Patents

Literature

35 results about "Bicone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A bicone or dicone (bi- comes from Latin, di- from Greek) is the three-dimensional surface of revolution of a rhombus around one of its axes of symmetry. Equivalently, a bicone is the surface created by joining two congruent right circular cones base-to-base.

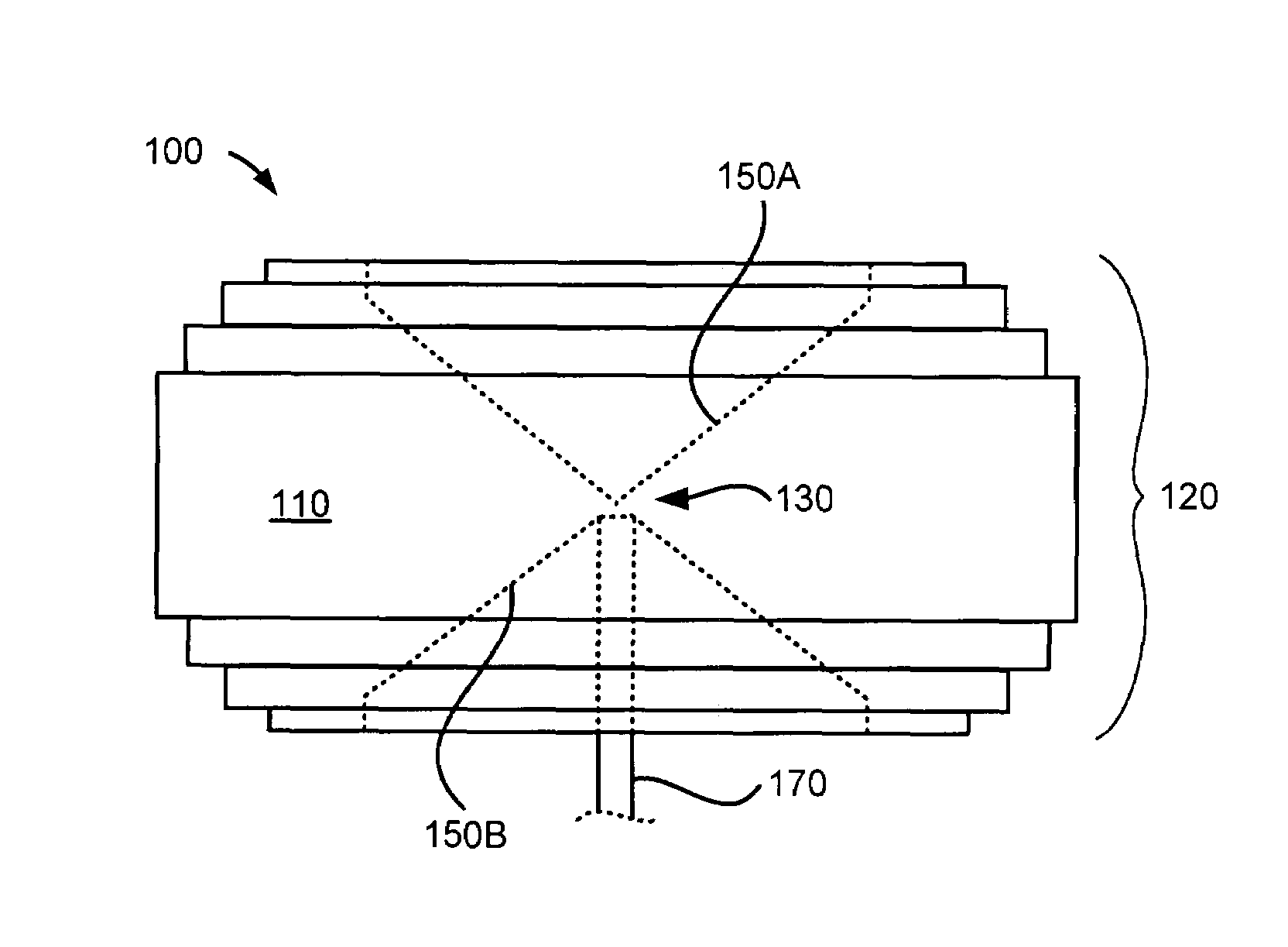

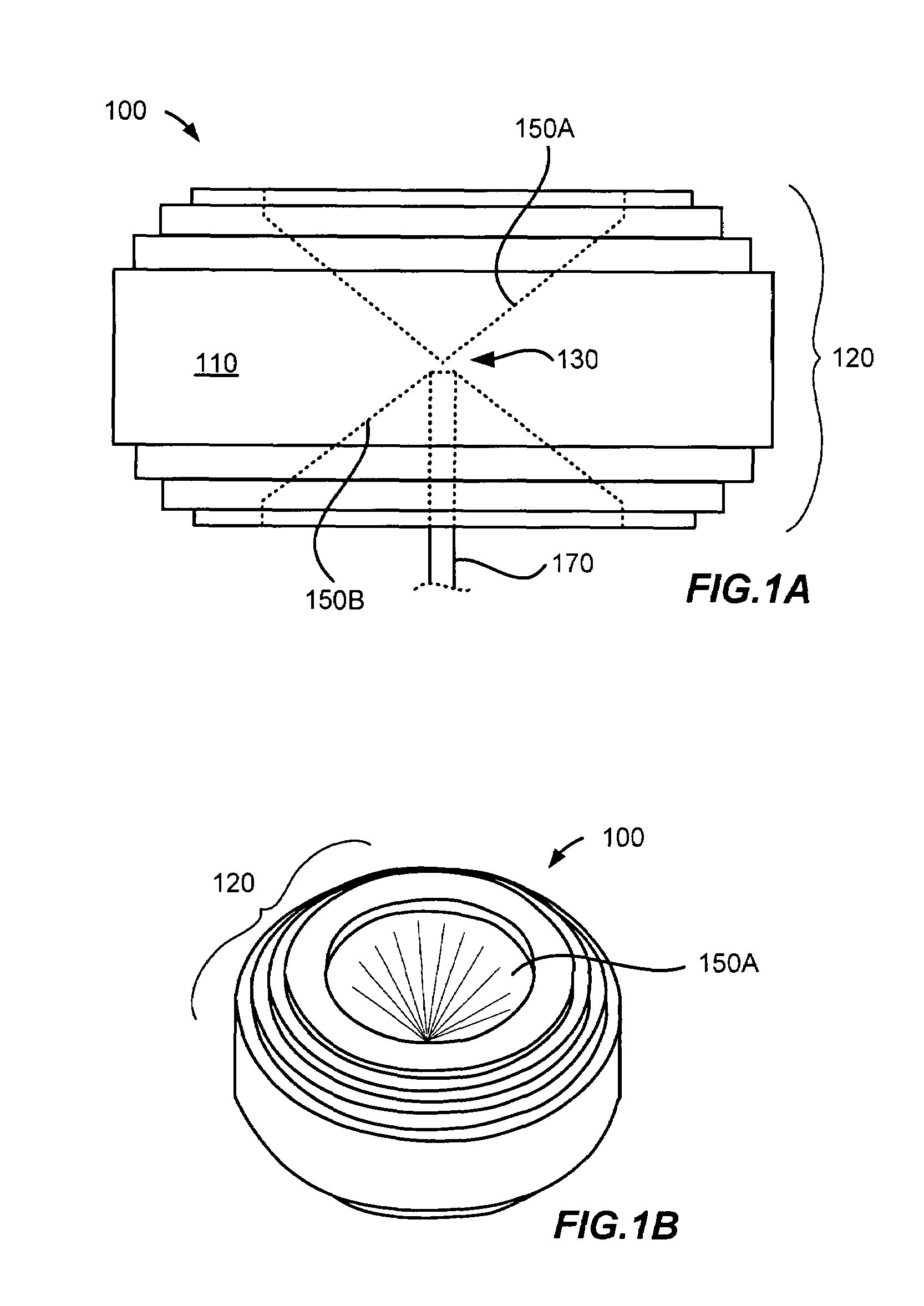

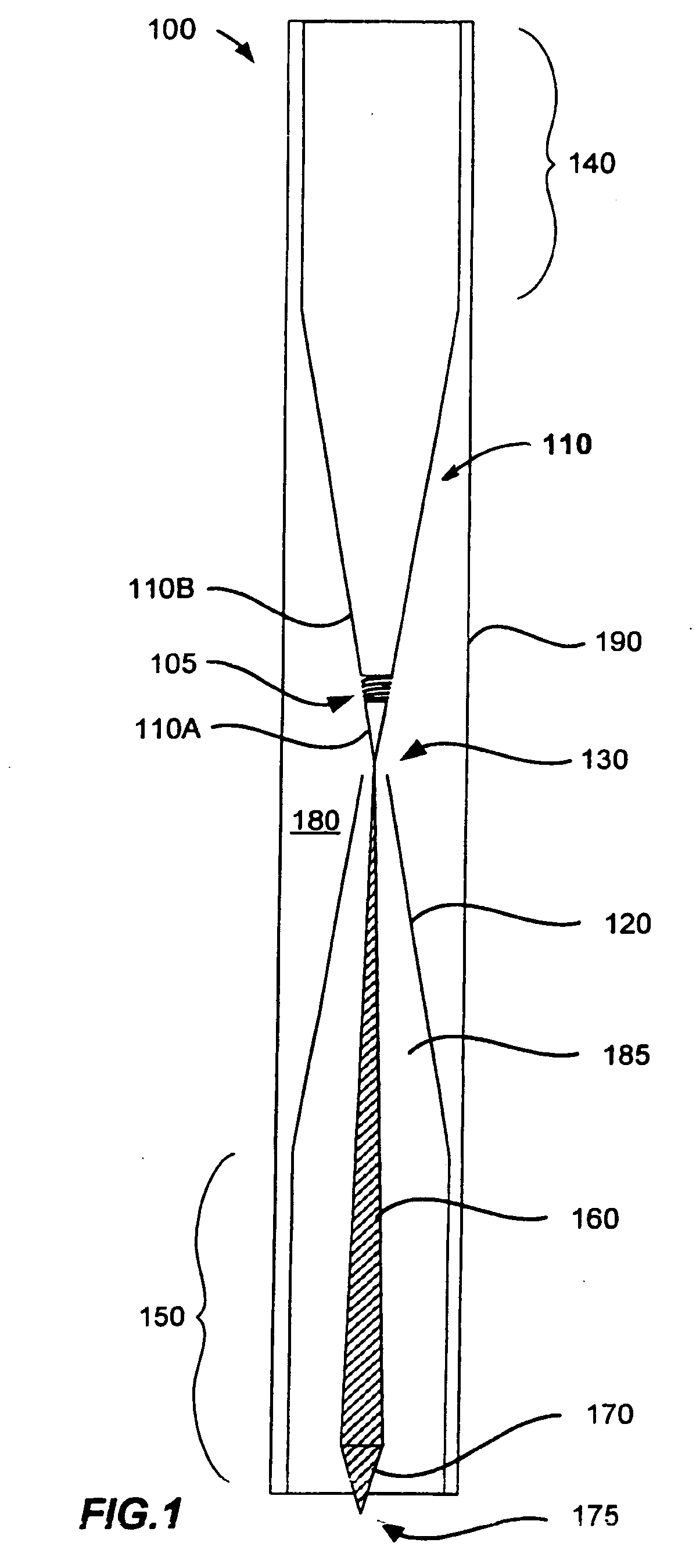

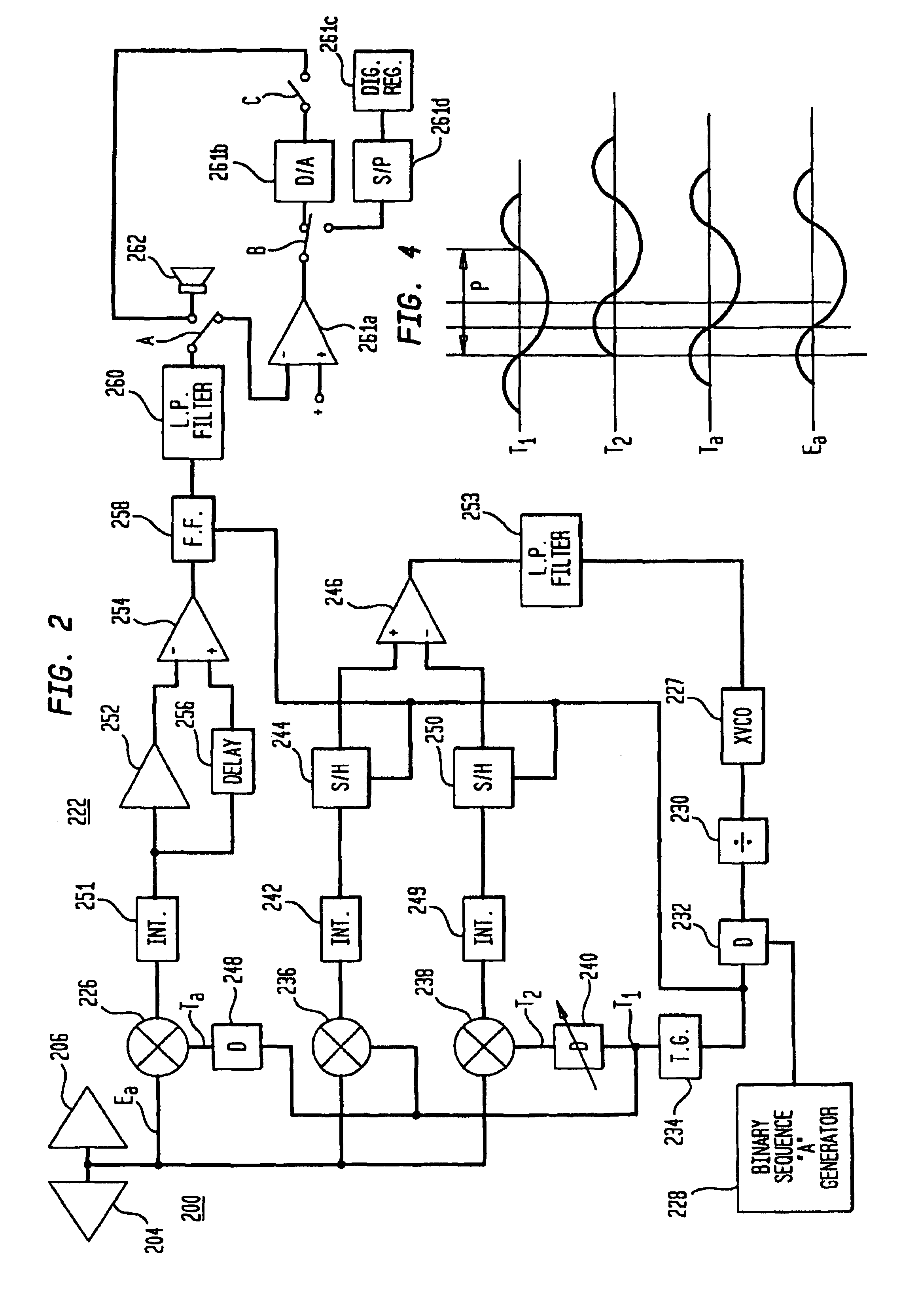

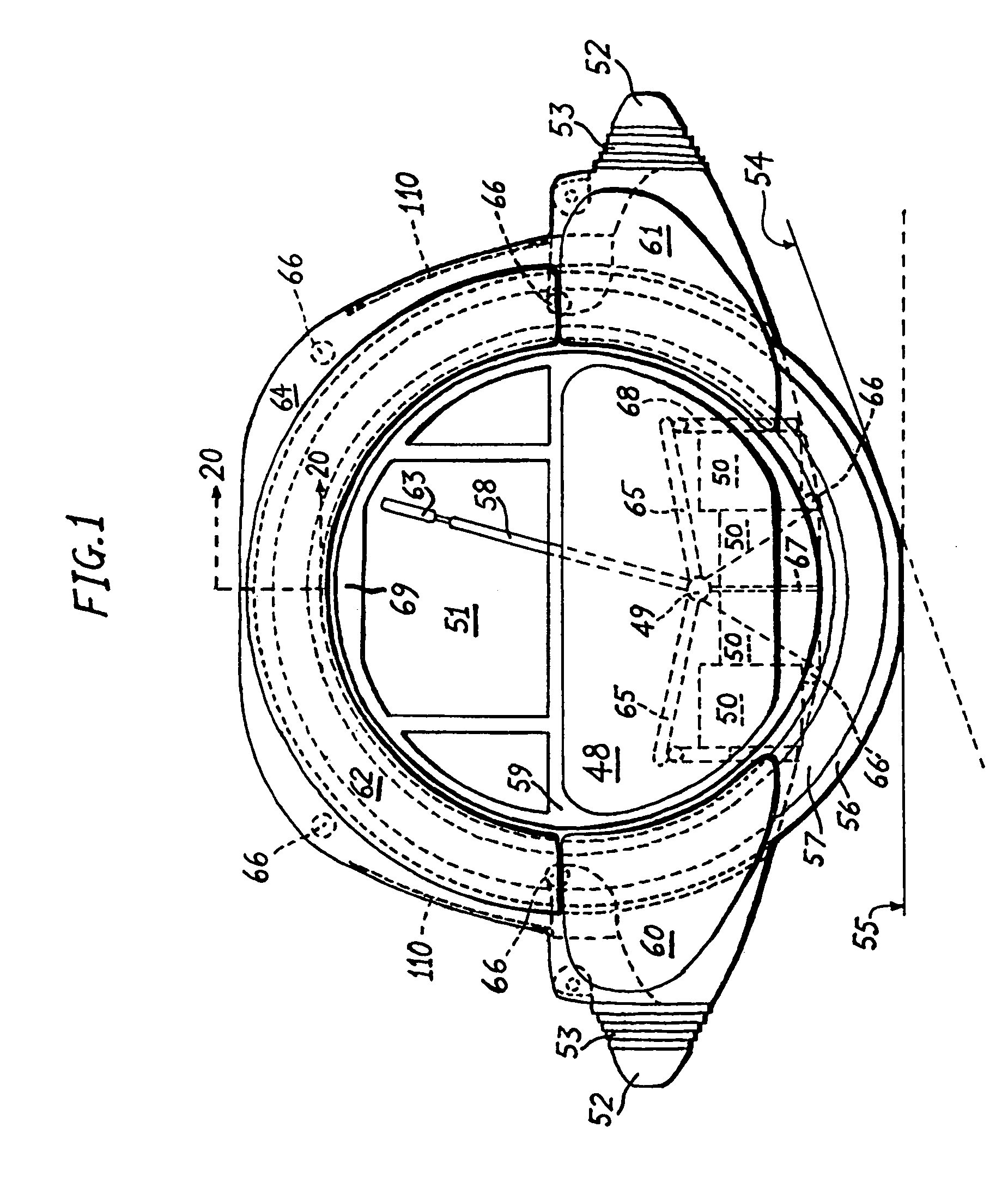

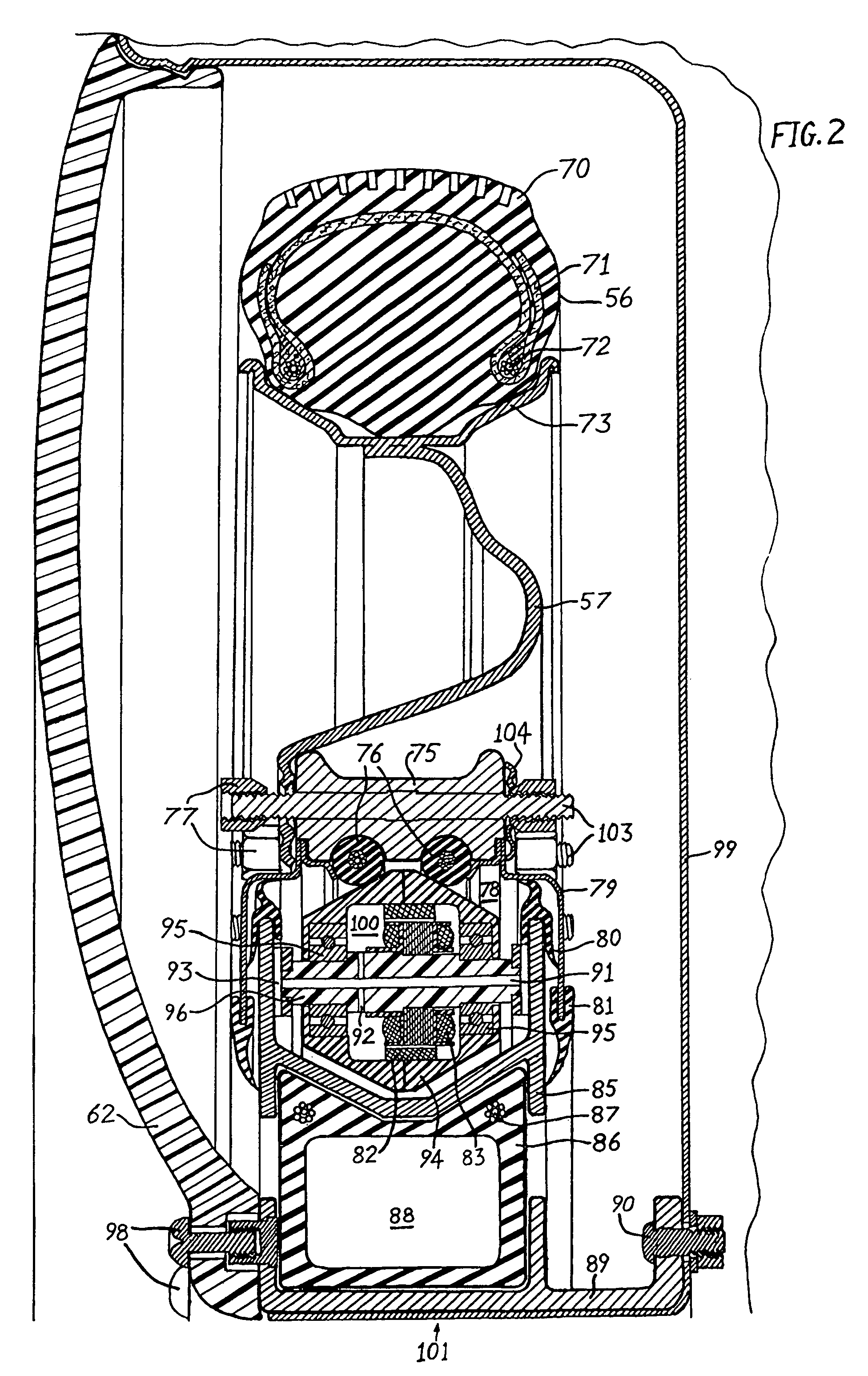

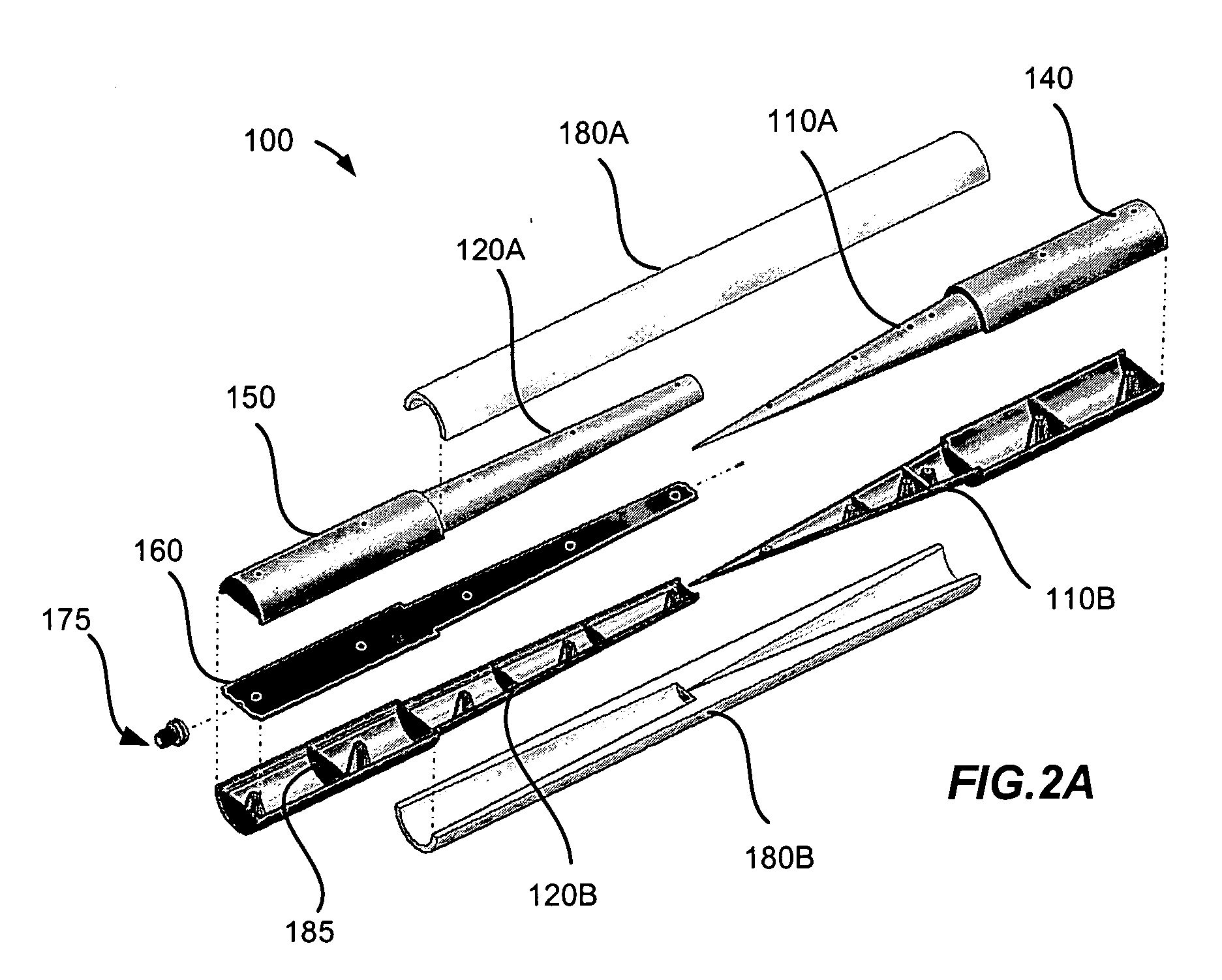

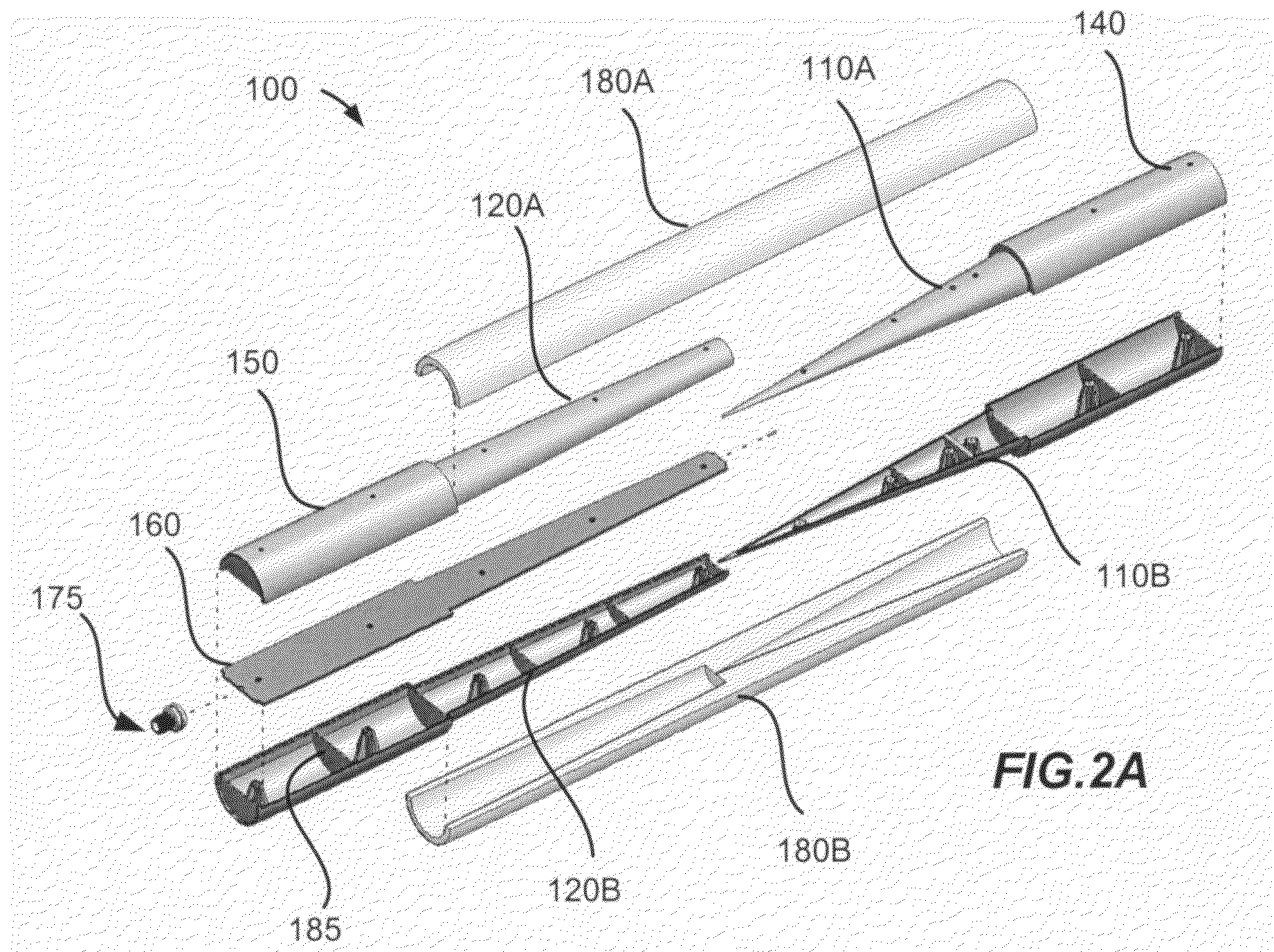

Bicone pattern shaping device

ActiveUS7525501B2Low costHigh gainAntenna feed intermediatesElectromagnetic radiationOmni directional

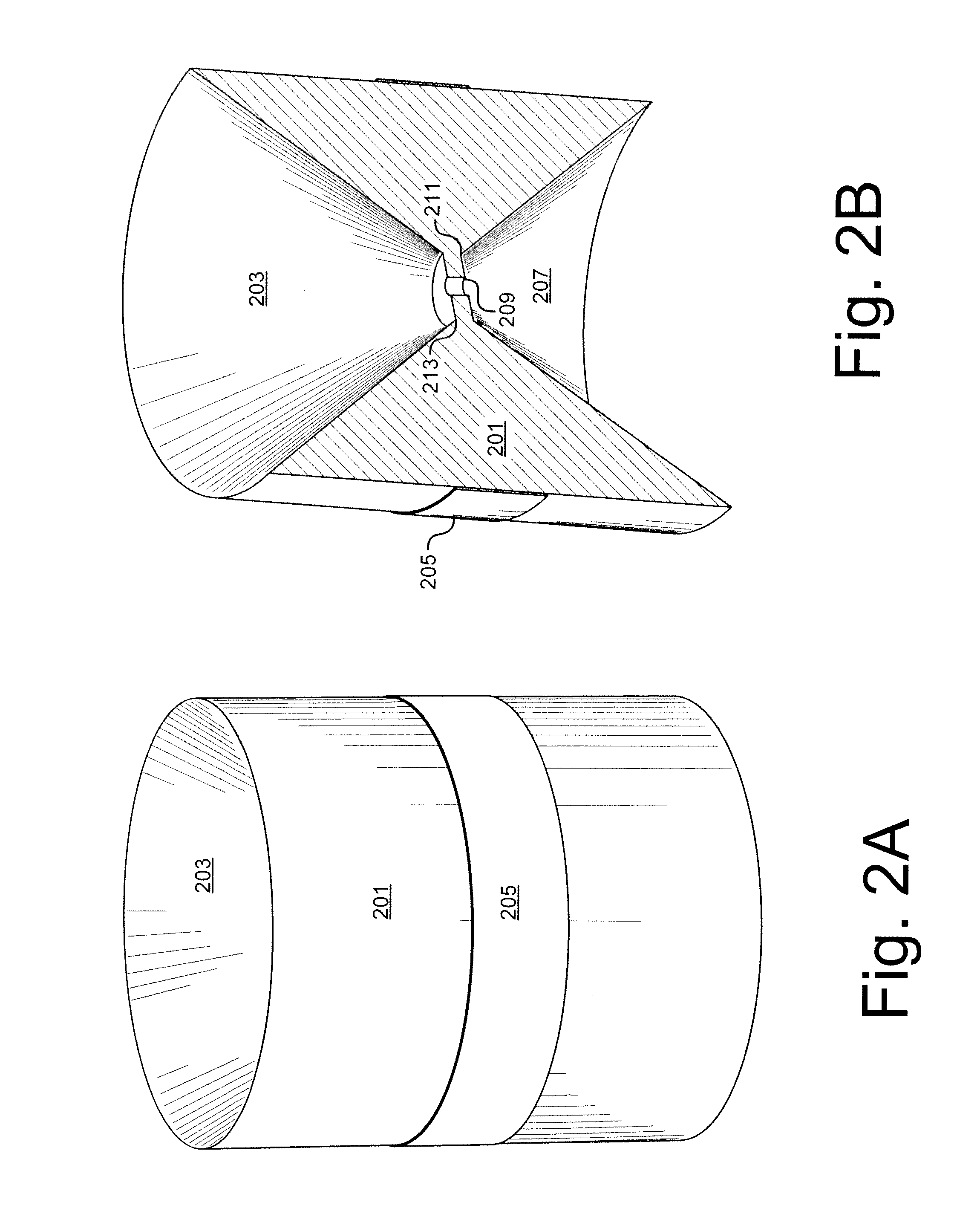

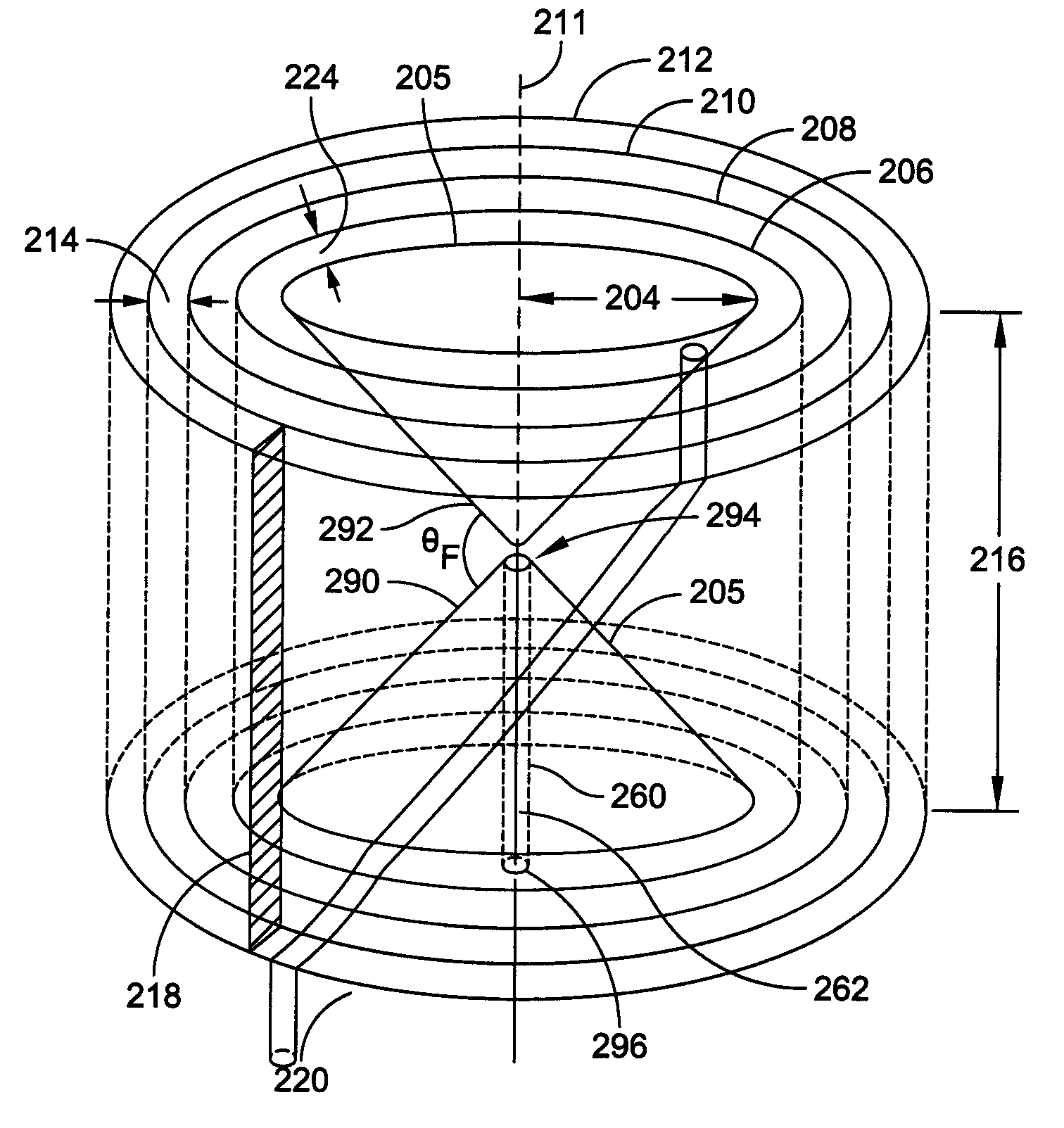

A broadband omni-directional bicone antenna. The antenna can comprise conductive surfaces of conical voids provided within a solid dielectric structure. The outside surface of the solid structure can support a radio frequency (RF) lens geometry operable for beam forming. The beam forming can modify the elevation pattern of the electromagnetic radiation from the bicone antenna. The solid dielectric structure may be machined or molded from a single piece of material. The conical voids provided within the solid structure can be metallized to provide conductive bicone radiators. The outer surface beam shaping lenses can be zoned or continuous and can provide elevation patterns with increased gain, cosecant squared falloff, or various other patterns. The beam shaping lens may be formed from any low-loss dielectric. Alternatively, the lens may be formed from a less dense material such as dielectric foam that can support radial conductive beam forming vanes.

