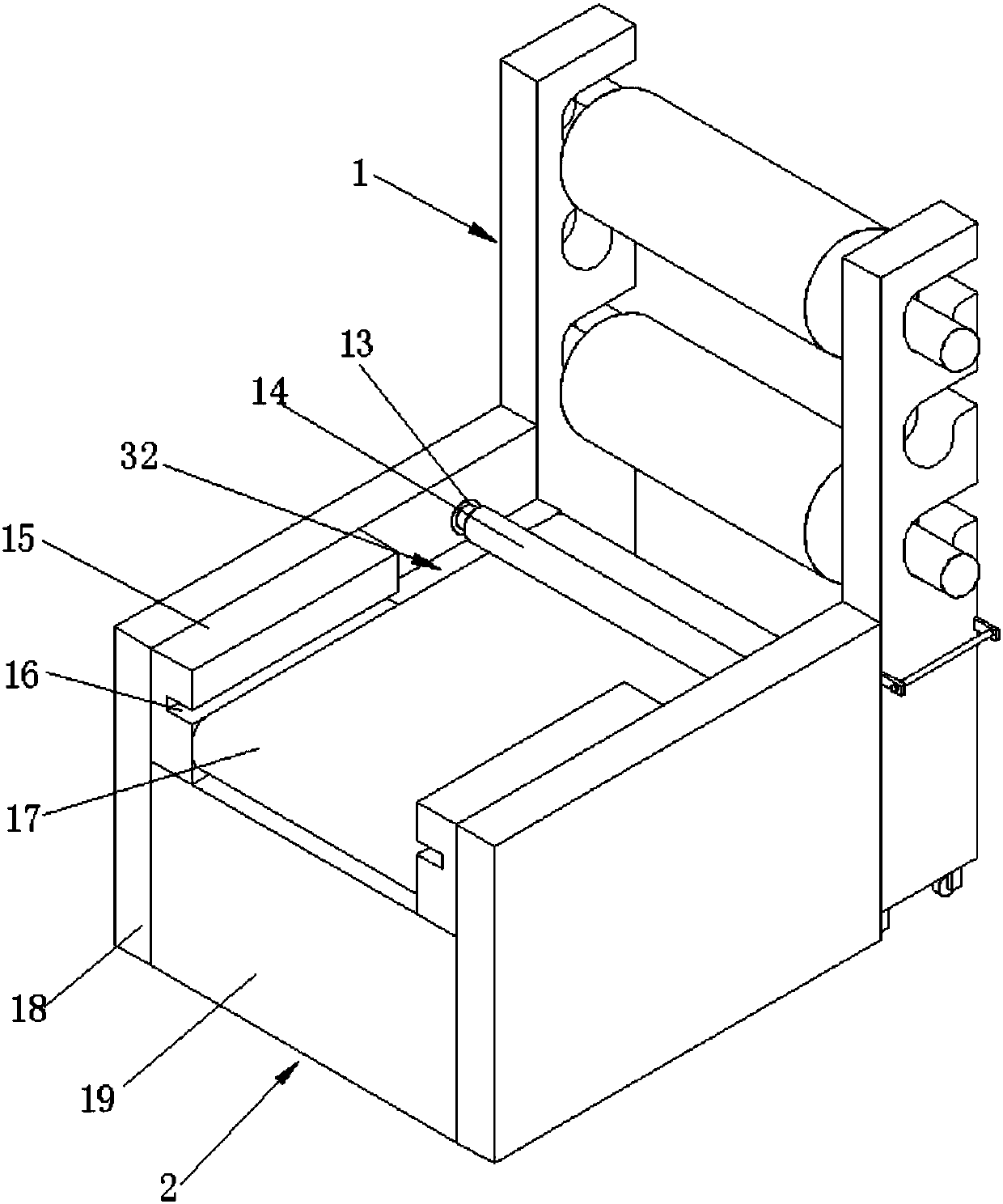

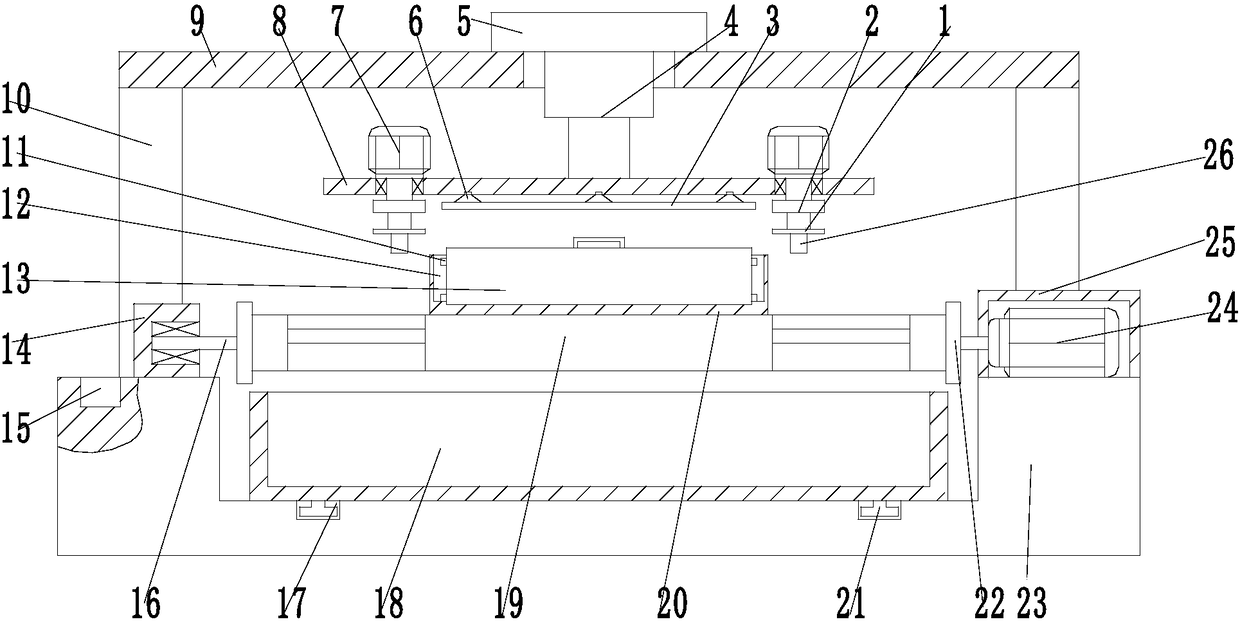

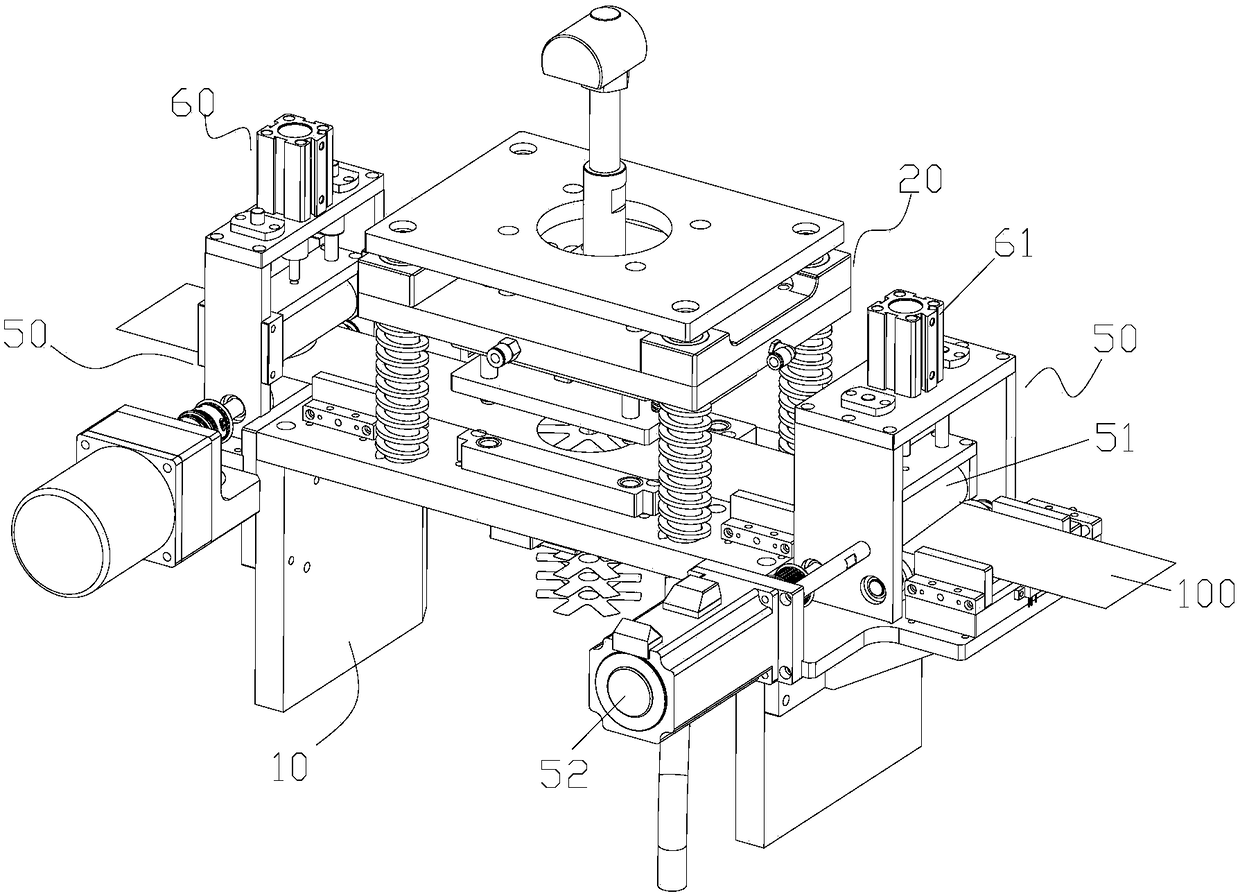

Portioning and transporting device for automatically vending foods and materials

InactiveCN107180485AGuaranteed accuracyImprove work efficiencyCoin-freed apparatus detailsApparatus for dispensing discrete articlesMechanical engineeringFood item

The invention relates to a portioning and transporting device for automatically vending foods and materials. The device comprises a material box, a vibration transporting device and a weighing device. The vibration transporting device is arranged below an outlet in the lower end of the material box, and the weighing device is arranged under a material discharging end of the vibration transporting device. A vibrating tank is vibrated by a vibrator so as to transport the foods or the materials, it is ensured that the foods or the materials are not damaged in the transporting process, and by means of the device, an independent individual or multiple objects can fall on the weighing device; when the independent individual needs to fall, a counting sensor can record the number of the individuals, and the counting function is achieved, so that the portioning and transporting of different foods and materials are achieved.

Owner:哈尔滨兴盛自动化设备制造有限公司

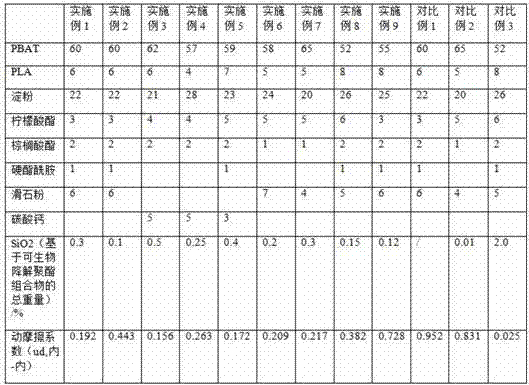

Biodegradable polyester composition

InactiveCN108003571AImprove the phenomenon of poor windingThere will be no slippage (film deviation, insufficient friction)Biodegradable polyesterSilicon dioxide

The invention discloses a biodegradable polyester composition. The biodegradable polyester composition comprises the following components: i) 52 to 70 parts of biodegradable aliphatic-aromatic polyester; ii) 4 to 9 parts of polylactic acid; iii) 20 to 30 parts of starch; and iv) 0 to 8 parts of an inorganic filling material. According to the invention, silicon dioxide is added into the biodegradable polyester composition, and the content of the silicon dioxide in the composition is controlled in a range of 0.1% to 0.5%, so the phenomenon of poor rolling of the biodegradable polyester composition in the process of film blowing can be greatly improved; the phenomenons of slipping and roll sticking of a thin film do not occur; and the thin film shows excellent rolling performance and has excellent food contact performance.