Owner:EMS TECHNOLOGIES

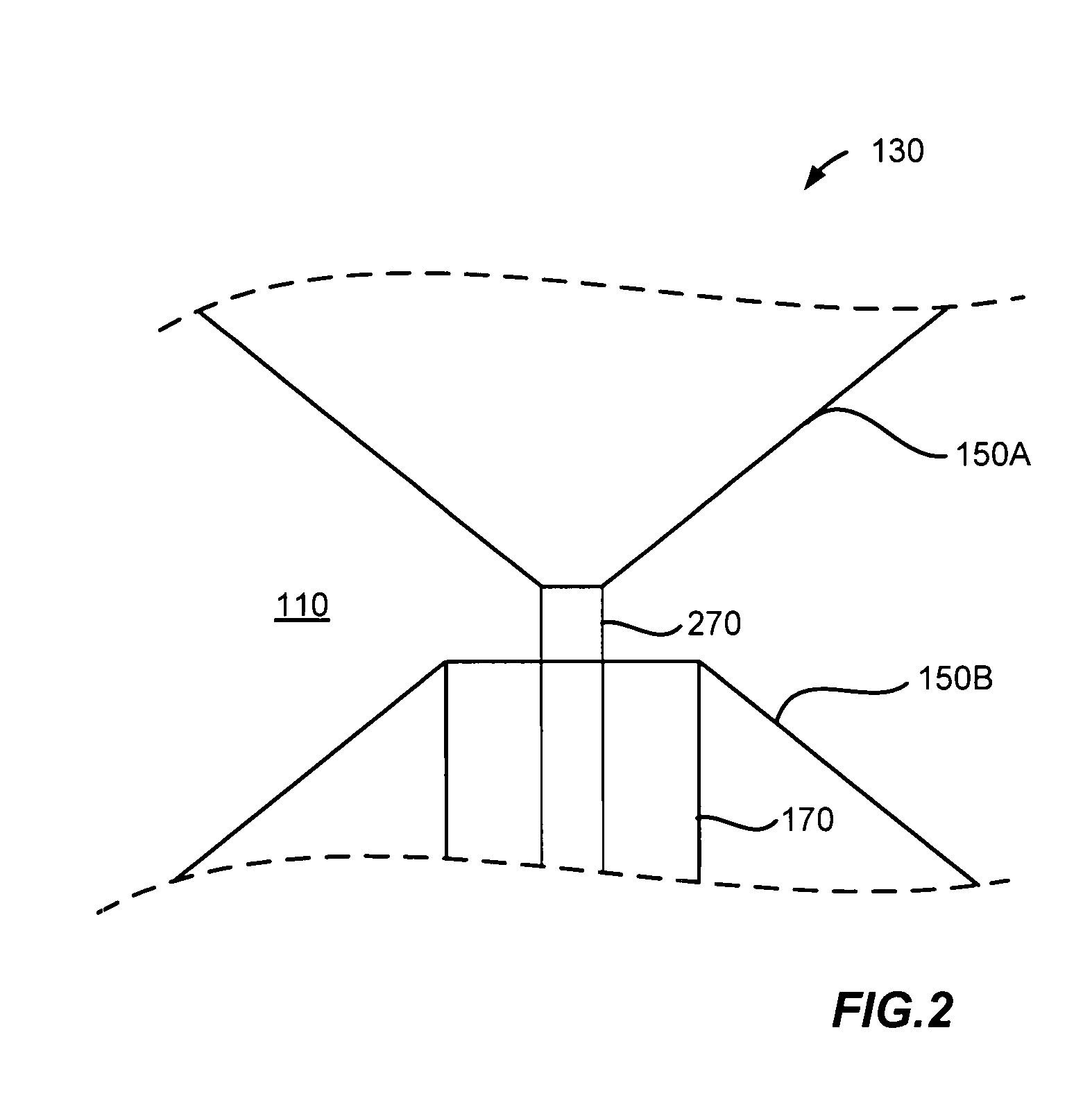

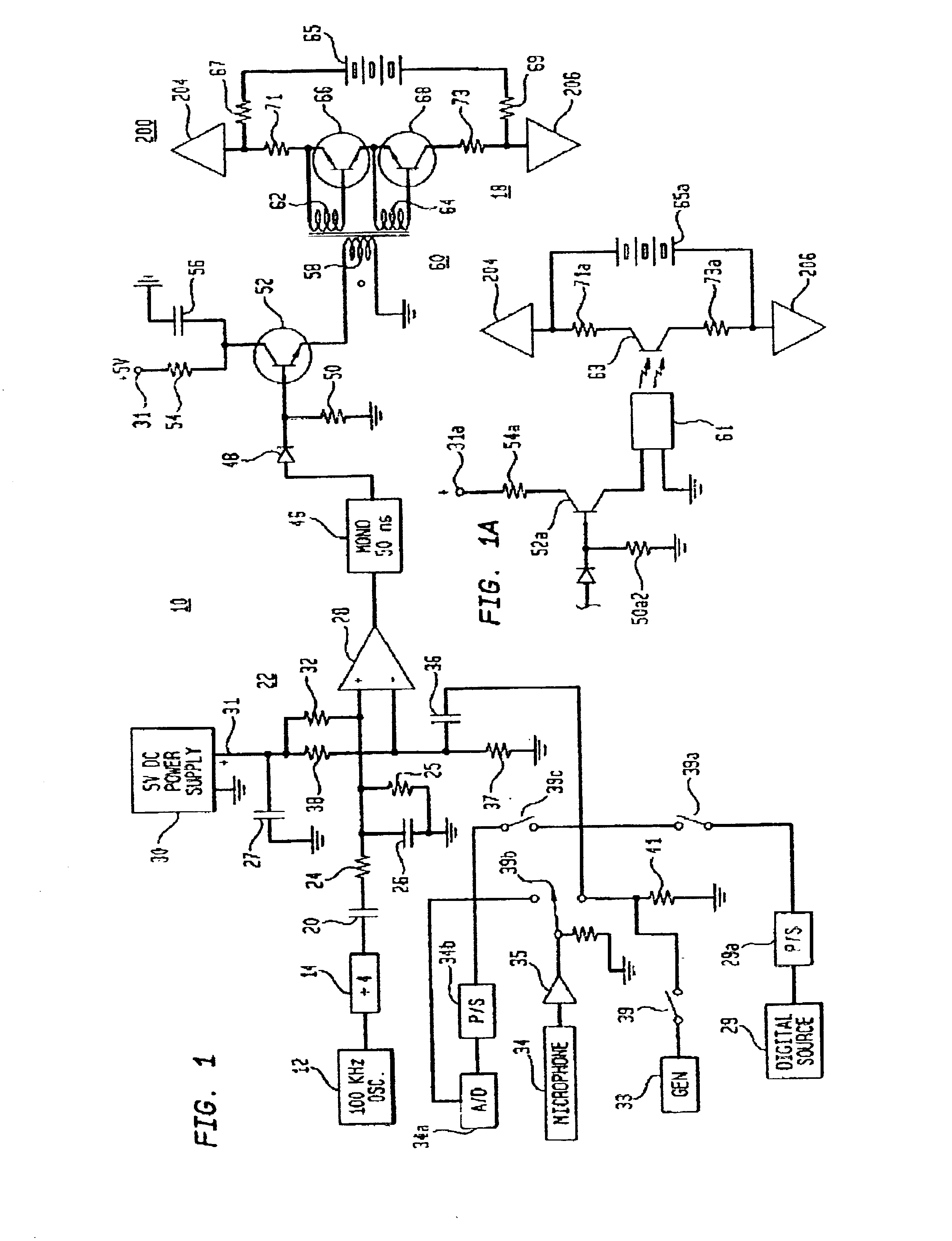

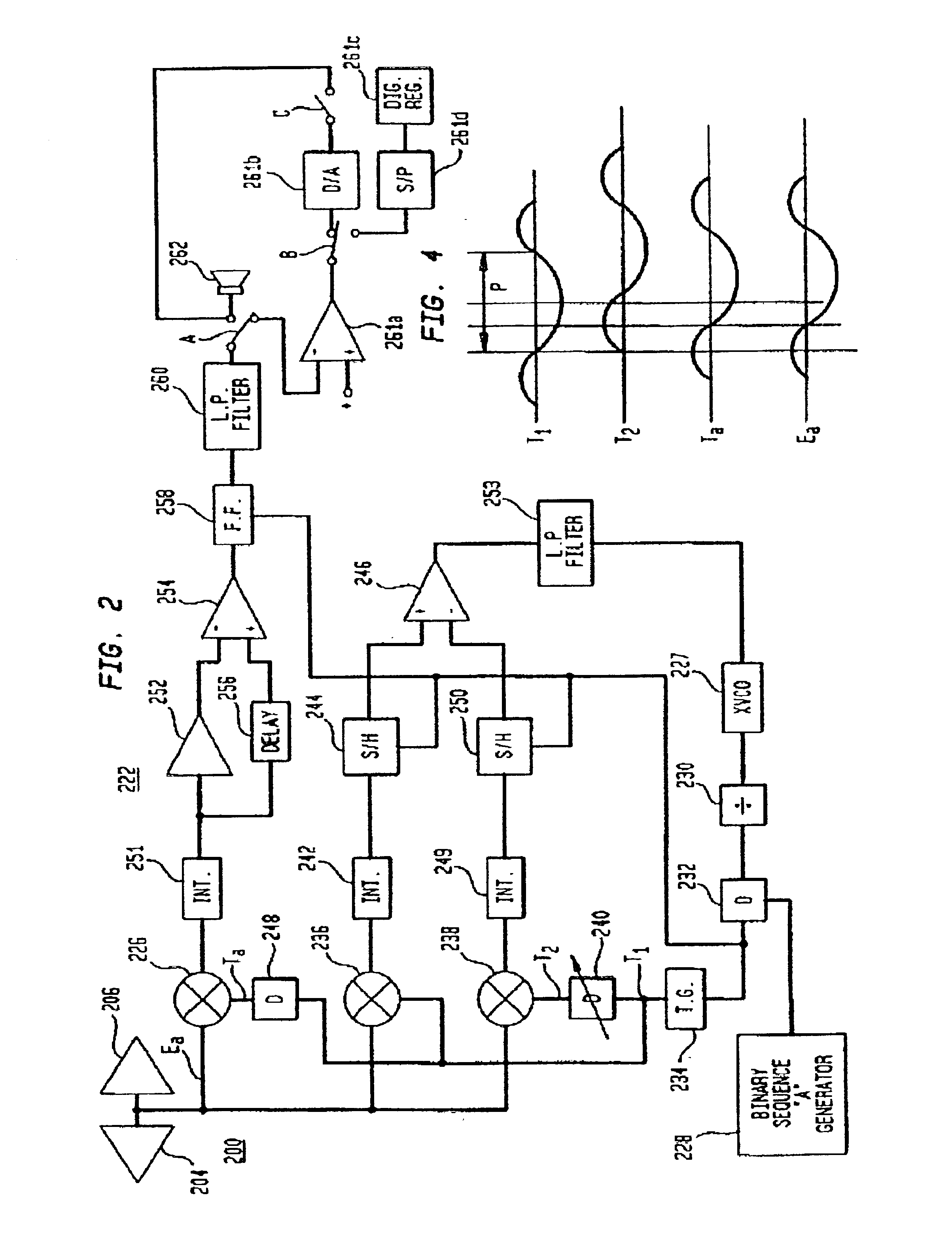

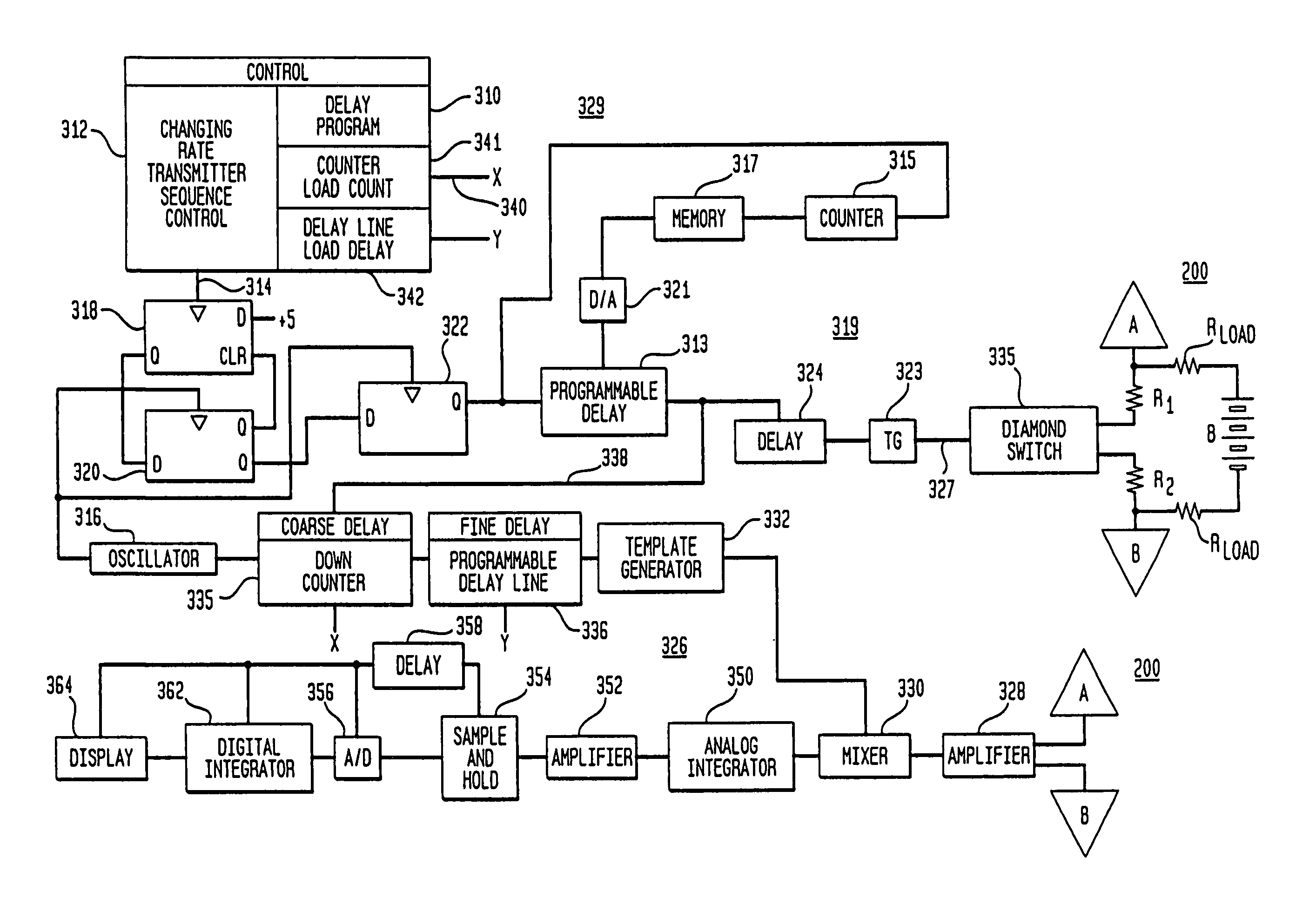

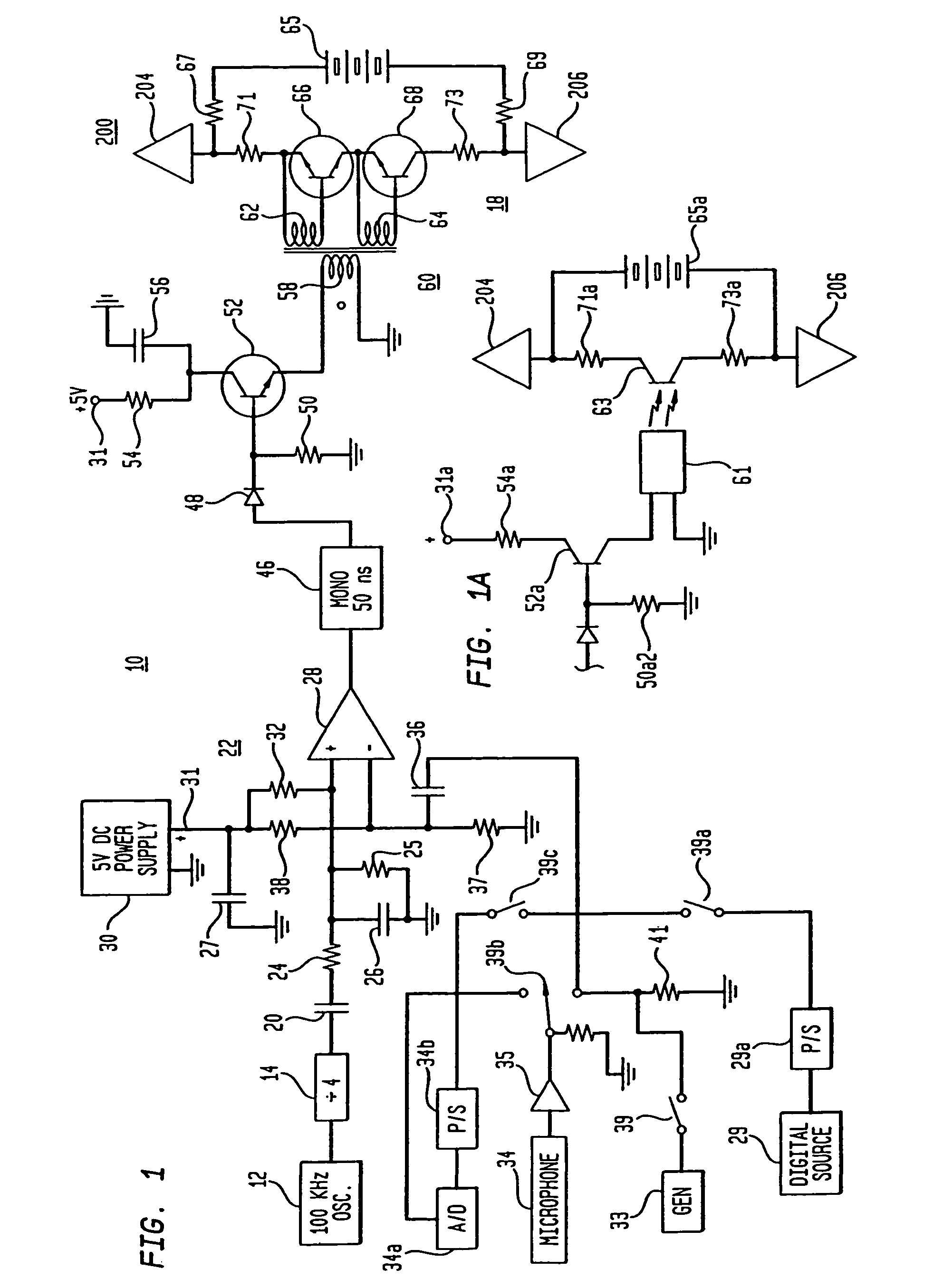

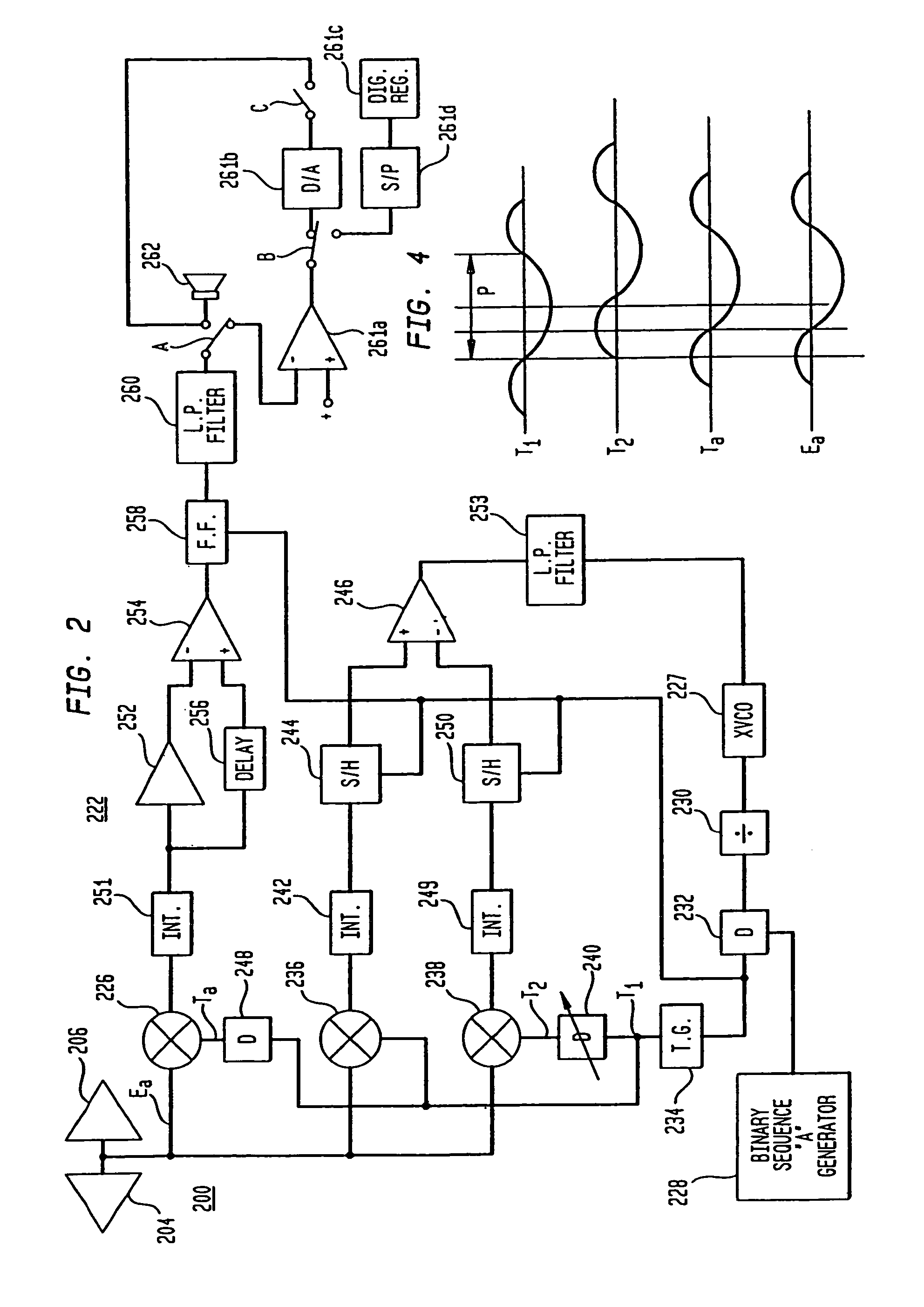

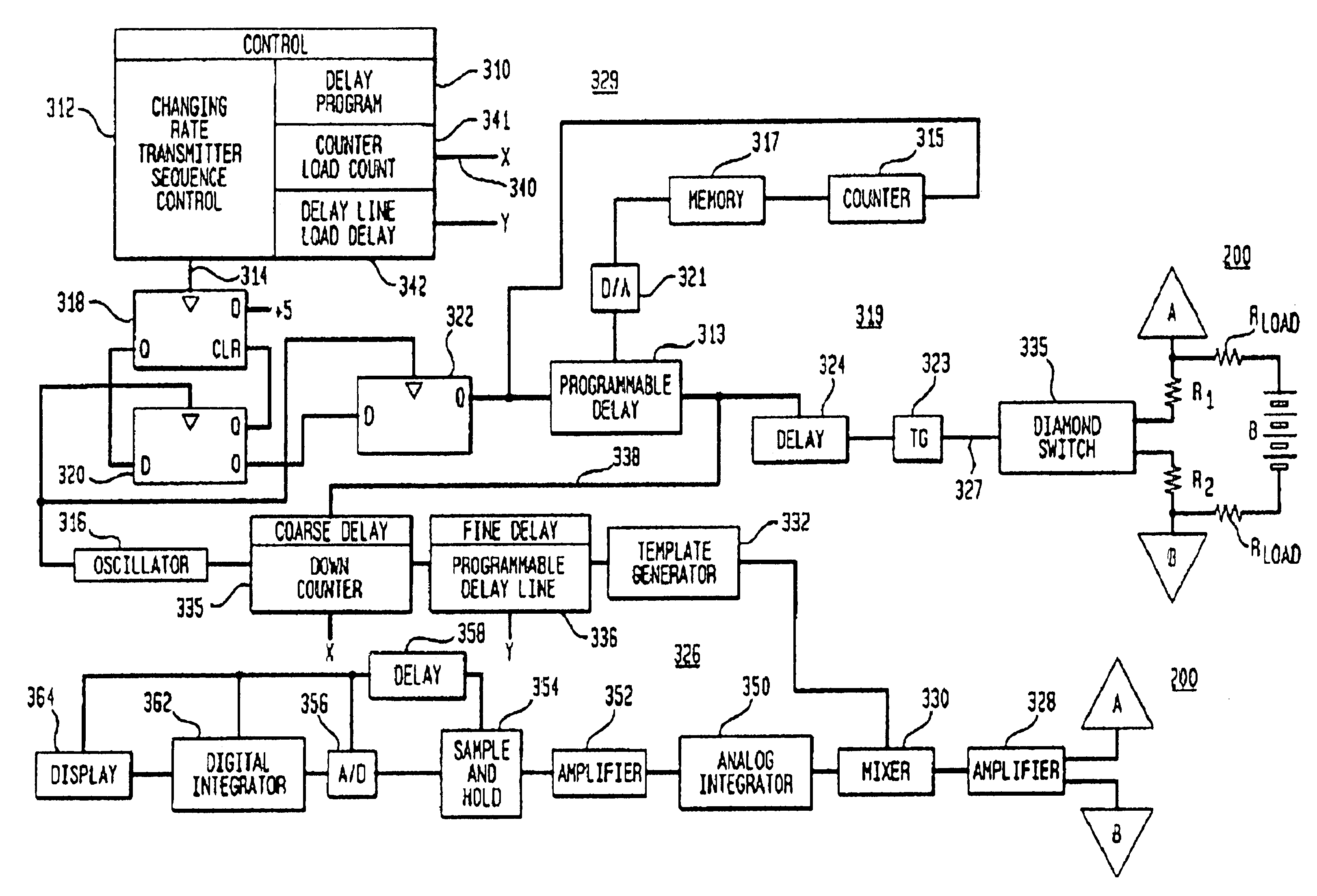

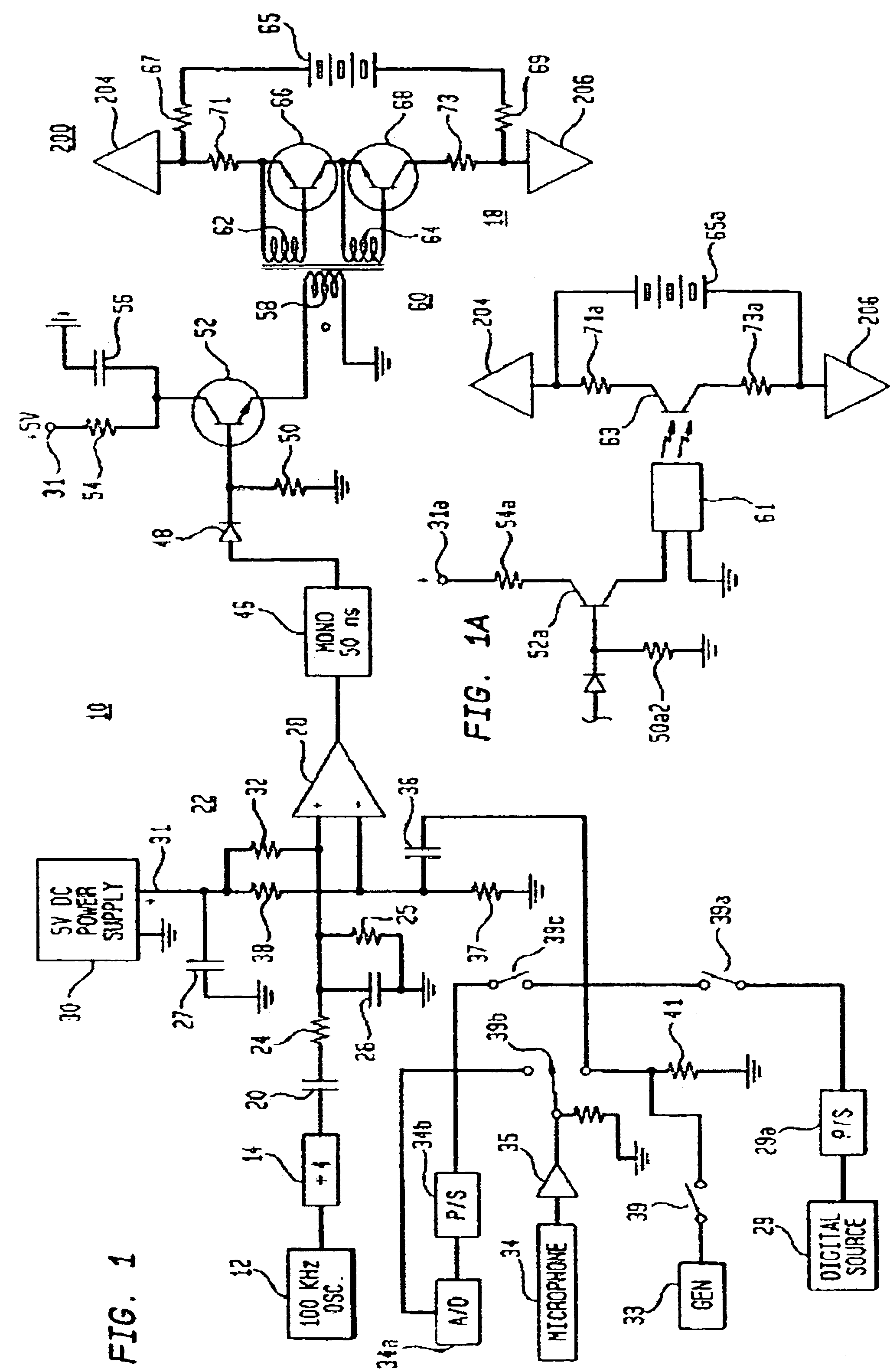

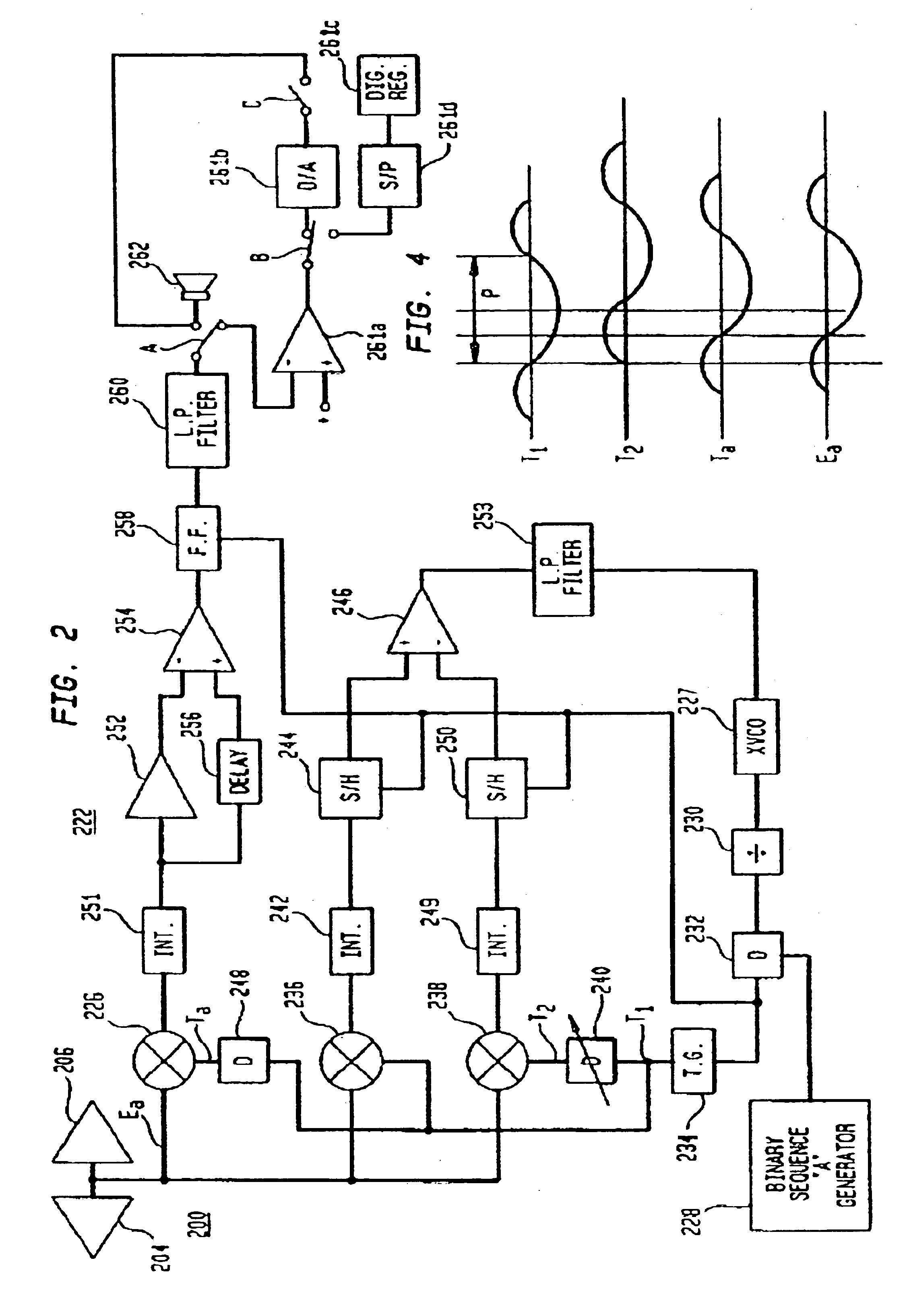

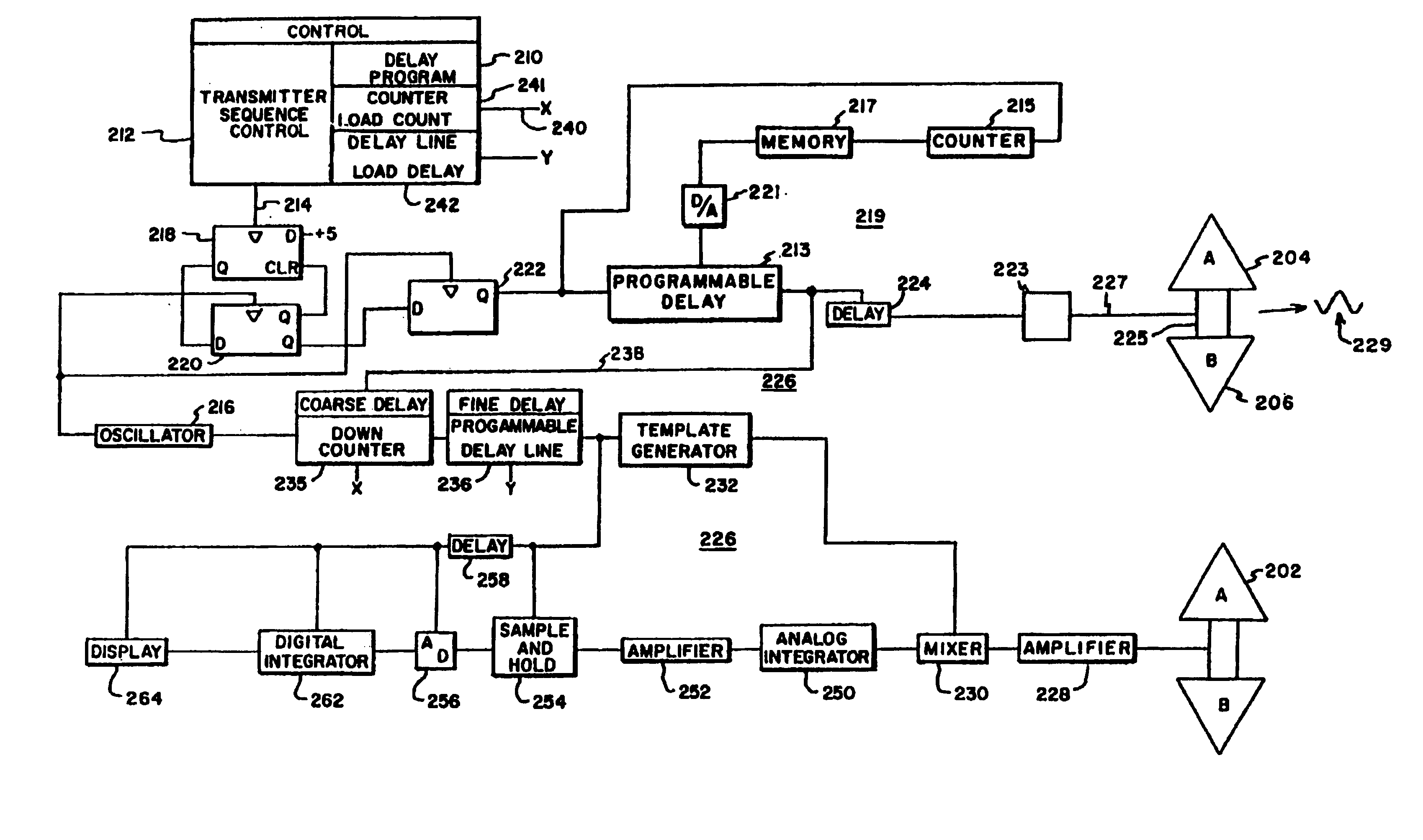

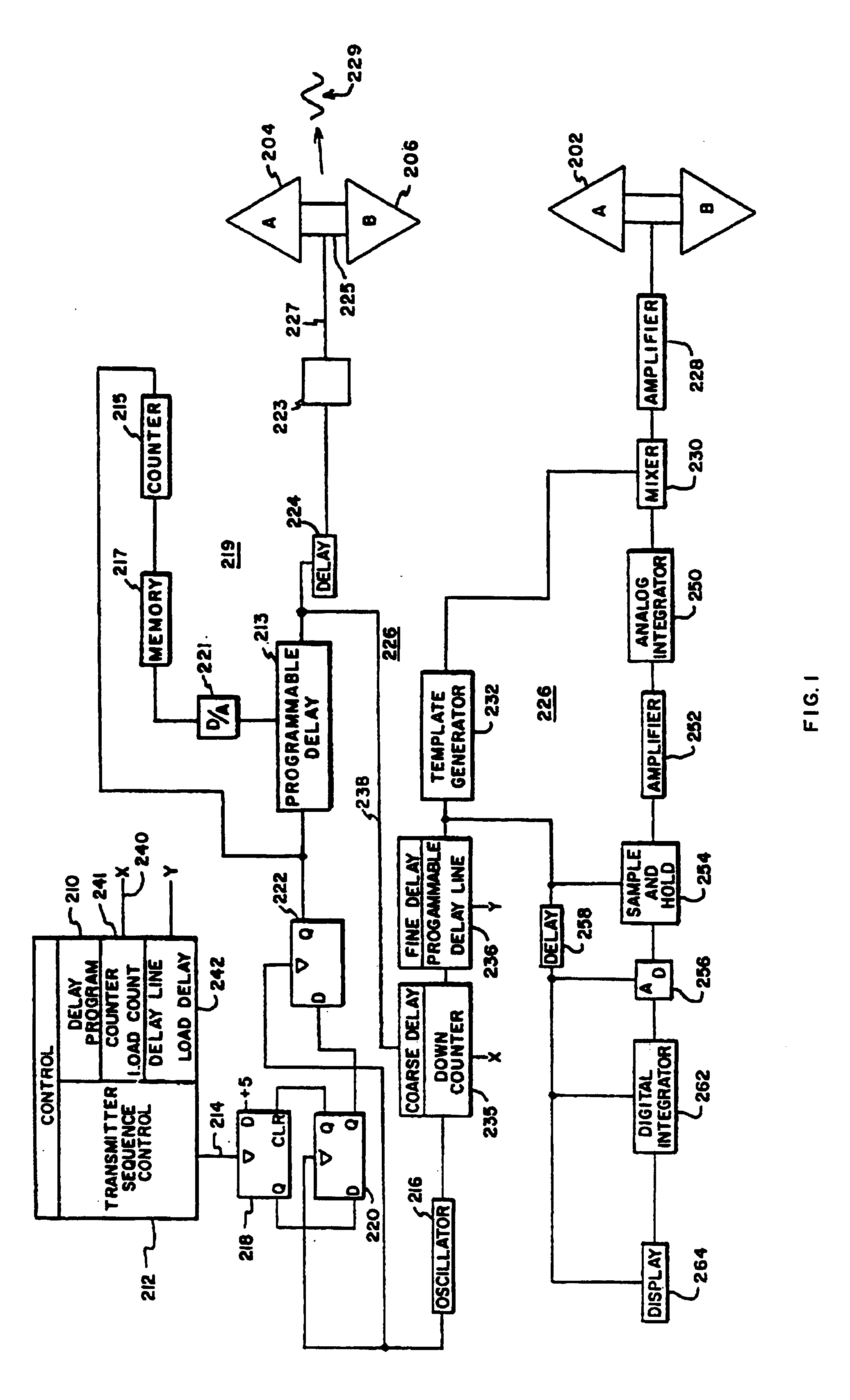

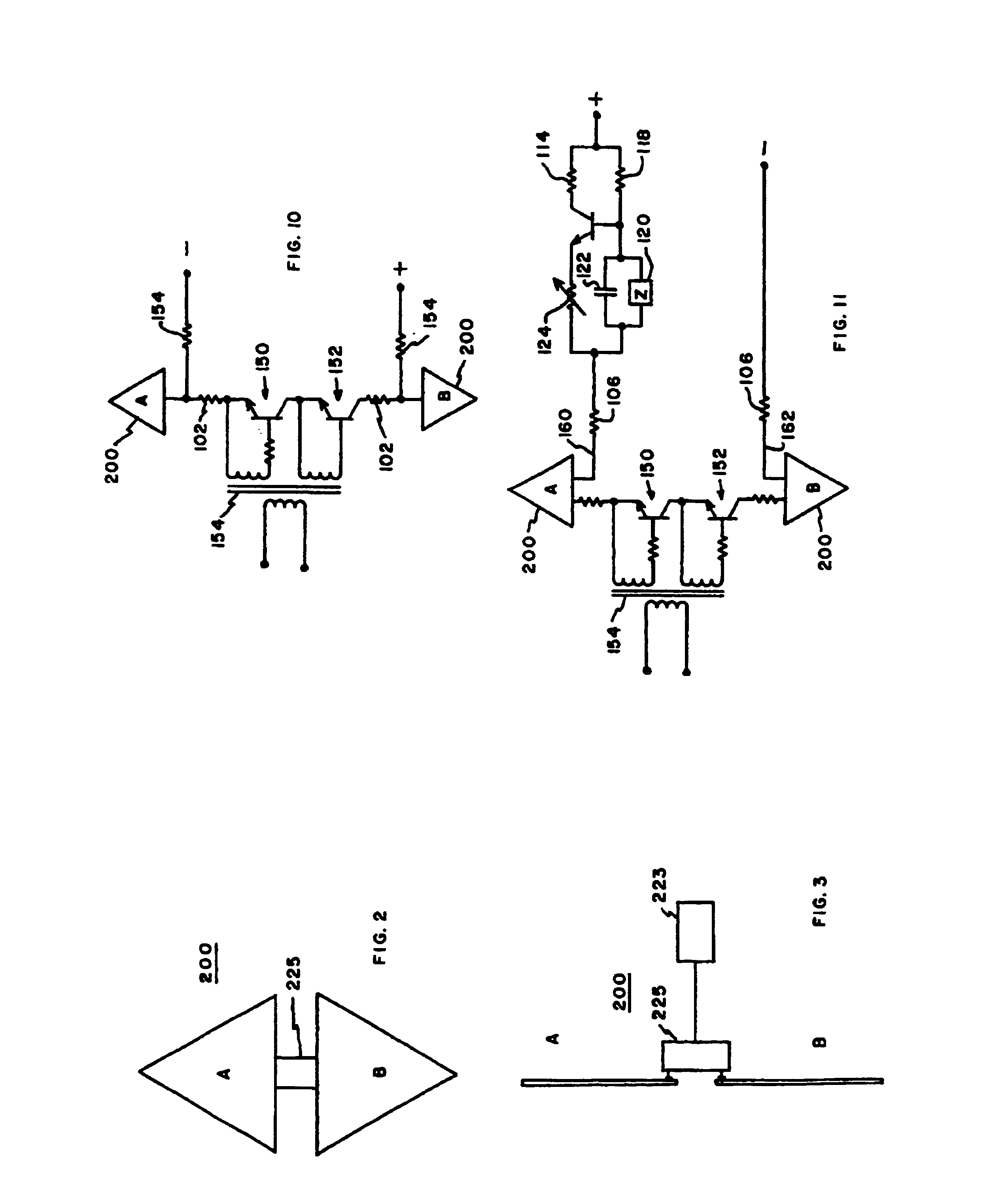

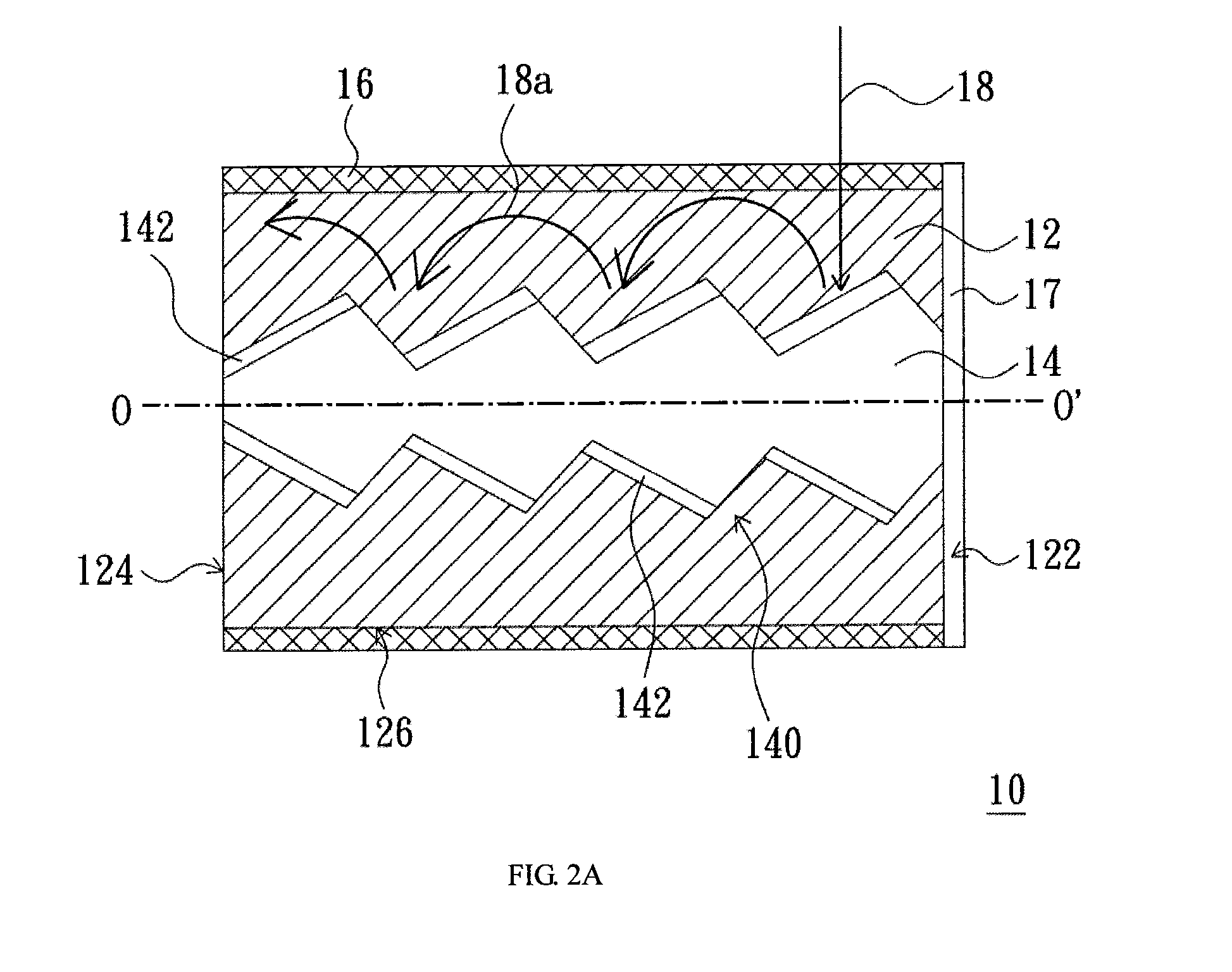

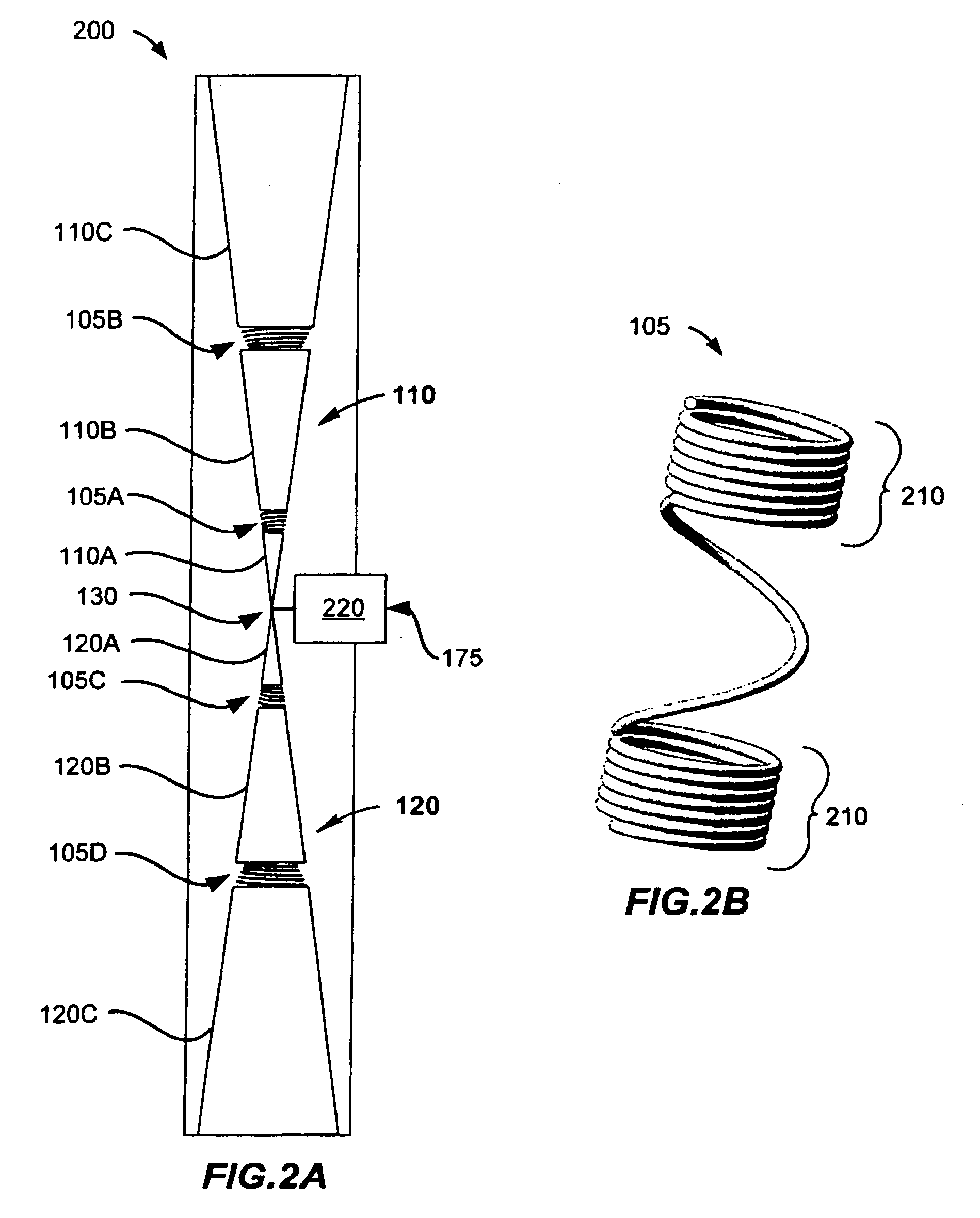

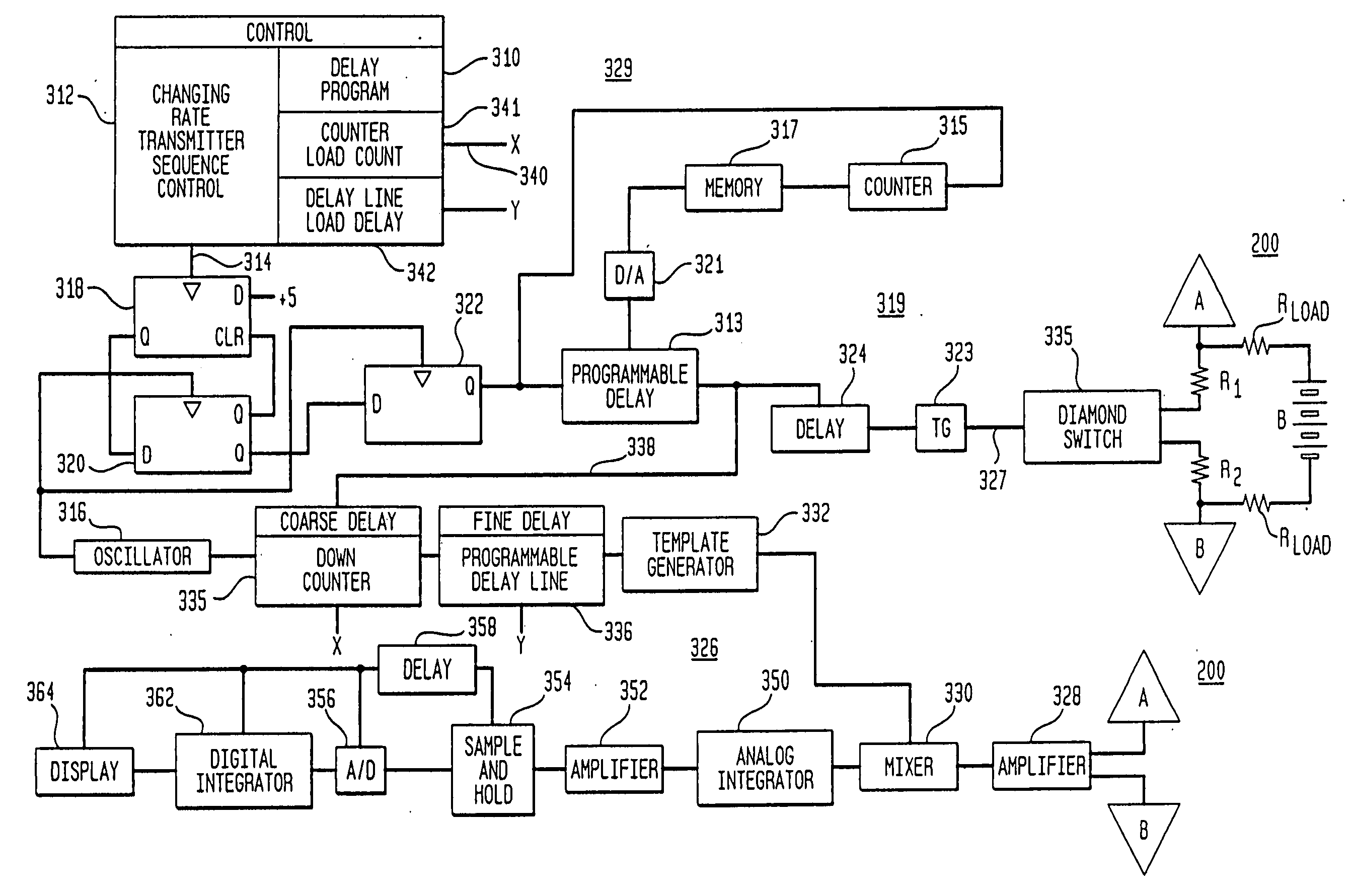

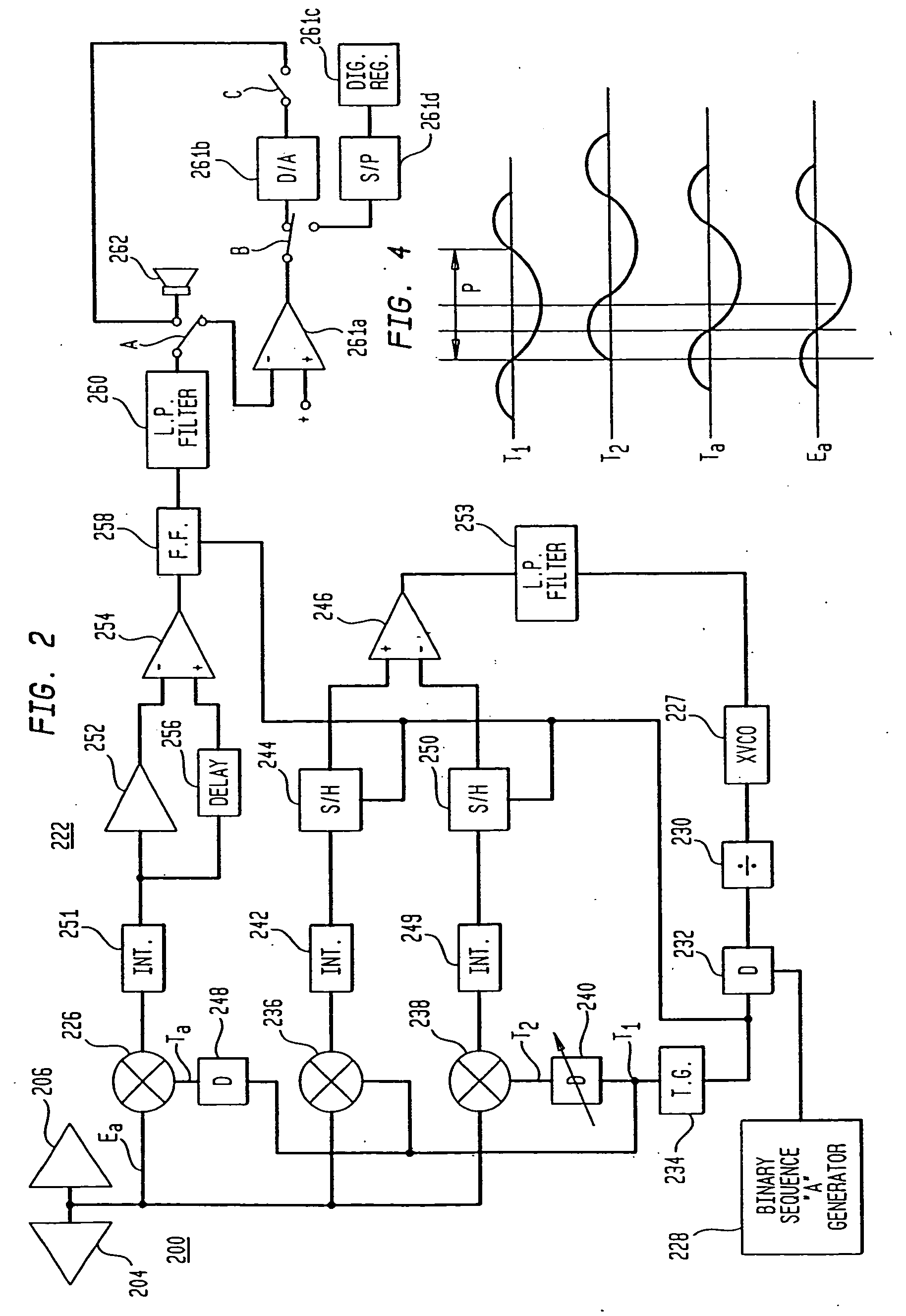

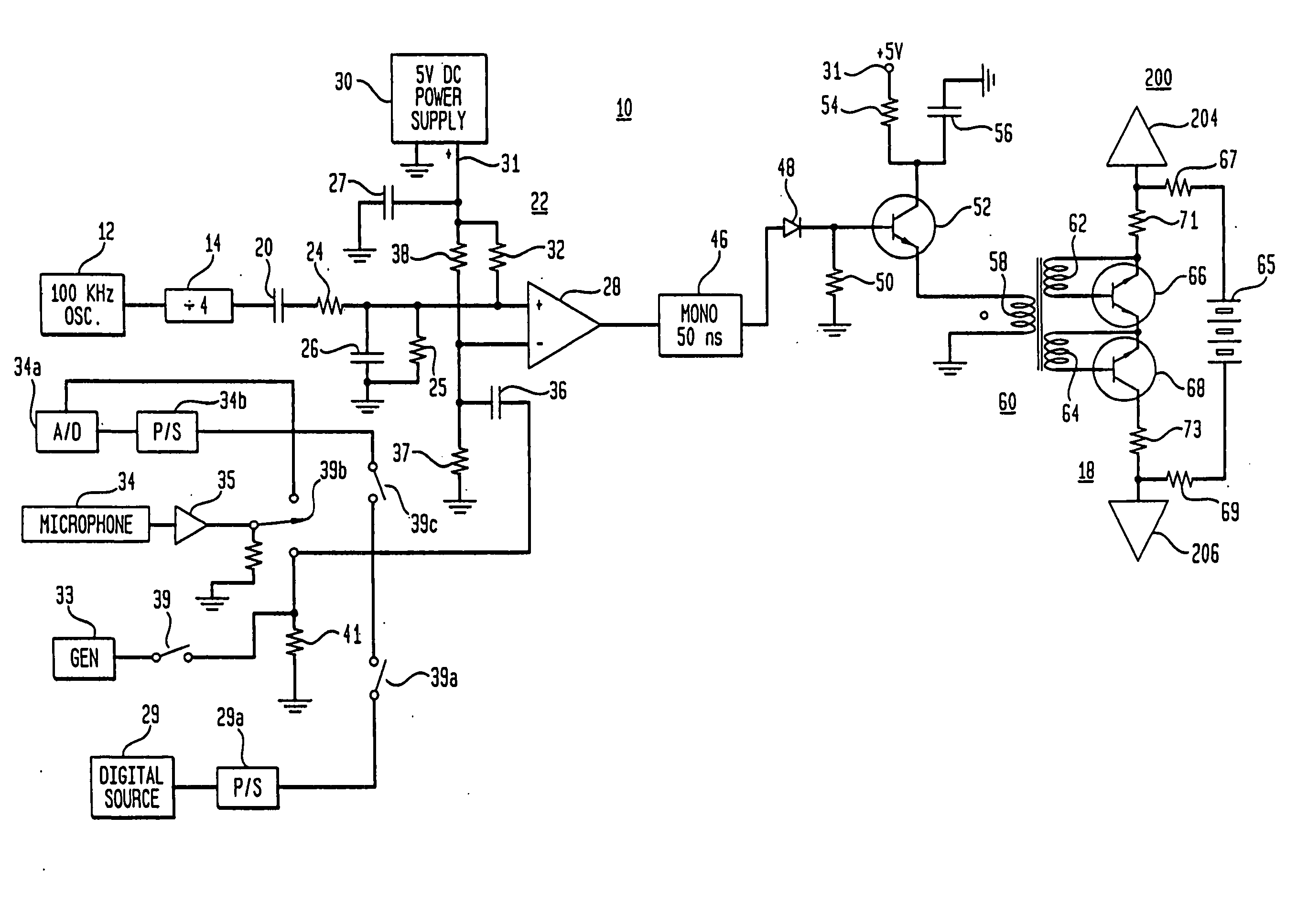

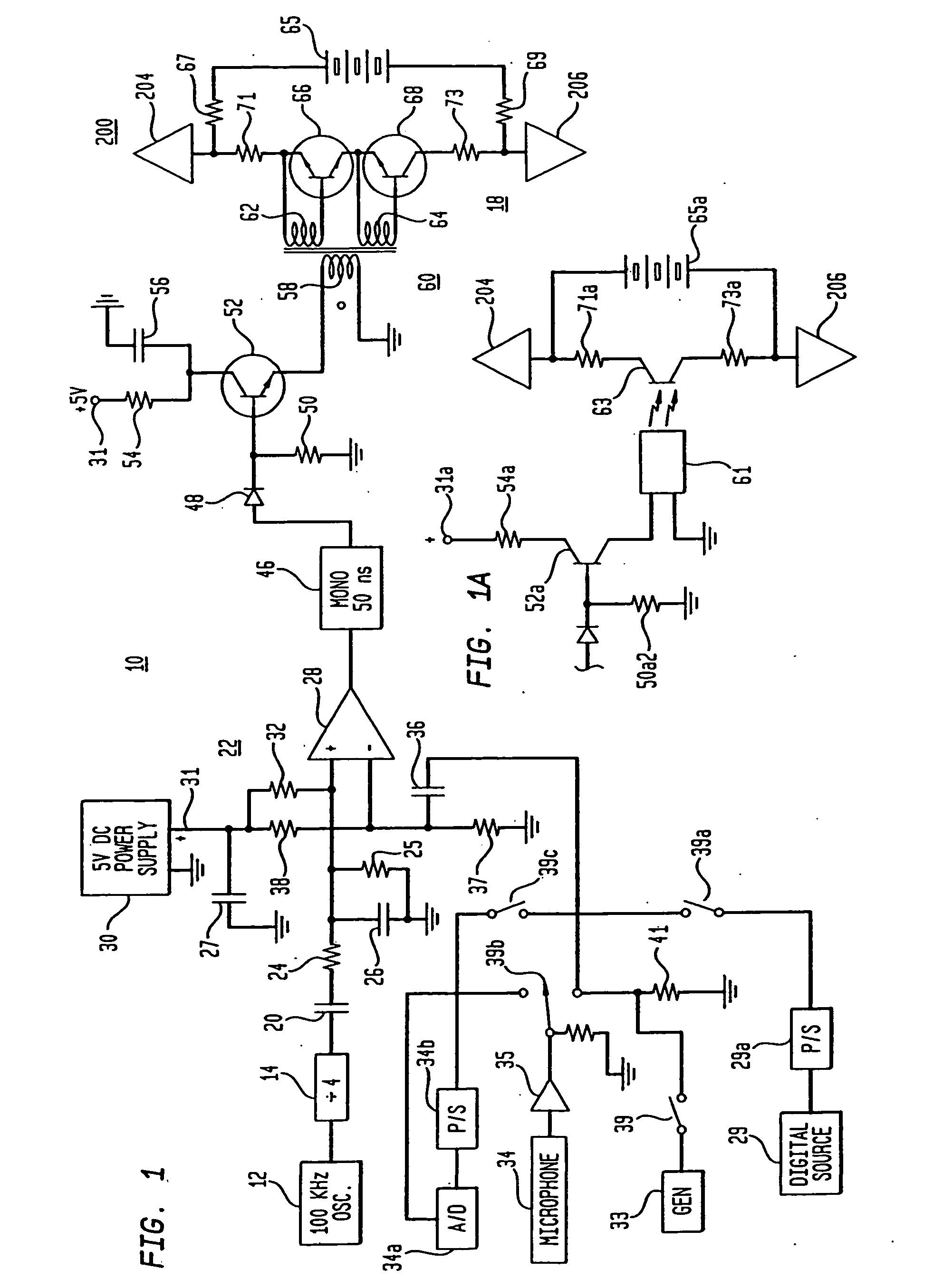

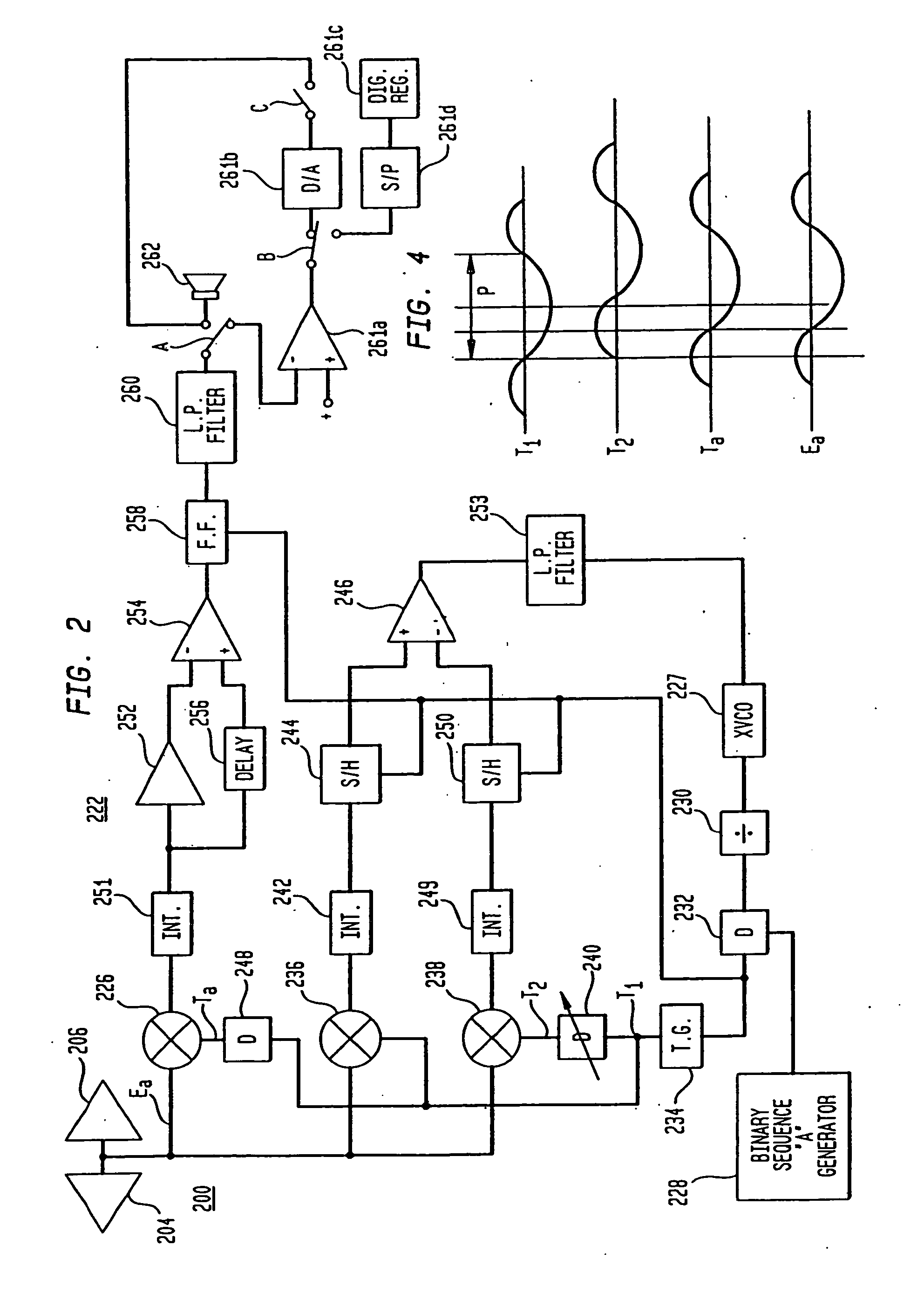

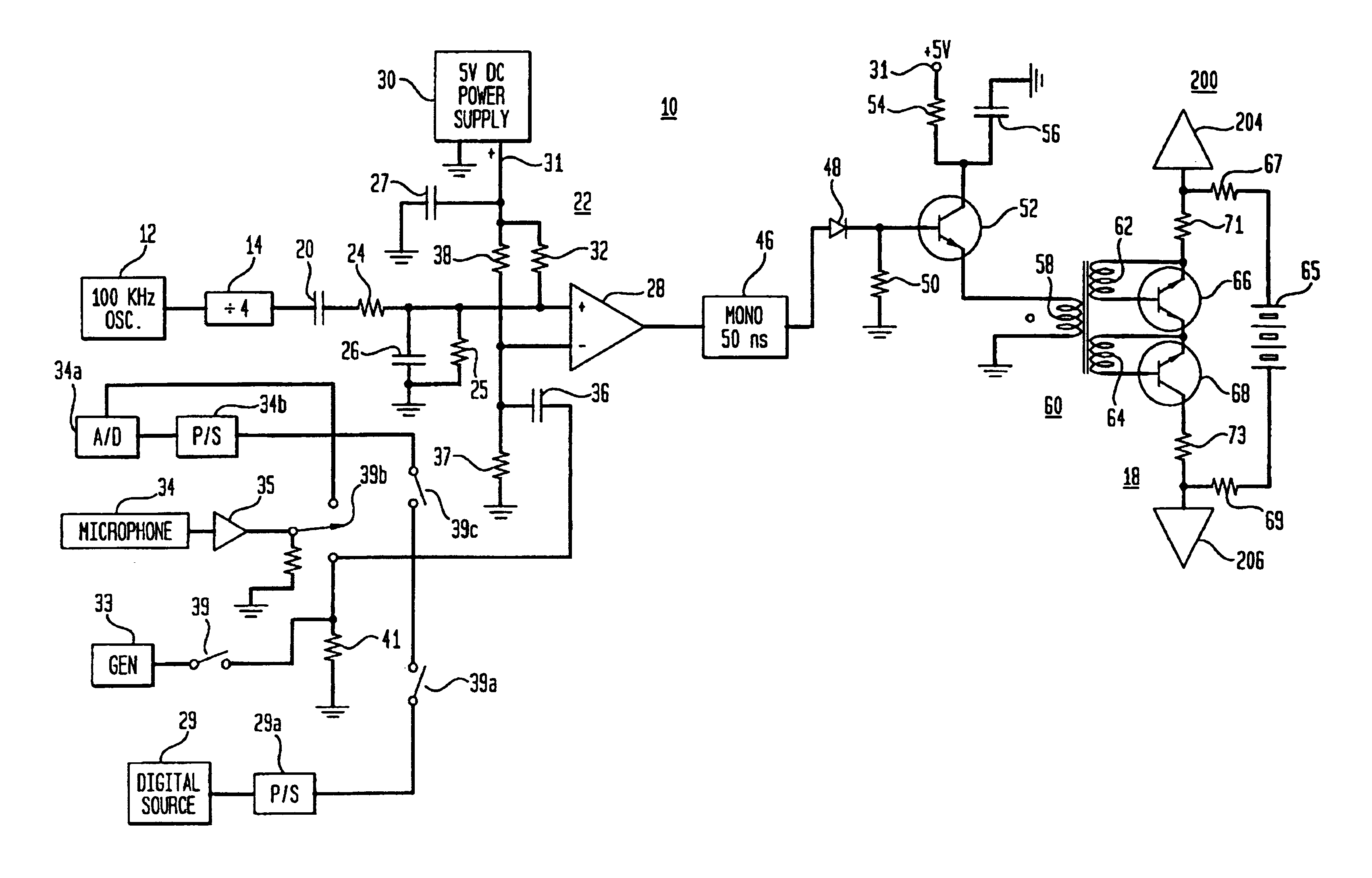

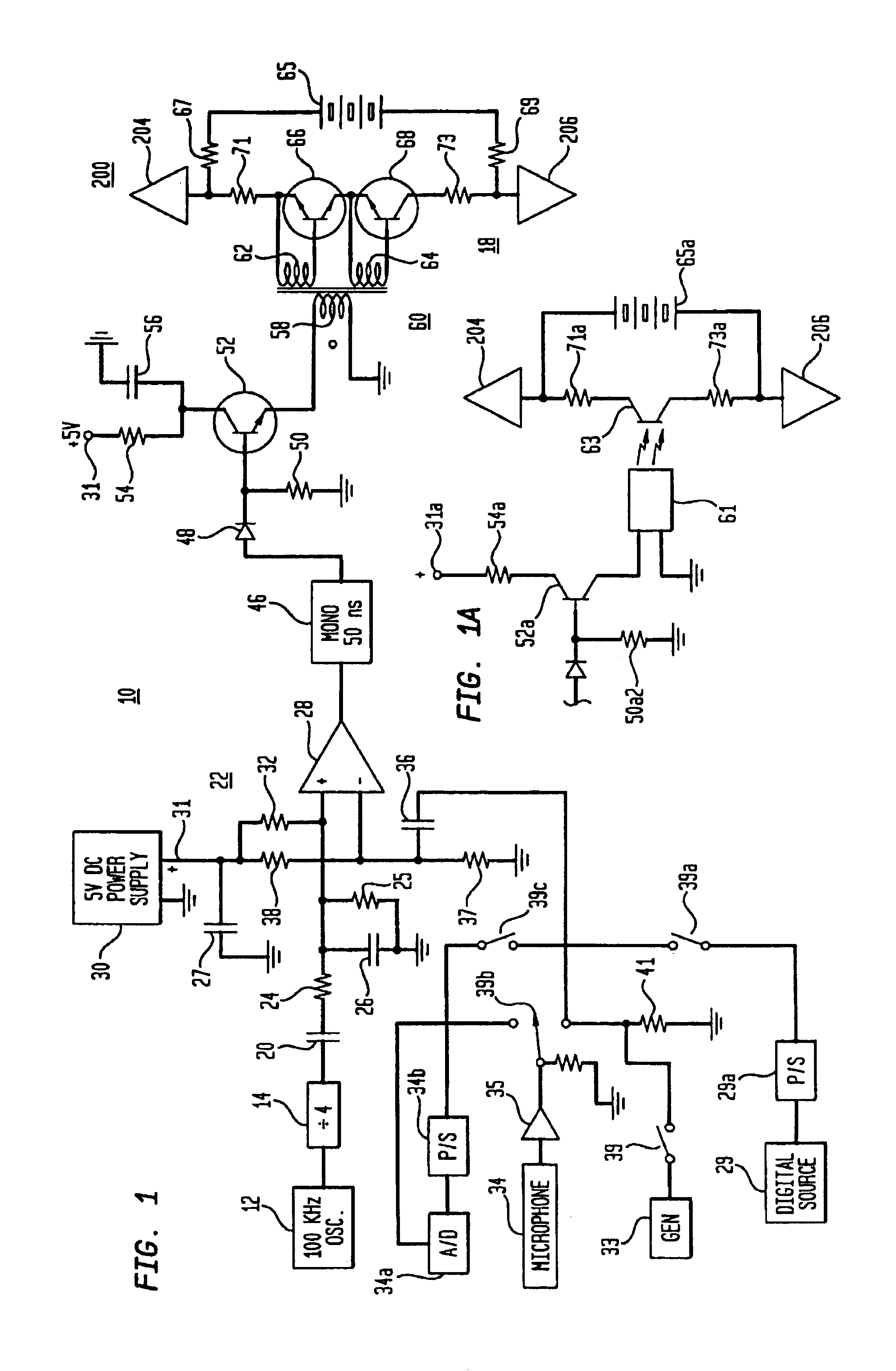

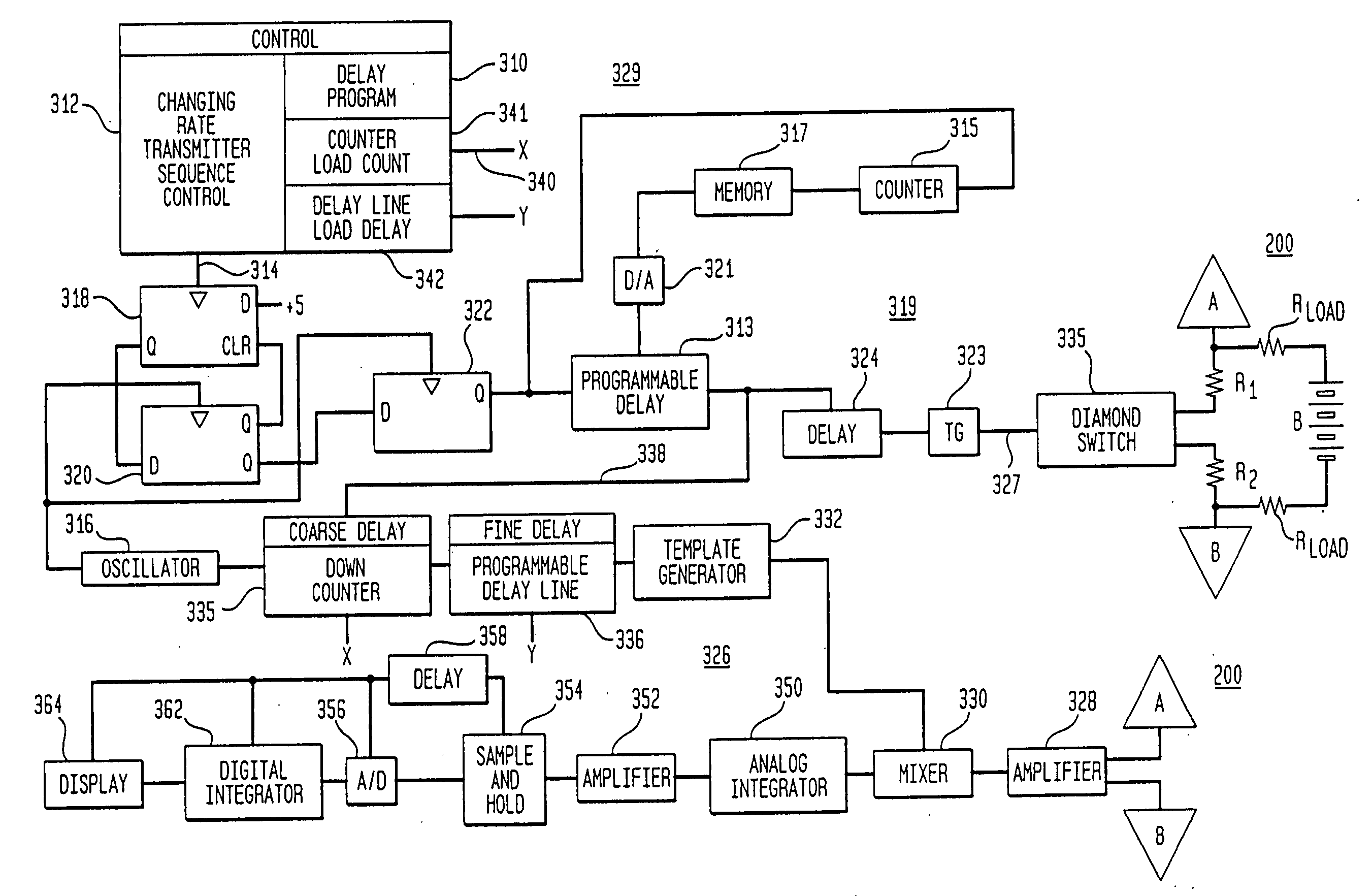

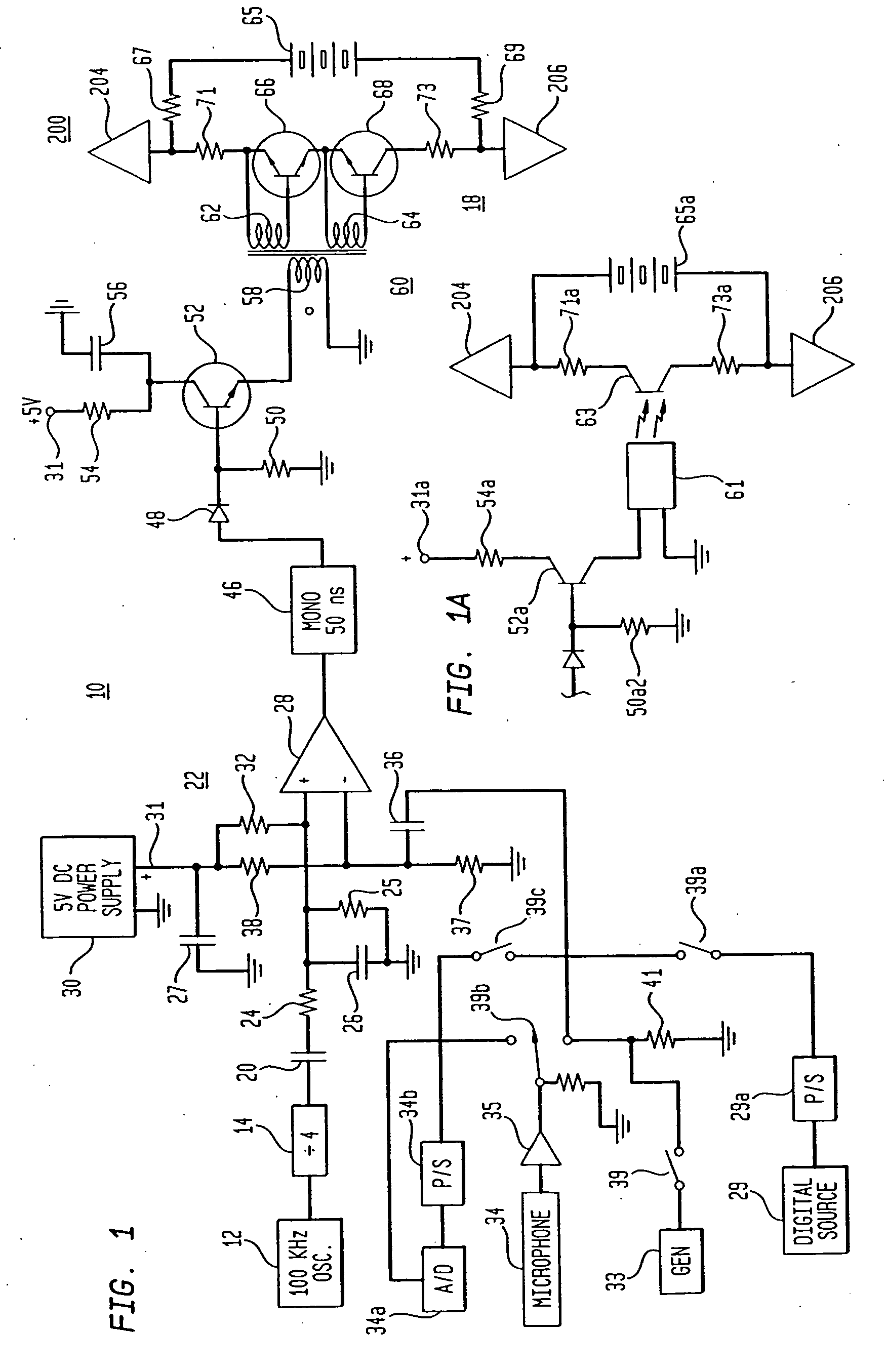

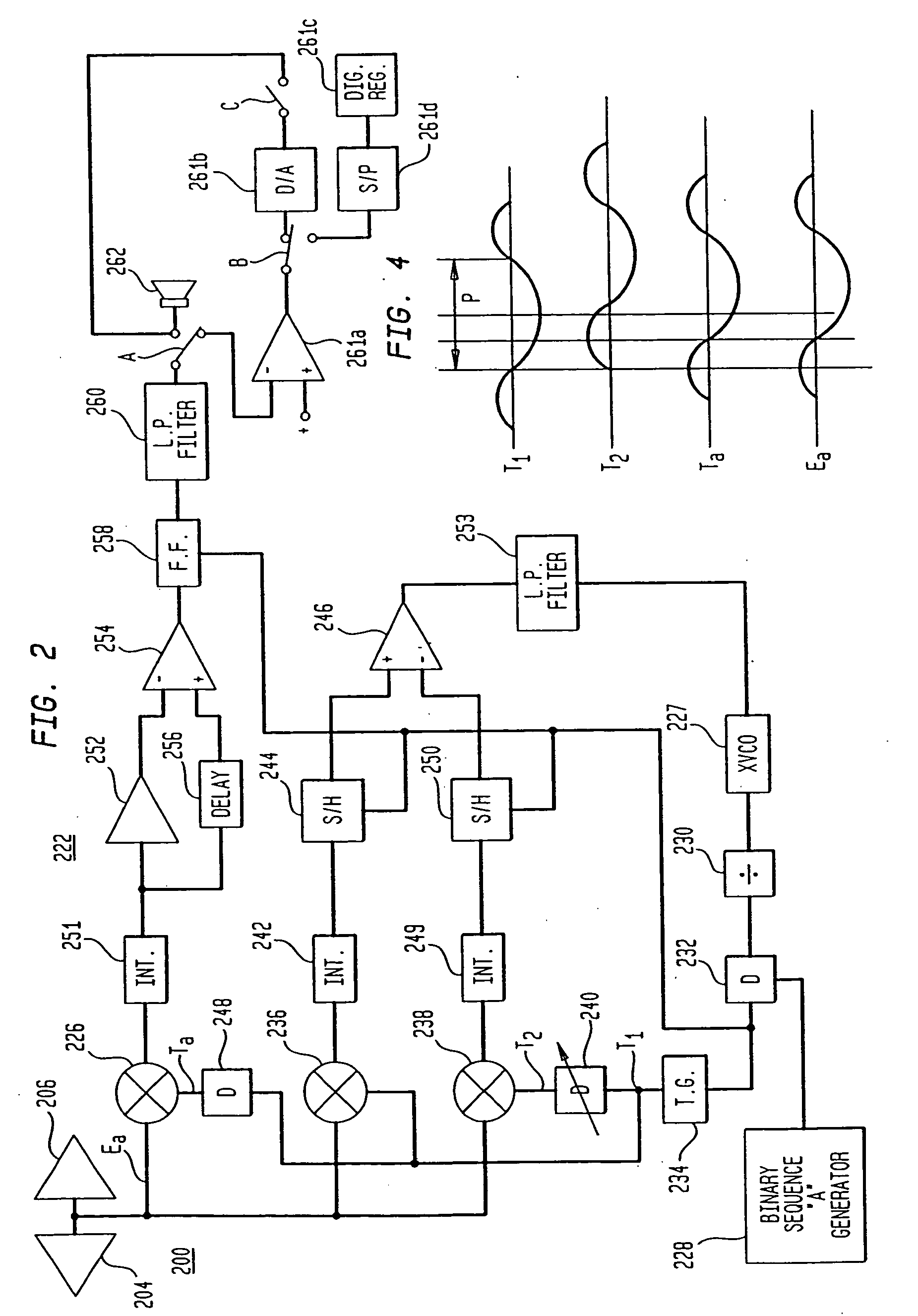

Time domain radio transmission system

InactiveUS6882301B2Easy to detectImprove signal-to-noise ratioBaseband system detailsModulated-carrier systemsTime domainCommunications system

A time domain communications system wherein a broadband of time-spaced signals, essentially monocycle-like signals, are derived from applying stepped-in-amplitude signals to a broadband antenna, in this case, a reverse bicone antenna. When received, the thus transmitted signals are multiplied by a D.C. replica of each transmitted signal, and thereafter, they are, successively, short time and long time integrated to achieve detection.

Owner:TIME DOMAIN

Time domain radio transmission system

InactiveUS7030806B2Easy to detectImprove signal-to-noise ratioDetection using electromagnetic wavesRadio wave reradiation/reflectionTime domainCommunications system

A time domain communications system wherein a broadband of time-spaced signals, essentially monocycle-like signals, are derived from applying stepped-in-amplitude signals to a broadband antenna, in this case, a reverse bicone antenna. When received, the thus transmitted signals are multiplied by a D.C. replica of each transmitted signal, and thereafter, they are, successively, short time and long time integrated to achieve detection.

Owner:TIME DOMAIN

Time domain radio transmission system

InactiveUS6933882B2Improve securityFast repetition rateModulated-carrier systemsIndividually energised antenna arraysTime domainCommunications system

A time domain communications system wherein a broadband of time-spaced signals, essentially monocycle-like signals, are derived from applying stepped-in-amplitude signals to a broadband antenna, in this case, a reverse bicone antenna. When received, the thus transmitted signals are multiplied by a D.C. replica of each transmitted signal, and thereafter, they are, successively, short time and long time integrated to achieve detection.

Owner:TIME DOMAIN

Time domain radio transmission system

InactiveUSRE39759E1Conveniently frequency modulationEliminate the effects ofSecret communicationIndividually energised antenna arraysTime domainCommunications system

A time domain communications system wherein a broadband of time-spaced signals, essentially monocycle-like signals, are derived from applying stepped-in-amplitude signals to a broadband antenna, in this case, a reverse bicone antenna. When received, the thus transmitted signals are multiplied by a D.C. replica of each transmitted signal, and thereafter, they are, successively, short time and long time integrated to achieve detection.

Owner:TIME DOMAIN

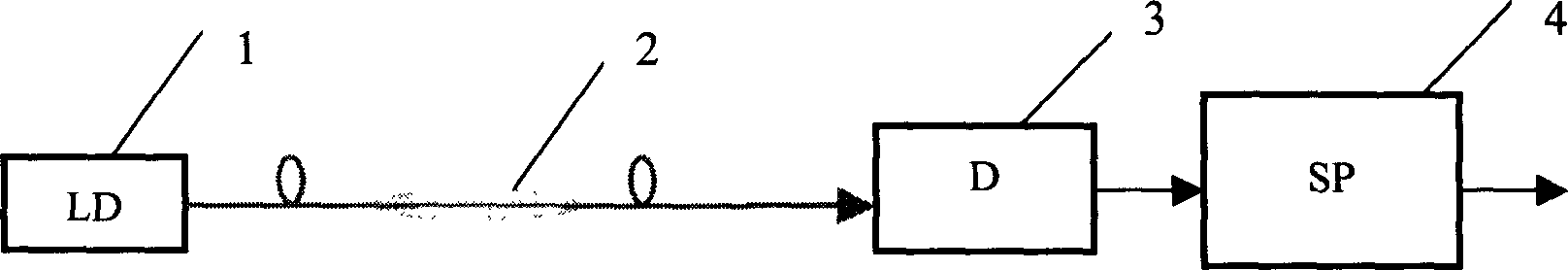

Hipyramid type optical fiber fade down wave temperature sensor and method for manufacturing its bipyramid optical fiber probe

InactiveCN1699943ASimple manufacturing methodGet quick and efficientThermometers using physical/chemical changesFiberOptical fiber probe