Owner:KINGFA SCI & TECH CO LTD +1

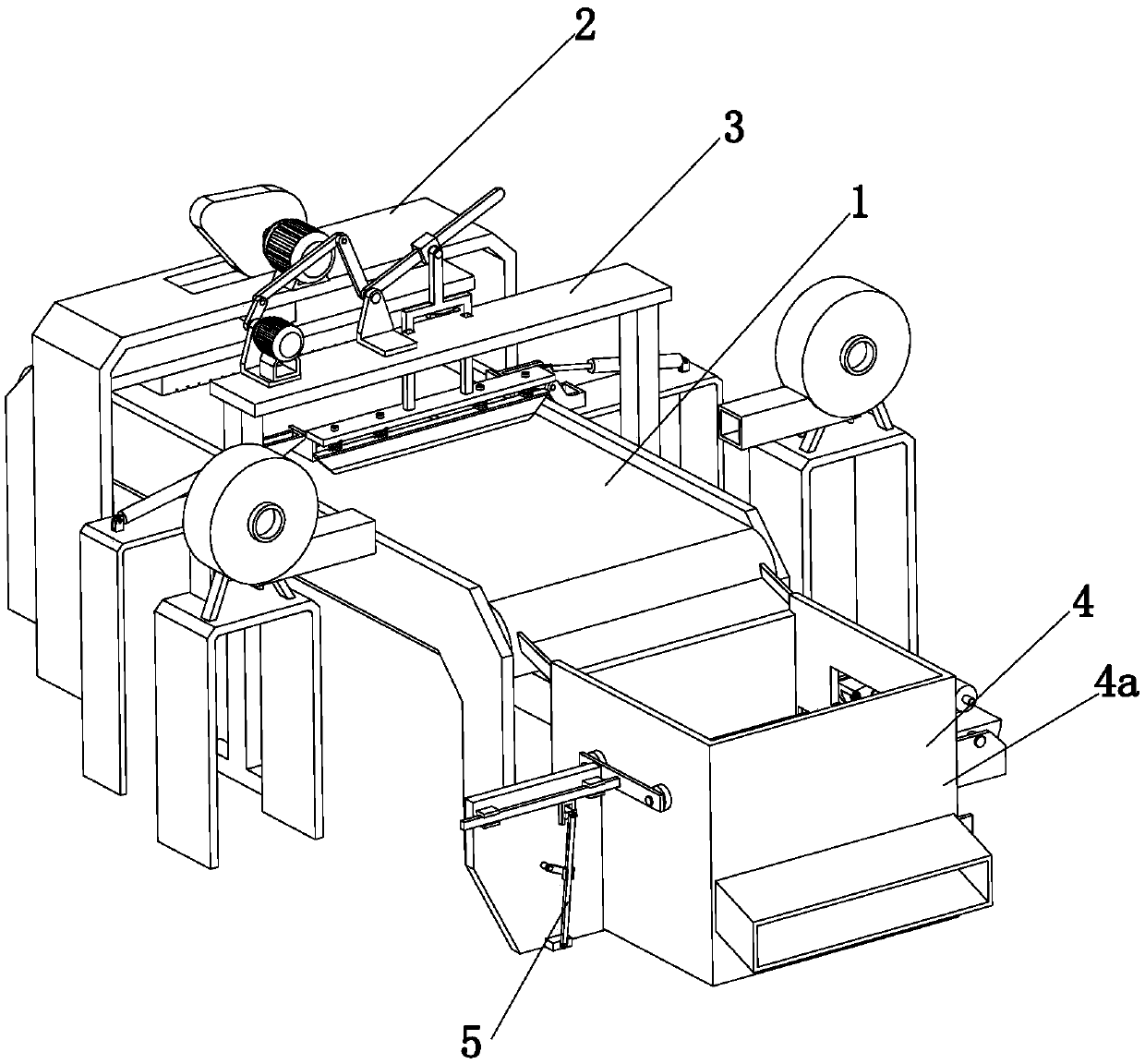

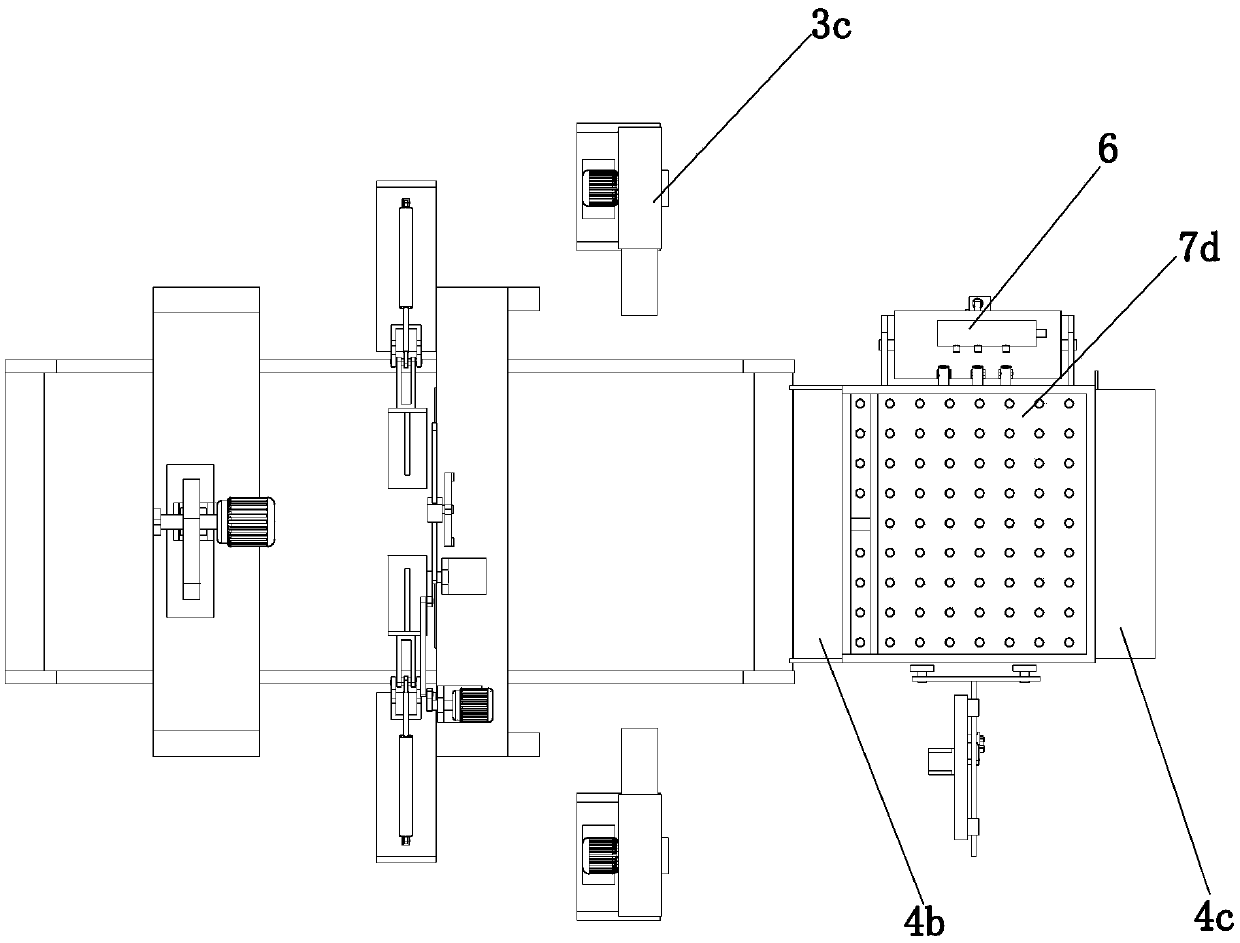

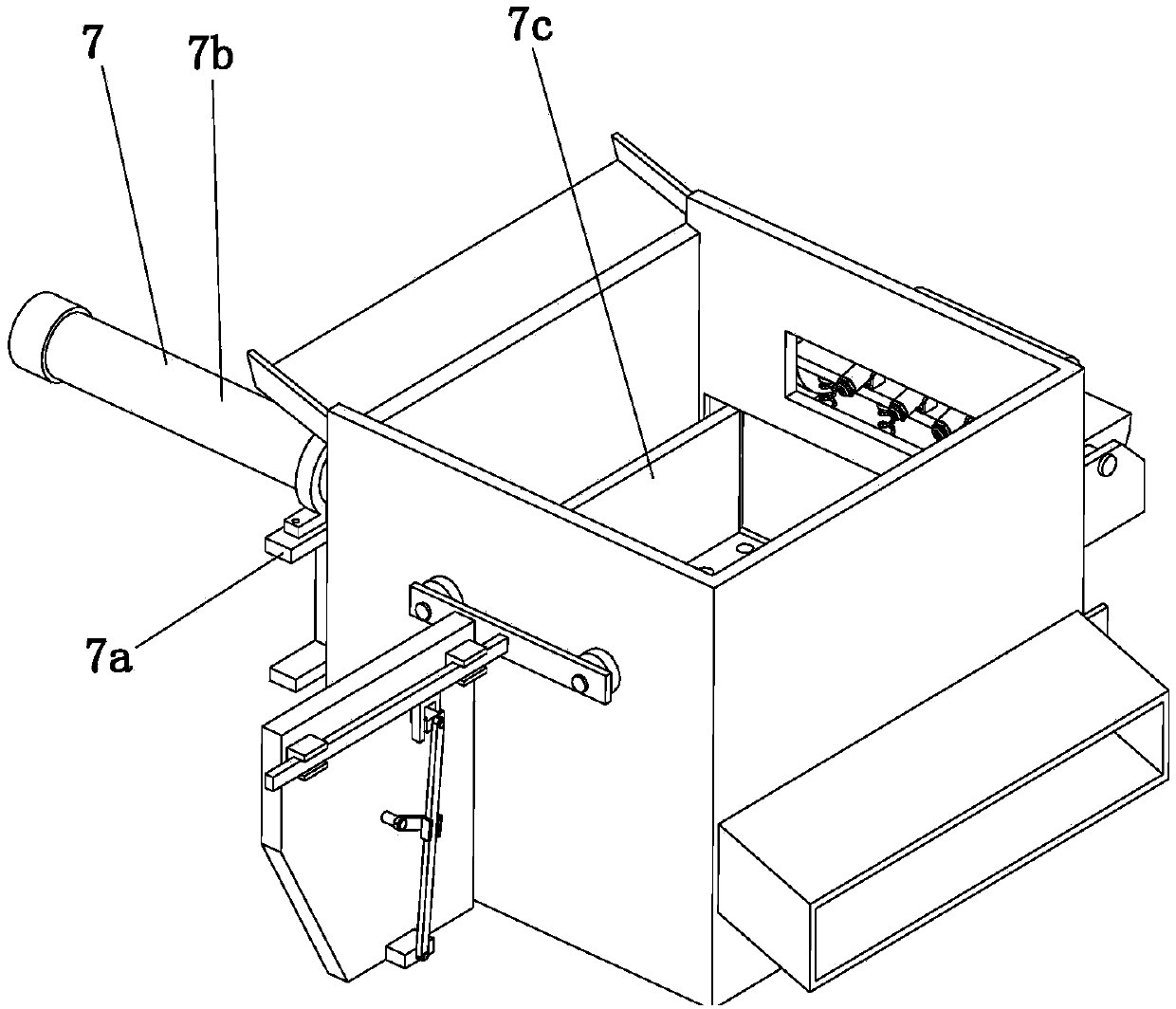

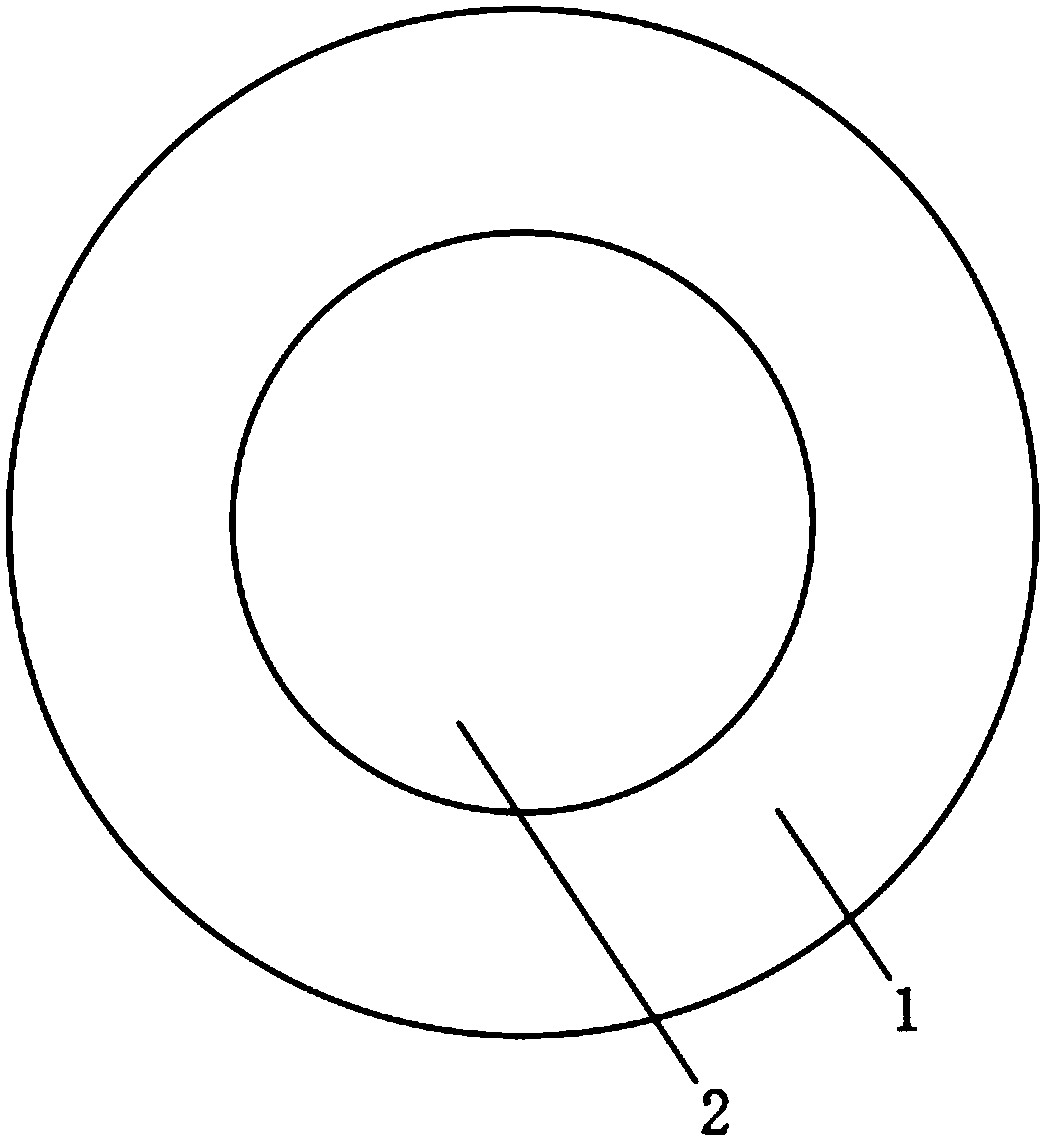

Waste paper disposal device

ActiveCN109653010ASolve the technical problem of sticking to the side wall of the deviceThere will be no sticking phenomenonPaper recyclingPulp bleachingReciprocating motionPulp and paper industry

The invention discloses a waste paper disposal device, and belongs to the field of waste paper disposal. The waste paper disposal device comprises a conveying belt, a waste paper compacting mechanism,a waste paper cutting-up mechanism and a pulp recycling mechanism; the pulp recycling mechanism comprises a recycling box, an adherent paper knocking-off assembly, a waste paper bleaching assembly and a material pushing assembly; a feeding sliding passage is arranged at the left end of the recycling box, a discharging funnel is arranged at the right end of the recycling box, and a closed door which cooperates with the sliding passage is arranged on the discharging funnel. According to the waste paper disposal device, the waste paper cutting-up mechanism can automatically compact and cut up waste paper on the conveying belt, and offset of the waste paper in the cutting process and influence of offset of the waste paper on cutting operation are avoided; the adherent paper knocking-off assembly can make a shock cylinder do reciprocating motion and knock the side wall of the recycling box so that the waste paper can be prevented from sticking to the inner side wall of the recycling box and the influence on cleaning by workers can be avoided, and waste of resources is also avoided.

Owner:山东天智信息科技有限公司

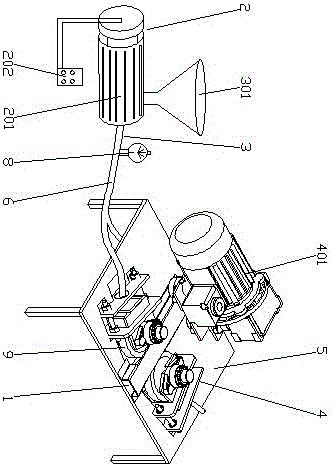

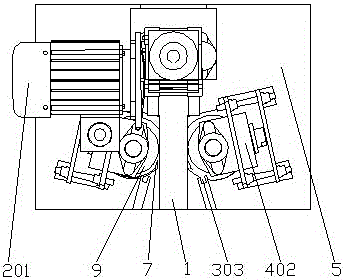

Automatic cooling traction equipment for plastic extruded strip

The present invention discloses automatic cooling traction equipment for plastic extruded strips. The equipment includes a rack and a traction device mounted in the rack; the traction device comprises a traction roller, a driven roller, a metal conveyor belt and a plurality of strip pressure rubber rollers; the metal conveyor belt has a feed surface for friction conveying of material strips; the feeding surface of the metal conveyor belt is a single straight bevel extending from a driven rubber roller end a traction rubber roller end and gradually rising. On the one hand, the present invention uses a single straight bevel conveyor belt structure to replace a traditional ''flat-oblique- flat'' three-stage conveyor belt structure, and with the reduced inclination angle of the conveyor belt, the driving force of the conveyor belt greatly reduces; on the other hand, the rubber rollers drive the metal conveyor belt, and as the hardness of the rubber rollers is small, a soft versus hard transmission mode is formed between the rubber rollers and the metal conveyor belt, so that little noise is produced. In general, the invention has the advantages of fewer components, low power dissipation of the driving motor, high efficiency, energy saving and great reduction of noise.

Owner:DONGGUANG HUI RU LAI POWER TECH CO LTD

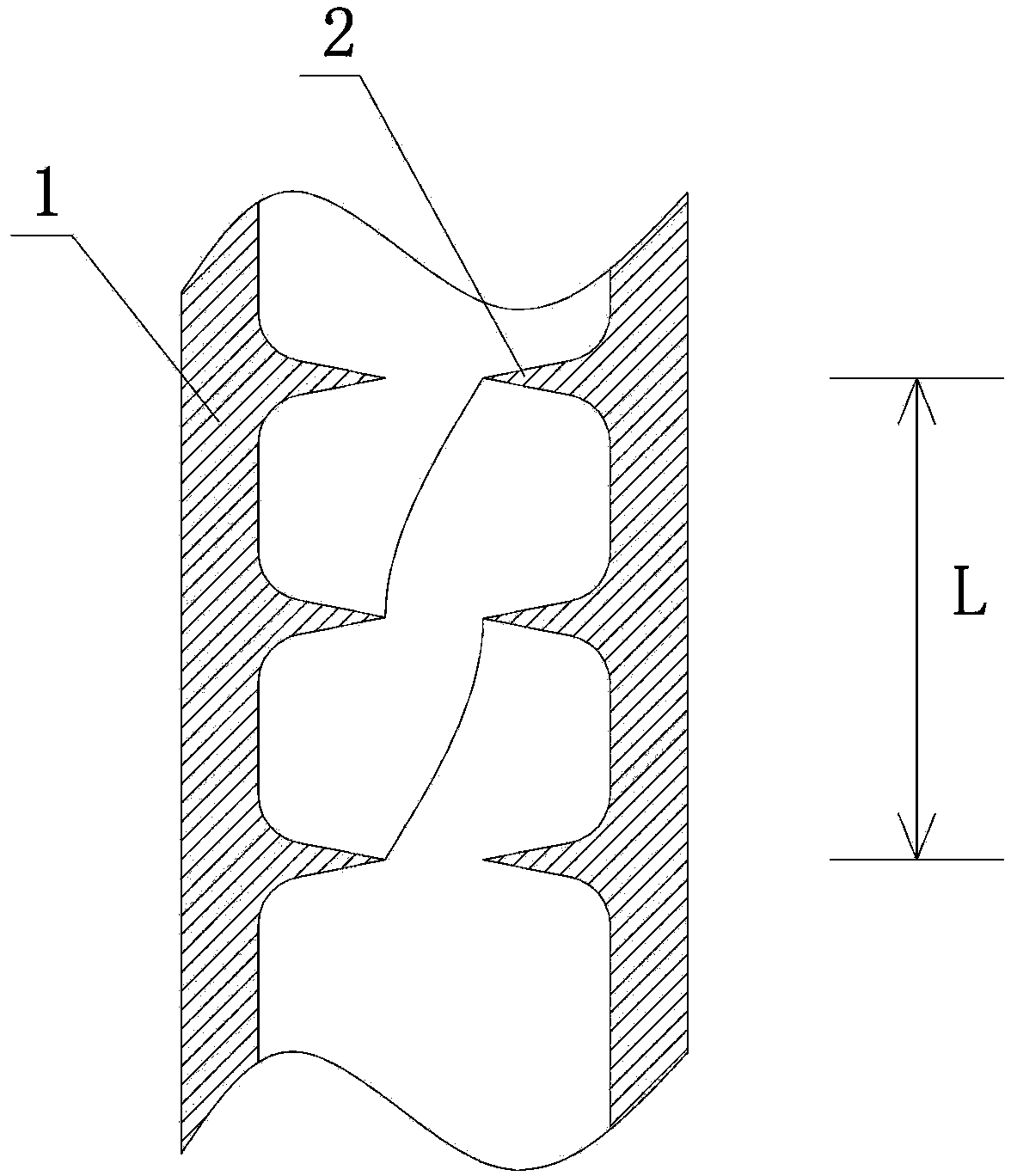

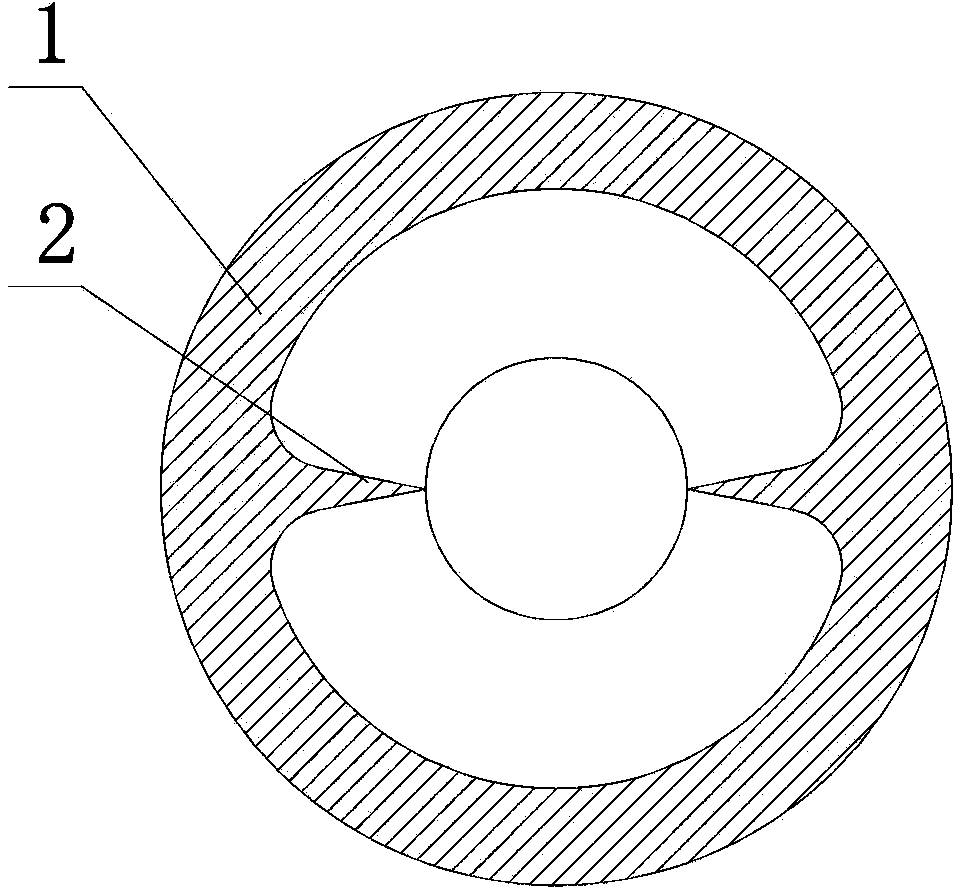

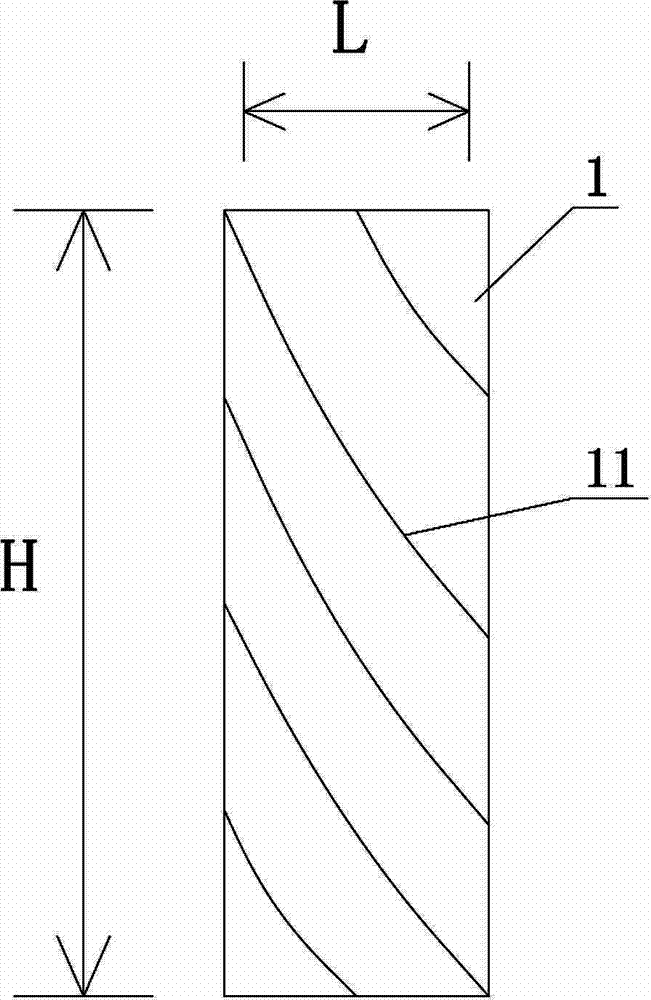

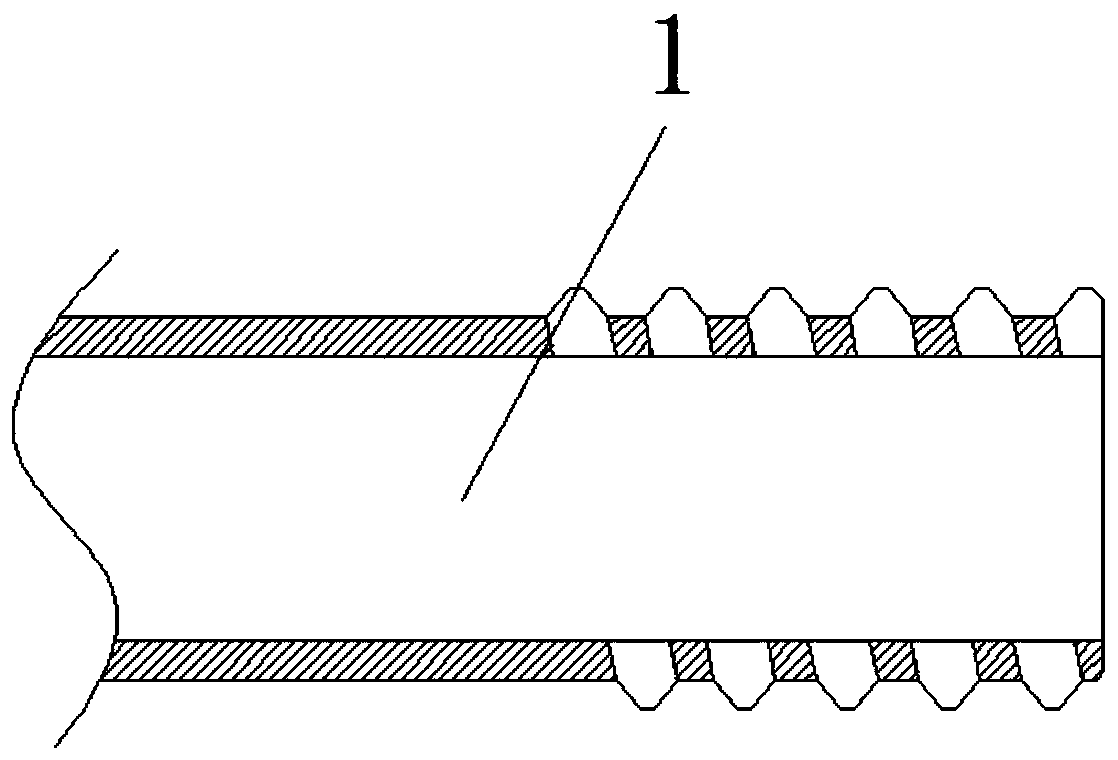

Pipeline

InactiveCN104235548AEasy to transportThere will be no sticking phenomenonPipe elementsPetroleumHelix

The invention discloses a pipeline. The pipeline is a straight pipe, wherein two flow-guiding ribs which face each other are arranged on the inner wall of the pipeline along the axial direction; the flow-guiding ribs are spirally arranged on the inner wall of the pipeline; and the screw pitch of helixes is two times the inner diameter of the pipeline. Due to the fact that the flow-guiding ribs are arranged on the inner wall of the pipeline, the pipeline is simple in structure and plays a flow-guiding effect on petroleum transmission; due to the fact that the flow-guiding ribs are spirally arranged, flowing petroleum does not retain and stick, the petroleum is convenient to deliver, and the effect is good.