The invention relates to a temperature sensor of double conical optic fiber fading down and method of making double conical optic fiber probe. The temperature sensor comprises light source through optic fiber probe connected with detector which connected with signal processing unit; wherein sensing fiber's energy changes with fading down filed of double conical zone changes aroused by censor temperature changes when the probe is in temperature changeable filed; bathometer switches optic signal into electric signal and inputs it into signal processing unit to get temperature information. The method of making double conical optic fiber is warming the individual fiber and fuse and awl it.

Owner:SHANGHAI UNIV

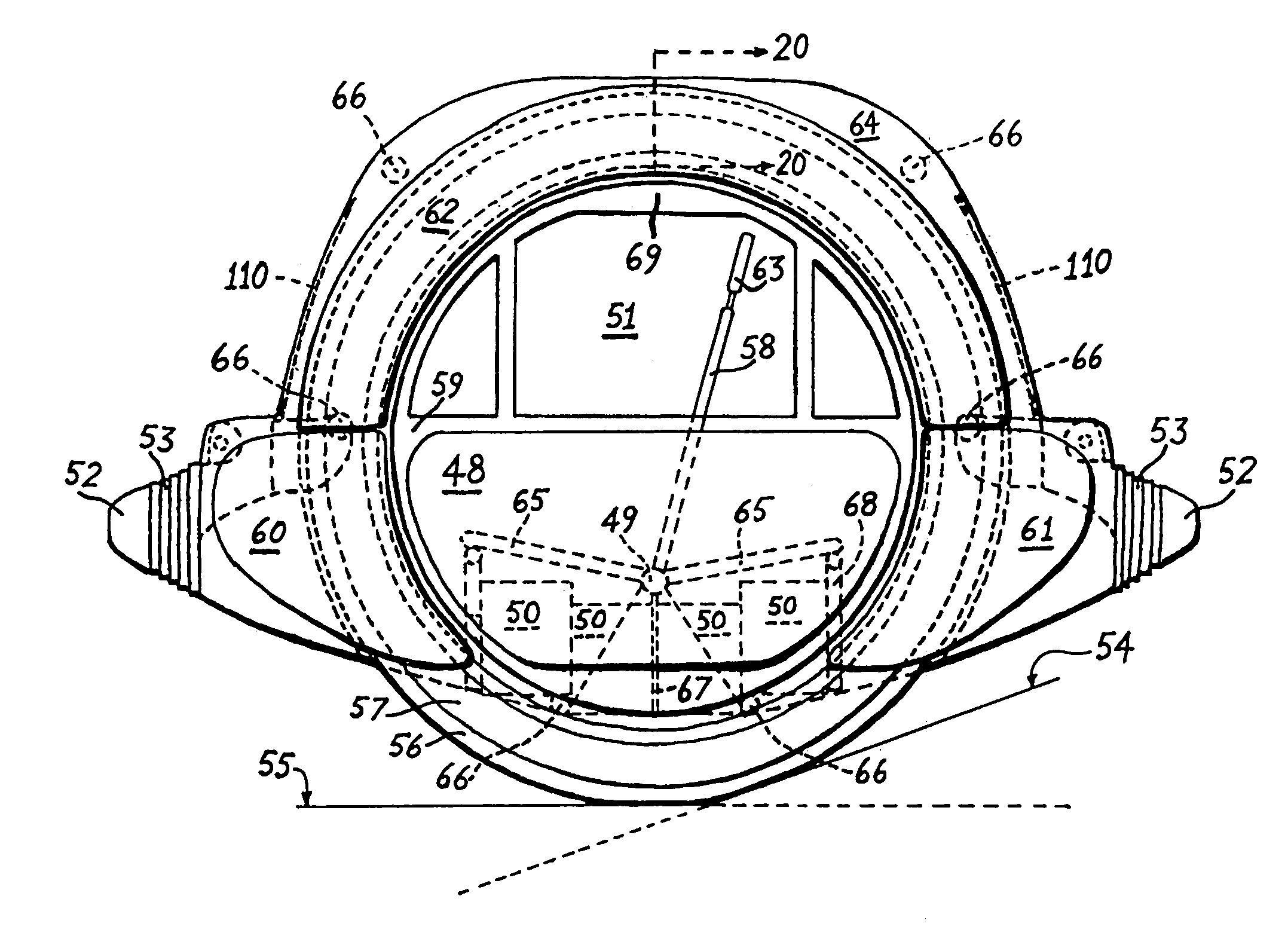

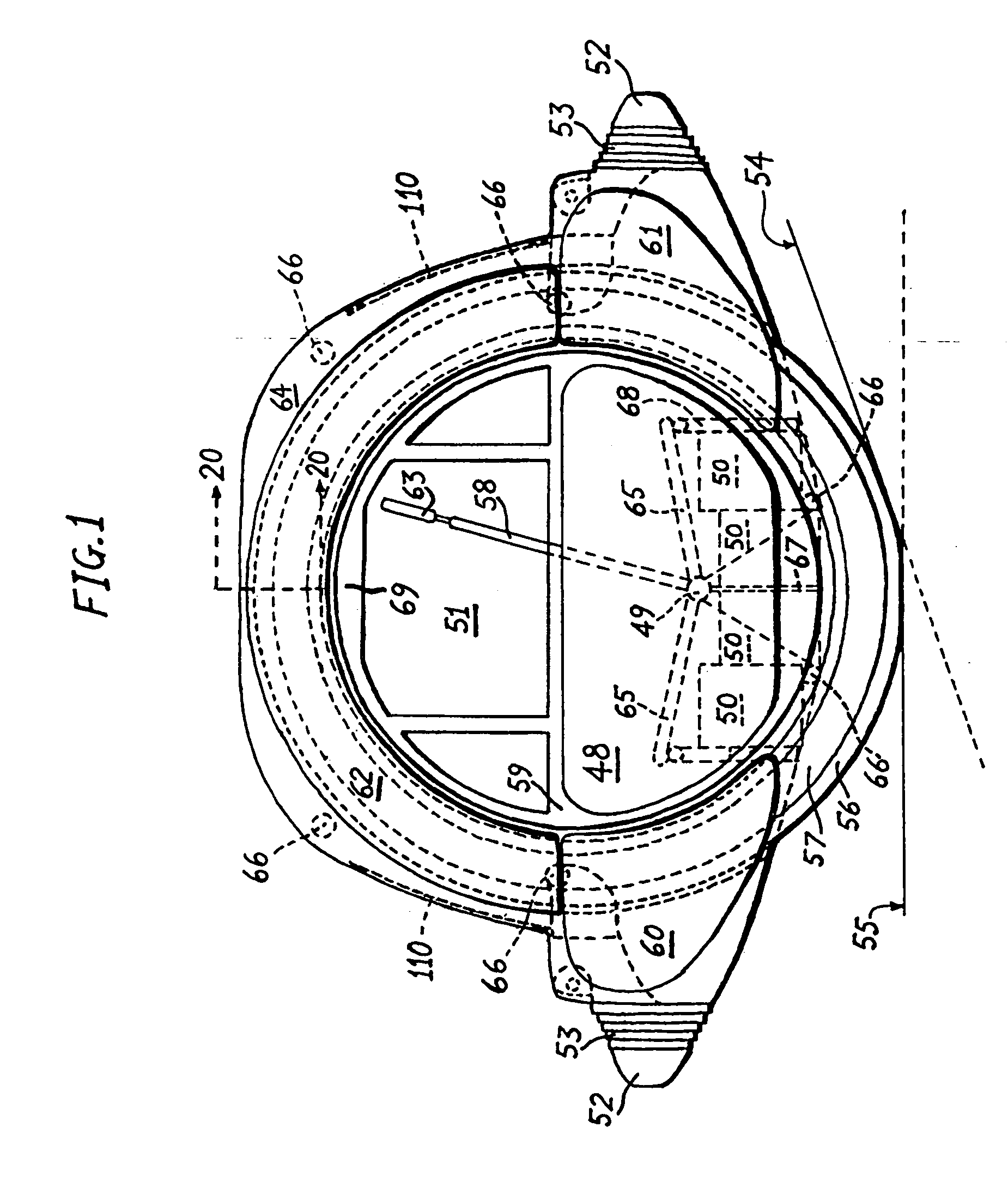

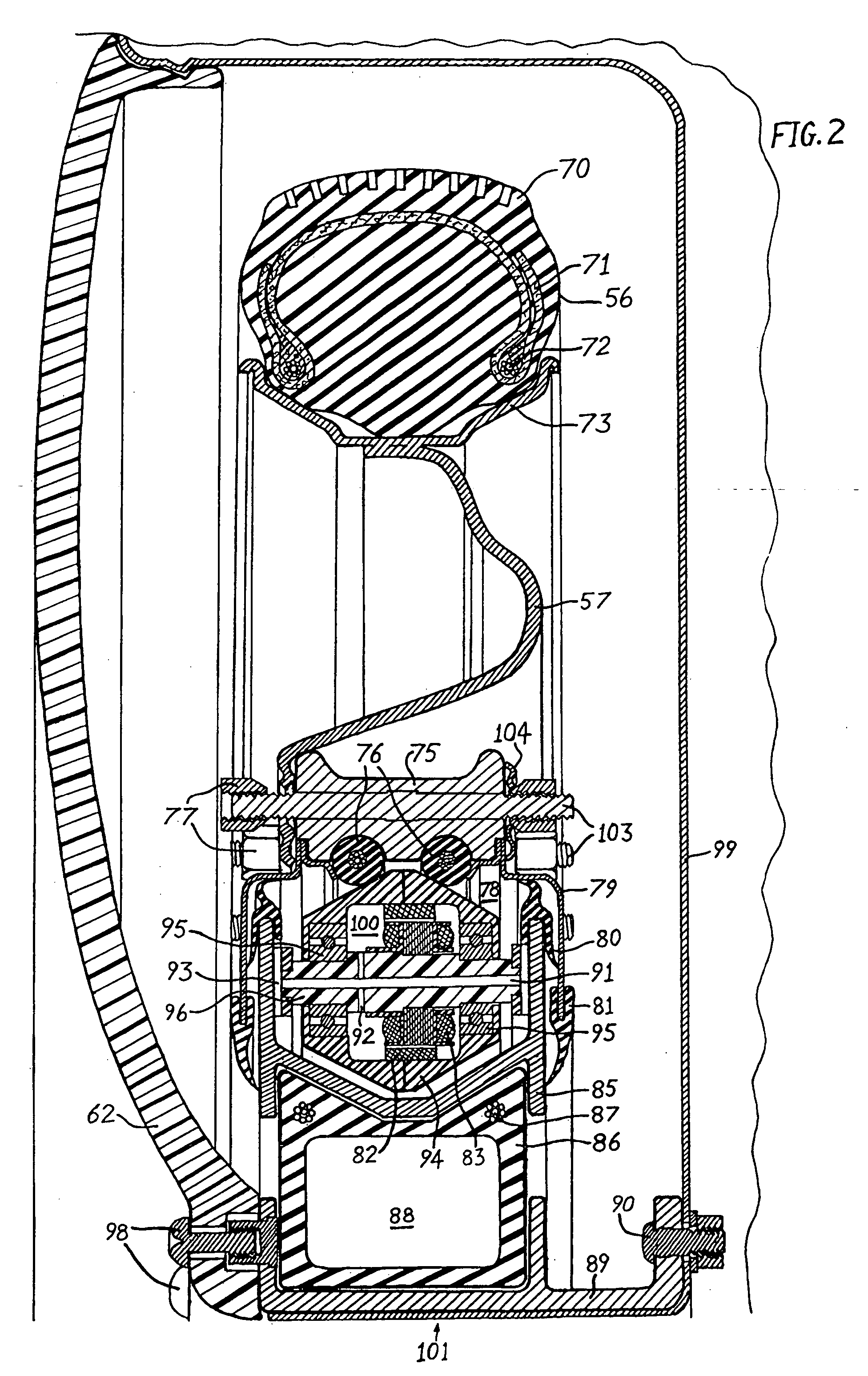

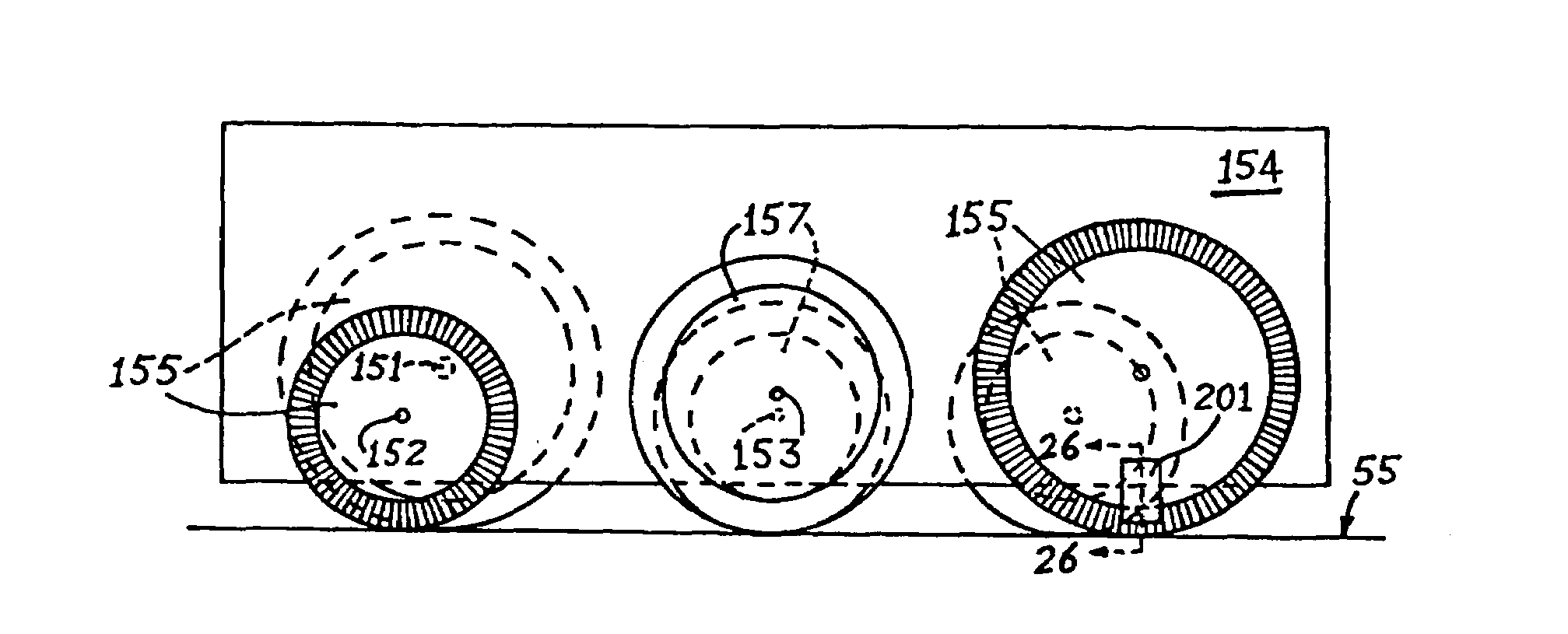

Two-parallel-wheeled electric motor vehicle with a provision for connecting electromagnetic holonomic wheels in tandem

InactiveUS20050072616A1Increase the diameterLends stability to the design—thisUnicyclesElectric propulsion mountingElectric machineEngineering

A vehicle with zero turning radius employing a minimum of two generally parallel matching annular wheels mounted with independent pneumatic toroidal suspensions fixed coaxially on a chassis. The wheels have mounted on their inner hub sides frictional linings along which run a respectively equal number of circumferentially distributed truncated-bicone-shaped rotors of brush-less dc motors with stator shafts fixed on to the axles of the wheels. Addition of a number of large holonomic wheels in tandem on either side of the two generally parallel wheels makes the vehicle longer and more stable. The large holonomic wheels have tires formed by a toroidal unanimity of disc-like rollers with magnetic or electromagnetic elements radially distributed evenly to make each disc-like roller rotate or resist rotation perpendicular to the holonomic wheel axis by acting as a rotor to motor stator windings attached to the chassis in proximity with the ground-engaging portion of the tire.