Owner:WUXI JINDING OIL PIPE FITTINGS

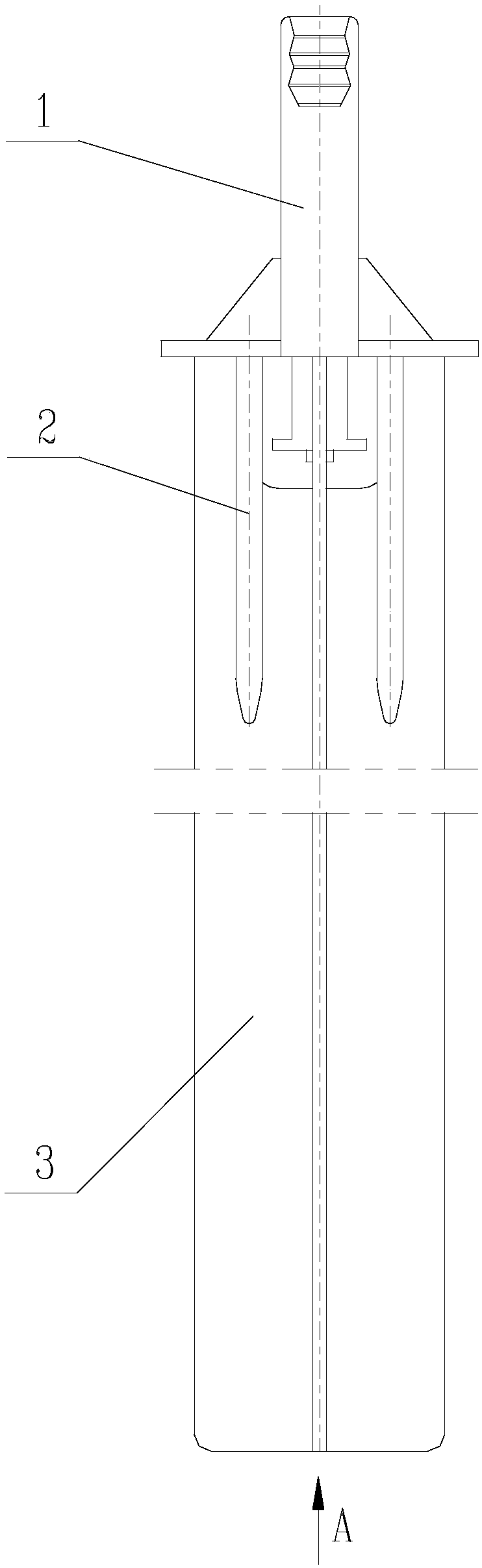

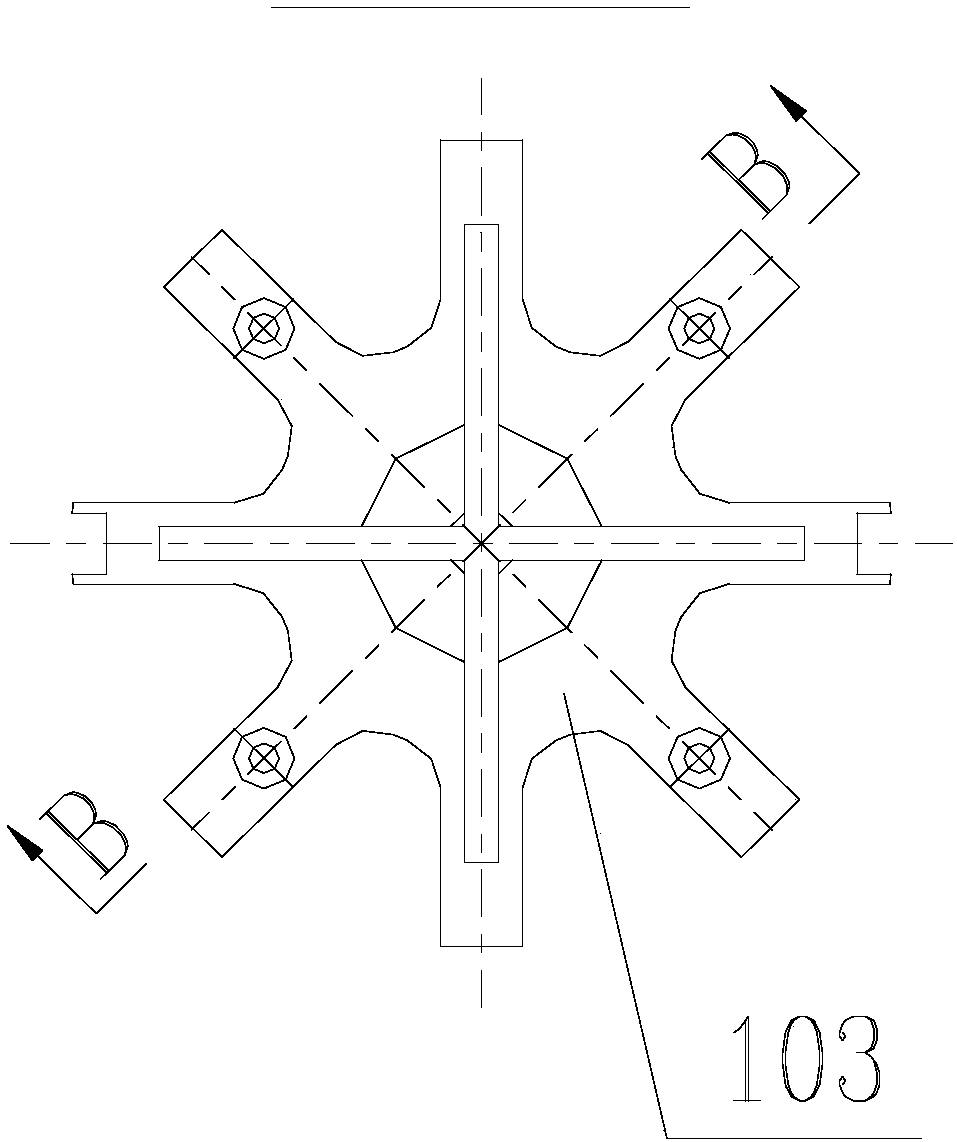

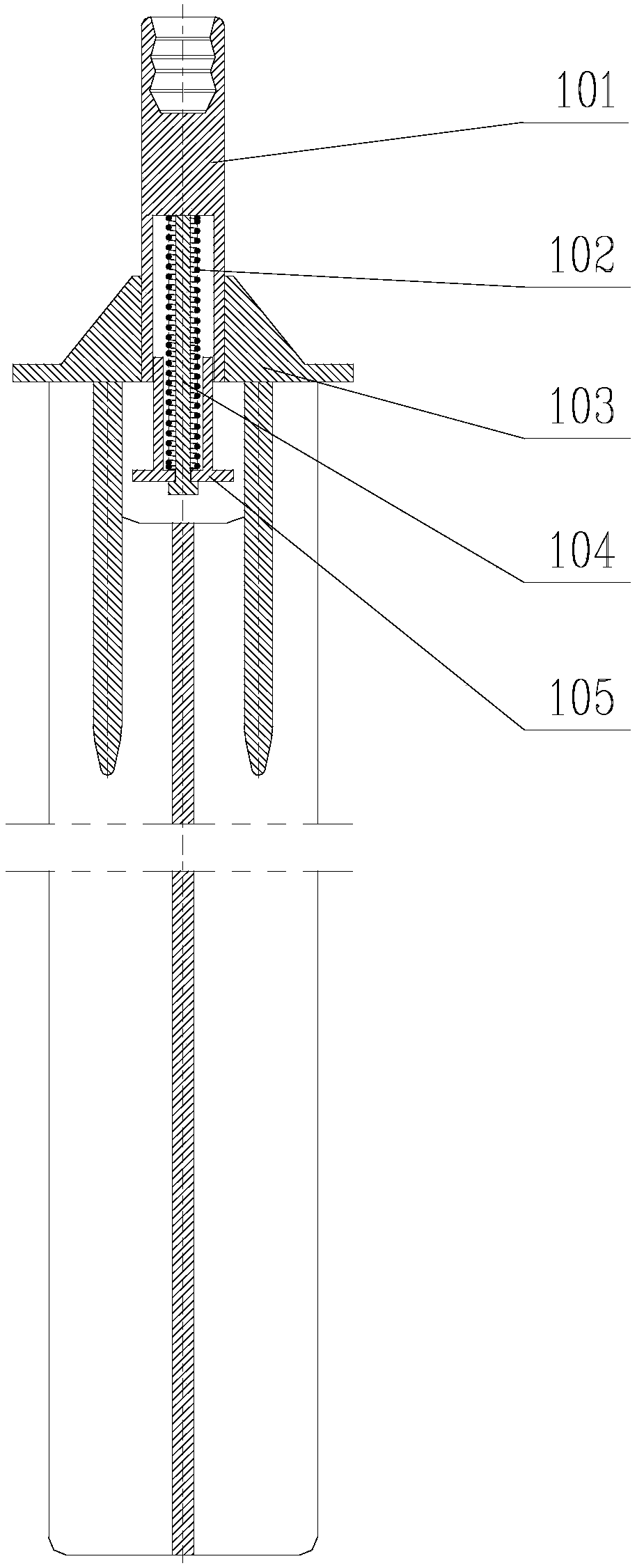

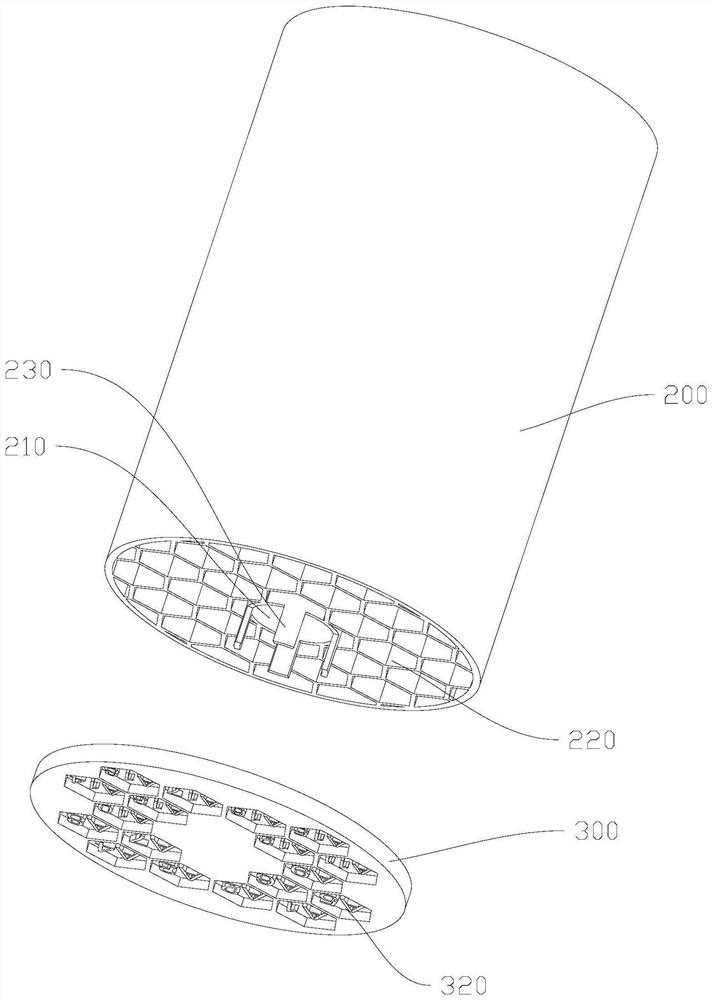

Control rod component and guide component structure applicable to supercritical reactor

InactiveCN107644688ANo limit on gap sizeChanging the way hydraulic cushioning worksNuclear energy generationNuclear reaction controlEngineeringOperations security

The invention discloses a control rod component and guide component structure applicable to a supercritical reactor, and aims to solve the problem that sufficient hydraulic buffer is not available byreducing the cross gap between a cross control rod and a fuel component in a conventional supercritical reactor. The structure comprises a control rod component and a guide component, wherein the control rod component comprises a connecting handle component, and a cross control rod of which the top end is mounted on the connecting handle component; a buffer rod parallel to the cross control rod isarranged on the connecting handle component; the guide component comprises a guide cylinder, and a hydraulic buffer structure which is arranged at the bottom end of the guide cylinder and is matchedwith the buffer rod to achieve hydraulic buffer. The structure has the advantages that hydraulic buffer is achieved, a rod clamping phenomenon is avoided, the hydraulic buffer effect is adjusted, andthe operation security is improved.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

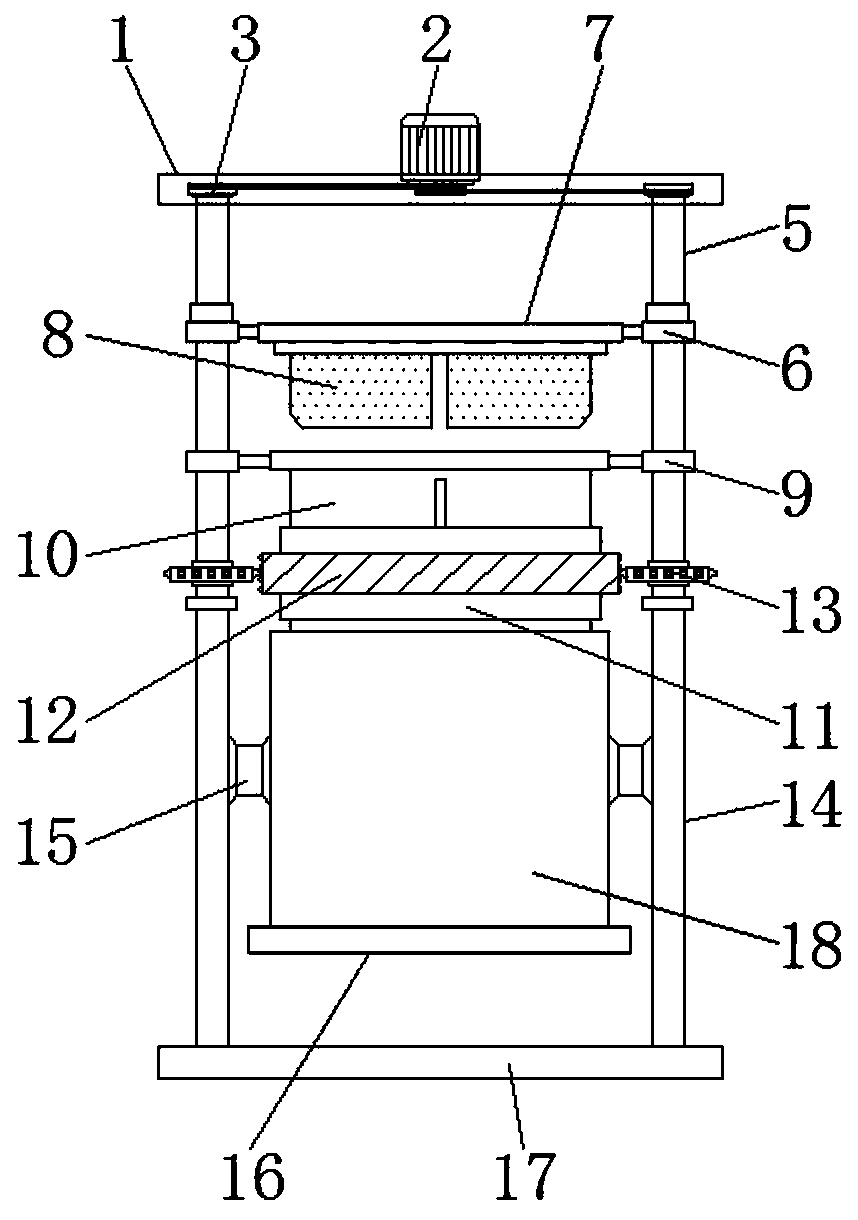

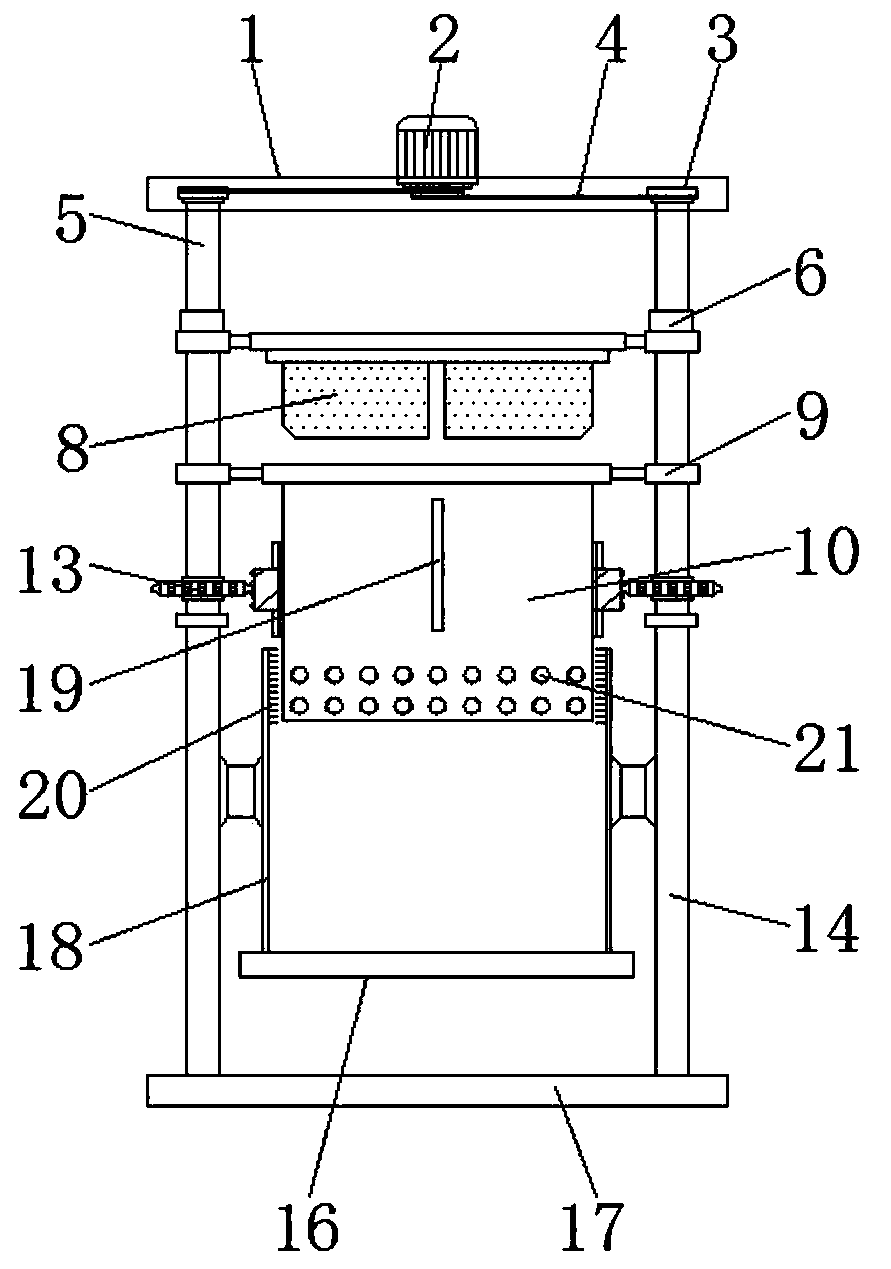

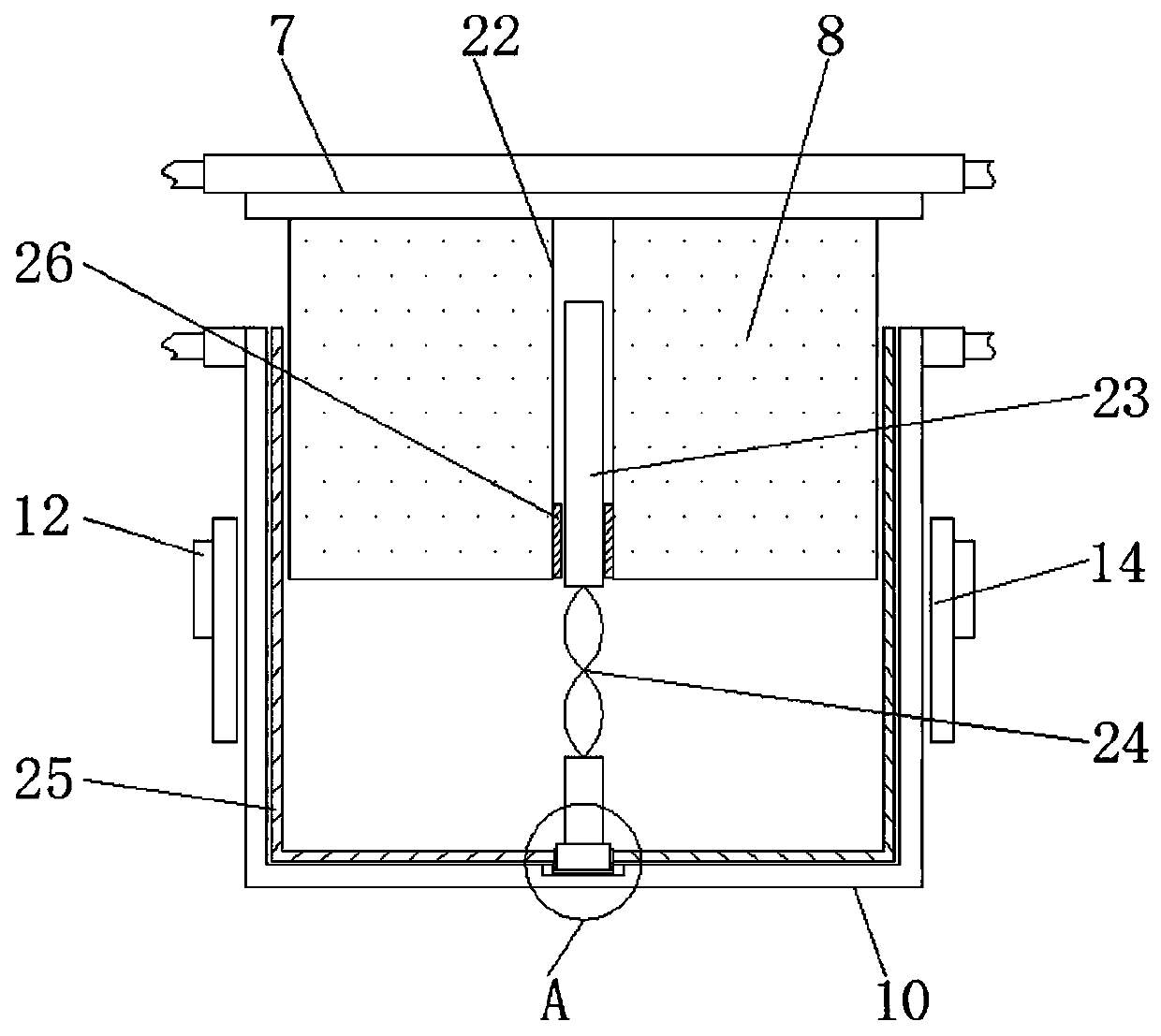

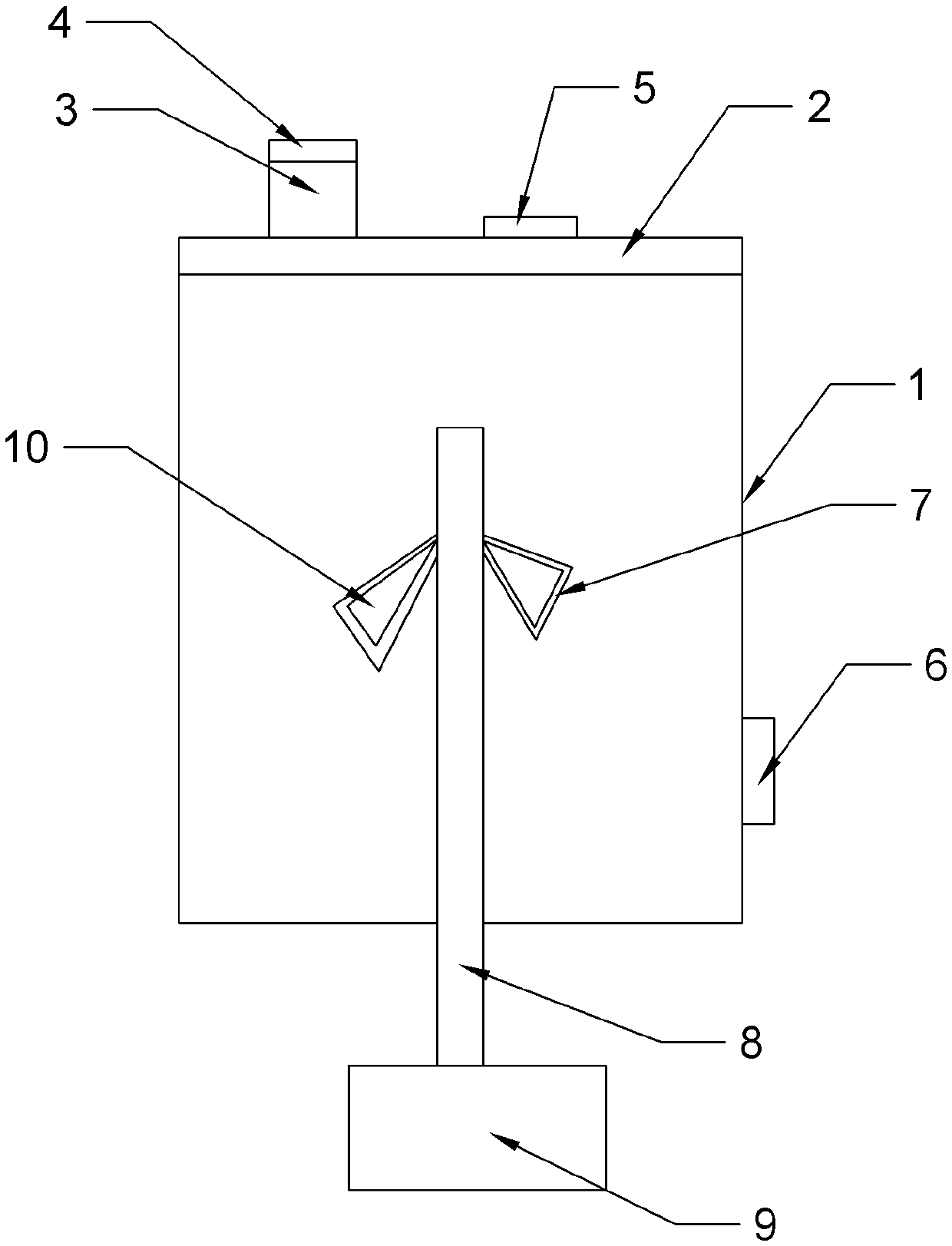

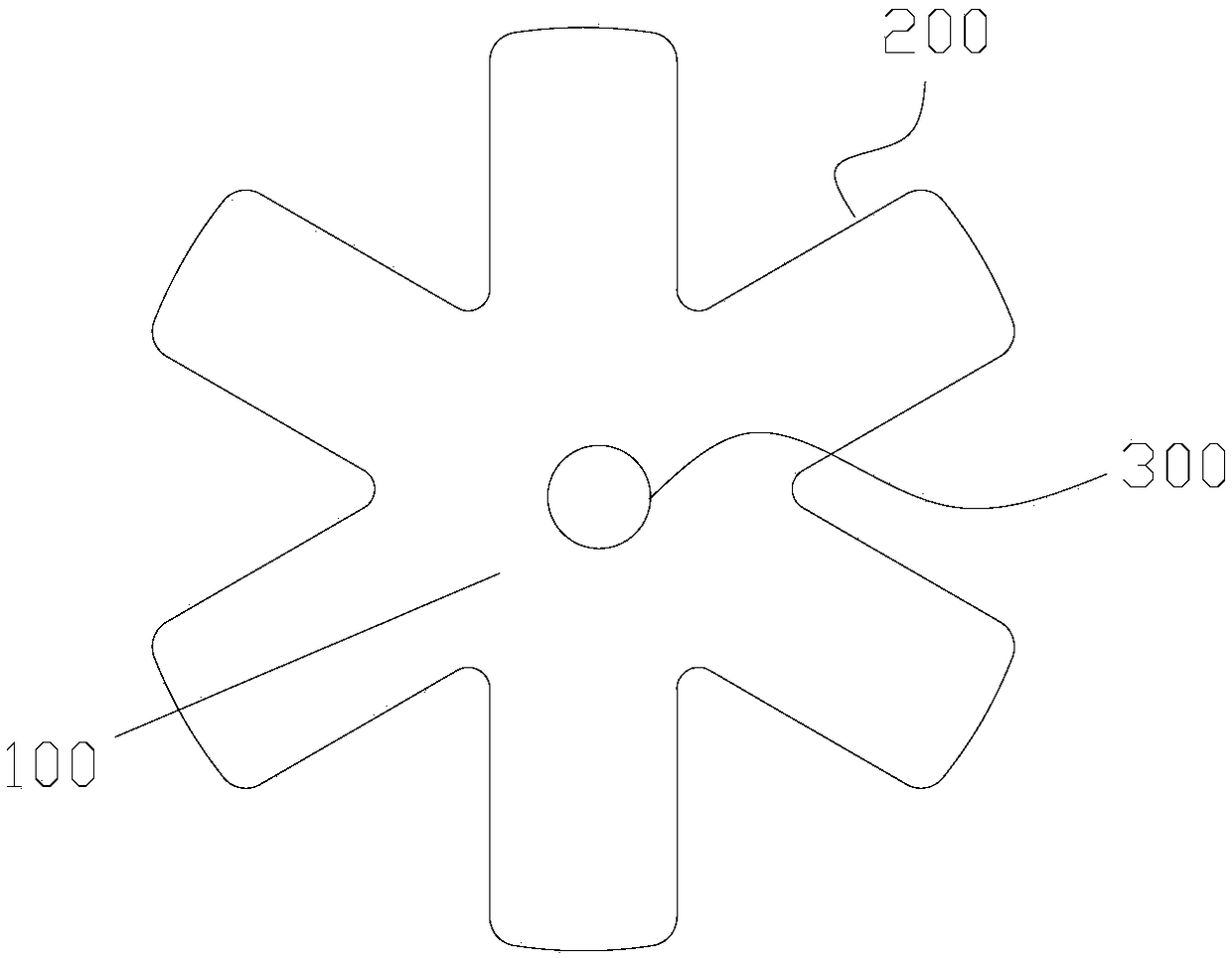

Granulator having anti-adhesion function and used for western medicine processing

ActiveCN110882659AWith anti-adhesive functionGranulation work wellPharmaceutical product form changeGranulation by material expressionPhysicsElectric machinery

The invention discloses a granulator having an anti-adhesion function and used for western medicine processing. The granulator includes an ejector rod, a motor, and a bottom plate. The motor is disposed at an upper middle position of the ejector rod, and the bottom of the motor is connected to a rotating disk through a belt. The rotating disk is arranged inside the ejector rod, and the bottom of the rotating disk is connected with fixed screw rods. Both sides of a blanking barrel are connected to support rods through vibrators, and the tops of the support rods and the fixed screw rods are connected by bearings. The bottom of the blanking barrel is provided with a blanking port, and the bottom plate is fixed to the bottoms of the support rods. The granulator, during use, can perform thorough granulation on the whole medicine slurry inside an accommodation barrel, and during granulation, a cutter blade can cut the medicine slurry at an extrusion place in time, and the phenomenon of bonding will not occur.

Owner:聊城锐利机械设备有限公司

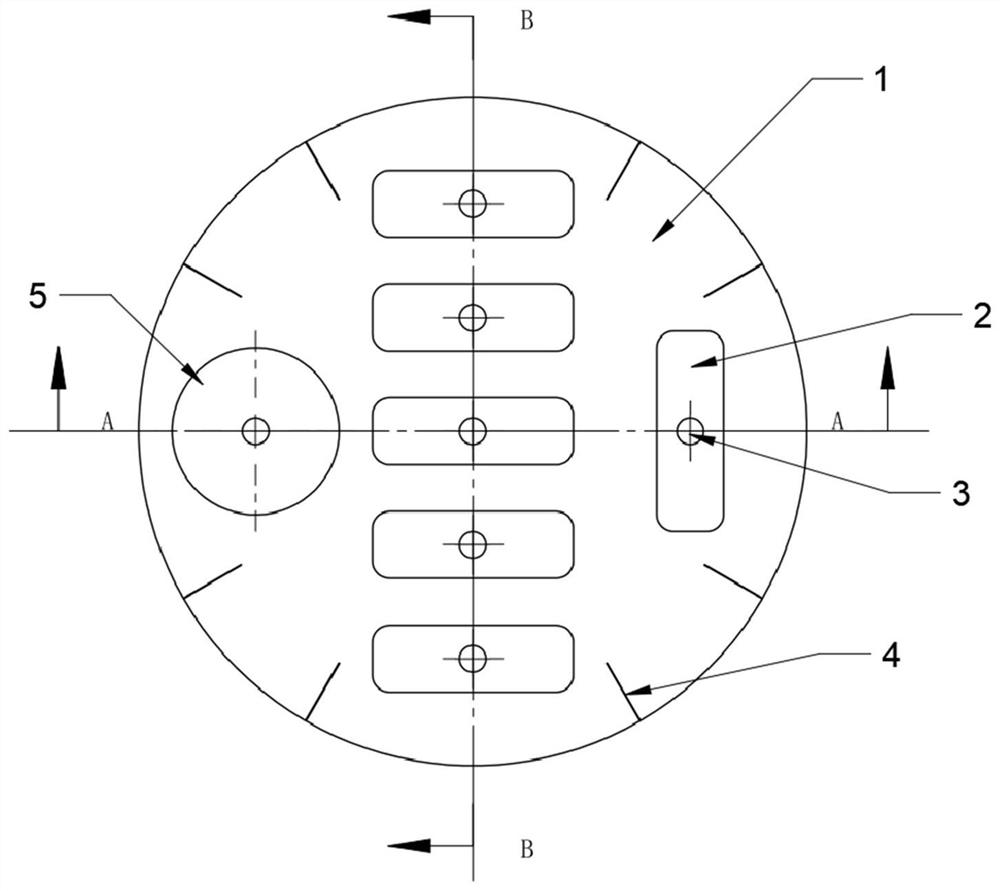

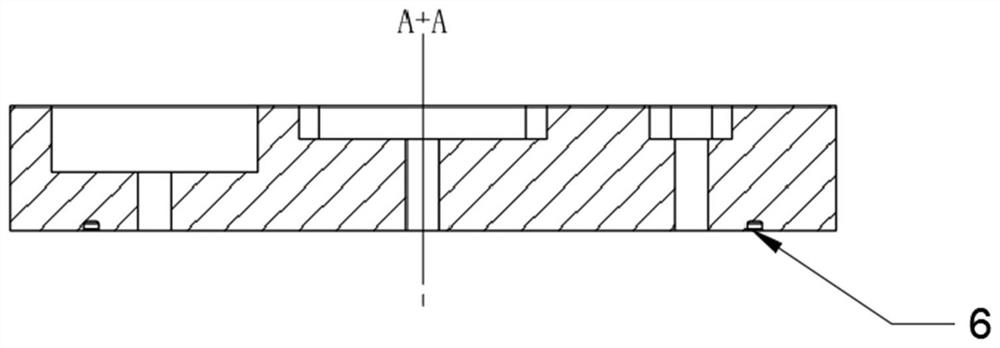

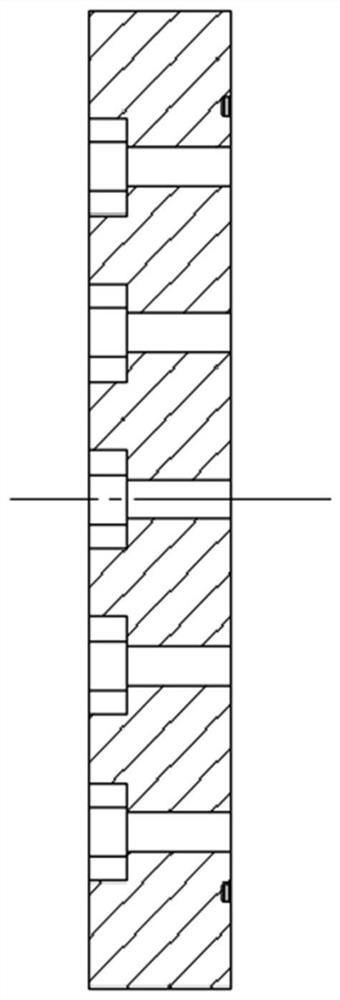

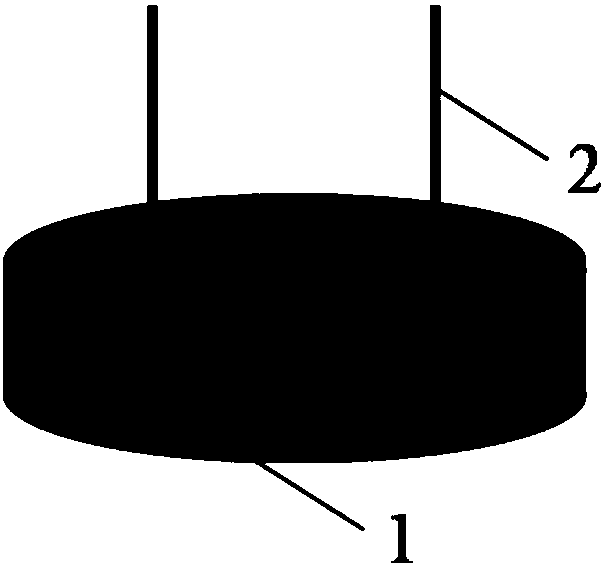

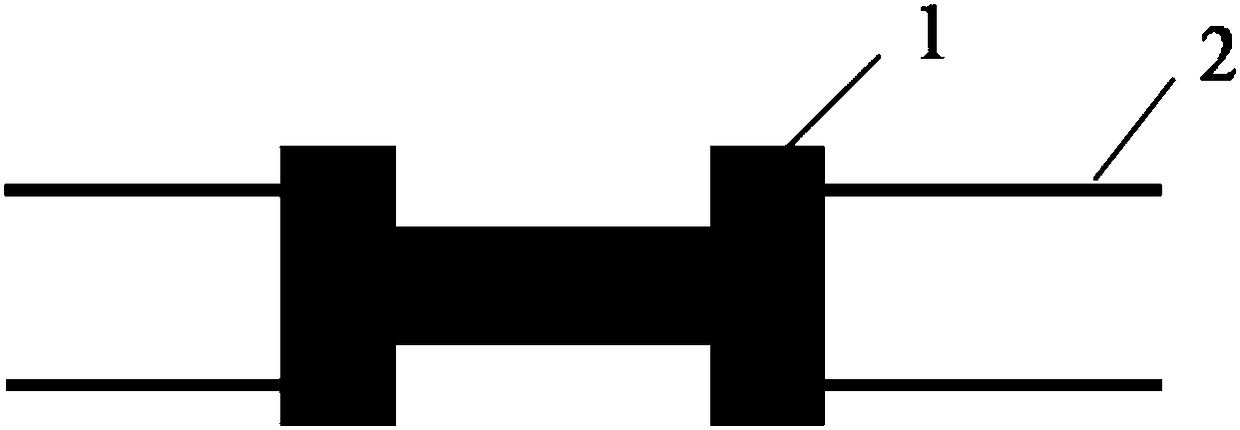

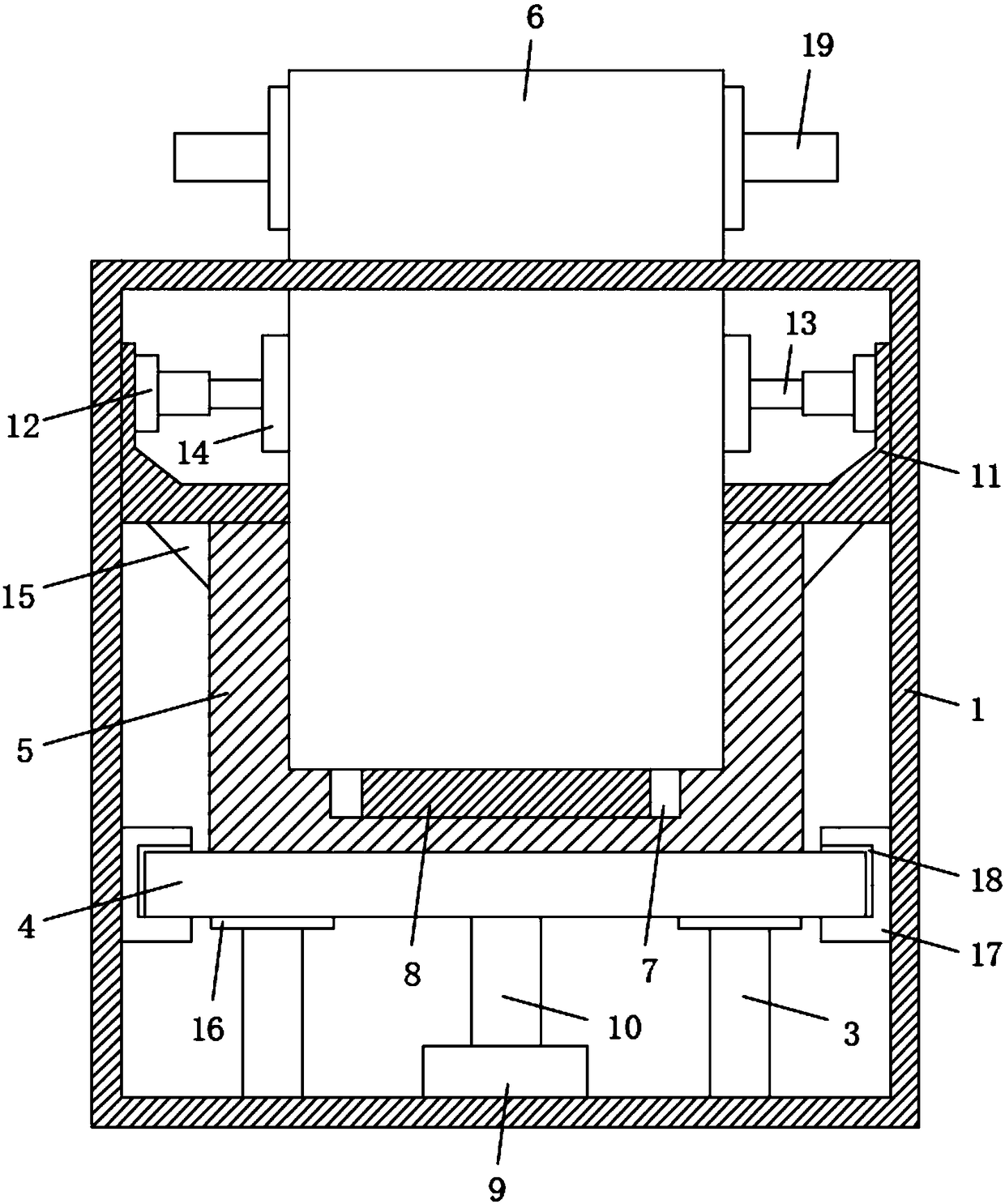

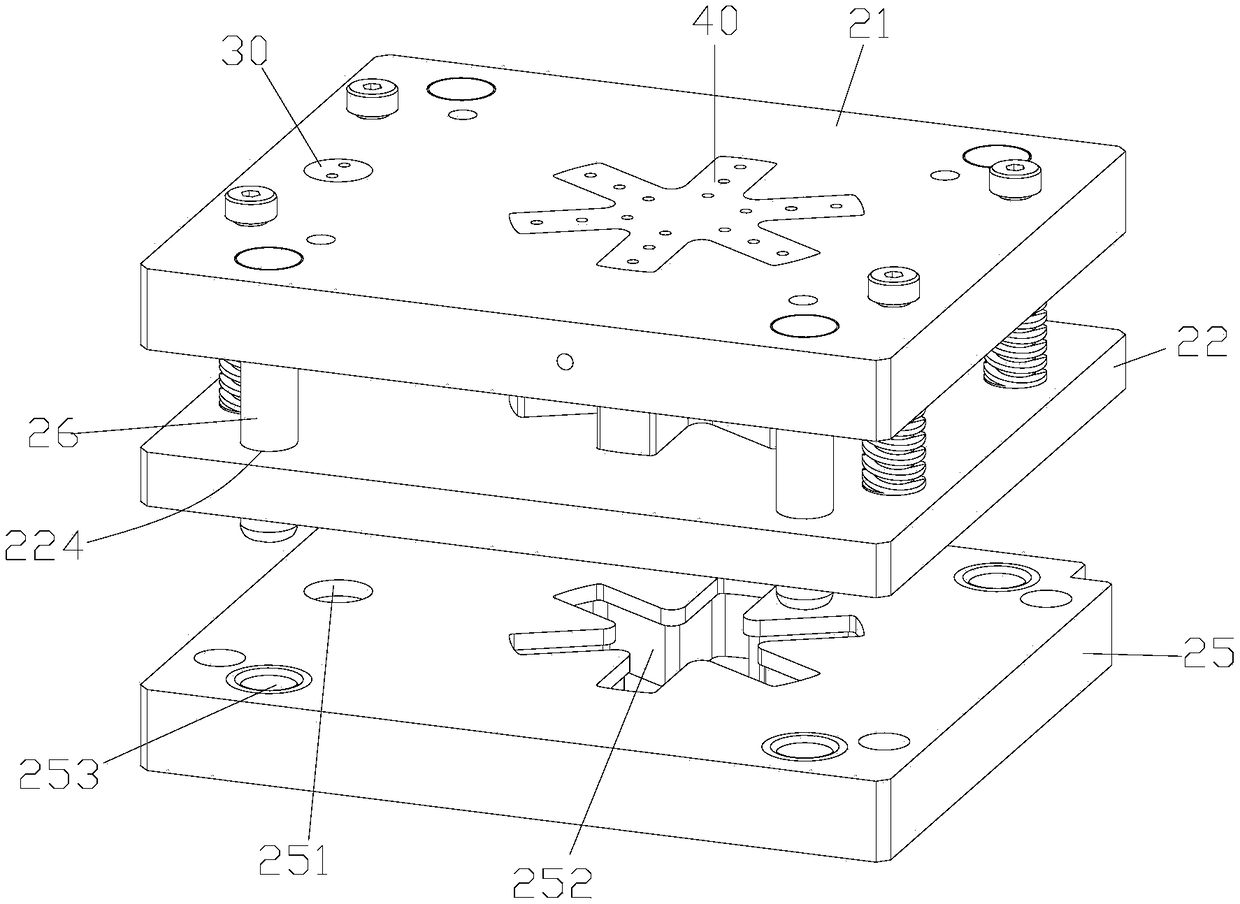

Assembly type base plate for powder bed melting additive manufacturing and using method thereof

PendingCN114082991AImprove assembly accuracyLow costAdditive manufacturing apparatusIncreasing energy efficiencyMetallurgyMetal powder

The invention relates to the field of metal powder bed melting additive manufacturing, in particular to an assembly type base plate for powder bed melting additive manufacturing and a using method thereof. The assembly type base plate comprises a standard substrate, at least one assembly groove is formed in the standard substrate, and a through hole is formed in the bottom of the assembly groove; and the base plate also includes small substrates that are in one-to-one correspondence with the assembly grooves, the small substrates are embedded in the assembly grooves in the standard substrate, and the small substrates are detachably mounted on the standard substrate. According to the invention, the product and the small substrate can be conveniently taken down from the main substrate; the standard substrate does not need to be leveled after one-time printing is completed, so that the production preparation time is greatly shortened, the production efficiency is improved, and the processing cost is reduced; and after the products are formed and manufactured, the small forming substrates can be detached from the standard substrate, so that the products can be independently treated according to detection requirements, and the utilization rate of equipment is improved.