Owner:PAL ANADISH KUMAR

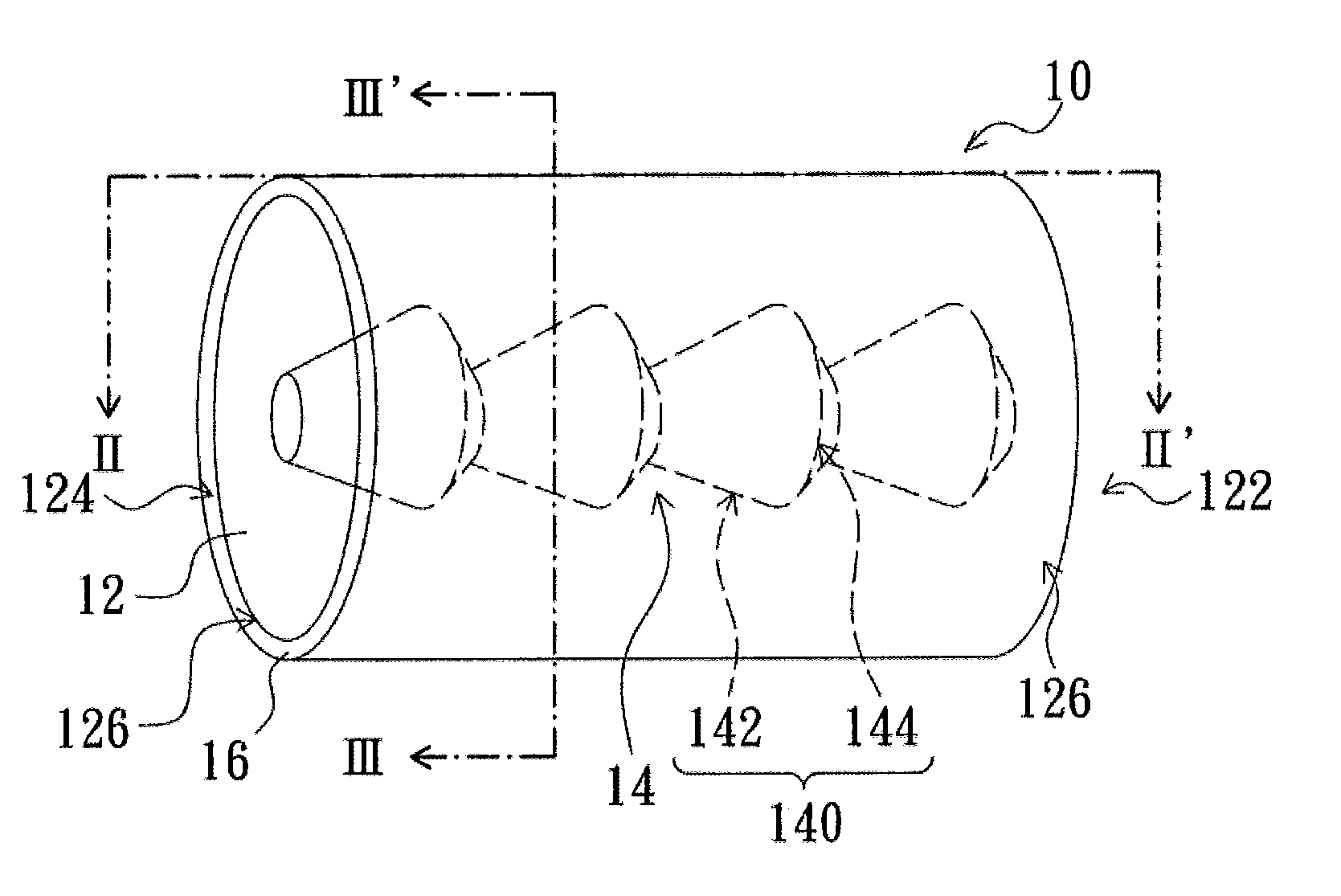

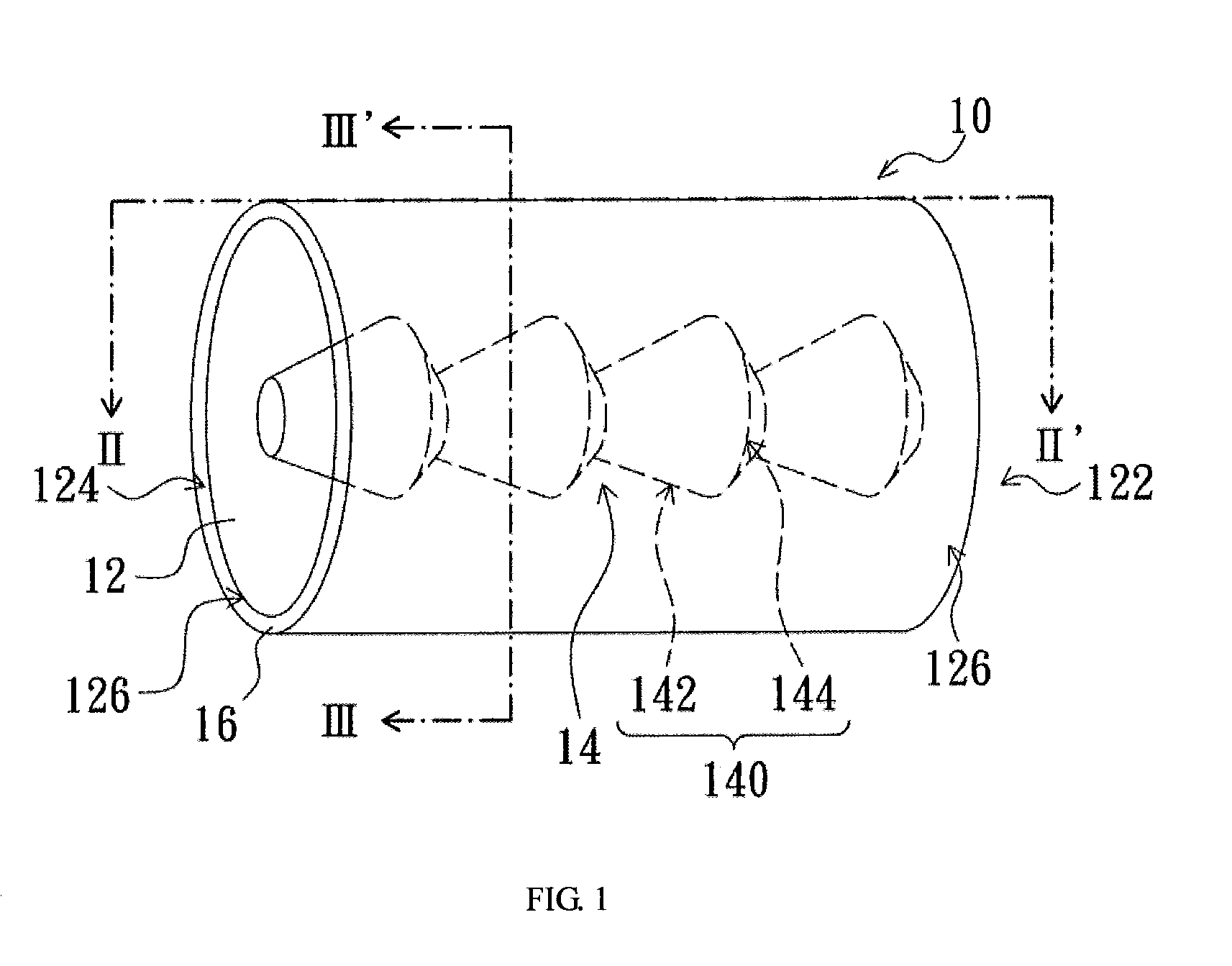

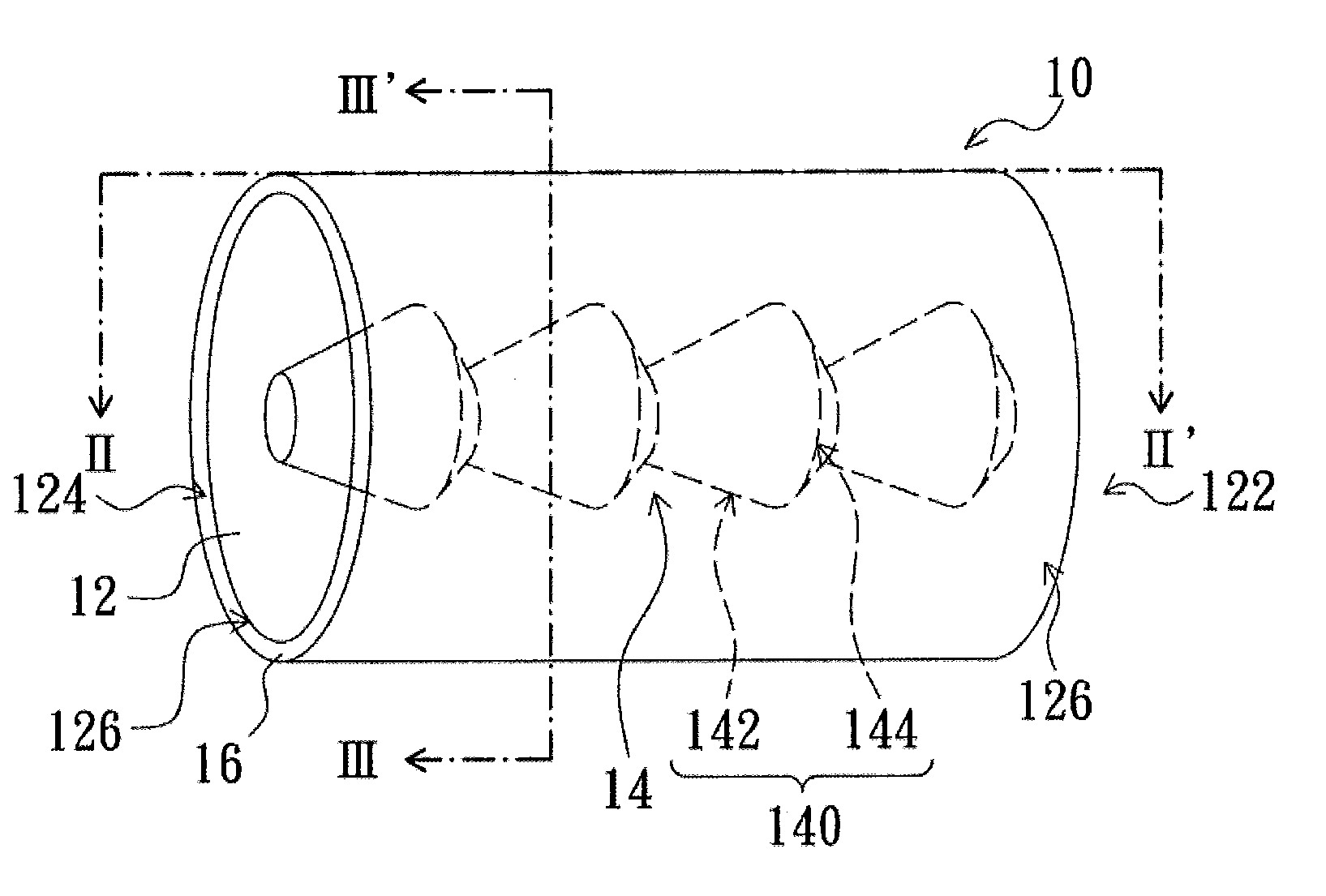

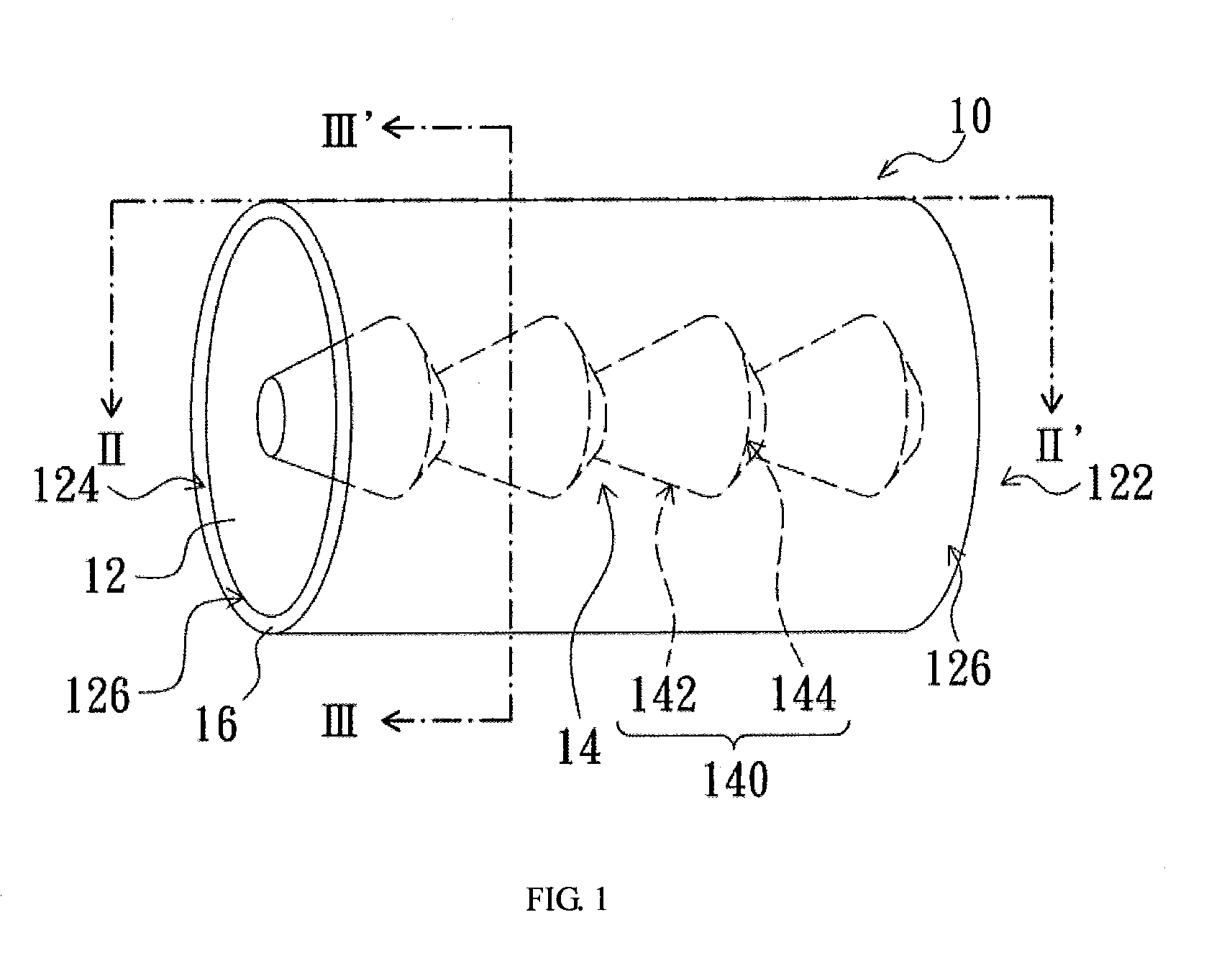

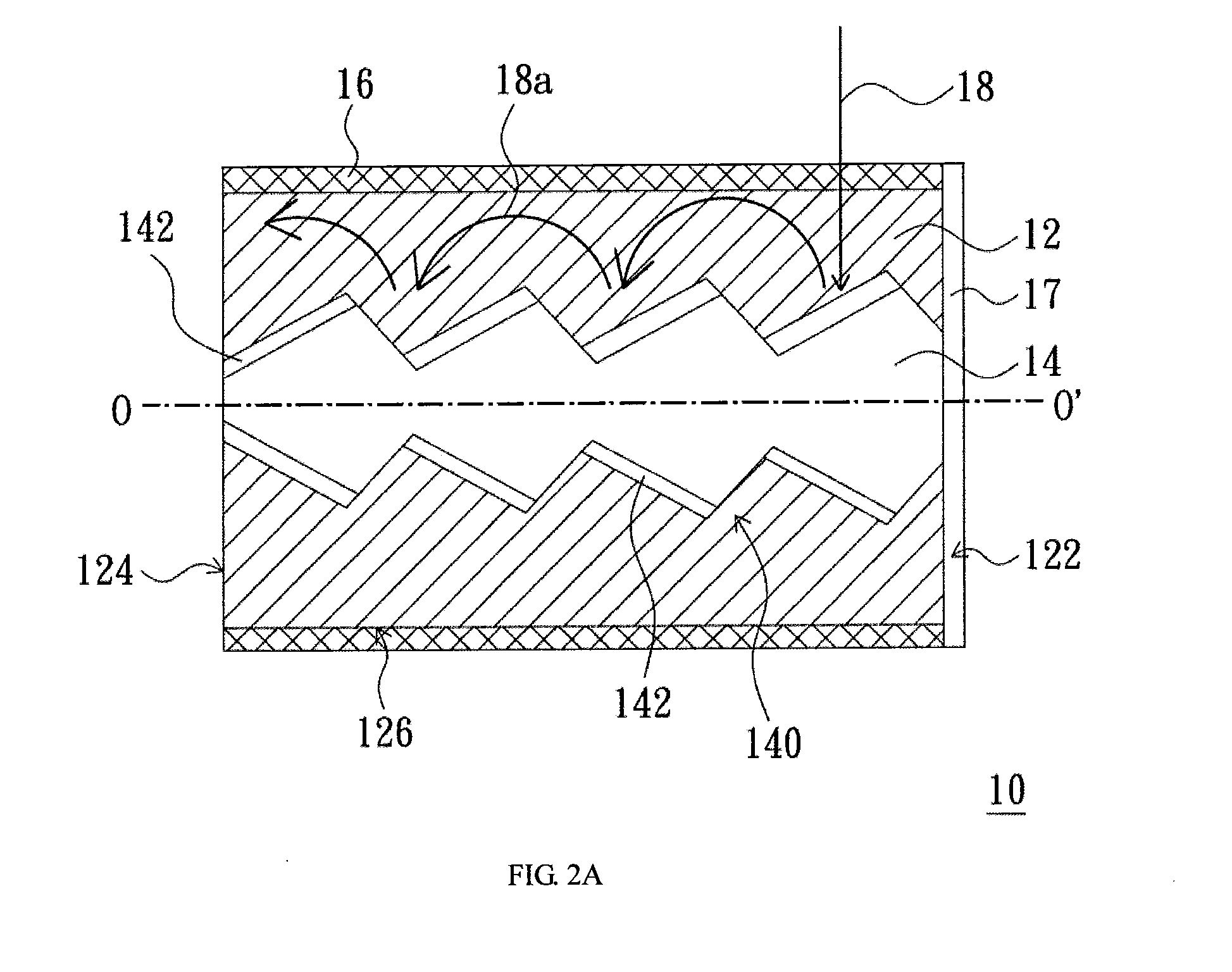

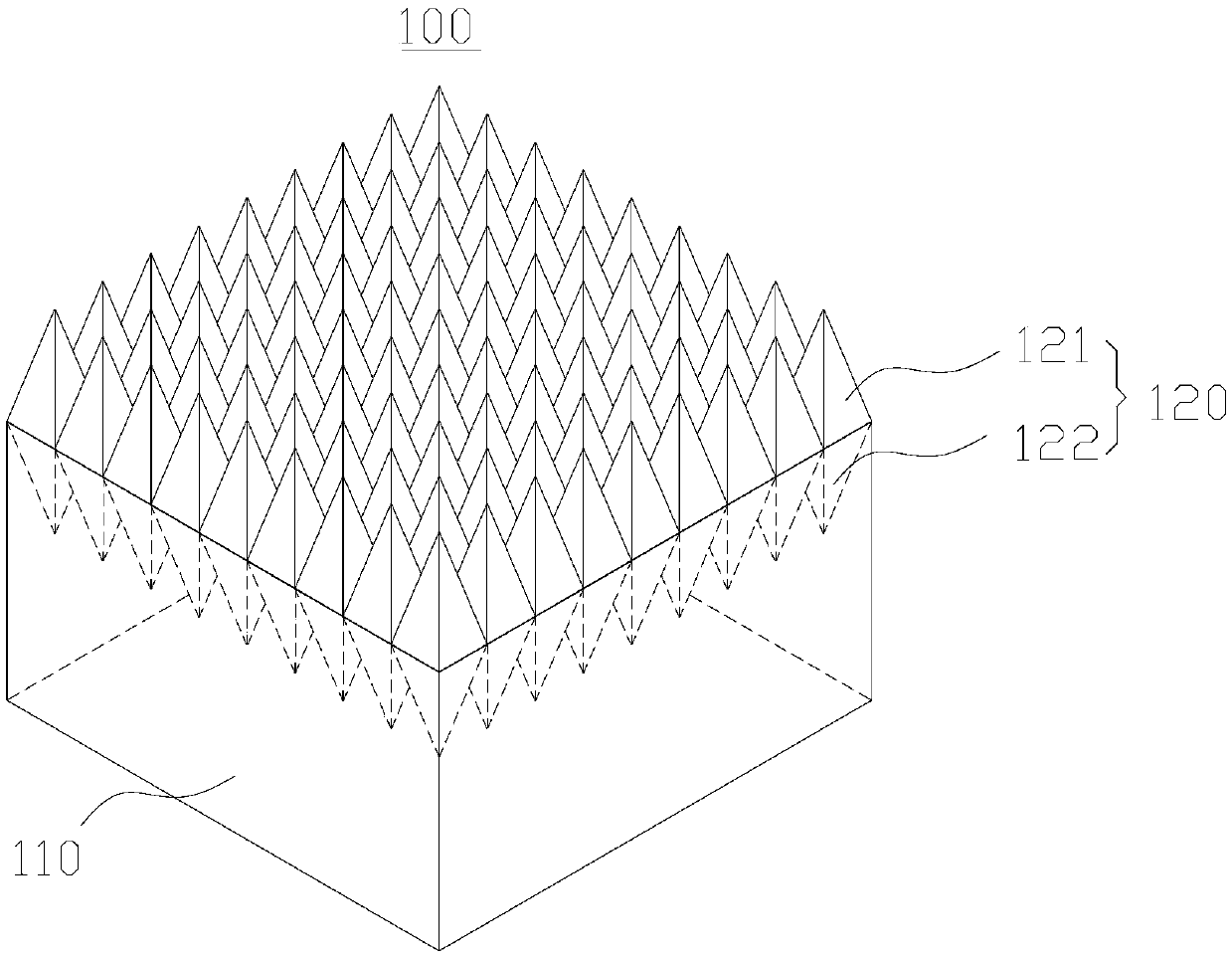

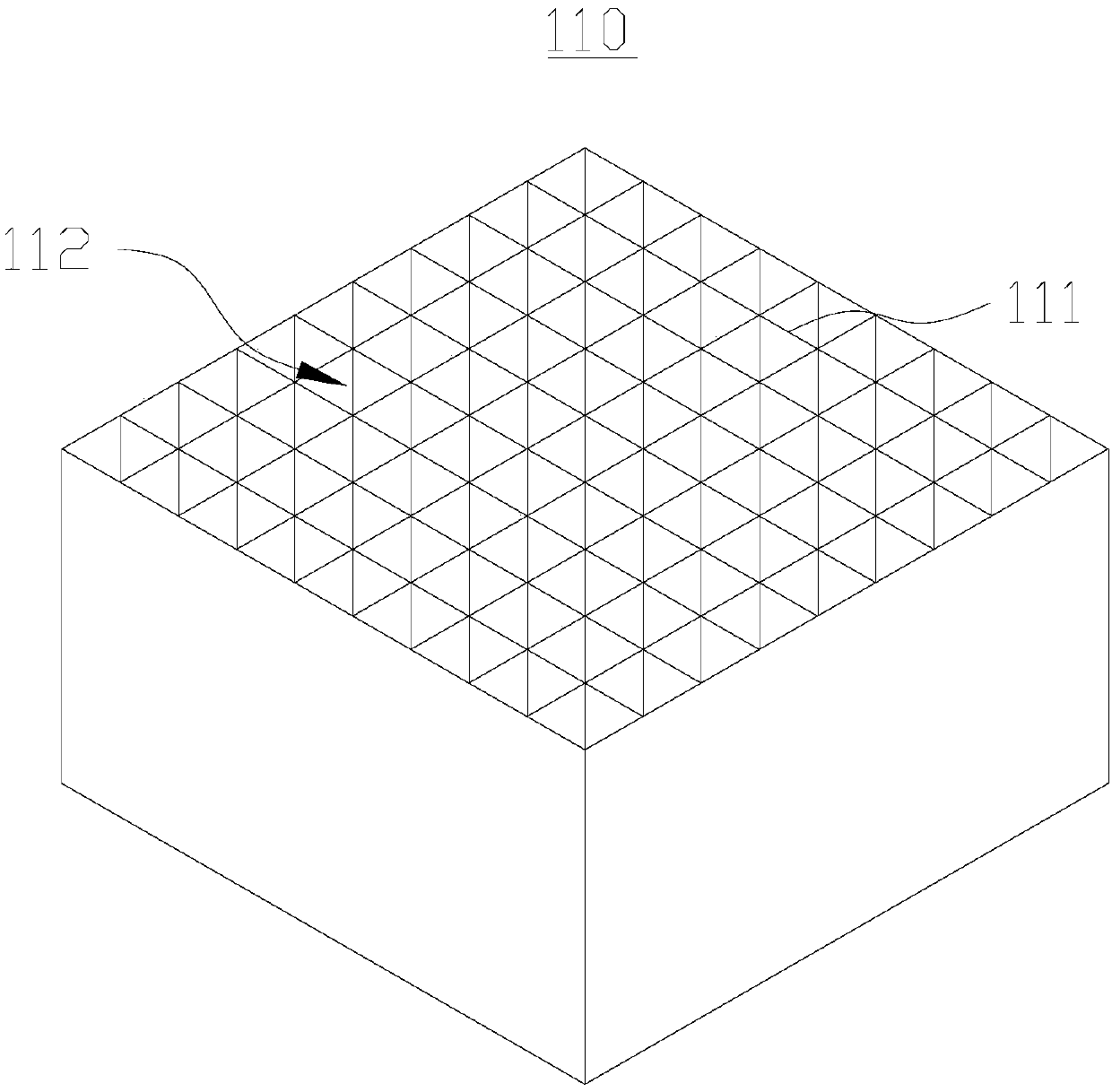

Electromagnetic wave gathering device and solar cell module having the same

ActiveUS8755665B2Lower the volumeEasy to useSolar heating energySolar heat devicesElectrical conductorElectrical battery

An electromagnetic wave gathering device includes a pillared electromagnetic waveguide body and a reflective structure. The reflective structure is located at about an axis of the pillared electromagnetic waveguide body. The reflective structure comprises a plurality of bicone reflective units. Each of the reflective units has a first reflective surface. The electromagnetic wave gathering device may have a smaller volume and is handy for use.

Owner:EPISTAR CORP

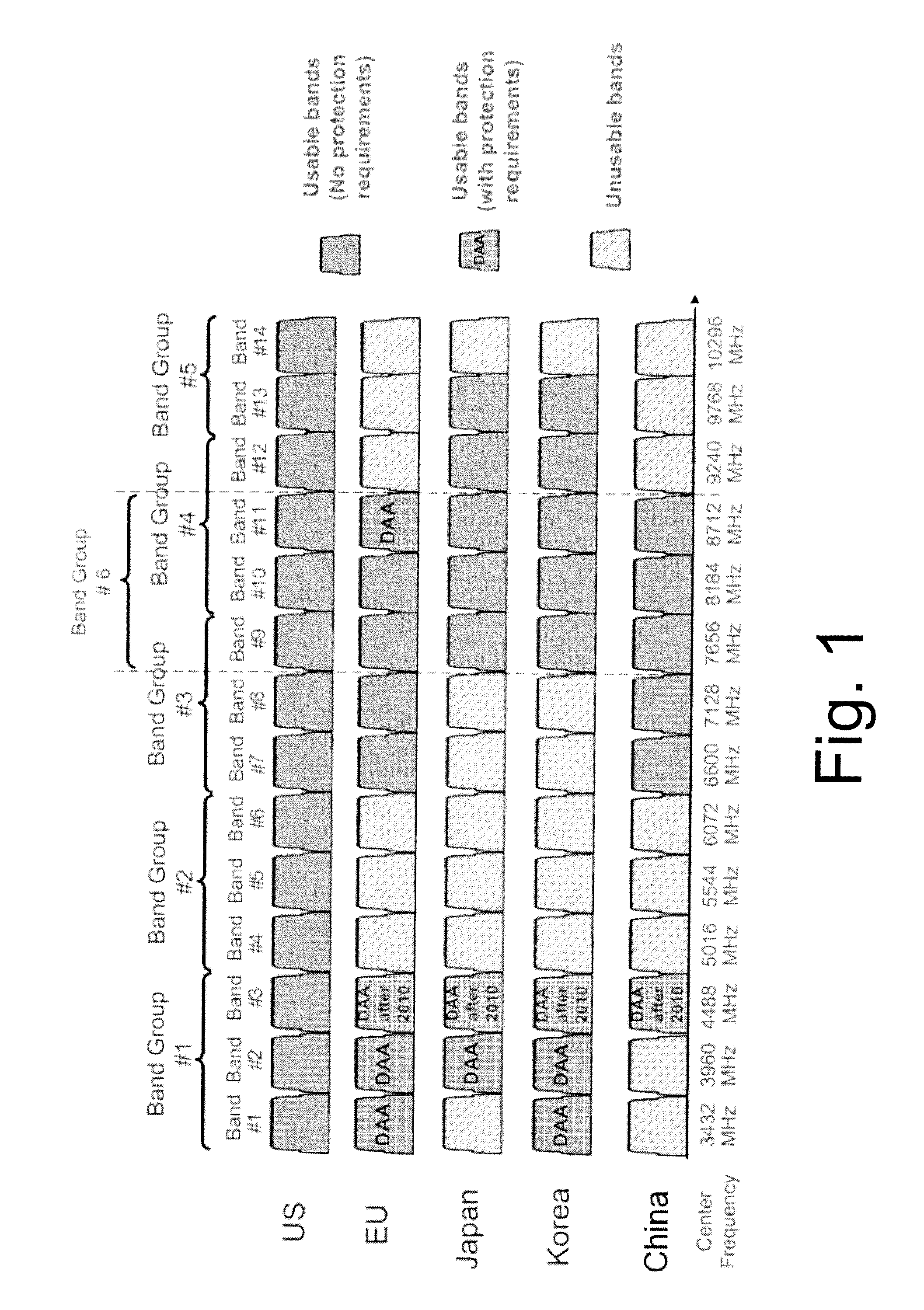

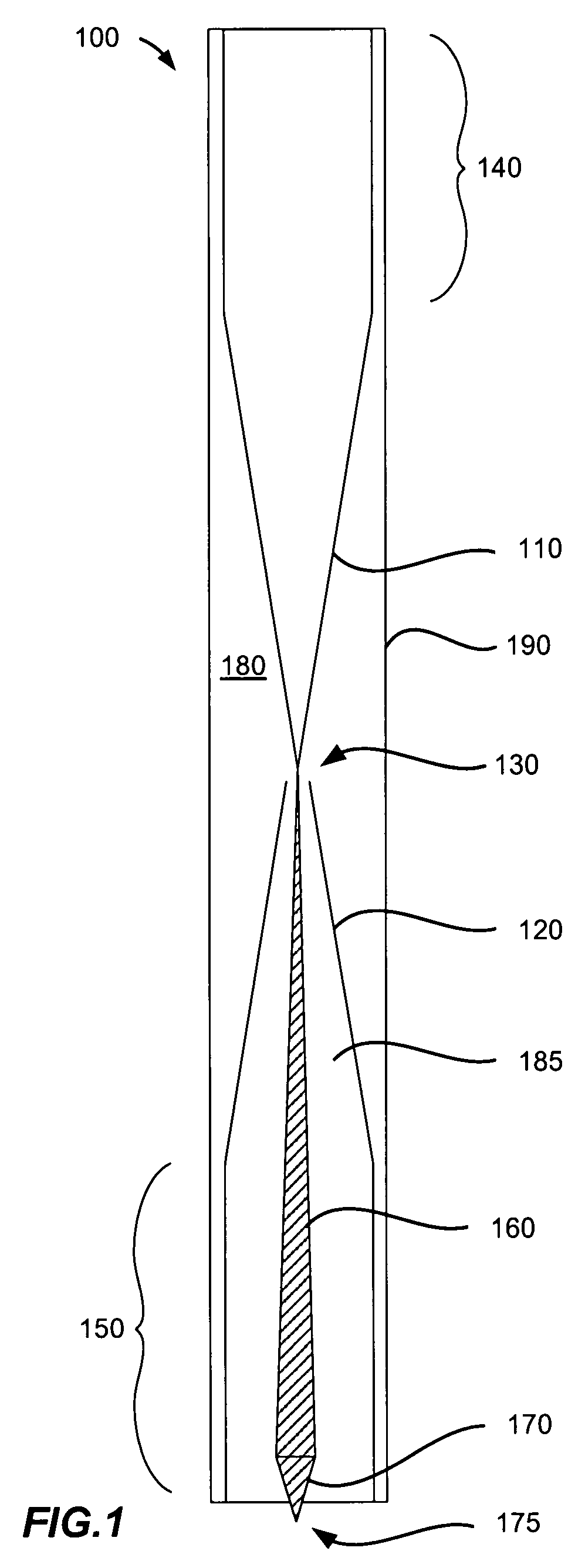

VSWR improvement for bicone antennas

InactiveUS20080186243A1Improved VSWR performanceEnhanced couplingWaveguide hornsAntenna feed intermediatesRadio frequency energyEngineering

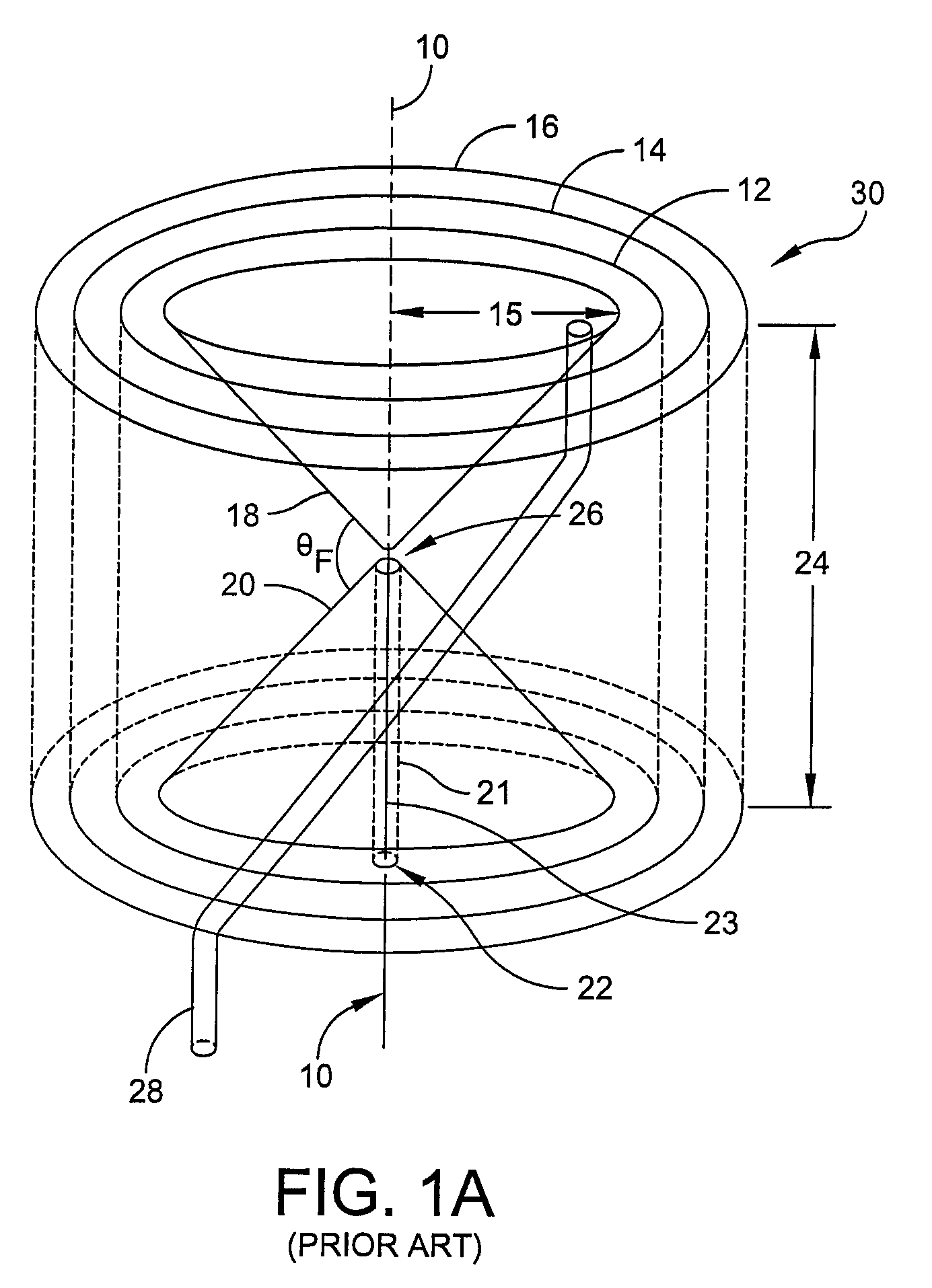

A broadband bicone antenna system supports improved VSWR operation of a high-impedance bicone antenna having a reduced aperture size, high input impedance at the central vertex of the cones, one or more pattern tuning filters associated with the cones, and input filtering for frequency selective impedance matching. Pattern tuning filters can improve the radiation pattern at different frequencies by controlling the electrical length of the antenna in response to the frequency components of the associated wideband signal. Impedance matching input filters can improve the signal matching to couple radio frequency energy into the antenna system from a feed line. Mutual tuning of the pattern tuning filters; the impedance matching input filters; and the impedance of the bicone antenna itself can improve the overall voltage standing wave ratio (VSWR) performance of the bicone antenna system over a broad range of operating frequencies.

Owner:EMS TECHNOLOGIES

Time domain radio transmission system

InactiveUS20050017894A1Improve securityFast repetition rateModulated-carrier systemsIndividually energised antenna arraysTime domainCommunications system

A time domain communications system wherein a broadband of time-spaced signals, essentially monocycle-like signals, are derived from applying stepped-in-amplitude signals to a broadband antenna, in this case, a reverse bicone antenna. When received, the thus transmitted signals are multiplied by a D.C. replica of each transmitted signal, and thereafter, they are, successively, short time and long time integrated to achieve detection.

Owner:TIME DOMAIN

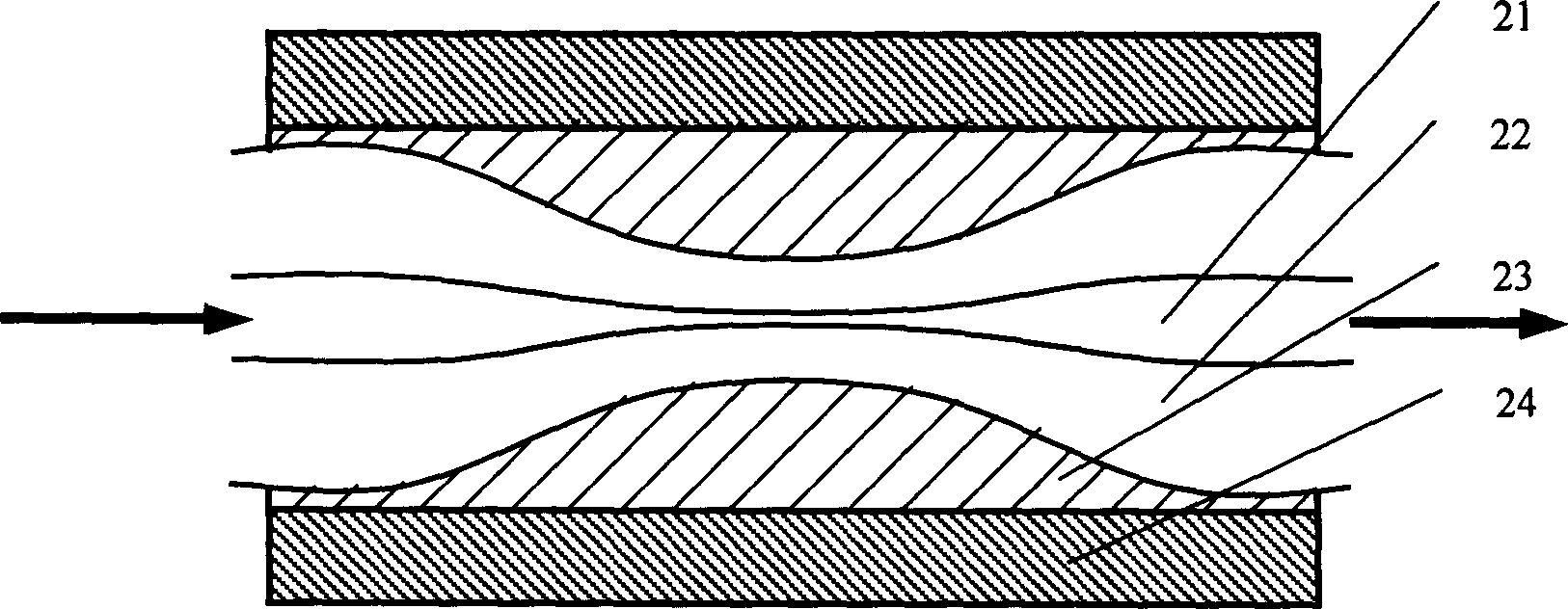

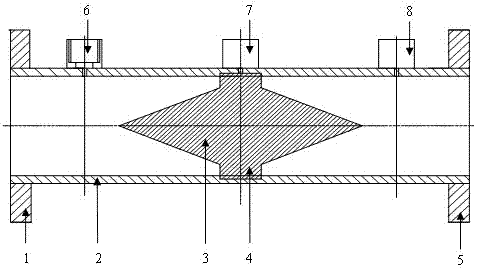

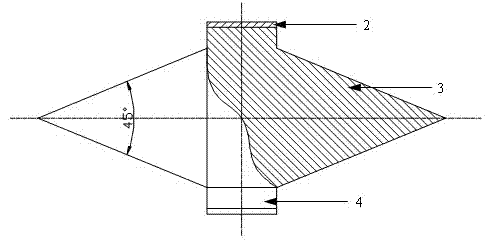

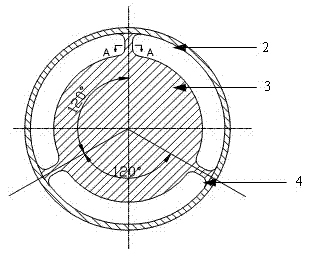

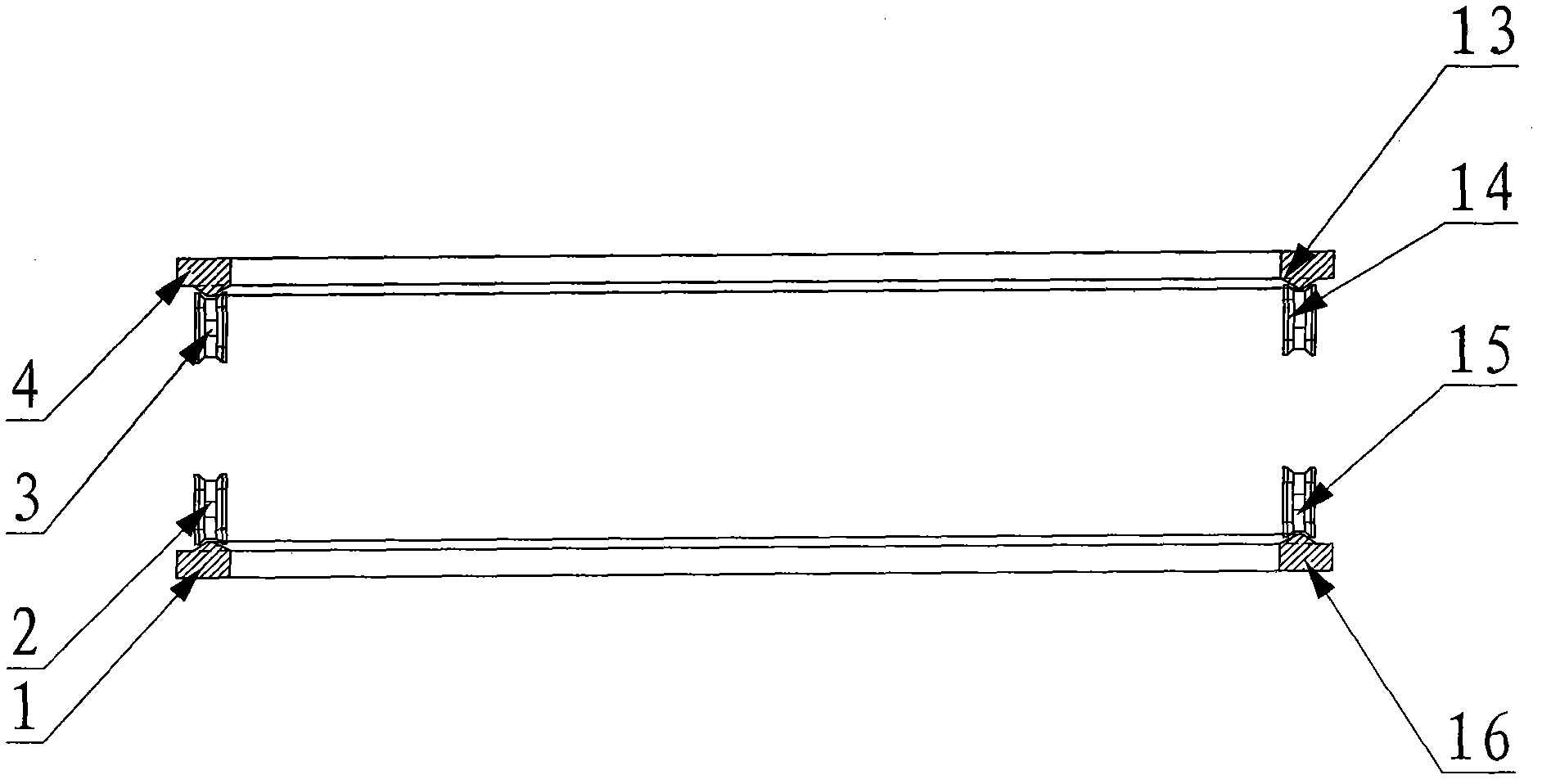

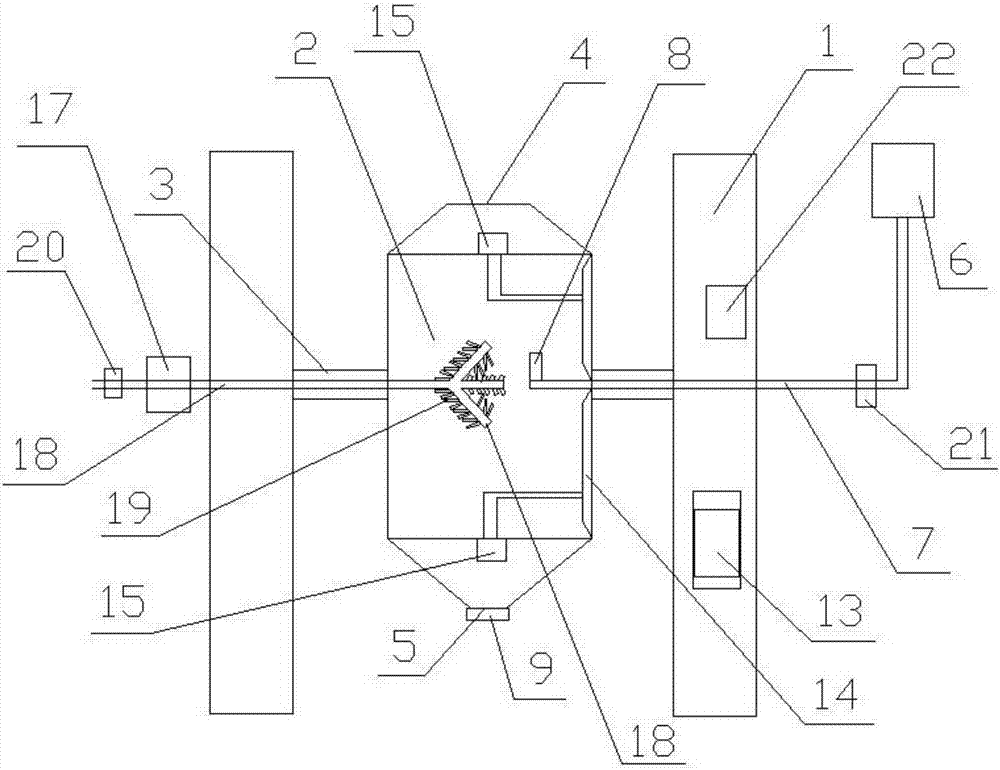

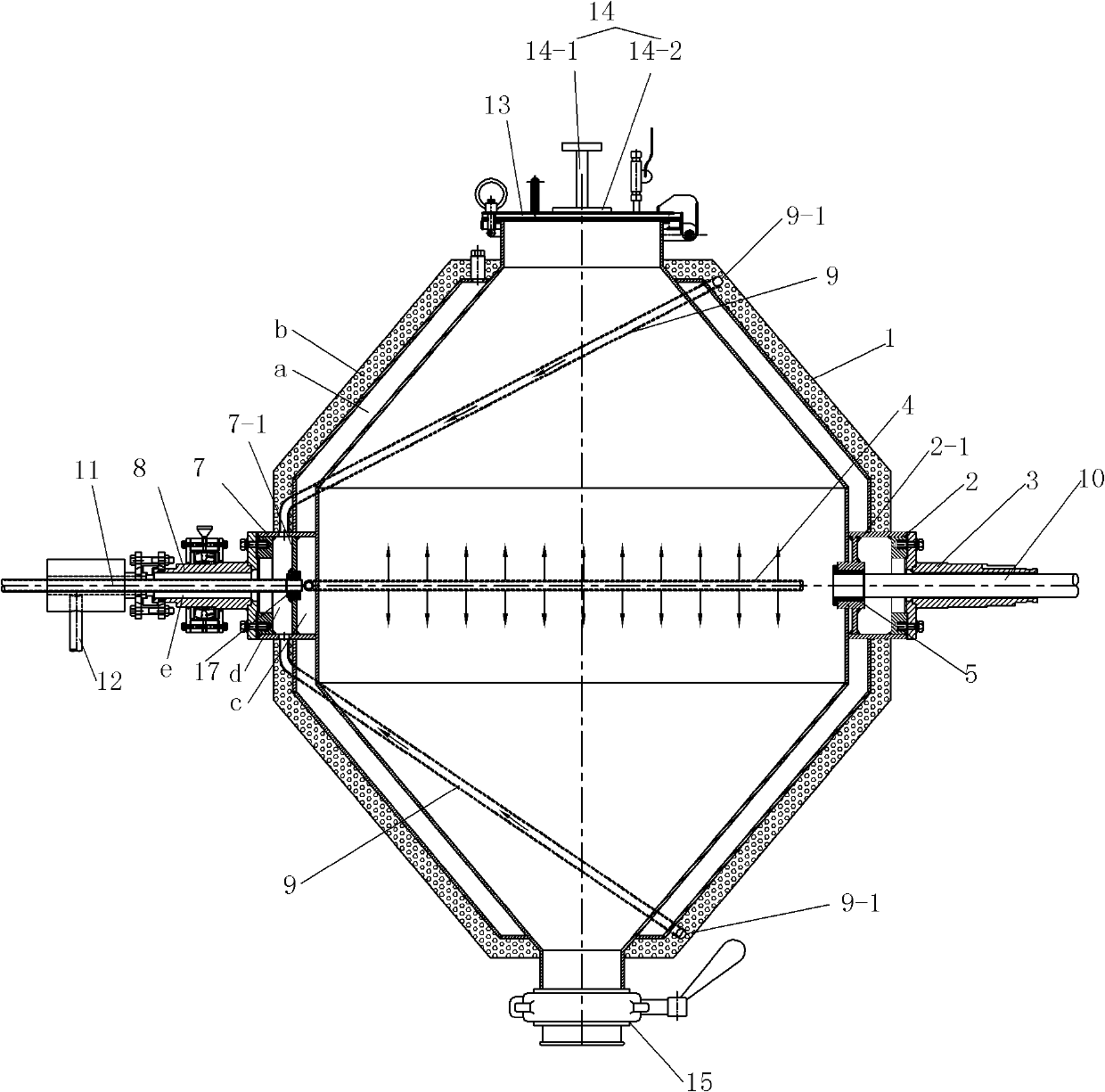

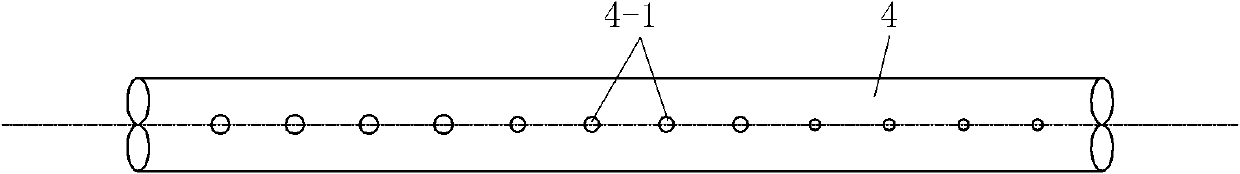

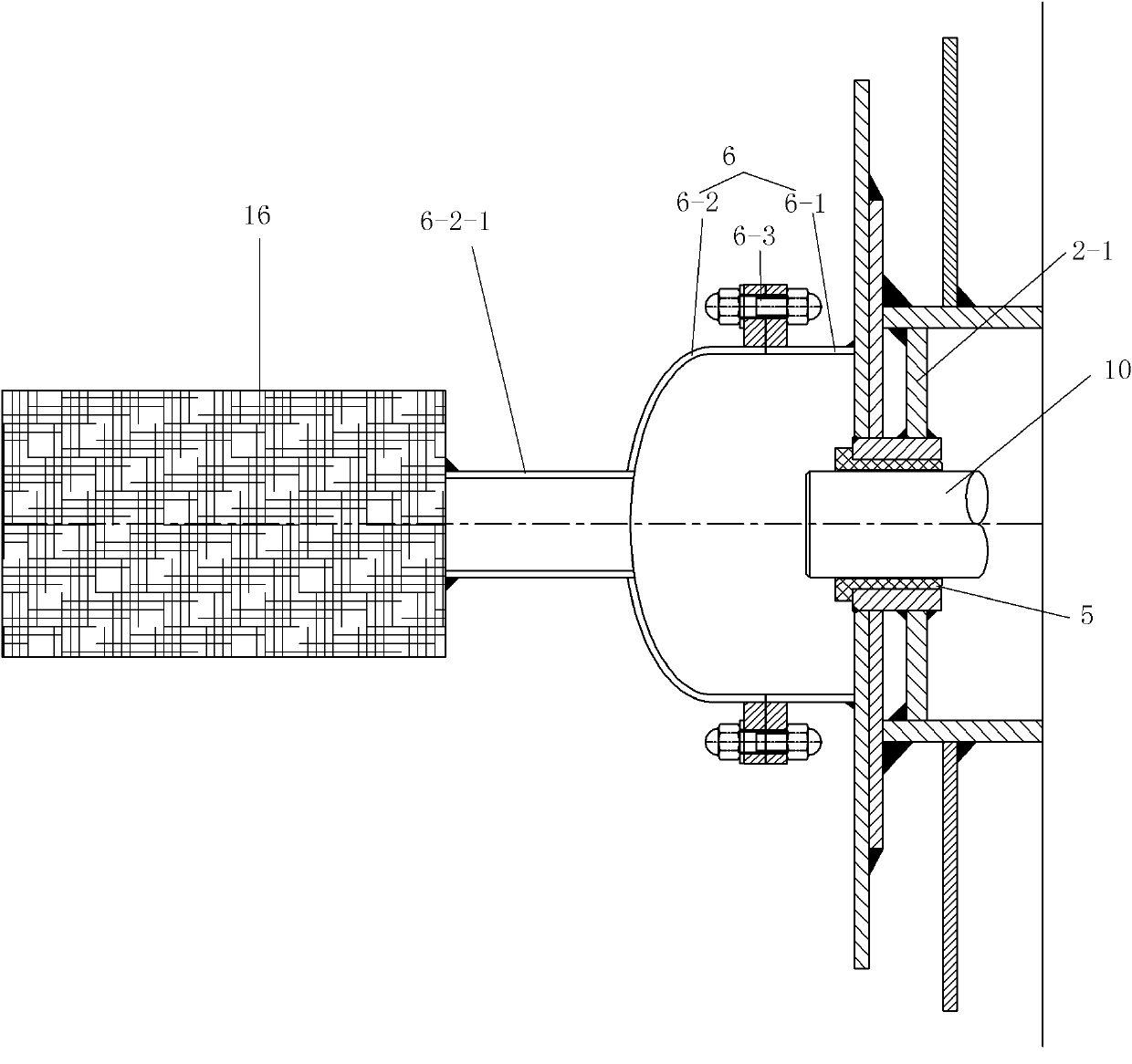

Full-symmetry double-cone flowmeter

InactiveCN102928028AShock resistanceHigh sensitivityVolume/mass flow by differential pressureDifferential pressureEngineering

The invention discloses a full-symmetry double-cone flowmeter. The full-symmetry double-cone flowmeter comprises a straight measurement pipe and a double-cone body, wherein an upstream pressure-taking port, a throat pressure-taking port and a downstream pressure-taking port are sequentially formed in the same axial section of the straight measurement pipe; the double-cone body consists of cone bodies at two ends and a middle cylinder body; three support column plates with the same thickness are arranged on the middle cylinder body at equal intervals along the circumference direction, and the length of each support column plate is equal to that of the middle cylinder; the double-cone body is coaxially arranged in the straight measurement pipe; the throat pressure-taking port is positioned between the two support column plates of the double-cone body and also positioned in the middle of the length of the double-cone body; and the cylinder part of the double-cone body is closely matched with the straight measurement pipe. The full-symmetry double-cone flowmeter can acquire a stable discharge coefficient under high Reynolds number, and has the characteristics of causing small pressure loss, being good in repeatability, requiring a short straight pipe section and the like. Double-differential pressure signals obtained by the three pressure-taking ports also can be applied to two-phase flow parameter measurement.

Owner:ZHEJIANG MEASUREMENT SCI RES INST

Time domain radio transmission system

InactiveUS20050242983A1Improve securityFast repetition rateDetection using electromagnetic wavesRadio wave reradiation/reflectionTime domainCommunications system

A time domain communications system wherein a broadband of time-spaced signals, essentially monocycle-like signals, are derived from applying stepped-in-amplitude signals to a broadband antenna, in this case, a reverse bicone antenna. When received, the thus transmitted signals are multiplied by a D.C. replica of each transmitted signal, and thereafter, they are, successively, short time and long time integrated to achieve detection.

Owner:TIME DOMAIN

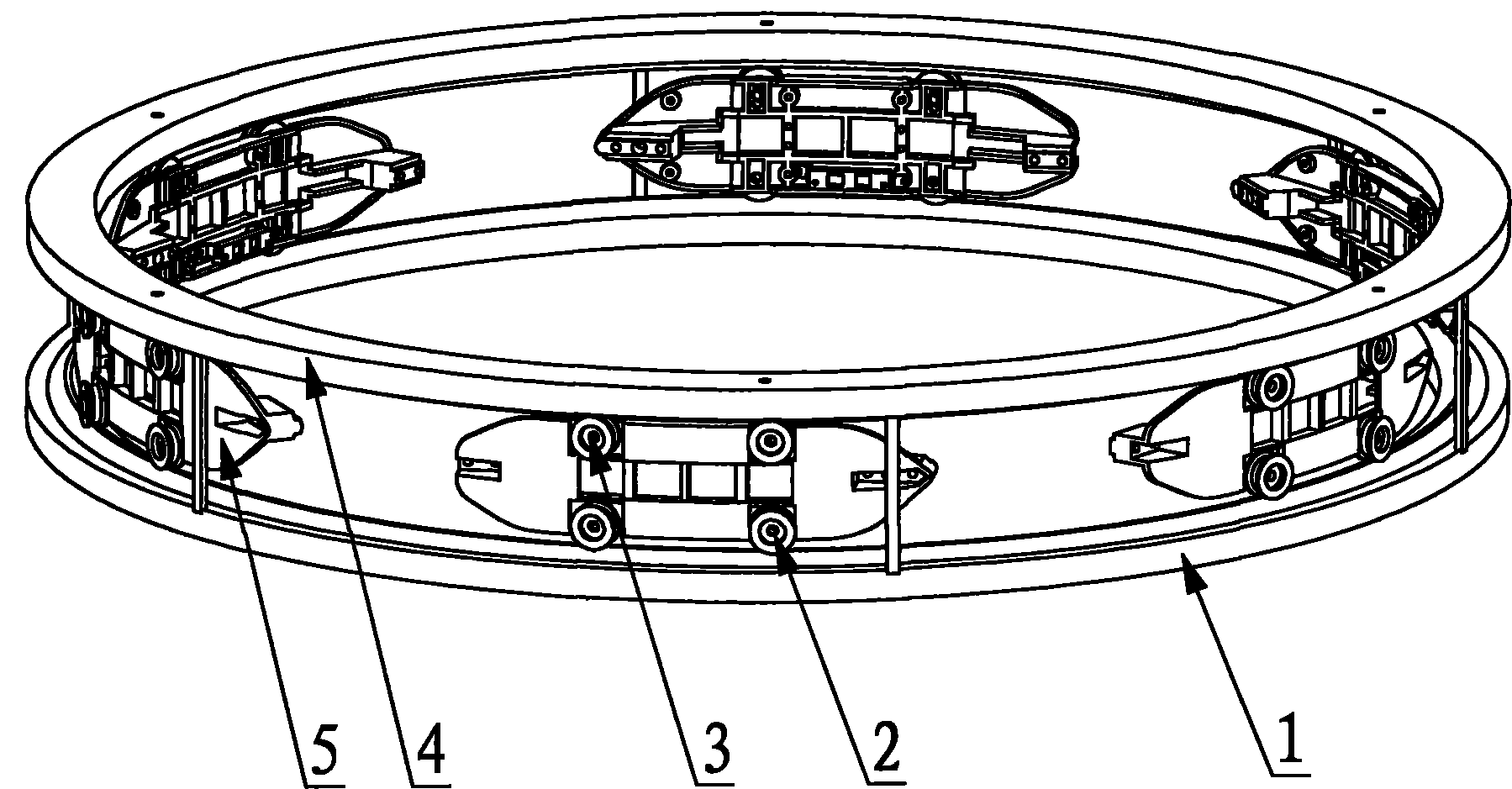

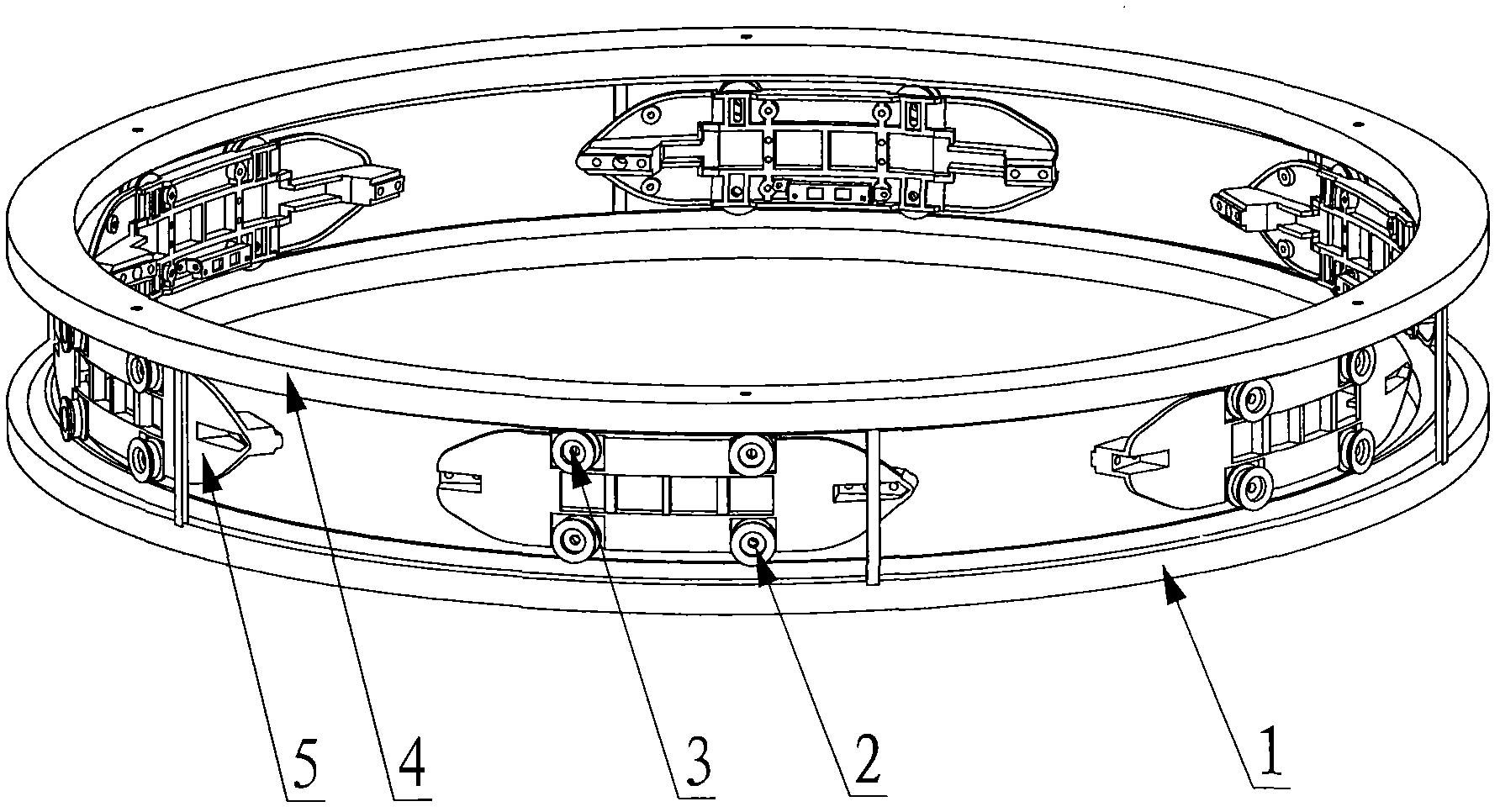

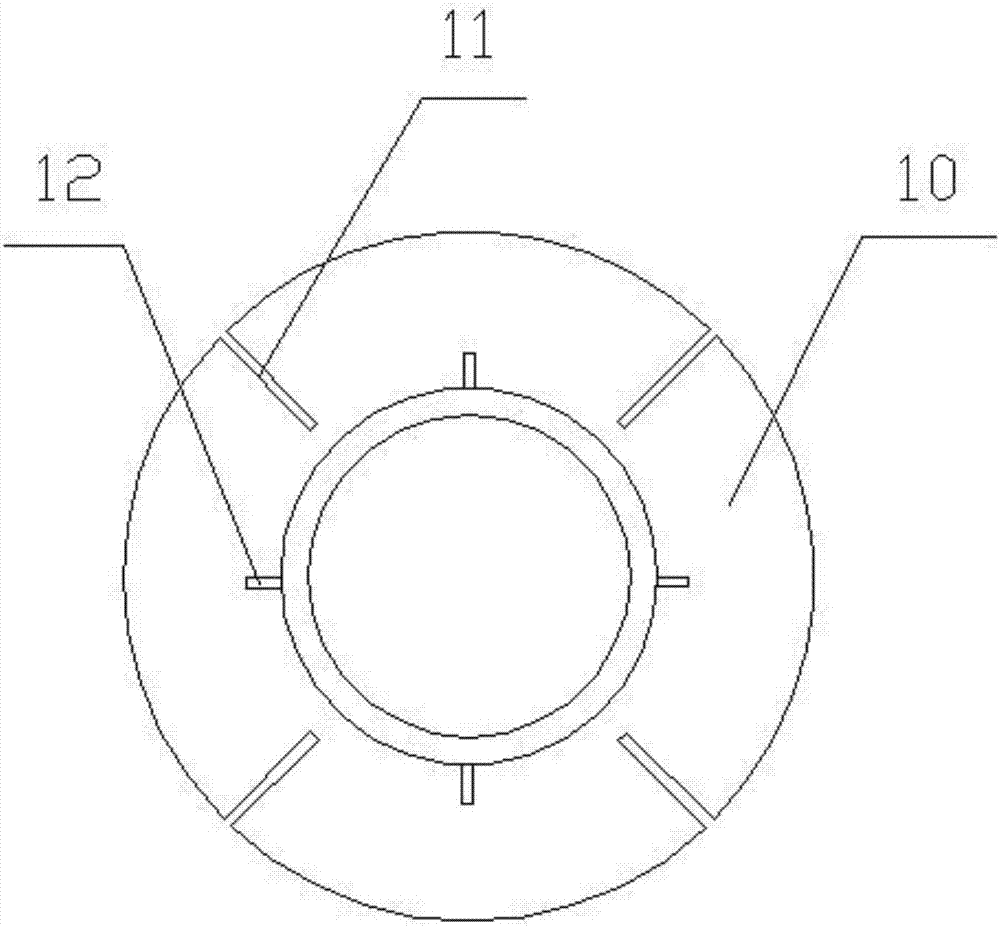

Concave shuttle wheel and double conical surface orbit structure of circular weaving machine

The invention relates to the field of plastic machinery, in particular to a concave shuttle wheel and double conical surface orbit structure of a circular weaving machine. The structure comprises a lower door ring, lower concave shuttle wheels, upper concave shuttle wheels, an upper door ring and a shuttle boat body, and the structure is characterized in that the lower edge of the upper door ring is designed into a double conical surface, the upper edge of the lower door ring is designed into a double conical surface, the shuttle boat body is arranged between the upper door ring and the lower door ring, the shuttle boat body is provided with four concave shuttle wheels, the two lower concave shuttle wheels and the double conical surface of the lower door ring are in rolling contact, the two upper concave shuttle wheels and the double conical surface of the upper door ring are in the rolling contact, and the concave shuttle wheels bear the centrifugal force of a whole shuttle when in operation to prevent shuttle flying. According to the invention, the defects of the shuttle boat and orbit structure on the circular weaving machine adopted at present are overcome, the operation is stable, the fault is less, the noise is low, quick-wear parts are less, the cost is low, and the electricity can be saved.