Owner:BEIJING UNIV OF TECH

Chinese chestnut stir-frying machine

InactiveCN103070459AAchieve separationImplement auto-rotationFood treatmentNumerical controlPulp and paper industry

The invention discloses a Chinese chestnut stir-frying machine, which relates to the field of food machinery and comprises a host machine, wherein a numerical control region is arranged on the host machine, a rolling tube is arranged in the host machine, the upper part of the rolling tube is connected with a feeder, the lower part of the roller is connected with a material collector, the material collector is arranged at the side surface of the host machine, a fault lamp and a prompt lamp are arranged above the host machine, the use is convenient, and new functions are given to the Chinese chestnut stir-frying machine, so the conditions can be known through observing the fault lamp and the prompt lamp arranged on the host machine in the operation process of the Chinese chestnut stir-frying machine, the illumination of the prompt lamp indicates that the stir-fry time is reached, people can prepare to load the Chinese chestnut, the illumination of the fault lamp indicates that the machine has fault temporarily, and people need to turn off a power supply to ensure the safety.

Owner:SUZHOU MAIKE FOOD MACHINERY PLASTIC CEMENT

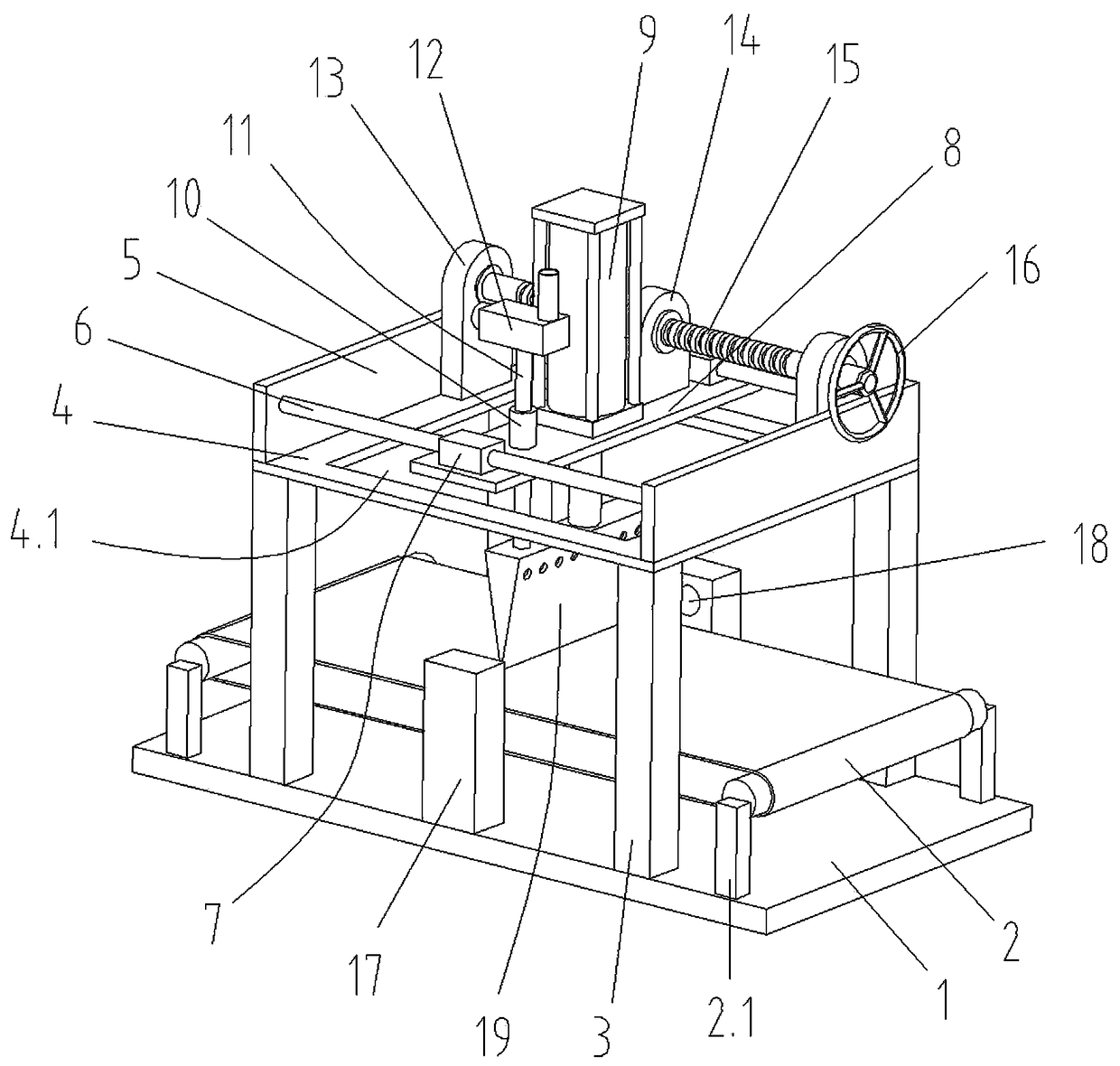

Rice band cutting-off machine

InactiveCN108515547AConvenient Quantitative CuttingImprove cutting effectMetal working apparatusPulp and paper industryPiston rod

The invention discloses a rice band cutting-off machine. The rice band cutting-off machine comprises a bottom plate. A top plate is connected with the upper portion of the bottom plate in a supportedmode through two sets of stand columns on the two sides correspondingly. A cutting-off air cylinder vertically arranged downwards is fixedly connected with the upper portion of a receding hole. A cutting knife is further fixedly connected with the tail end of a piston rod of the cutting-off air cylinder. A conveying belt is further arranged in the center of the upper portion of the bottom plate and fixedly connected to the upper side of the bottom plate through supports. The conveying belt is arranged below the top plate and corresponds to the cutting knife. Two air bellows are fixedly connected with the sides of the bottom plate and symmetrically arranged on the two sides of the conveying belt. The cutting knife is arranged between the two air bellows. An air outlet pipe is arranged on the side, facing the cutting knife, of each air bellow. The rice band cutting-off machine has the advantages that the rice band cutting-off machine provided by the invention is good in cutting-off effect, the cutting position of the cutting knife can be changed, rice bands can be cut quantitatively and conveniently, a cavity is formed in the cutting knife and filled with sponge, hot oil is absorbedby the sponge after entering the cavity and then flows out slowly through an oil discharging hole, and thus the knife sticking phenomenon in the cutting process is avoided.

Owner:蚌埠市优乃德自动化机械设备制造有限公司

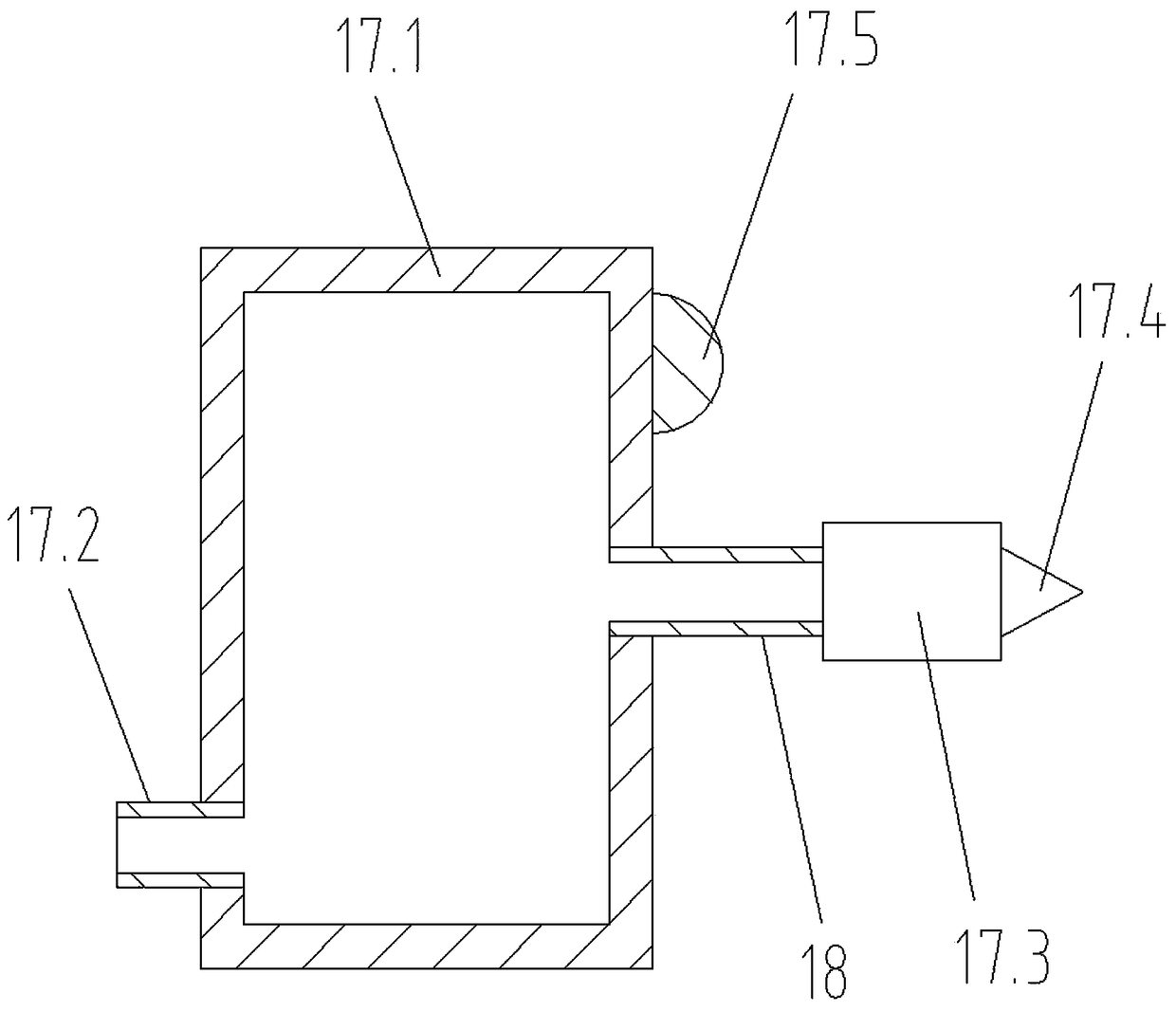

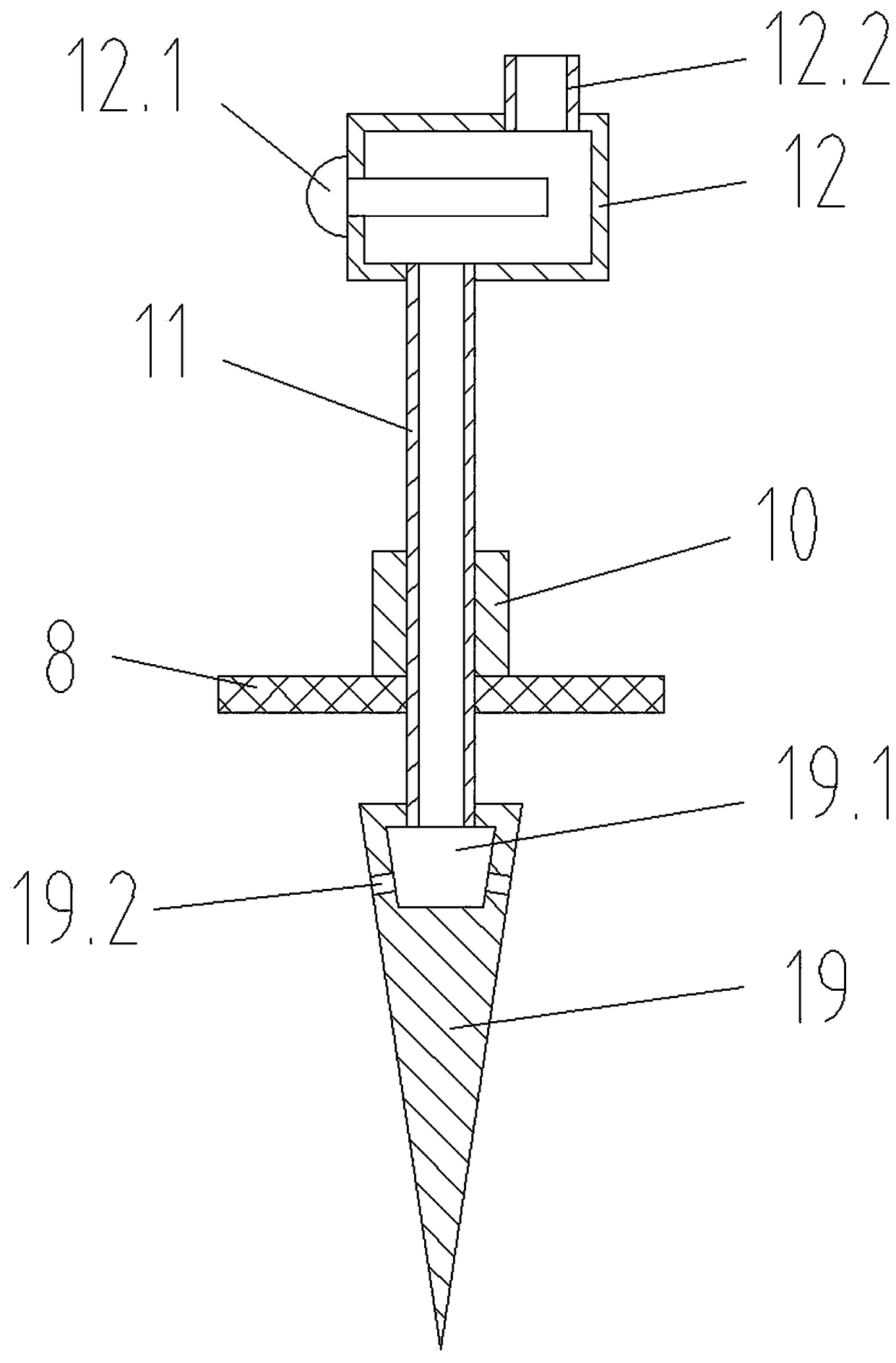

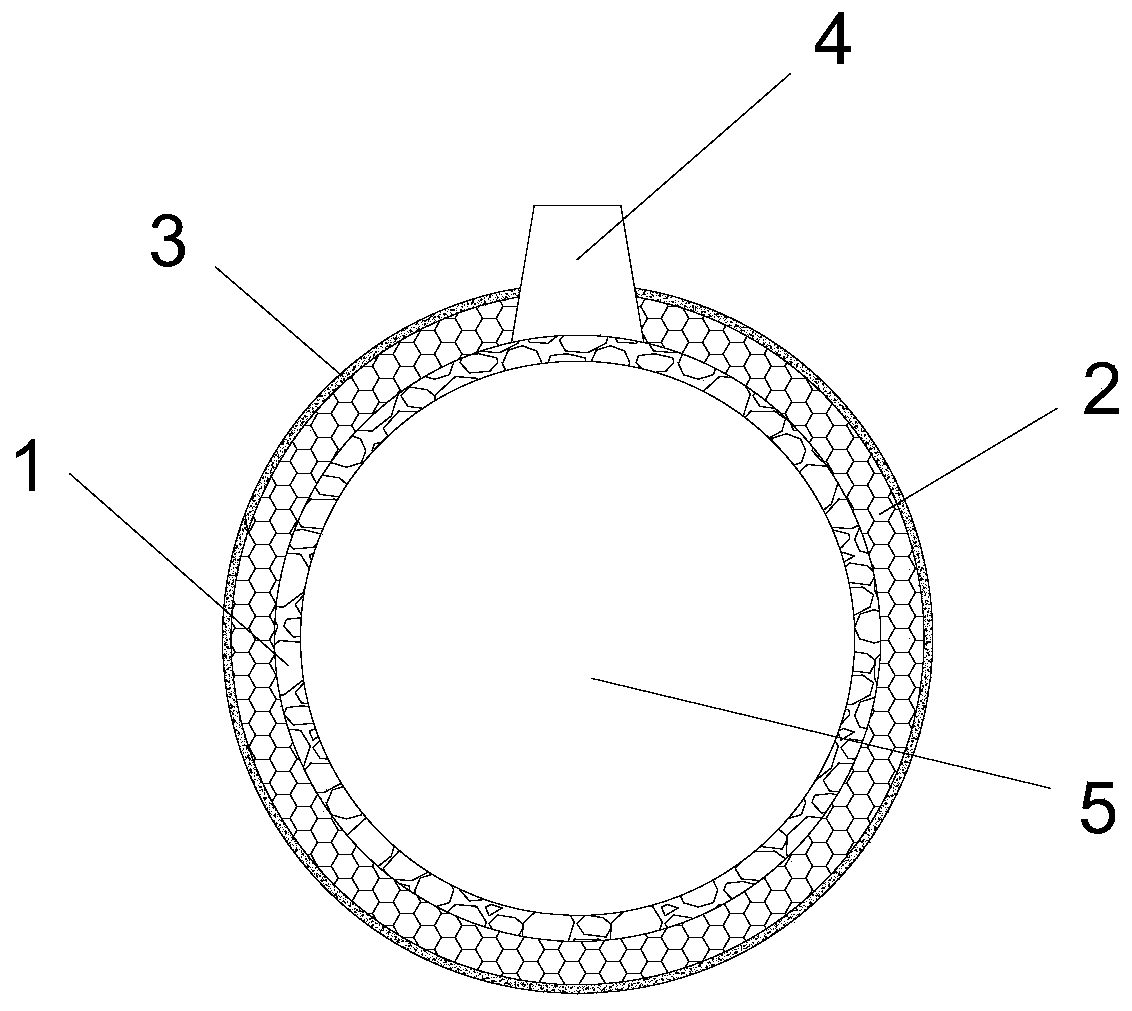

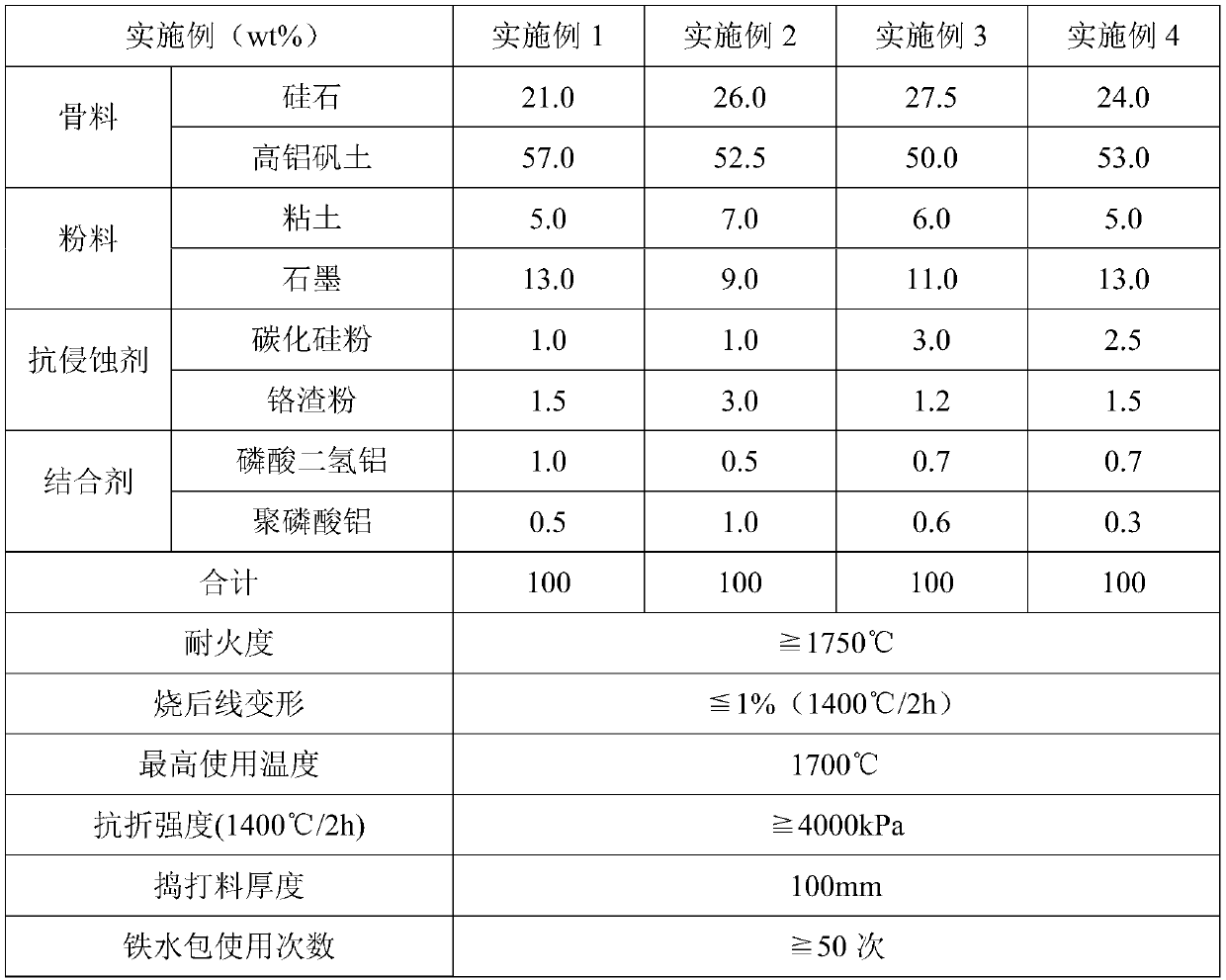

Refractory ramming mass for hot metal ladle of ferrosilicon electric furnace and preparation method for refractory ramming mass

The invention relates to refractory ramming mass for a hot metal ladle of a ferrosilicon electric furnace and a preparation method for the refractory ramming mass. The refractory ramming mass is prepared from the raw materials in percentage by mass: 71%-85.5% of aggregates, 14%-25% of powders, 0.2%-8% of anti-erosion agent and 0.6%-2% of binder. The aggregates comprise silica and high bauxite, thepowders comprise clay and graphite, the anti-erosion agent comprises silicon carbide powder and chromium slag powder, and the binder comprises aluminum dihydrogen phosphate and polyaluminum phosphate. The refractory ramming mass and the preparation method therefor have the advantages that during use, the structural strength is relatively high, a stopper ladle accident caused by damages such as loosening and spalling will not occur during use, and thus, the safety of peripheral persons and equipment during the hoisting of the hot metal ladle is guaranteed; and meanwhile, a phenomenon that hotmetal is stuck to the ladle will not occur, the condition that the hot metal is wrapped in slag is avoided, the recovery rate of the hot metal is increased, and thus, both safety and economical efficiency are greatly improved.

Owner:鄂尔多斯市瀚博科技有限公司

Anti-pot sticking sticky candy stirring device

InactiveCN105494832AGuaranteed tasteThere will be no sticking phenomenonConfectionerySweetmeatsAgricultural engineering

The invention relates to the processing field of sticky candy, in particular to an anti-pot sticking sticky candy stirring device, comprising a shell which is of a cylindrical structure; a sealing cover is arranged at the upper end of the shell and is provided with a charging port; a discharging port is formed in one side of the shell internally vertically provided with a rotary shaft; the rotary shaft penetrates through the bottom of the shell and is connected with a motor; a stirring blade is arranged in the middle of the rotary shaft and is provided with a heating layer. Due to the device, sticky candy liquid is not sticky to the stirring device, a burning phenomenon is avoided, and mouth feeling of the sticky candy is ensured.

Owner:CHONGQING LONGYUE FOOD

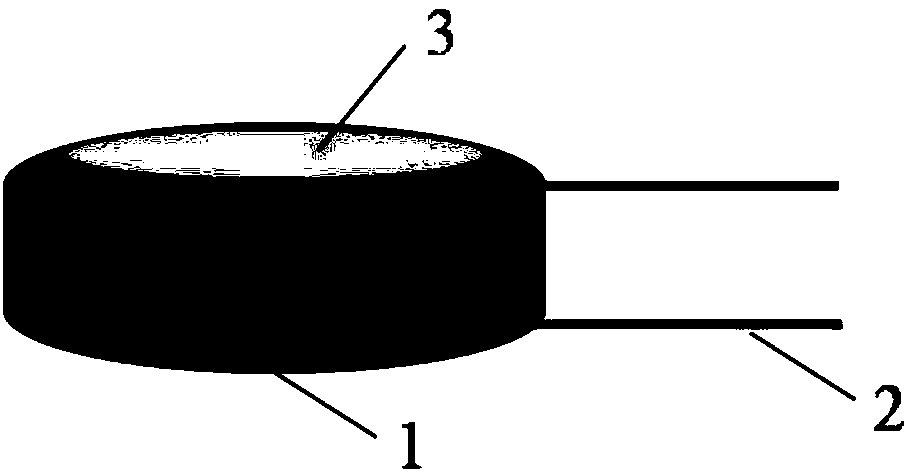

Method for preparing dense precursor ceramic temperature sensor

ActiveCN108344518AConductivity effectGood process repeatabilityThermometers using electric/magnetic elementsCeramic shaping apparatusOxidation resistantUltimate tensile strength

The invention relates to a method for preparing a dense precursor ceramic temperature sensor. The method comprises the steps of: placing a liquid ceramic precursor in a liquid forming mold and keepingthe iquid ceramic precursor at 150 to 200 degrees centigrade for 0.5 to 2h to obtain a formed precursor; keeping the formed precursor at 350 to 450 degrees centigrade for 3 to 6h to obtain a precursor block; pyrolyzing the precursor block at 1000 to 1450 degrees centigrade for 3 to 6h to obtain a precursor ceramic; connecting an electrode to the precursor ceramic to obtain a dense precursor ceramic temperature sensor. The invention uses a liquid forming method, and directly cures the liquid ceramic precursor at a high temperature without adding a curing agent, thereby obtaining a dense precursor ceramic temperature sensor suitable for an extreme environment. The temperature sensor has good oxidation resistance, high strength and accurate measurement results.

Owner:HARBIN INST OF TECH

Production technology of synthetic composite material

ActiveCN105289417AThere will be no sticking phenomenonReduce electricity lossUltra-high pressure processesElectricityMetallurgy

The invention relates to a production technology of a synthetic composite material. The material is placed in a roasting furnace to be roasted, after roasting, the roasted material is placed in a mould and placed on a 6-surface hinge press to be synthesized, the roasting temperature is 800-1400 DEG C, roasting is carried out under the inert atmosphere, and when the material is roasted in the roasting furnace, the material is placed in a C-N composite material, so that the material is isolated from the furnace wall of the roasting furnace. By means of the production technology, electricity used for production is saved over 50%, efficiency is improved by over 80%, the synthesis time of the press is short, and produced material is stable in quality.

Owner:湖南泰鼎新材料有限责任公司

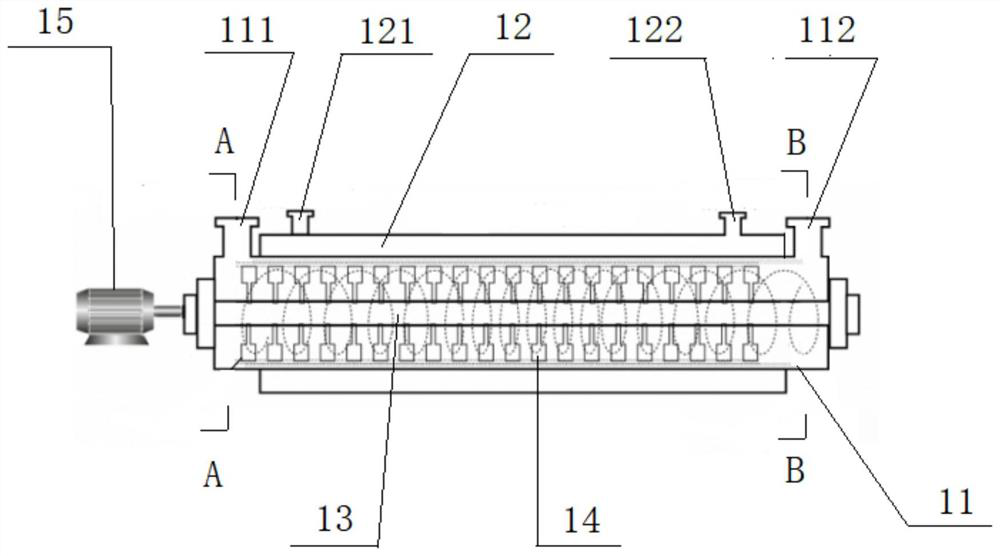

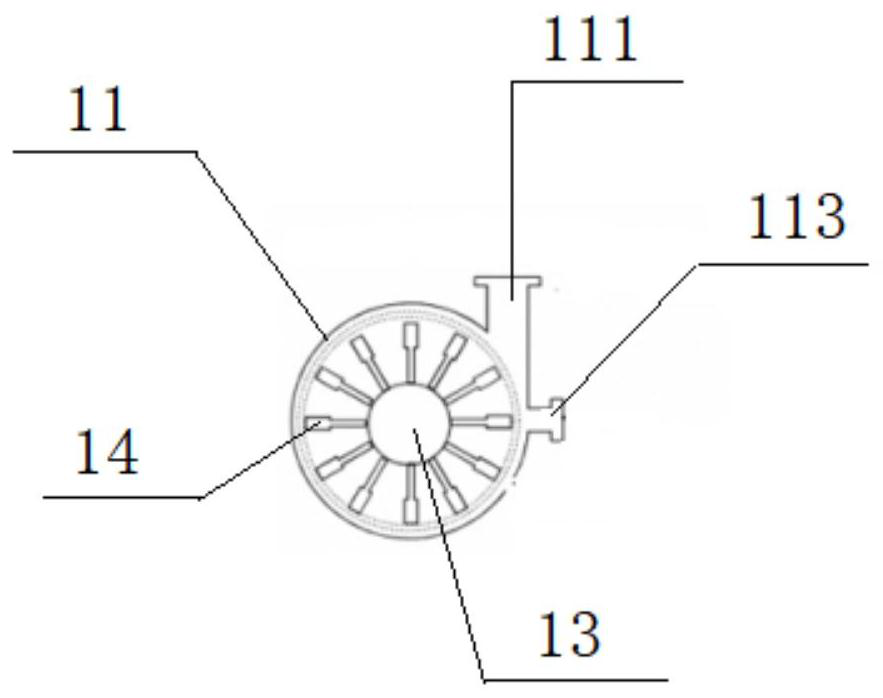

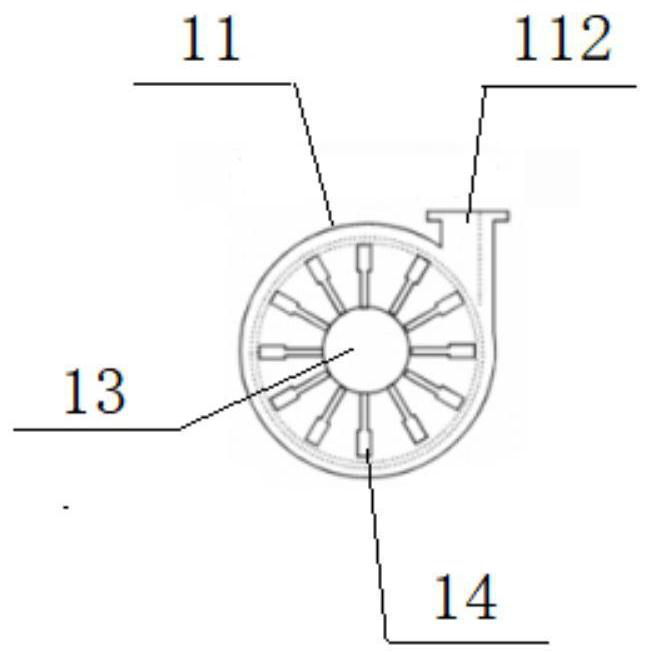

Rotational flow thermal vibration drying machine and rotational flow thermal vibration drying system

PendingCN113024056ARealize self-cleaningThere will be no sticking phenomenonCombination devicesSludge treatment by de-watering/drying/thickeningSludgeElectric machinery

The invention relates to the technical field of wet sludge drying, in particular to a rotational flow thermal vibration drying machine and a rotational flow thermal vibration drying system. The rotational flow thermal vibration drying machine comprises: a hollow drying chamber, wherein one end of the drying chamber is provided with a feeding port and an air inlet, and the other end of the drying chamber is provided with a discharging port; a heat source jacket which is arranged around the outer side of the drying chamber, wherein a medium serving as a heat source circulates in the heat source jacket, and a heat source outlet and at least one heat source inlet are formed in the heat source jacket; a rotating shaft which is arranged in the middle of the drying chamber and penetrates through the two ends of the drying chamber, wherein a driving motor used for driving the rotating shaft to rotate is arranged on the outer side of the drying chamber; and paddles which are mounted on the rotating shaft. The drying machine has a self-cleaning capability, so that the wall sticking phenomenon is avoided; The safe operation of the system is ensured by high-degree inerting circulation; and the drying machine is high in heat exchange efficiency, high in heat transfer speed and high in sludge drying speed. When the drying system is used, irritant gas cannot be discharged to the periphery, and secondary pollution to air is avoided.