Owner:黄美昌 +2

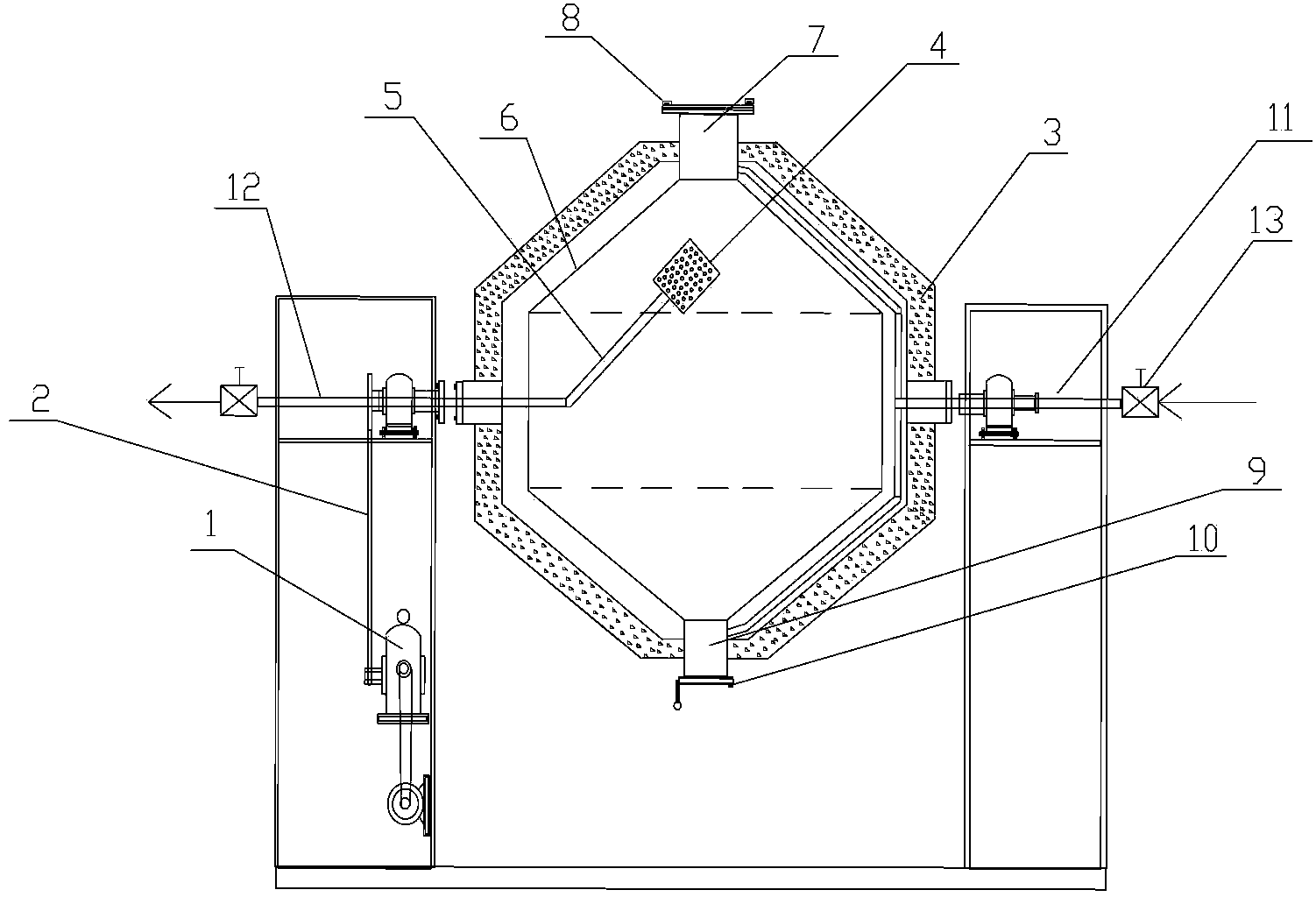

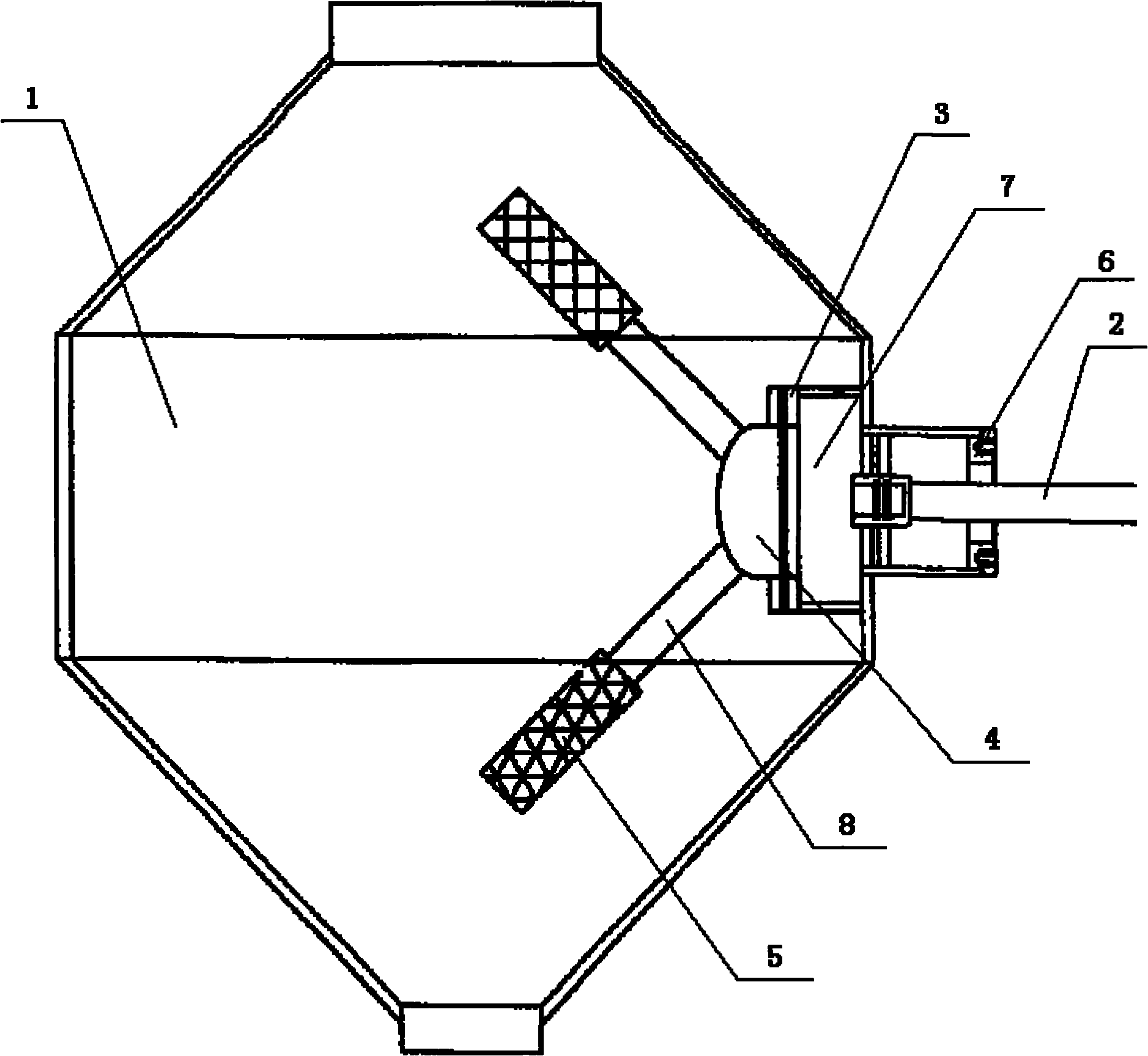

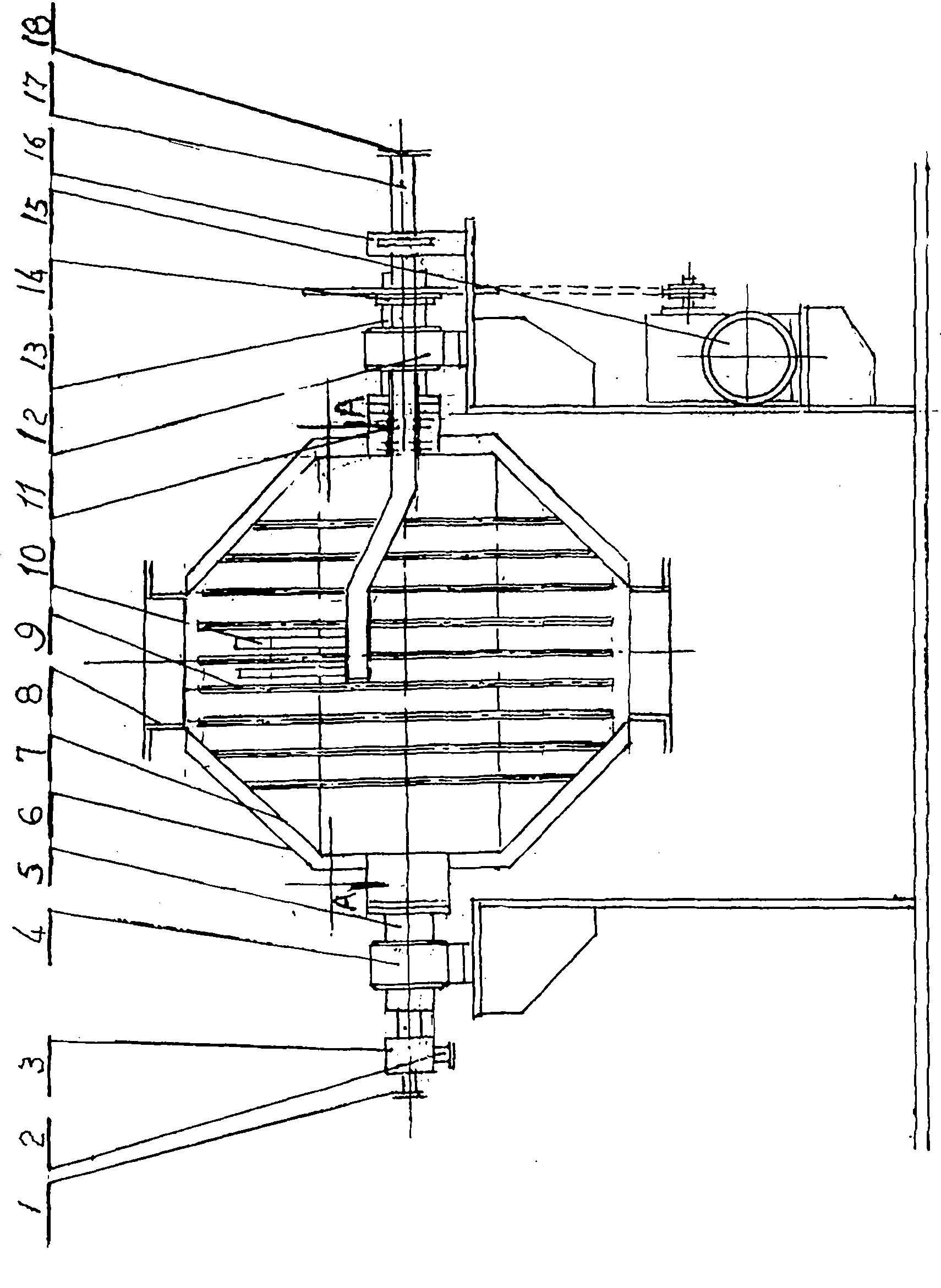

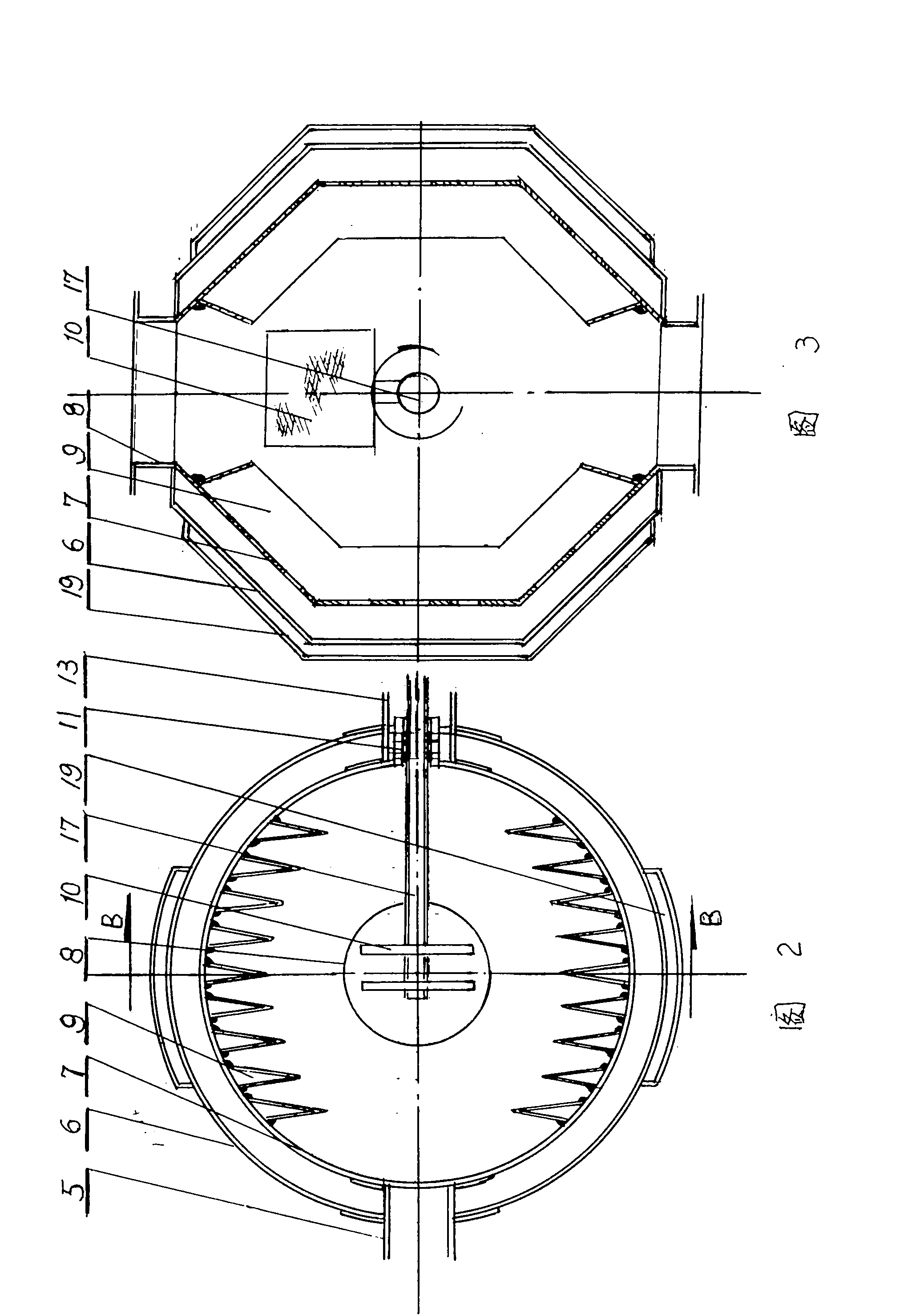

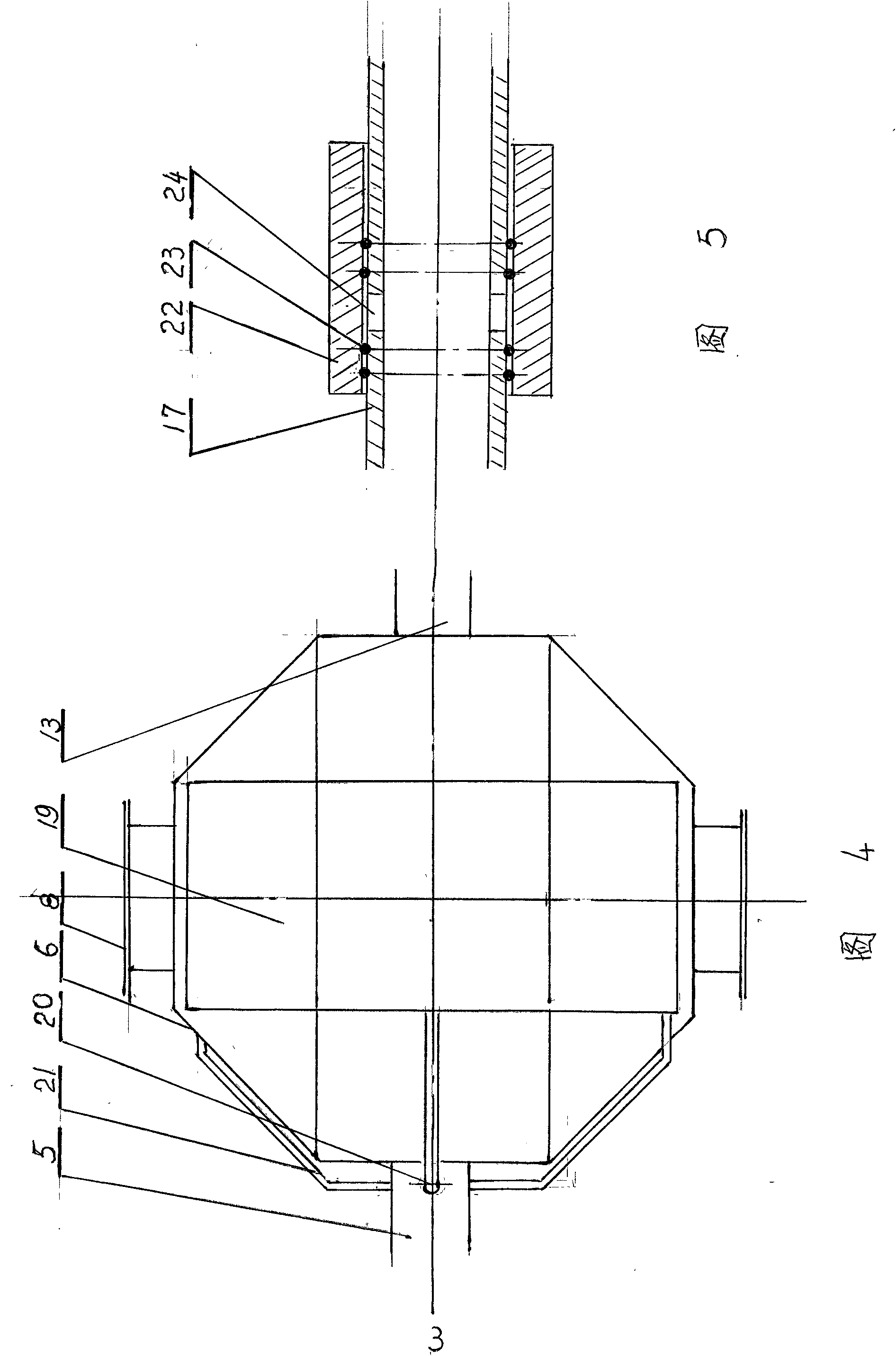

Bipyramid rotation vacuum drier

InactiveCN103411401AReduce pollutionSave manpower and material resourcesDrying gas arrangementsDrying chambers/containersEnamel structureBicone

The invention discloses a bipyramid rotation vacuum drier. The bipyramid rotation vacuum drier comprises a pot body, a stirring motor, a thermal resistor, a vacuum cover and a pipe opening, wherein the pot body is composed of the interlayer outer wall and the interlayer inner wall, the inner wall of the pot body is the enamel inner wall, and a feed port of the pot body and a discharge port of the pot body are provided with a feed valve and a discharge valve respectively. Preferably, a steam electromagnetic valve can be arranged in a steam inlet. By means of the technical scheme, the pressure inside a pot can range from -0.09Mpa to 0.096Mpa. The bipyramid rotation vacuum drier has the functions of reacting, concentrating, crystallizing, washing, filtering, centrifugating, drying and the like, the technological processes can be finished on one device, and pollution produced in the process of transshipment of materials is reduced. Meanwhile, labor and materials in the process of operation are saved, and the safety of the production process is improved. The inner wall structure is of an enamel structure, so that the bipyramid rotation vacuum drier is washed more easily. Due to the fact that the feed valve and the discharge valve are arranged, the sealing performance inside the pot can meet the demand of the designed pressure.

Owner:NANJING TENGFEI DRYING EQUIP

Time domain radio transmission system

InactiveUSRE41479E1Improve securityFast repetition rateFrequency/rate-modulated pulse demodulationSecret communicationTime domainCommunications system

A time domain communications system wherein a broadband of time-spaced signals, essentially monocycle-like signals, are derived from applying stepped-in-amplitude signals to a broadband antenna, in this case, a reverse bicone antenna. When received, the thus transmitted signals are multiplied by a D.C. replica of each transmitted signal, and thereafter, they are, successively, short time and long time integrated to achieve detection.

Owner:TIME DOMAIN

Bicone antenna

InactiveUS8576135B1High bandwidthBeneficial return loss performanceSimultaneous aerial operationsAntenna supports/mountingsHigh bandwidthGround plane

A bicone antenna is provided with high bandwidth and beneficial return loss performance. The antenna is dipole based and thus its radiation pattern is not strongly influenced by shape and size of a nearby ground plane. A parasitic element comprising a conductive band encircling the antenna's feed structure improves matching, gain flatness, and makes the antenna less susceptible to detuning.

Owner:OLYMPUS CORP

Zero degree grid antenna

A vertically polarized dipole or bicone antenna is positioned cylindrically with in many cylindrical layers of polarizing grids that slowly rotate the incident field to cross 0 degrees, i.e., 90 degrees to the horizon, and to attenuate or minimize the effects of gain nulls from reflections off of the innermost grid layer. Such an antenna is used for detecting both horizontal and vertical polarized signals over a broad bandwidth whereby the response to both polarizations is equal.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Multipurpose motor vehicle with two coaxial parallel wheels and more electromagnetic holonomic wheels in tandem

InactiveUS7284628B2Increase the diameterLends stability to the design—thisUnicyclesElectric propulsion mountingEngineeringConductor Coil

Owner:PAL ANADISH KUMAR

Double-cone rotation vacuum drier internally provided with water spray pipes and scrapers

InactiveCN106918199ASimple structureDesign scienceDrying solid materials without heatDrying chambers/containersElectric machinerySpray nozzle

The invention discloses a double-cone rotation vacuum drier internally provided with water spray pipes and scrapers. The problems that a drying device in the prior art is troublesome to clean, has potential safety hazards and is troublesome to use are solved. The double-cone rotation vacuum drier comprises a supporting frame, a double-cone-shaped drier body provided with a feed port and a discharge port, a rotating shaft, a vacuum pump, a vacuum filter pipe, a filter head, a discharge device, a drive motor, the two scrapers making slide contact with the inner wall of the double-cone-shaped drier body, scraper motors arranged on the portions, located at the positions of the feed port and the discharge port, of the double-cone-shaped drier body, a cleaning device arranged in the double-cone-shaped drier body, a vacuum pump electromagnetic valve used for opening and closing the vacuum pump, and a controller used for controlling the vacuum pump electromagnetic valve to be opened and closed. The discharge device comprises a discharge circular ring provided with an inner ring and an outer ring, screw grooves formed around the outer ring, and bag fixing strips arranged around the inner ring. The cleaning device comprises a water pipe, a pressurization pump, the water spray pipes, spray nozzles and a water pipe electromagnetic valve.

Owner:CHENGDU BOTAI TECH

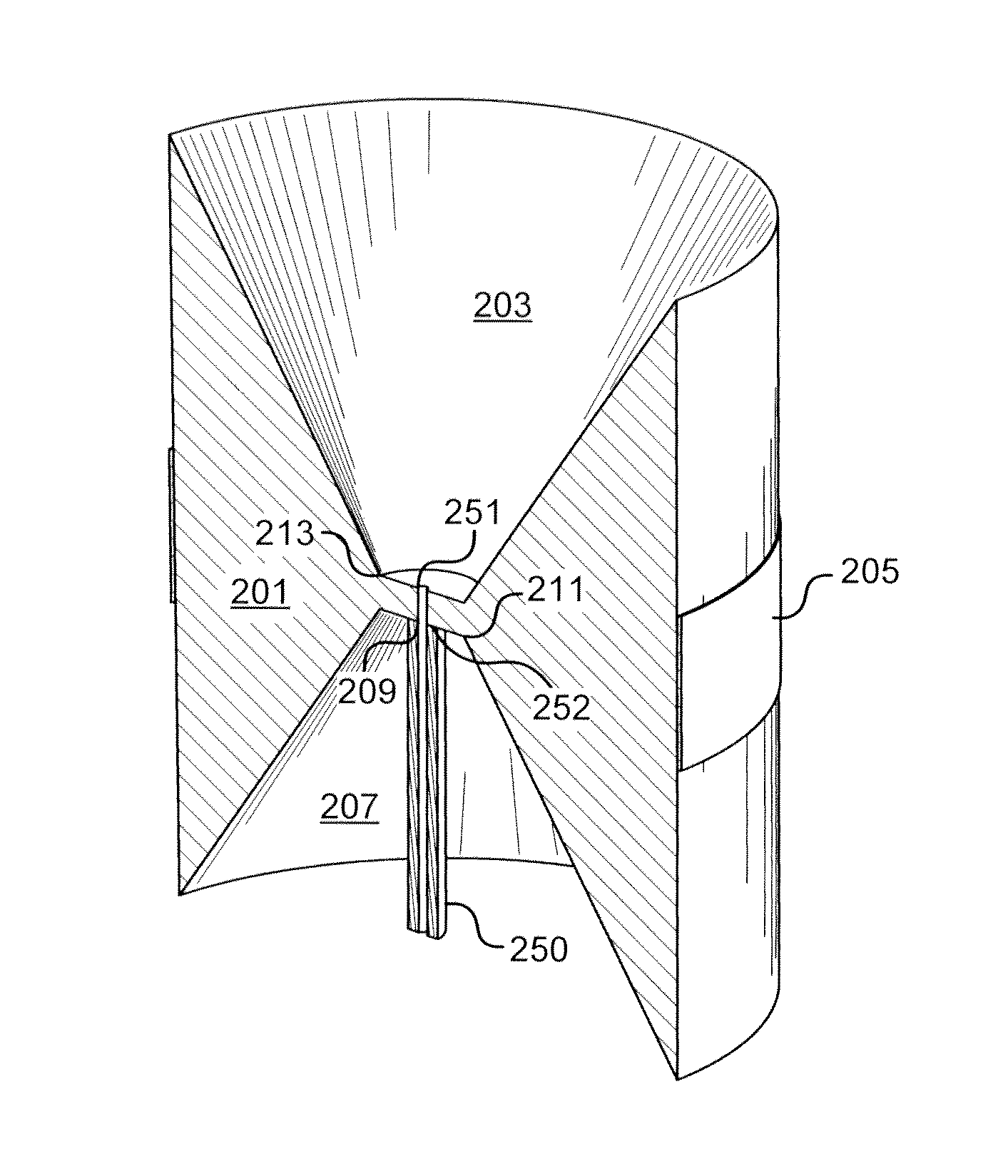

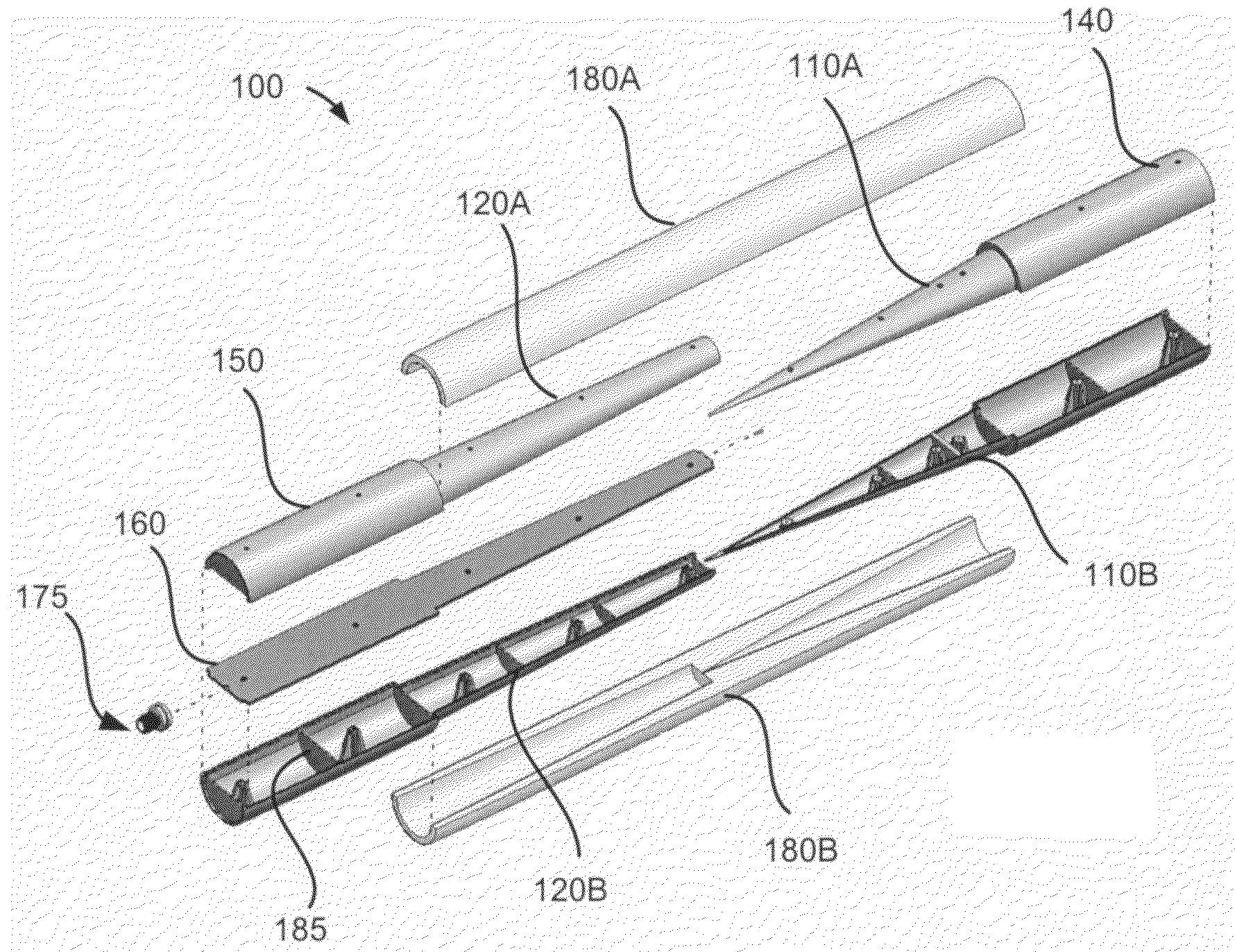

High impedance bicone antenna

InactiveUS20070205951A1Small aperture sizeHigh input impedanceWaveguide hornsAntennas earthing switches associationUltra-widebandElectrical conductor

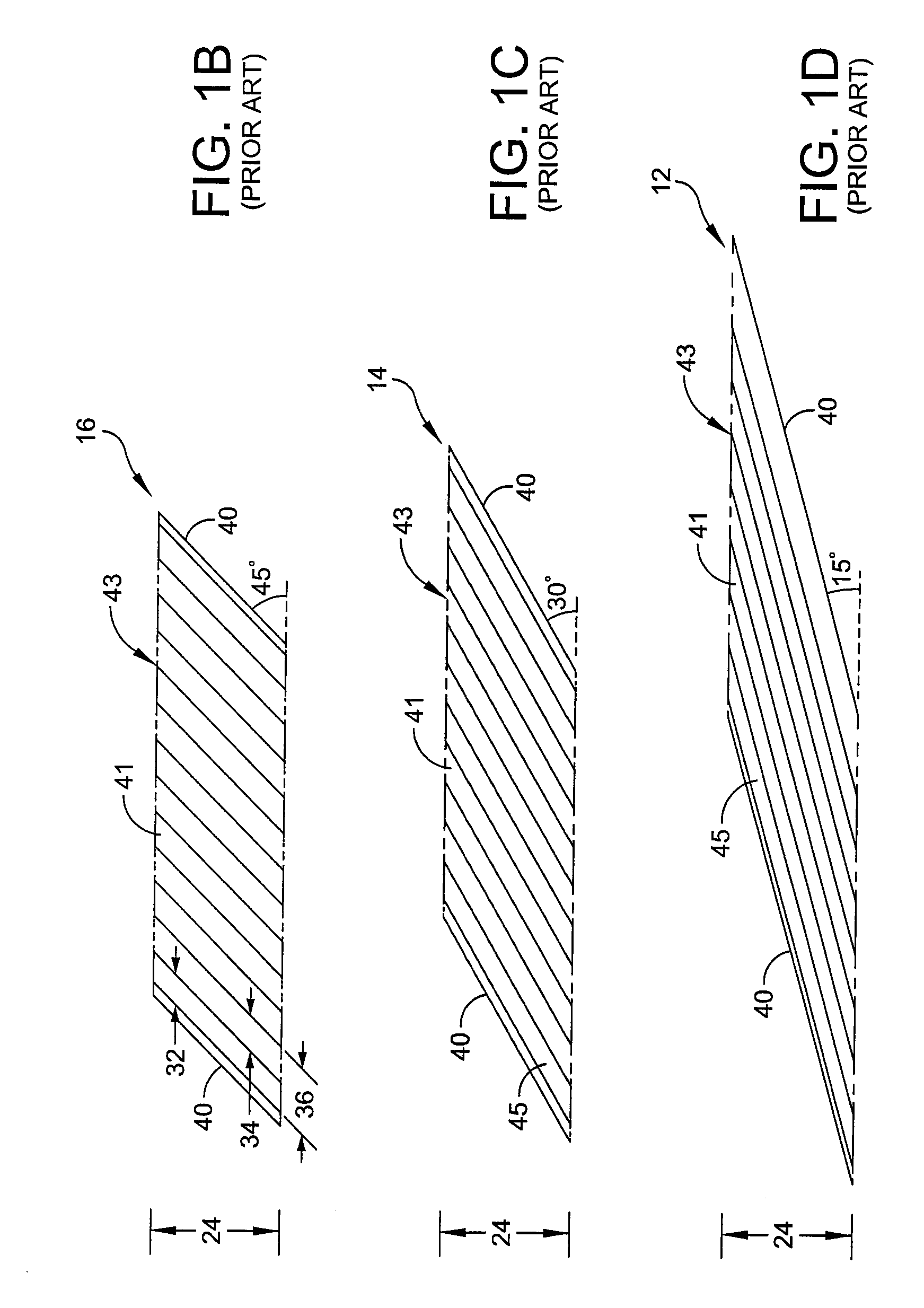

A high impedance bicone antenna system supporting ultra wideband operation. The antenna may comprise a reduced aperture size and reduced half-angles of the conductive cones forming the antenna. Reduction in cone angles may increase the impedance of the cones. An impedance matching mechanism for interfacing to the high impedance bicone may be positioned within one of the cones by a dielectric material. The impedance matching mechanism may be a flat conductive taper functioning as an impedance matching transmission line between an external feed line and the antenna. The conductive taper may function as a center conductor of a coaxial feed mechanism where the inside of the cone around the taper serves as the outside conductor, or return, of the tapered feed. The geometry of the cones may be modified to provide one or more end segments that are substantially cylindrical.

Owner:EMS TECHNOLOGIES

Time domain radio transmission system

InactiveUS20050017893A1Improve securityFast repetition rateModulated-carrier systemsIndividually energised antenna arraysTime domainCommunications system

A time domain communications system wherein a broadband of time-spaced signals, essentially monocycle-like signals, are derived from applying stepped-in-amplitude signals to a broadband antenna, in this case, a reverse bicone antenna. When received, the thus transmitted signals are multiplied by a D.C. replica of each transmitted signal, and thereafter, they are, successively, short time and long time integrated to achieve detection.

Owner:TIME DOMAIN

Electromagnetic wave gathering device and solar cell module having the same

ActiveUS20120002291A1Lower the volumeEasy to useSolar heating energySolar heat devicesElectrical conductorElectrical battery

An electromagnetic wave gathering device includes a pillared electromagnetic waveguide body and a reflective structure. The reflective structure is located at about an axis of the pillared electromagnetic waveguide body. The reflective structure comprises a plurality of bicone reflective units. Each of the reflective units has a first reflective surface. The electromagnetic wave gathering device may have a smaller volume and is handy for use.