Owner:山东驰盛新能源设备有限公司

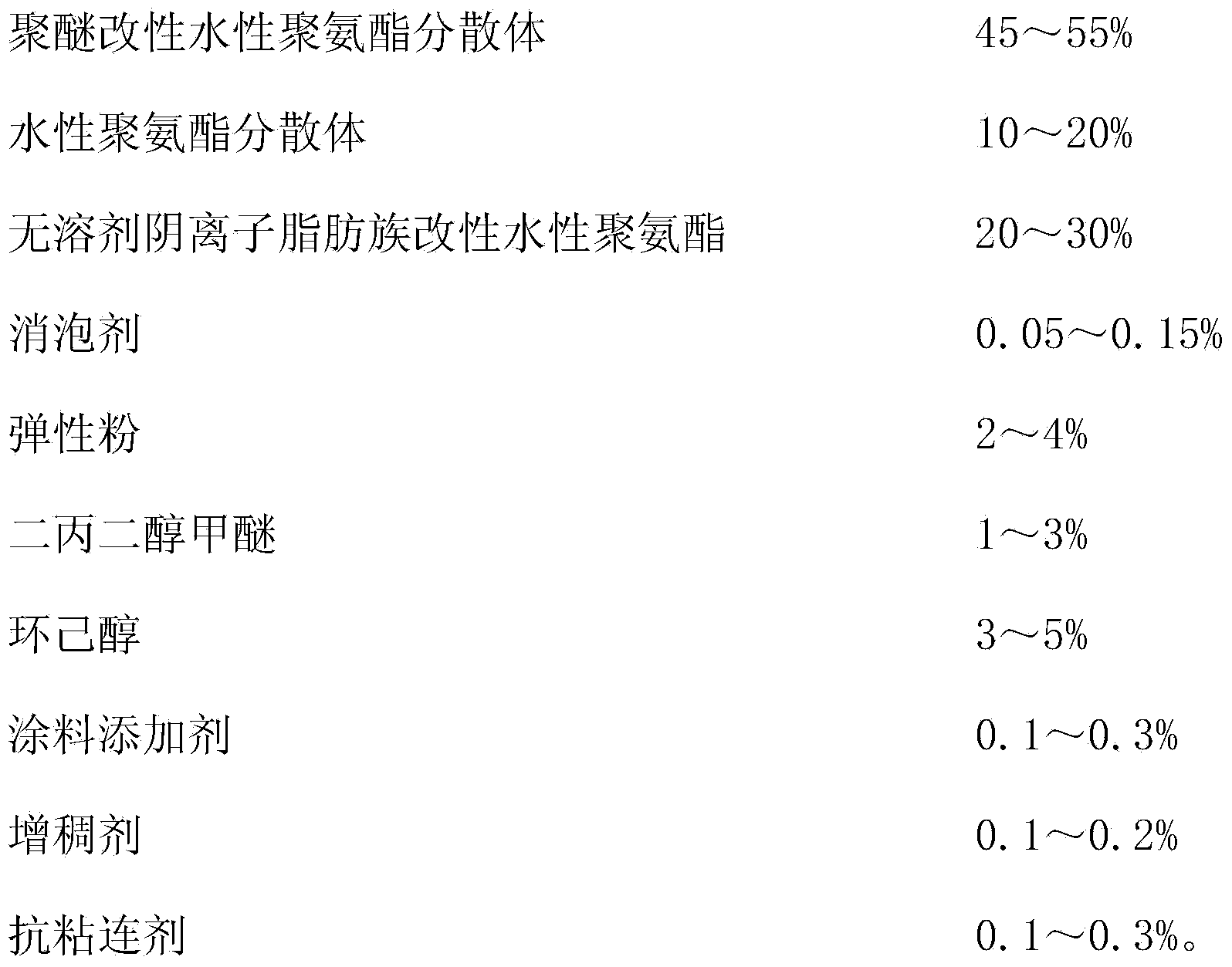

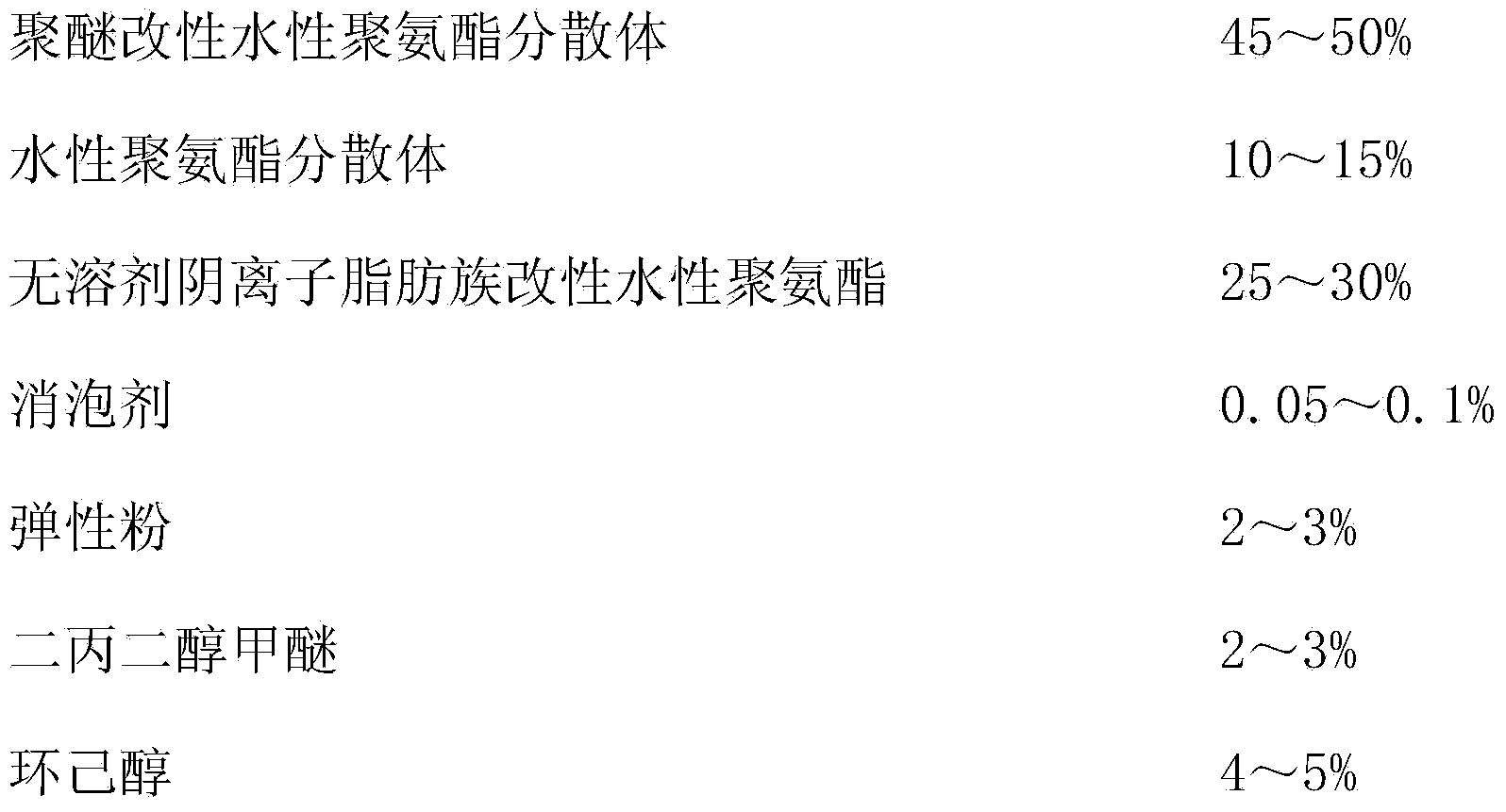

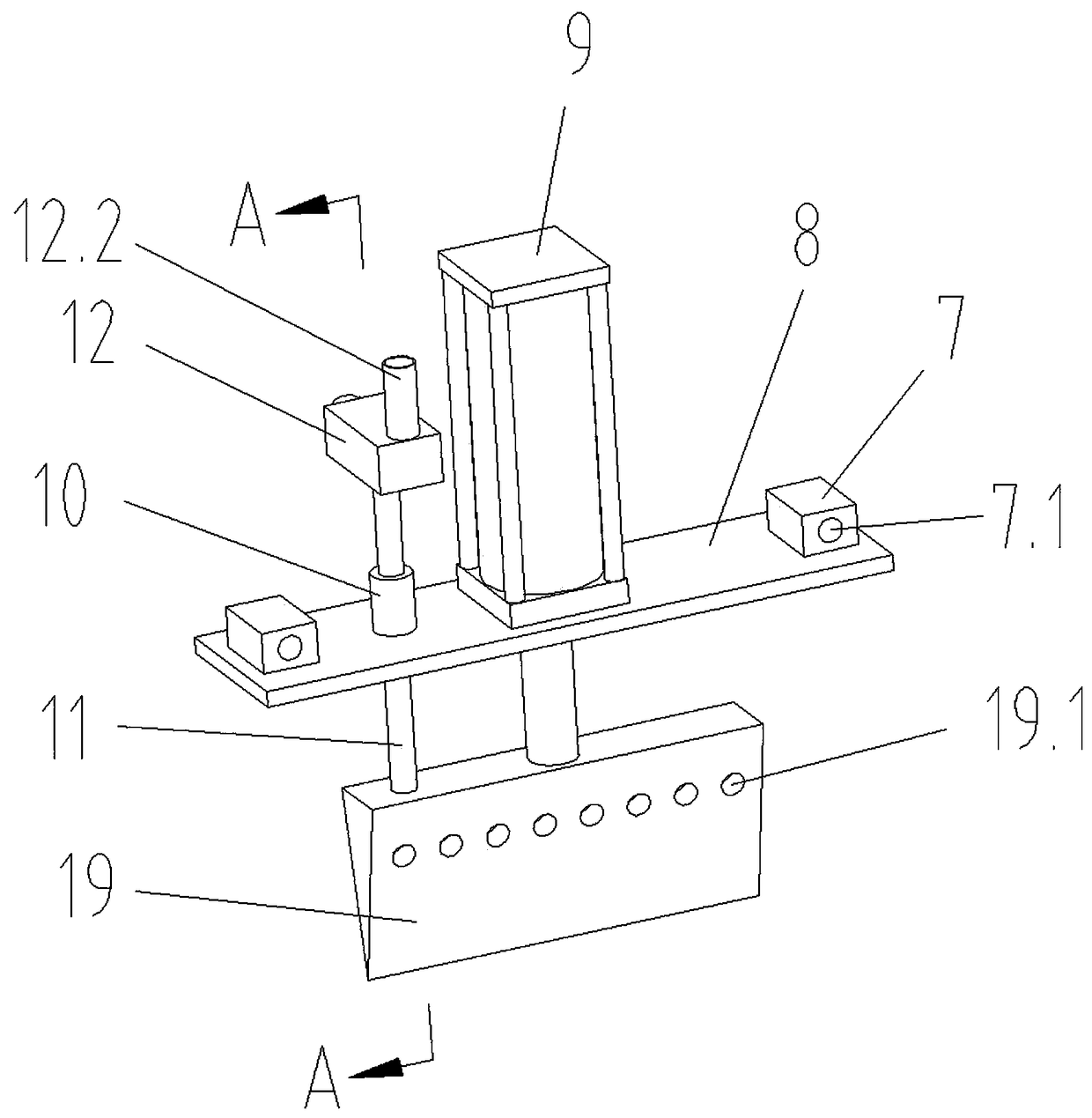

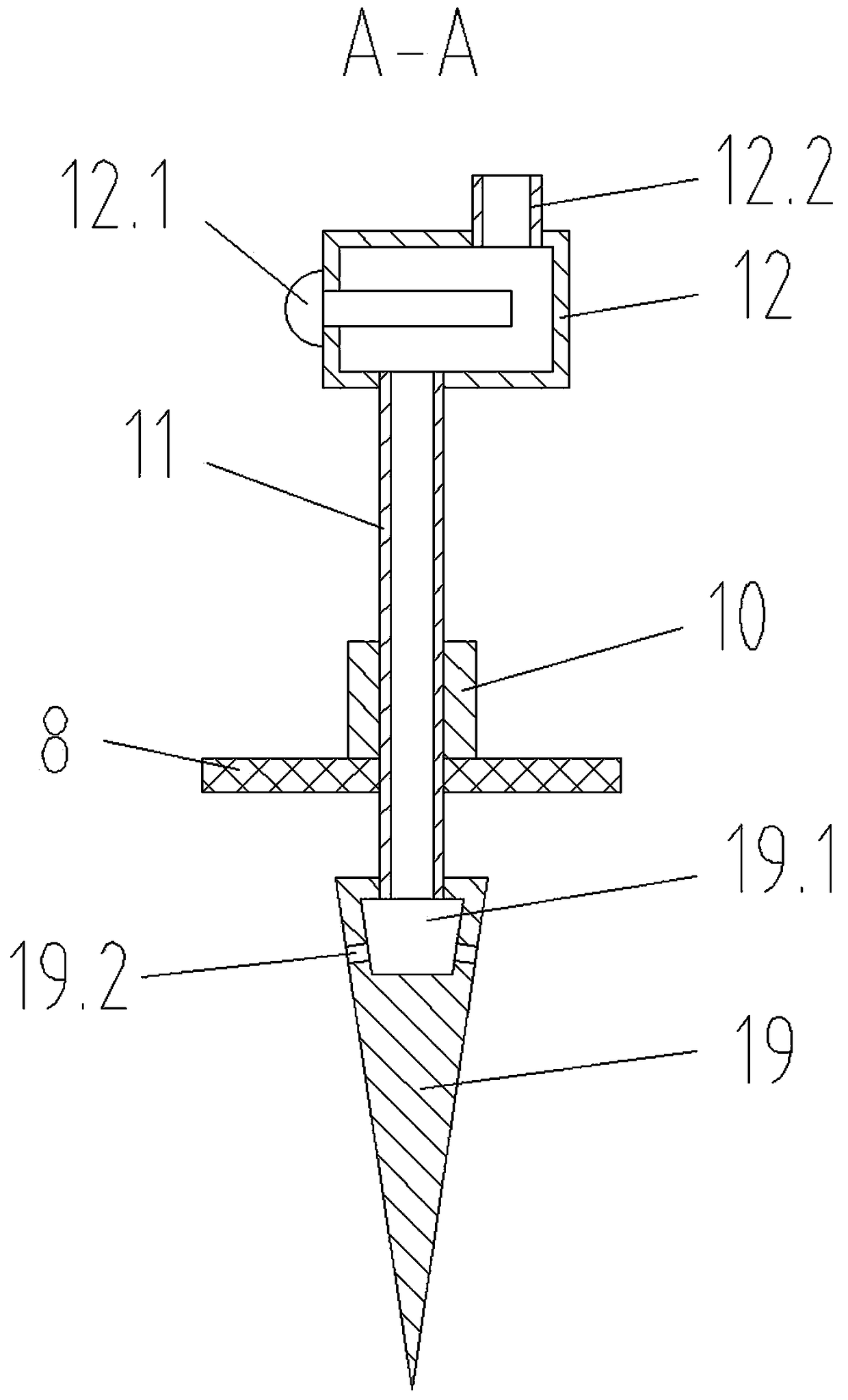

Water-borne touch oil and preparation method thereof

InactiveCN103965766AThere will be no whitening of the surfaceNo whiteningPolyurea/polyurethane coatingsPolyurethane dispersionSolvent free

The invention relates to the technical field of chemical products, in particular to water-borne touch oil and a preparation method thereof. The water-borne touch oil comprises raw materials in percentage by mass as follows: 45%-55% of polyether modified waterborne polyurethane dispersoid, 10%-20% of waterborne polyurethane dispersoid, 20%-30% of solvent-free anionic aliphatic modified waterborne polyurethane, 0.05%-0.15% of a defoaming agent, 2%-4% of elastic powder, 1%-3% of dipropylene glycol monomethyl ether, 3%-5% of cyclohexanol, 0.1%-0.3% of a coating additive, 0.1%-0.2% of a thickening agent and 0.1%-0.3% of an antiblocking agent. The phenomenon that the surface of a gift box or a printing carrier becomes white cannot be caused when the surface of the gift box or the printing carrier is coated with the water-borne touch oil and the gift box or the printing carrier is placed for a period of time, the product quality is good, and the economic benefit is good; when the gift box or the printing carrier coated with the water-borne touch oil is used for offset printing, the phenomenon of adhesion / smudging between printed matters cannot be caused, the defective percentage is low, and the production cost is reduced.

Owner:东莞市双虹实业有限公司

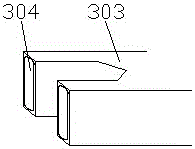

Cutter assembly used for rice strip cutting-off machine

InactiveCN108393945AImprove cutting effectThere will be no sticking phenomenonMetal working apparatusPulp and paper industryPiston rod

The invention discloses a cutter assembly used for a rice strip cutting-off machine. The cutter assembly comprises a mounting plate. A receding hole is formed in the center of the mounting plate, andthe upper portion of the receding hole is fixedly connected with a cutting-off air cylinder arranged in a vertically-downward mode; a piston rod of the cutting-off air cylinder penetrates through theinterior of the receding hole, and the tail end of the piston rod of the cutting-off air cylinder is further fixedly connected with a cutter; the cutter is arranged below the mounting plate, and a positioning hole is further formed in the mounting plate; a positioning sliding sleeve is further arranged on the upper portion of the positioning hole, and the interior of the positioning sliding sleeveis slidably connected with a positioning pipe; and the two ends of the positioning pipe both stretch out of the positioning sliding sleeve, and the lower end of the positioning pipe is fixedly connected with the cutter. The cutter assembly has the advantages that the cutter assembly used for the rice strip cutting-off machine is good in cutting-off effect, the cutting position of the cutter can be changed, and rice strips are quantitatively cut conveniently; and a cavity is formed inside the cutter and filled with a sponge, hot oil is absorbed by the sponge after entering the cavity and thenflows out slowly from oil drainage holes, and thus the cutter sticking phenomenon is avoided in the cut-away process.

Owner:蚌埠市优乃德自动化机械设备制造有限公司

Plastic film cutting making device

InactiveCN108673618AEasy to moveImprove stabilityBag making operationsPaper-makingEngineeringPlastic film

The invention discloses a plastic film cutting making device. The plastic film cutting making device comprises a feeding device, an edge sealing device, a feeding set and a cutting set. The edge sealing device comprises first side plates and a first base connecting and fixing the positions of the first side plates. The first base is provided with a first conveying belt. The first conveying belt isarranged on the upper end face of the first base. The first conveying belt moves in the front-back direction along the first base. The first side plates are hinged to the left side edge and the rightside edge of the first base. The rear side of the edge sealing device is connected with the feeding device. The cutting set is arranged on the front side of the edge sealing device. The feeding set is connected between the edge sealing device and the cutting set. The front side of the cutting set is connected with a material collecting box. The feeding device is provided with a supporting frame and raw material rollers. The supporting frame is supported and fixed to the raw material rollers. According to the plastic film cutting making device, product specification uniformity is guaranteed, automatic feeding is conducted, the economic cost is reduced, and the production efficiency is improved.

Owner:刘林平

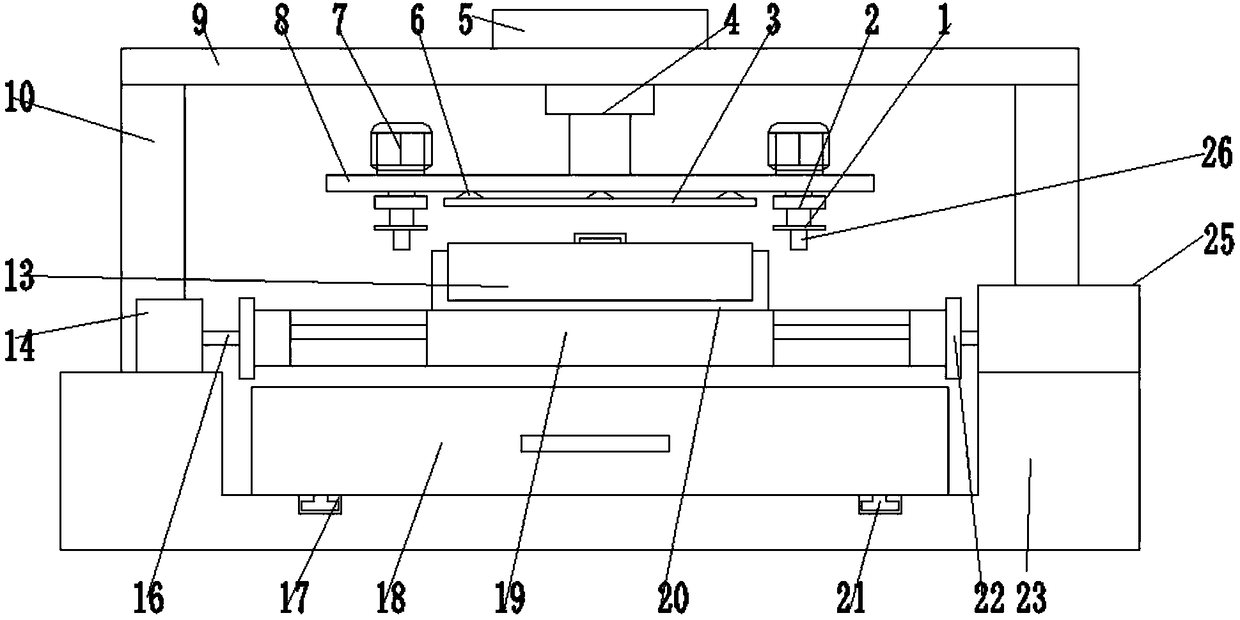

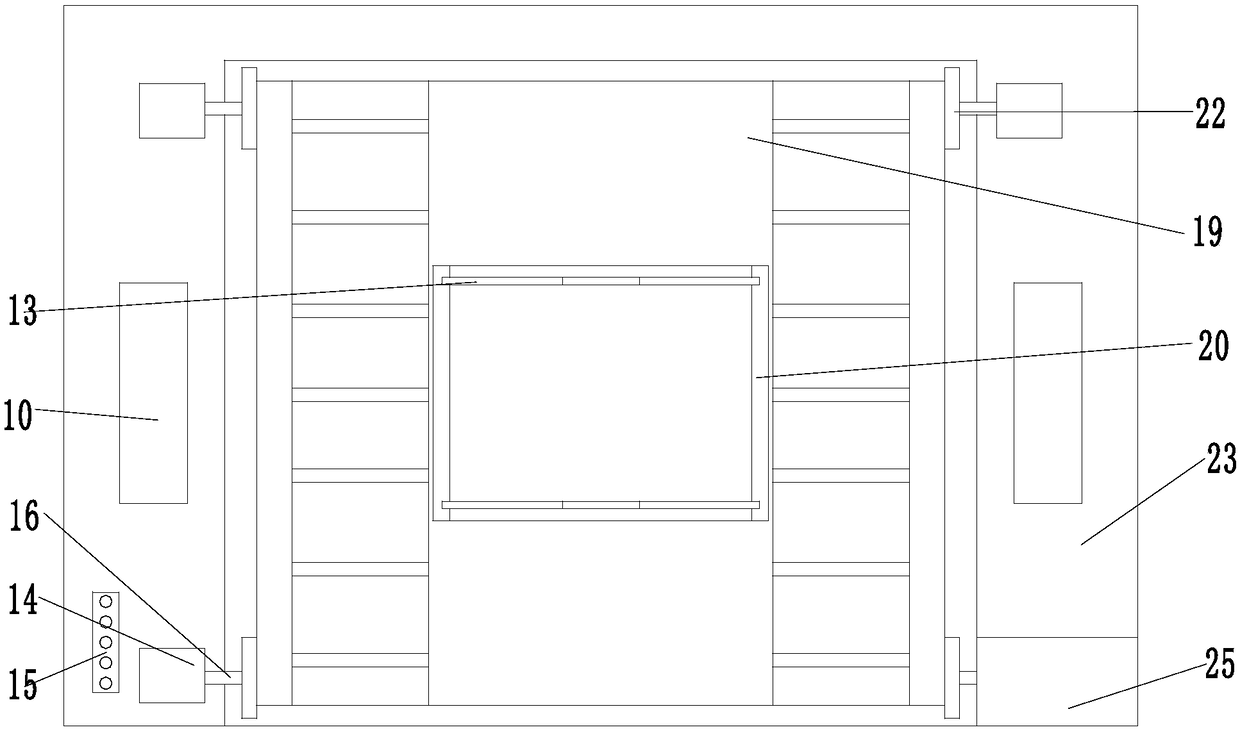

Building decorative material machining device capable of pressing and cutting polished tile

The invention discloses a building decorative material machining device capable of pressing and cutting a polished tile. The building decorative material machining device comprises a transverse plate,a conveying belt and a base; a hydraulic cylinder is fixed to the middle of the upper surface of the transverse plate through bolts; a hydraulic rod is installed in the hydraulic cylinder; the two sides of the hydraulic rod are provided with stepping motors; electric telescopic rods are installed at the lower ends of stepping motor output shafts; cutter fixing plates are fixed to the movably endsof the electric telescopic rods through bolts; cutters are fixed to the lower ends of the cutter fixing plates through bolts, and the inner sides of the cutter fixing plates are provided with an upper die seat; the upper die seat is made of high-density polyethylene and fixed to the bottom of a connection plate through suction cups; a lower die seat is arranged below the suction cups; the two ends of the conveying belt are installed on conveying belt pulleys which are installed on a rotary shaft; and the rotary shaft is connected with a motor through a coupler. According to the building decorative material machining device, the lower die seat, the upper die seat and a baffle are all made of the high-density polyethylene and have lubricity, and the adhering phenomenon is avoided during demolding.

Owner:浙江企聘通网络技术有限公司

Pumping type automatic gluing apparatus

ActiveCN106040521AReasonable structureEasy to controlLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention relates to a pumping type automatic gluing apparatus, comprising a conveyer belt, a power mechanism, a feeding mechanism, a gluing mechanism and a workbench, wherein the feeding mechanism utilizes power provided by the power mechanism to convey glue to the gluing mechanism via a conduit for gluing, the power mechanism comprises an electric pump and a control panel controlling working of the electric pump, the gluing mechanism comprises one gluing motor and two gluing platforms, the centers of the two gluing platforms are respectively provided with gluing rollers horizontally rotating around the center shaft under the driving of the gluing motor, and the gluing rollers are respectively located at two sides of the conveyer belt. The pumping type automatic gluing apparatus is reasonable in structure, uniform in gluing and free of glue waste in usage, adjusts glue feeding amount according to product needs, and overcomes the technical problems that conventional gluing machines are unreasonable in structure and nonuniform in gluing, greatly waste glue in usage, cannot adjust glue feeding amounts according to product needs, etc.; compared with the prior art, the pumping type automatic gluing apparatus is a great technological innovation and has good market prospect and development space.

Owner:PINGDINGSHAN ANTAIHUA MINING SAFETY EQUIP MFG

Automatic cooker without manual stir-frying

ActiveCN108634766AEasy to clamp and fixEasy to take outCooking vessel constructionsHeat transmissionEngineering

The invention discloses an automatic cooker without manual stir-frying. The automatic cooker comprises a box; a cavity is formed in the box; a circular blind hole is formed in the upper surface of thebox, and the circular blind hole and the cavity mutually communicate; a plurality of supporting columns are symmetrically and fixedly connected to the inner wall of the cavity, and a rotating plate is arranged on the upper surfaces of the supporting columns jointly; a mounting seat is fixedly connected to the upper surface of the rotating plate; a circular placement groove is formed in the mounting seat, and a cylindrical frying pan is placed in the circular placement groove; a mounting cavity is further formed in the mounting seat, and the mounting cavity and the circular placement groove mutually communicate; and an electromagnetic heater is mounted on the mounting cavity. The automatic cooker has the advantages that operation is easy, using is convenient and quick, food materials makecontact more frequently, heat transmission between the food materials is more even, and the food materials do not adhere to the inner wall of the cylindrical frying pan through rotation, so that the pot sticking phenomenon is avoided.

Owner:山东大树欧亚天然调味品有限公司

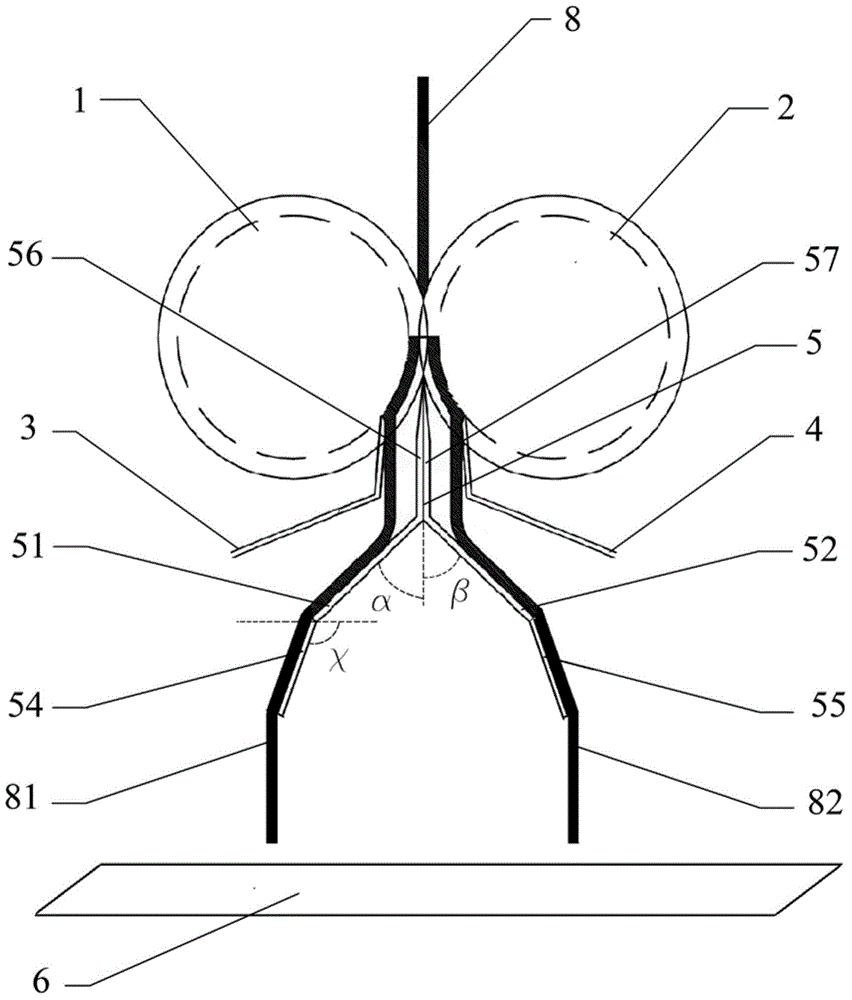

Layered noodle cutting device

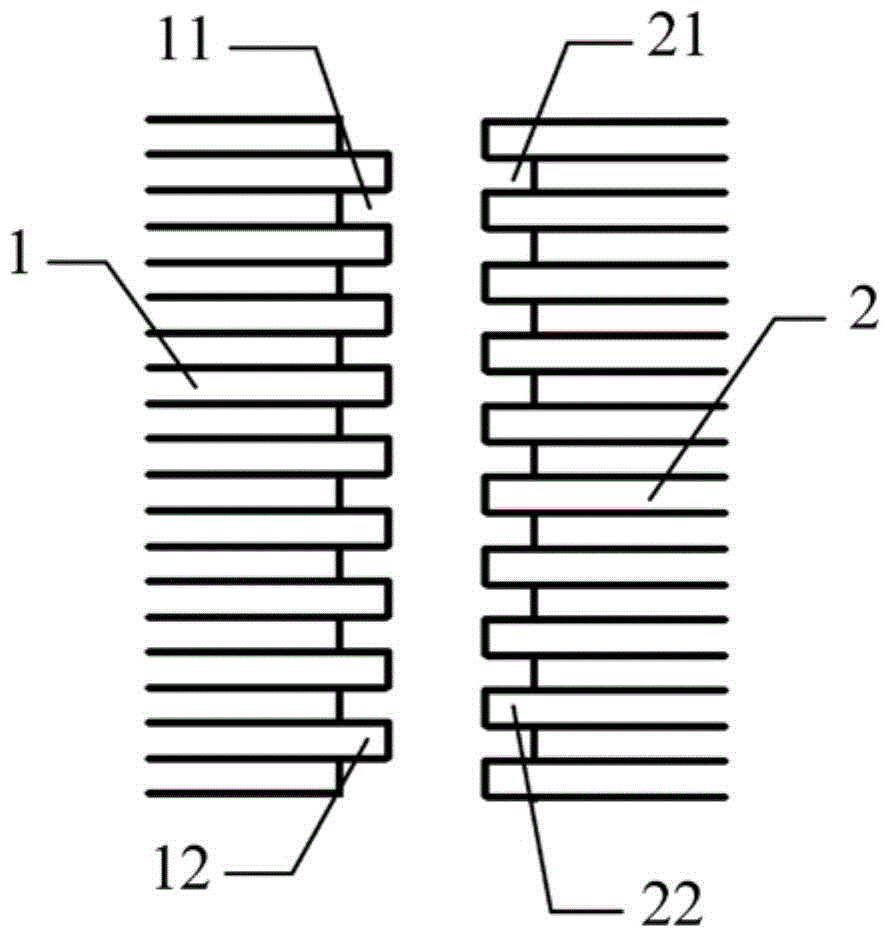

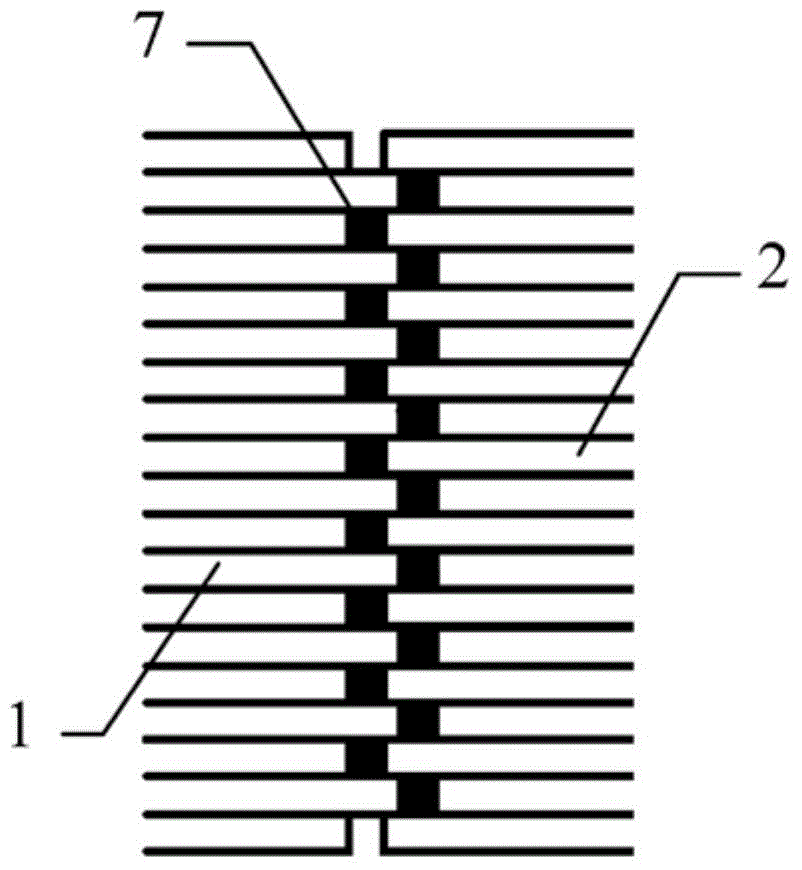

ActiveCN105010454AReduce the possibility of drawingThere will be no sticking phenomenonNoodles cutting outContinuous/uninterruptedTooth part

The invention provides a layered noodle cutting device which comprises a first noodle cutting knife roll, a second noodle cutting knife roll, a first noodle comb, a second noodle comb, a noodle divider and a conveying net belt, wherein the first noodle cutting knife roll and the second noodle cutting knife roll are mutually meshed; the first noodle comb and the second noodle comb are correspondingly arranged below the first noodle cutting knife roll and the second noodle cutting knife roll; the noodle divider is arranged between the first noodle comb and the second noodle comb; the conveying net belt is arranged below the noodle divider; the first noodle comb and the second noodle comb are both provided with tooth parts which are correspondingly embedded into a cutter groove of the first noodle cutting knife roll and a cutter groove of the second noodle cutting knife roll; the noodle divider comprises a first noodle dividing panel and a second noodle dividing panel which both form included angles with a plumb line. According to the layered noodle cutting device provided by the invention, cut-off noodles are divided into two groups, so that the noodles can fall to different positions of the conveying net belt, and are continuously conveyed along with the conveying net belt; the two groups of noodles are stacked together in a layered manner, so that the possibility that produced noodles are stuck is effectively reduced; in addition, as the space between every two adjacent noodles is greater, the phenomenon that the end parts of the cut-off noodles are adhered is avoided.

Owner:TINGYI (CAYMAN ISLANDS) HOLDING CORPORATION

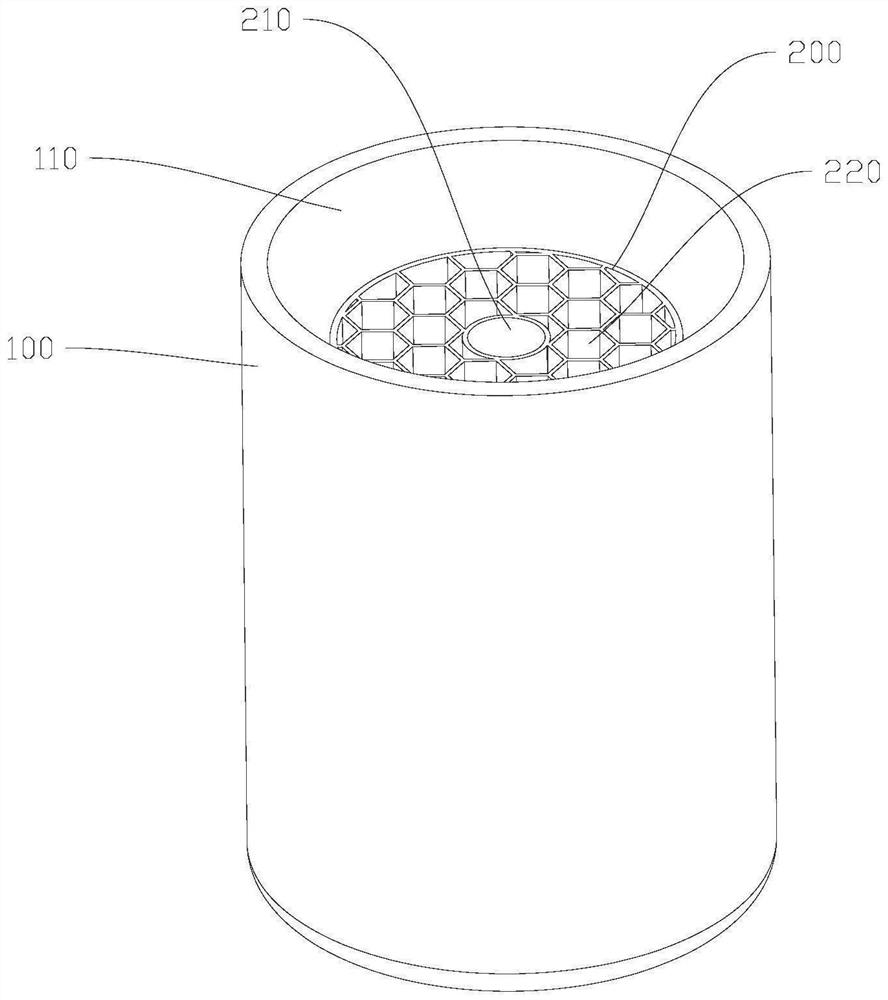

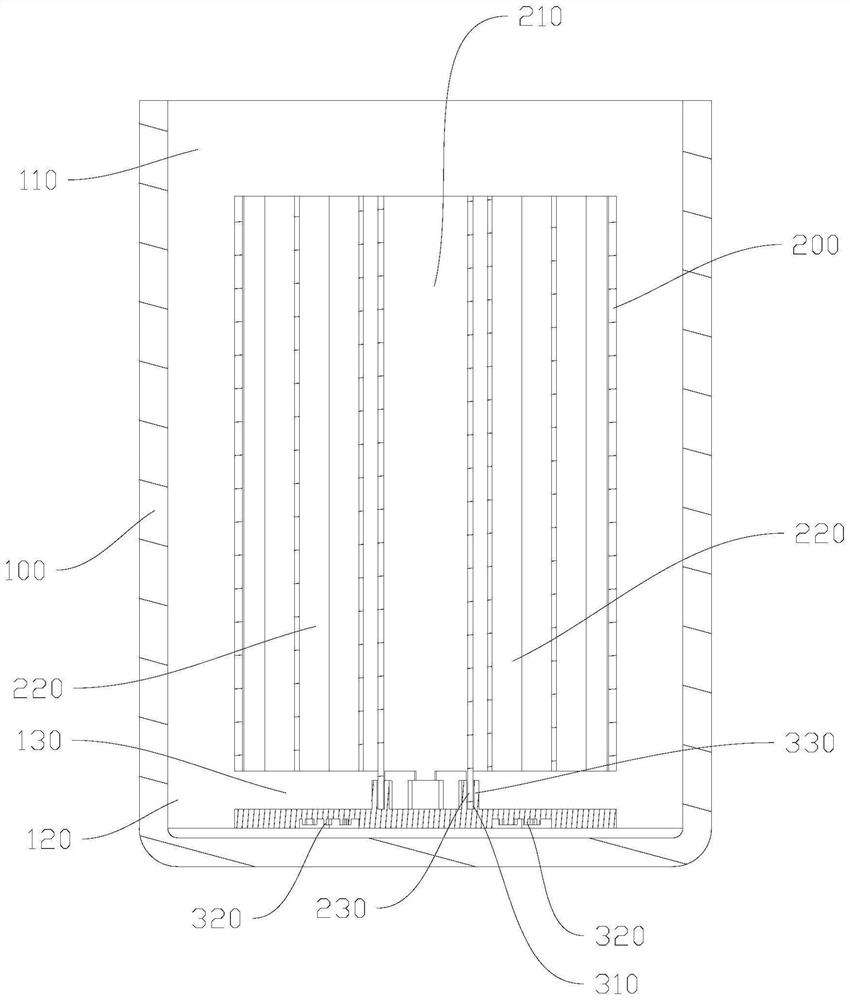

Organoid culture device and organoid culture method

PendingCN113755328AGrowth ruleAvoid necrosisBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyEngineering

The invention belongs to the technical field of cell culture, and particularly discloses an organoid culture device and an organoid culture method. The organoid culture device comprises a supporting piece and a separating piece, wherein the supporting piece is provided with a culture tank; the separating piece is positioned in the culture tank; a liquid flowing gap is formed between the lower surface of the separating piece and the tank bottom of the culture tank; and the separating piece is provided with liquid changing through holes and a plurality of culture through holes which respectively communicate with the liquid flowing gap. The culture through holes separate a plurality of organoid cell balls, so that the phenomenon that two or more organoid cell balls adhere to each other is avoided, contact exchange between nutrient substances and oxygen and the center part of the organoid is facilitated, and the culture effect of the organoid cell balls is ensured; and moreover, no organoid cell ball is arranged in the liquid changing through holes, so that when cell liquid changing treatment is performed, the organoid cell balls with smaller volume can be prevented from being sucked away, the organoid cell balls with larger volume can be prevented from being damaged, and the normal growth of the organoid cell balls is ensured.

Owner:SUN YAT SEN UNIV +1

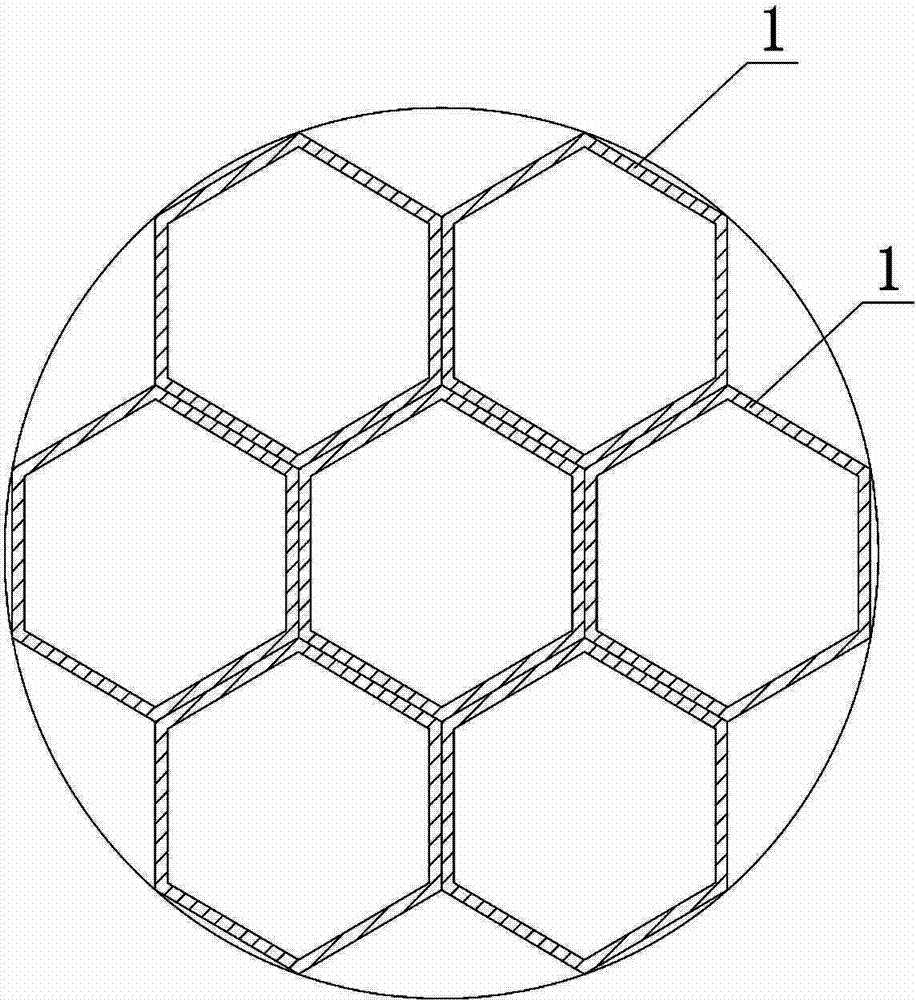

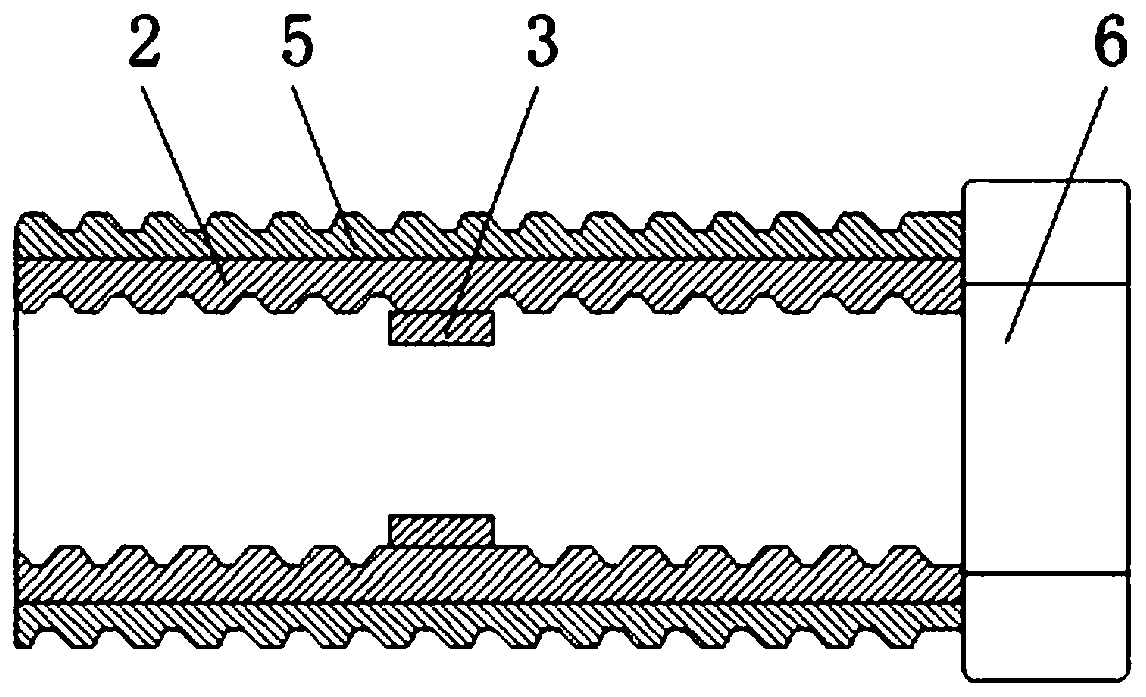

Petroleum pipeline

InactiveCN104279377AEasy to transportThere will be no sticking phenomenonRigid pipesDiagonalPetroleum

The invention discloses a petroleum pipeline. The cross section of the petroleum pipeline is a square, and a spiral is arranged along the axis of the petroleum pipeline. Pitch of the spiral is twice a diagonal of the square. The petroleum pipeline is in the spiral structure which is simple and capable of guiding petroleum in delivery; the spiral enables the flowing petroleum to flow without retention or adhesion, and petroleum delivery is facilitated and effective.

Owner:WUXI JINDING OIL PIPE FITTINGS

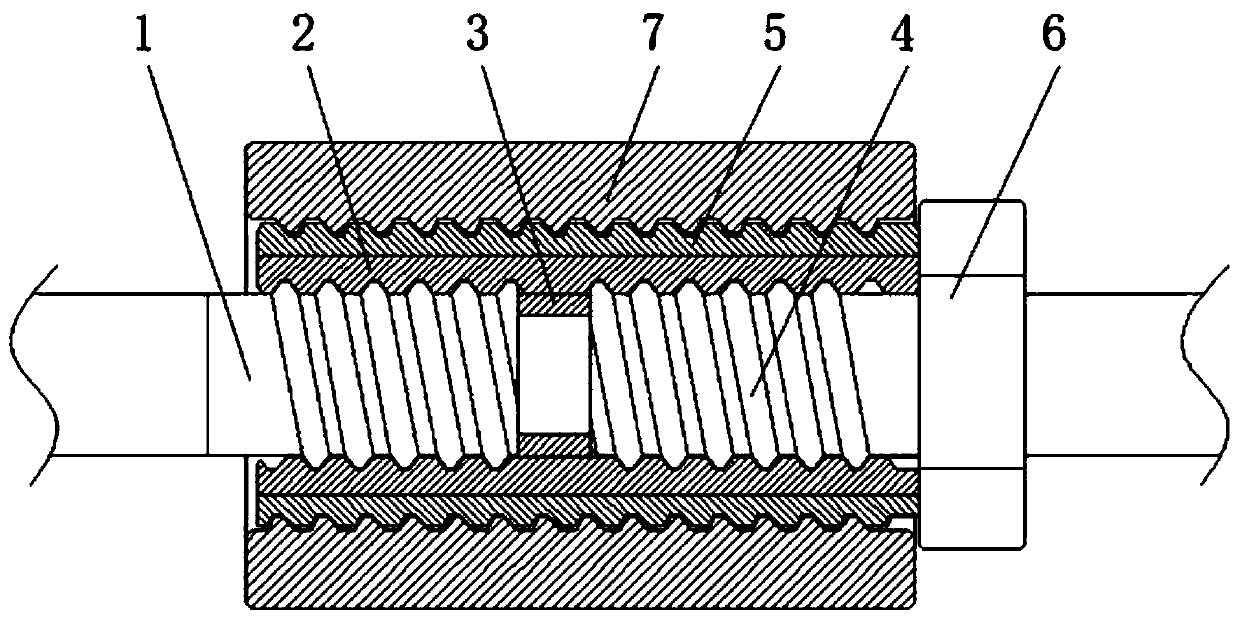

Tight coupling oil pipe for packer

The invention relates to the technical field of oil exploitation equipment and discloses a tight coupling oil pipe for a packer. The tight coupling oil pipe for the packer comprises a coupling oil pipe I, wherein a threaded cutting sleeve is arranged on one side of the outer surface of the coupling oil pipe I; one side of the inner wall of the threaded cutting sleeve is in threaded connection withthe outer surface of the coupling oil pipe I; an annular cutting sleeve is fixedly arranged in the middle of the inner wall of the threaded cutting sleeve; one side of the annular cutting sleeve is contacted with one end of the coupling oil pipe I; the other side of the inner wall of the threaded cutting sleeve is in threaded connection with a coupling oil pipe II. Compared with the existing oilpipe connection technology, the tight coupling oil pipe for the packer has the advantages that the firmness and sealing property of the coupling oil pipe I and the coupling oil pipe II during connection are effectively increased, and leakage does not occur in the oil and gas transportation process. Meanwhile, since the threaded cutting sleeve and threads on the coupling oil pipe I and the couplingoil pipe II are always tightly meshed together, a phenomenon that the oil pipes are released is avoided, and the stability and reliability of the coupling oil pipe are effectively improved.

Owner:DAQING CITY HUAYU PETROLEUM MASCH MFG CO LTD

Punching device

InactiveCN108406938AGuaranteed separation effectThere will be no sticking phenomenonMetal working apparatusPunchingEngineering

The invention provides a punching device. The punching device comprises a machine frame, a punching portion and a conveying portion, wherein the punching portion is arranged on the machine frame, a first cutter bit and a second cutter bit are arranged on the punching portion in a spaced mode, the first cutter bit is used for punching a material into a first preset shape, the second cutter bit is used for punching the material into a second preset shape, and the second preset shape is arranged on the outer side of the first preset shape in a surrounding mode; and the conveying portion is arranged on the machine frame and enables the materials to pass through the first cutter bit and the second cutter bit in sequence. According to the technical scheme, the problem that in the prior art, aluminum foil is prone to having burrs after being punched and consequently the subsequent automatic electric core welding process is affected is solved through the punching device.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com