Owner:EPISTAR CORP

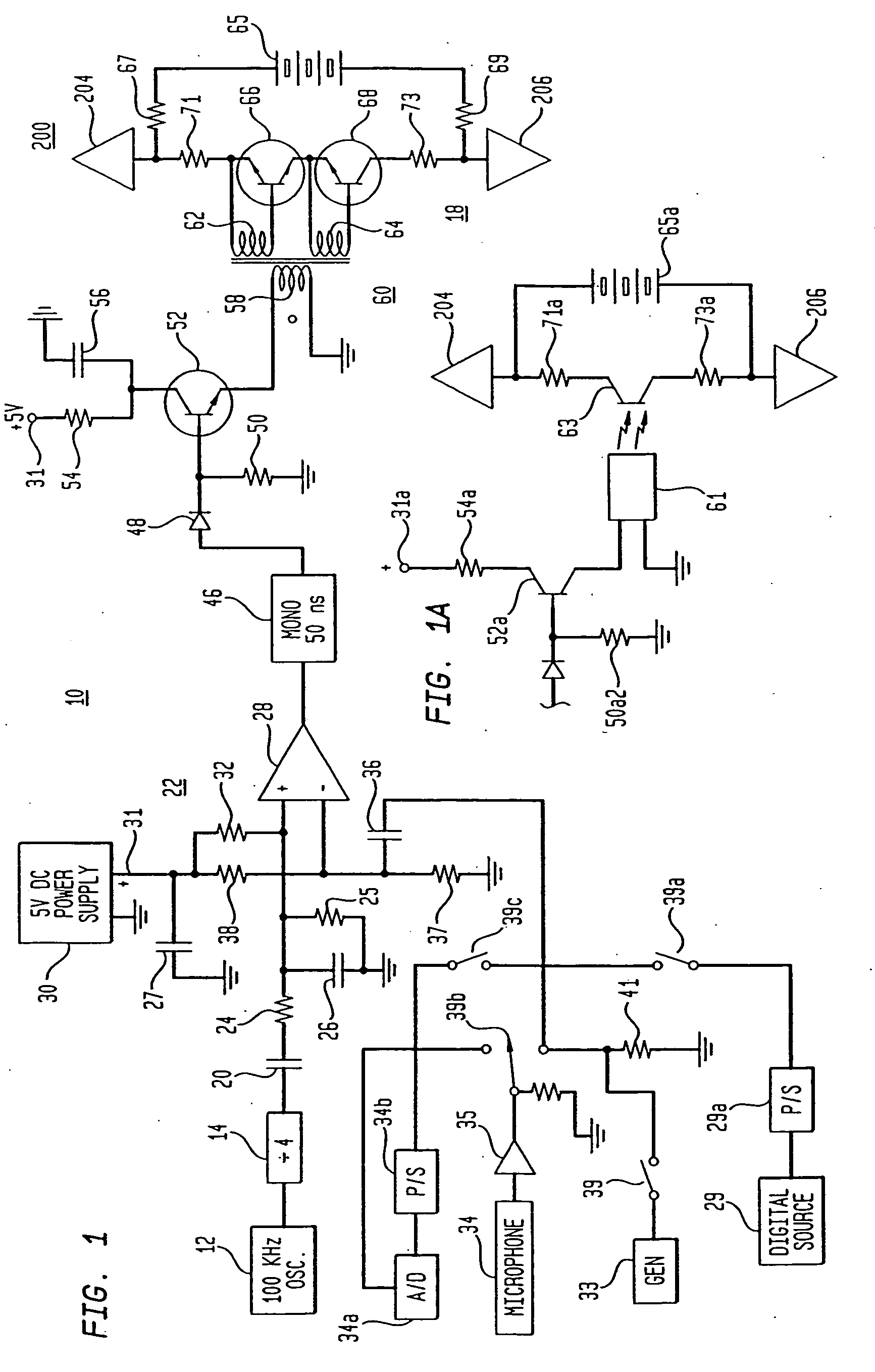

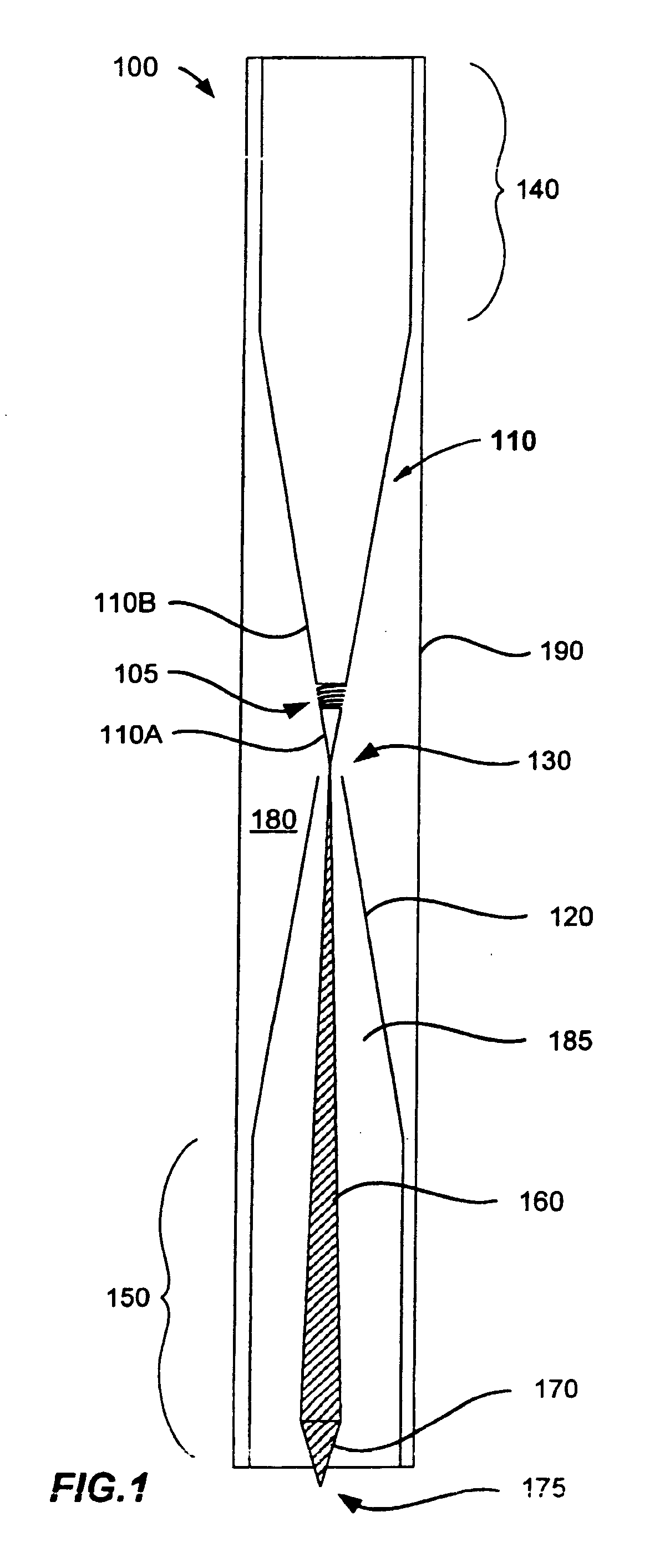

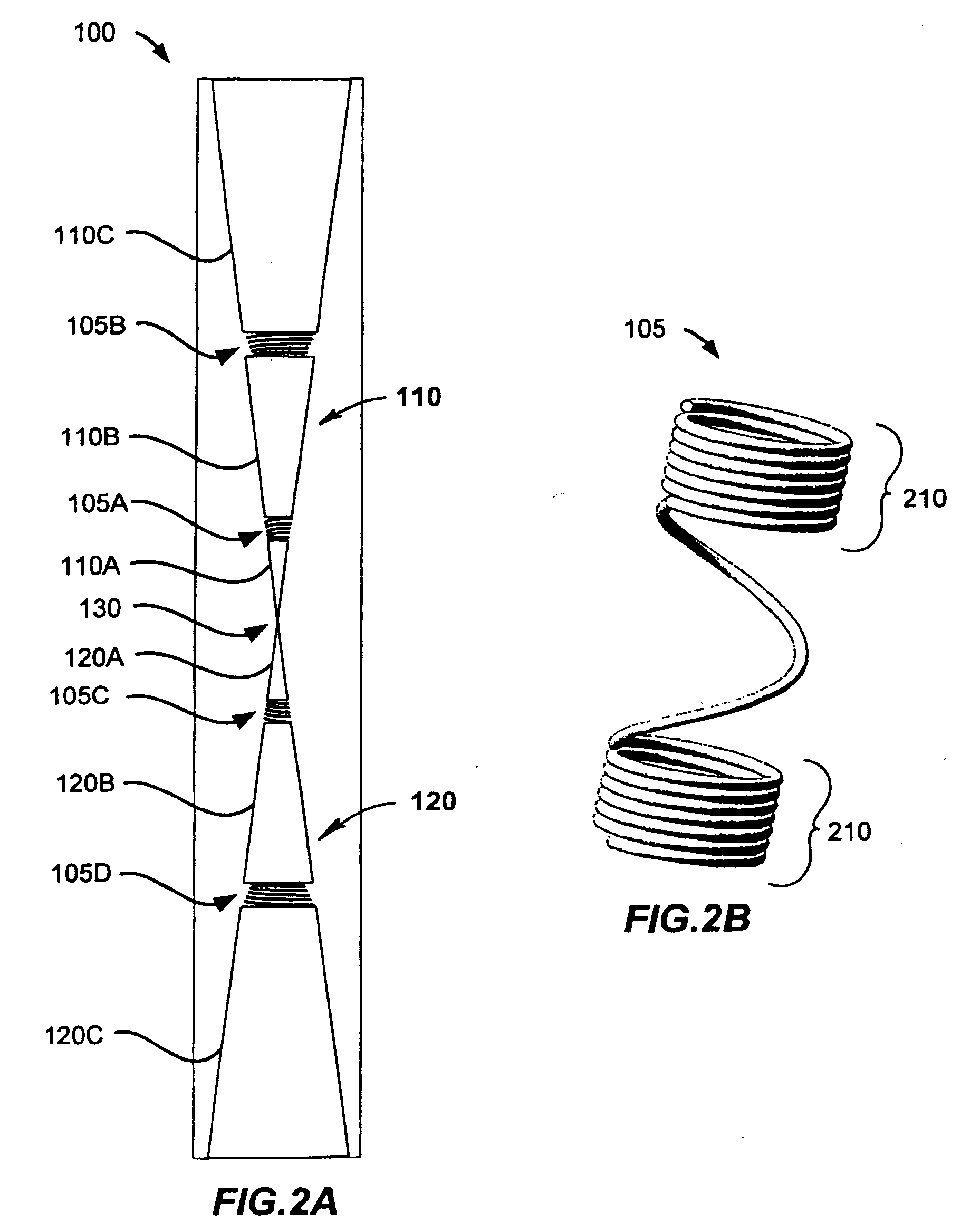

Frequency control of electrical length for bicone antennas

InactiveUS20080186244A1Small aperture sizeHigh input impedanceWaveguide hornsAntenna feed intermediatesAntenna radiation patternsEngineering

A broadband bicone antenna supports frequency selective control of electrical length. Frequency selective control of the electrical length of an antenna can provide an antenna exhibiting two or more different electrical lengths where use of each length depends upon the operating frequencies of the signals. The electrical length of the bicone antenna may be reduced in response to higher operating frequencies. Such reduction in electrical length at higher frequencies can provide improved antenna radiation patterns for the antenna. Further, the electrical length of the bicone antenna may be increased in response to low frequency operation. Such increase in electrical length may improve VSWR performance at lower frequencies. Simultaneous operation of the bicone antenna at varied electrical lengths for varied frequency bands can provide improved broadband performance of the antenna.

Owner:EMS TECHNOLOGIES

High impedance bicone antenna

InactiveUS7538737B2Small sizeHigh input impedanceWaveguide hornsAntennas earthing switches associationUltra-widebandElectrical conductor

A high impedance bicone antenna system supporting ultra wideband operation. The antenna may comprise a reduced aperture size and reduced half-angles of the conductive cones forming the antenna. Reduction in cone angles may increase the impedance of the cones. An impedance matching mechanism for interfacing to the high impedance bicone may be positioned within one of the cones by a dielectric material. The impedance matching mechanism may be a flat conductive taper functioning as an impedance matching transmission line between an external feed line and the antenna. The conductive taper may function as a center conductor of a coaxial feed mechanism where the inside of the cone around the taper serves as the outside conductor, or return, of the tapered feed. The geometry of the cones may be modified to provide one or more end segments that are substantially cylindrical.

Owner:EMS TECHNOLOGIES

Biconical rotary vacuum drying main machine

ActiveCN102168906AEvenly distributedGuaranteed uniformityDrying using combination processesDrying chambers/containersDrive shaftHeat conducting

The invention relates to a biconical rotary vacuum drying main machine, which comprises a cylinder body, wherein two built-in oil supply branch pipes which are arranged horizontally on front and back sides are arranged on the middle part of a clamp sleeve of the cylinder body and are communicated with an oil inlet cavity of a driven shaft base; oil return holes are formed at the positions, which are away from the oil inlet ends of the built-in oil supply branch pipes, at upper and lower ends of the clamp sleeve of the cylinder body; built-in oil return branch pipes which are arranged on upper and lower parts respectively are arranged in an insulating layer of the cylinder body; one end of each of the built-in oil return branch pipes is connected with a corresponding oil return hole on the clamp sleeve, and the other end of each of the built-in oil return branch pipes is inserted into an oil return cavity of the driven shaft base; a gap between an oil supply pipe and the inner wall of a driven half shaft serves as an oil return channel; and one end of the oil return channel is communicated with the driven shaft base, and the other end of the oil return channel is connected with an oil return pipe. By the biconical rotary vacuum drying main machine, heat conducting oil can be distributed to integral clamp sleeve space uniformly to ensure the uniformity of clamp sleeve heating, the problem that biconical rotary vacuum drying is 'semi-hot and semi-cold' for a long term is solved, the quality of products and the work efficiency are improved, and energy is saved.

Owner:JIANGSU XIANFENG DRYING ENG

Double cone rotating vacuum drier

InactiveCN101995146AStop pollutionHigh yieldDrying using combination processesDrying machines with non-progressive movementsBlack spotBicone

The invention discloses a double cone rotating vacuum drier, which consists of a machine body, a double cone drum body, a transmission mechanism, a heat supply device and a vacuum sealing device, wherein the vacuum sealing device comprises a vacuum tube, a connecting part, a round sealing head and a filtering vacuum head, wherein a support is arranged outside the vacuum tube; the vacuum tube is connected with the double cone drum body; one end of the connecting part is welded with the double cone drum body; the end face of the vacuum tube is arranged in a cavity formed by the connecting part and the double cone drum body; the other end of the connecting part is connected with the round sealing head; and the arc surface of the round sealing head is provided with a connecting section with the filtering vacuum head. The drier can avoid generating cross pollution sources and black spots, prevent materials from being polluted due to the friction of microfine powder entering a sealing ring and improve material yield and can be disassembled easily for cleaning.

Owner:JIANGSU JIUSHOUTANG ORGANISMS MFGS

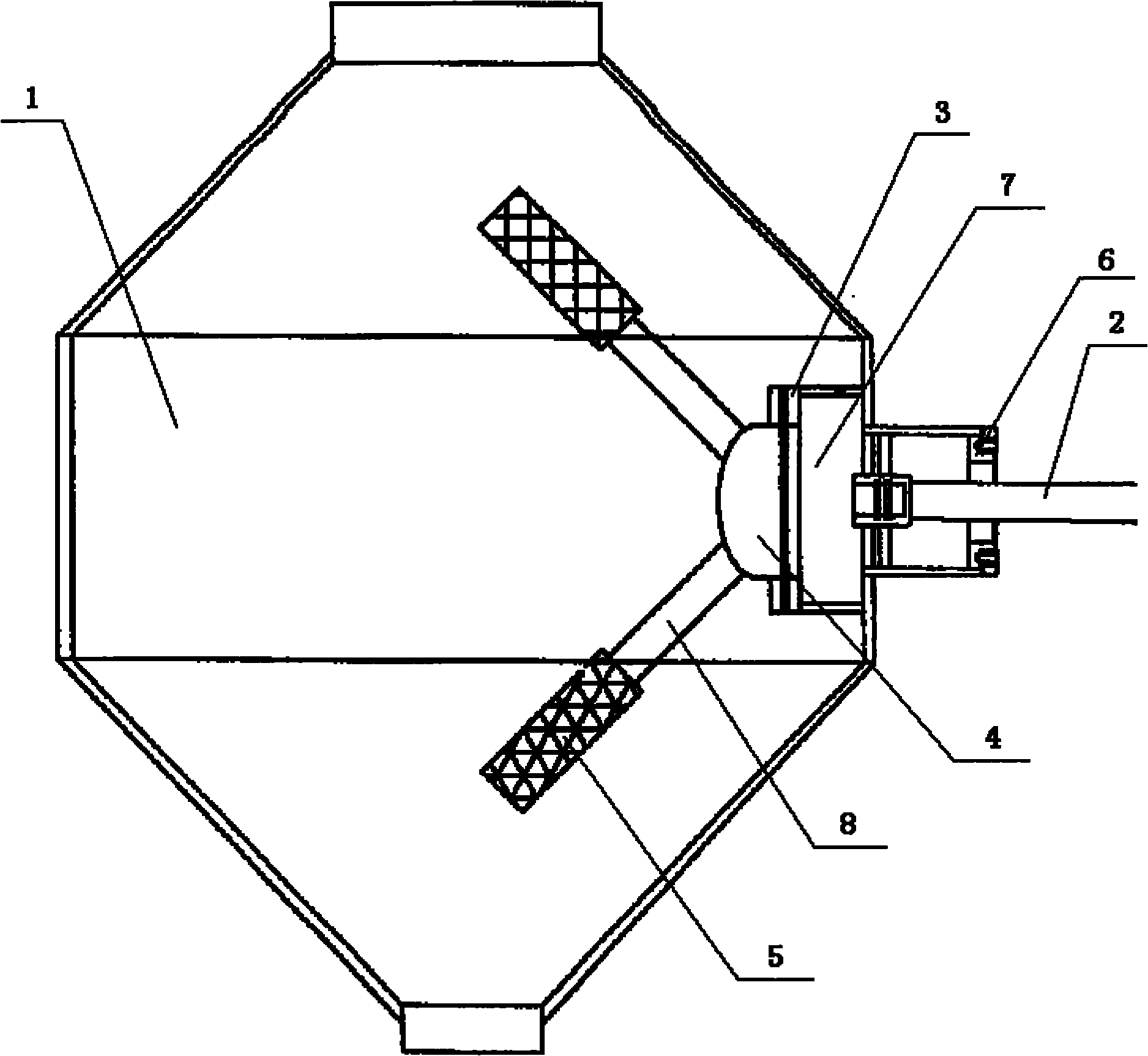

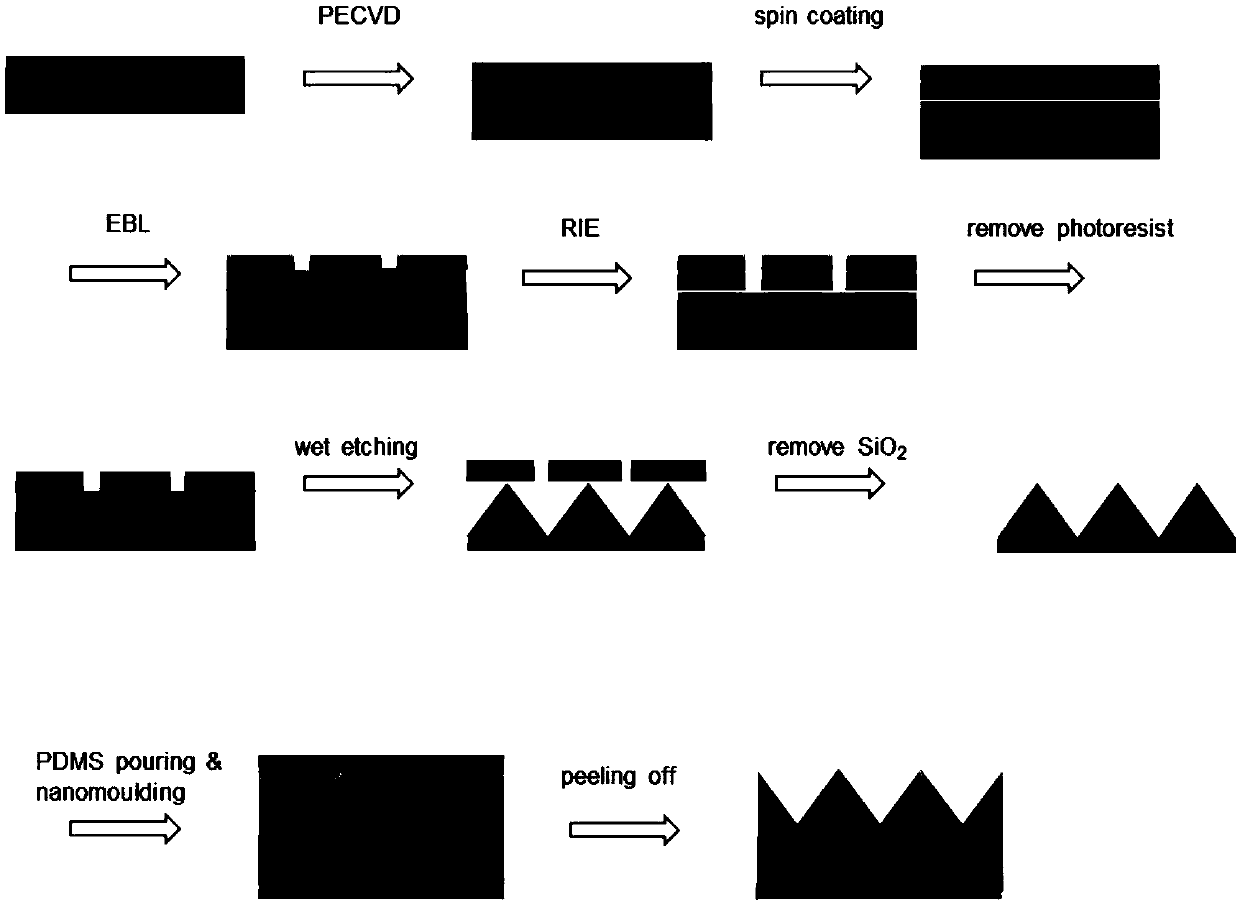

Double grating nanostructure composed of quadrangular double cone arrays and preparing method thereof

ActiveCN109581559AImprove photosensitivityImprove light energy collection ratePhotomechanical apparatusNanoopticsGratingLight energy

The invention relates to a double grating nanostructure composed of quadrangular double cone arrays, and relates to the field of optical devices. The double grating nanostructure comprises a porous silicon substrate and a plurality of grating nanostructure units. Each grating nanostructure unit is in a quadrangular double-cone shape, wherein a half is buried in the porous silicon substrate, and the other half is exposed outside the porous silicon substrate. The grating nanostructure units in the quadrangular double-cone shapes can provide more gradual effective refractive index distribution between air and the device, and the light sensitivity, the light energy collection rate and the like of the device are further improved. A preparation method of the double grating nanostructure composedof the quadrangular double cone arrays is simple in operation, not high in requirement for equipment, and capable of being conveniently used for preparation of the double grating nanostructure composed of the above quadrangular double cone arrays.

Owner:THE CHINESE UNIV OF HONG KONG SHENZHEN

Double-cone vacuum drier with narrow-wedge internal heating plate

InactiveCN102735029AIncrease the number ofIncrease the heating areaDrying using combination processesDrying machines with non-progressive movementsHeat resistanceEngineering

The invention relates to a d double-cone vacuum drier with a narrow-wedge internal heating plate, belonging to the field of a pharmaceutical chemical heat exchange technology and aiming at carrying out dynamic vacuum low-temperature drying meeting GMP standard requirements on pharmaceutical and fine chemical product filter cakes. The double-cone vacuum drier with the narrow-wedge internal heating plate comprises a double-cone body, a low-temperature saturated vapor generator, a vapor heating jacket, a left (right) rotating shaft, a left (right) bearing seat, a narrow-wedge internal heating plate, a filter, a hidden hazard free vacuum sealing piece, a driving machine and an exhaust pipe, wherein the low-temperature saturated vapor generator supplies a low-temperature saturated vapor heat source of 30-100-DEG C for vacuum drying; the heating area of the double-cone drier with the narrow-wedge internal heating plate is 2-3 times that of the traditional double-cone drier; and the wall thickness of the internal heating plate is one fourth-one third that of the double-cone body, heat resistance is low and the equipment weight is greatly reduced, thus the manufacturing cost of the drier is greatly lowered while improving the efficiency of the drier; and the hidden hazard free vacuum sealing piece has no structure pollution hazard of the traditional sealing piece, thus the drier truly meets the GMP standard requirements.

Owner:沈善明

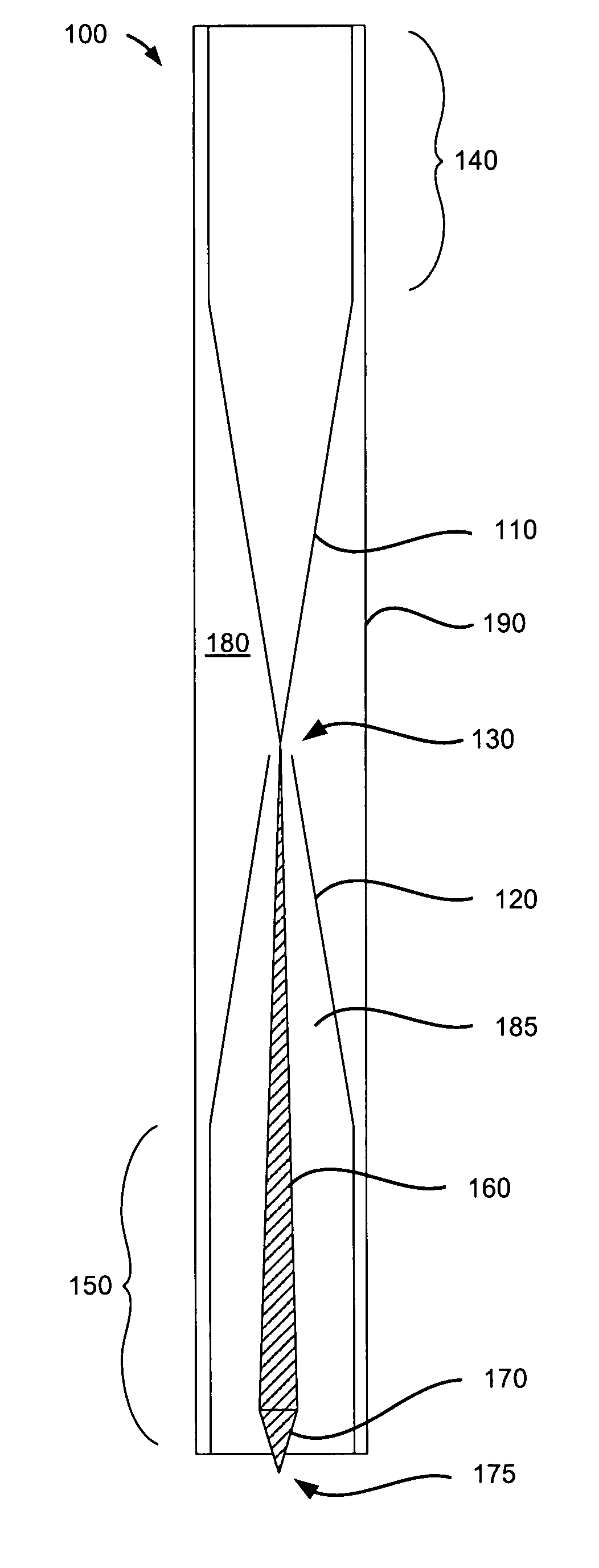

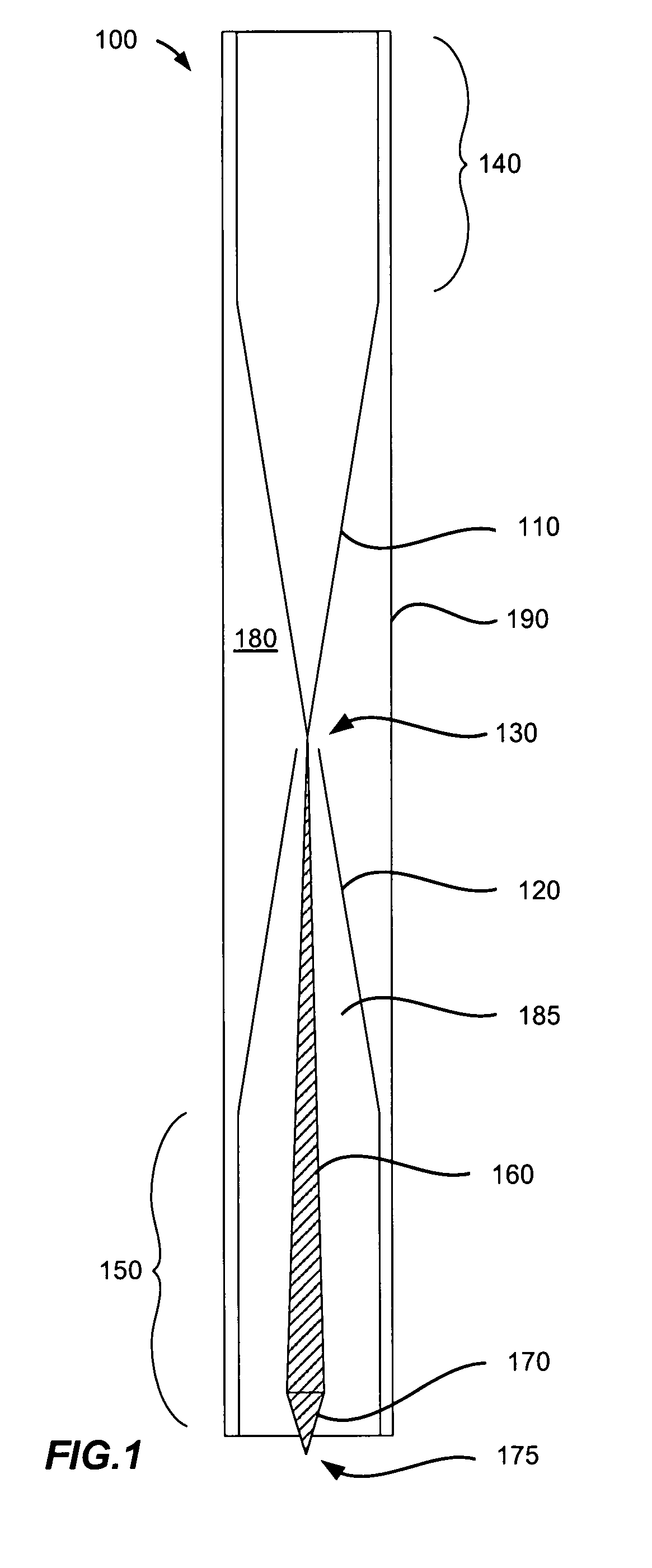

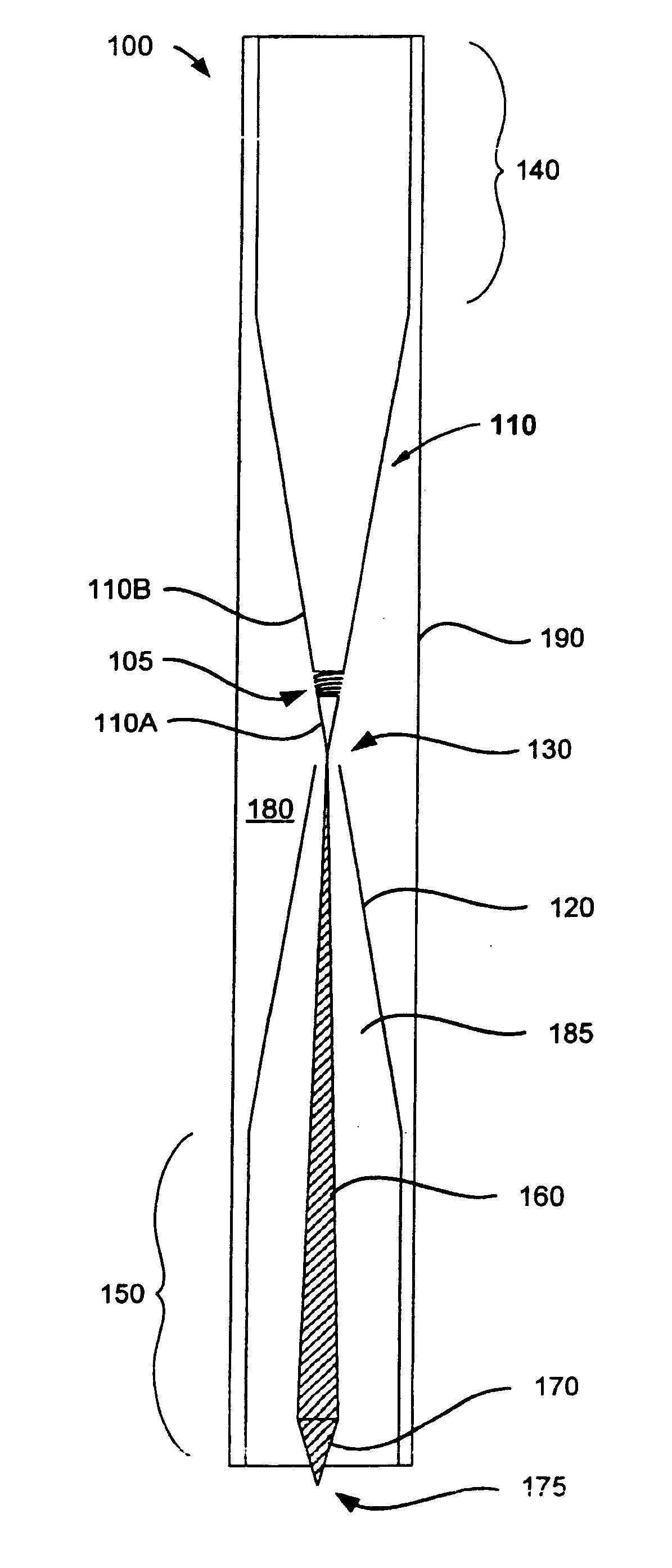

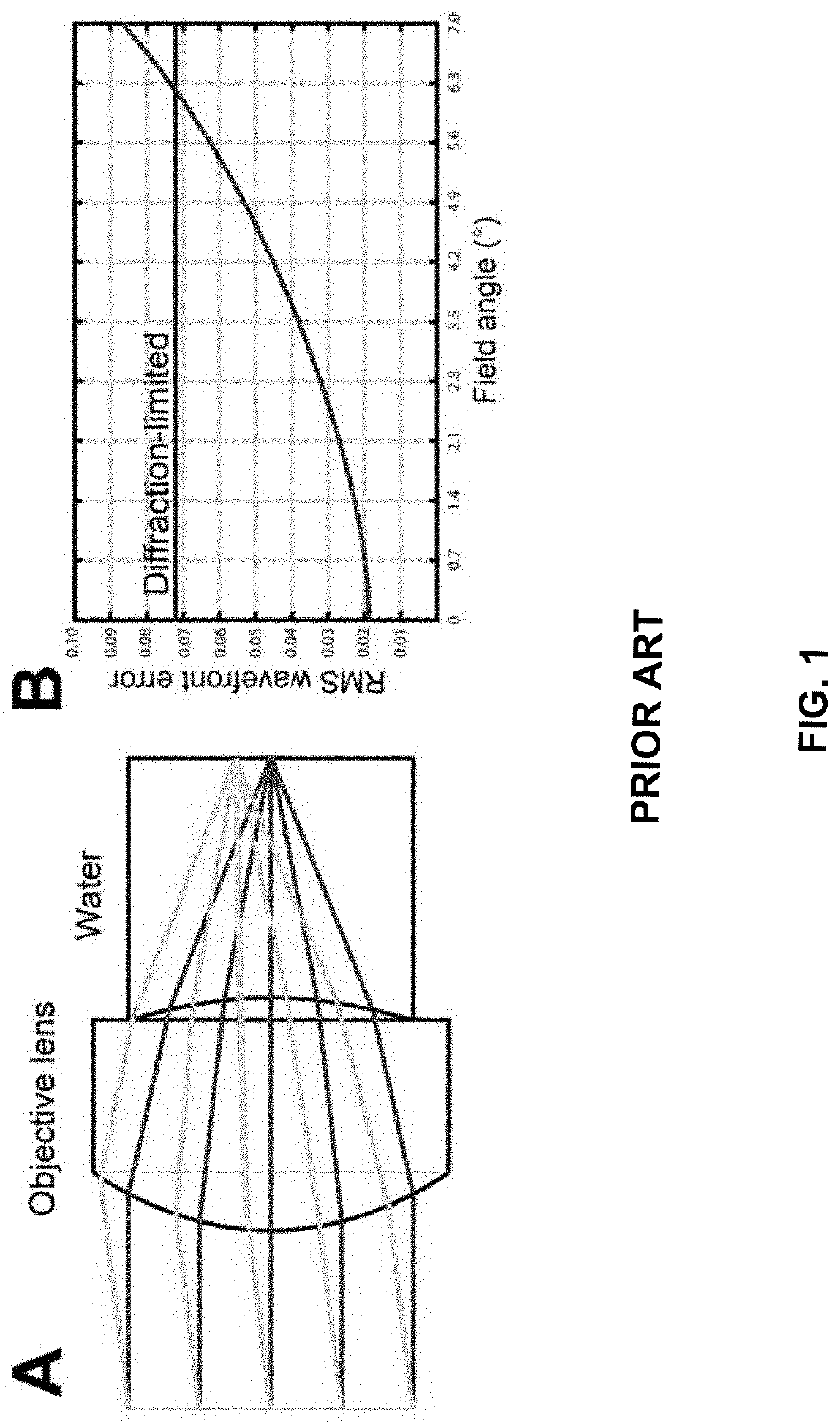

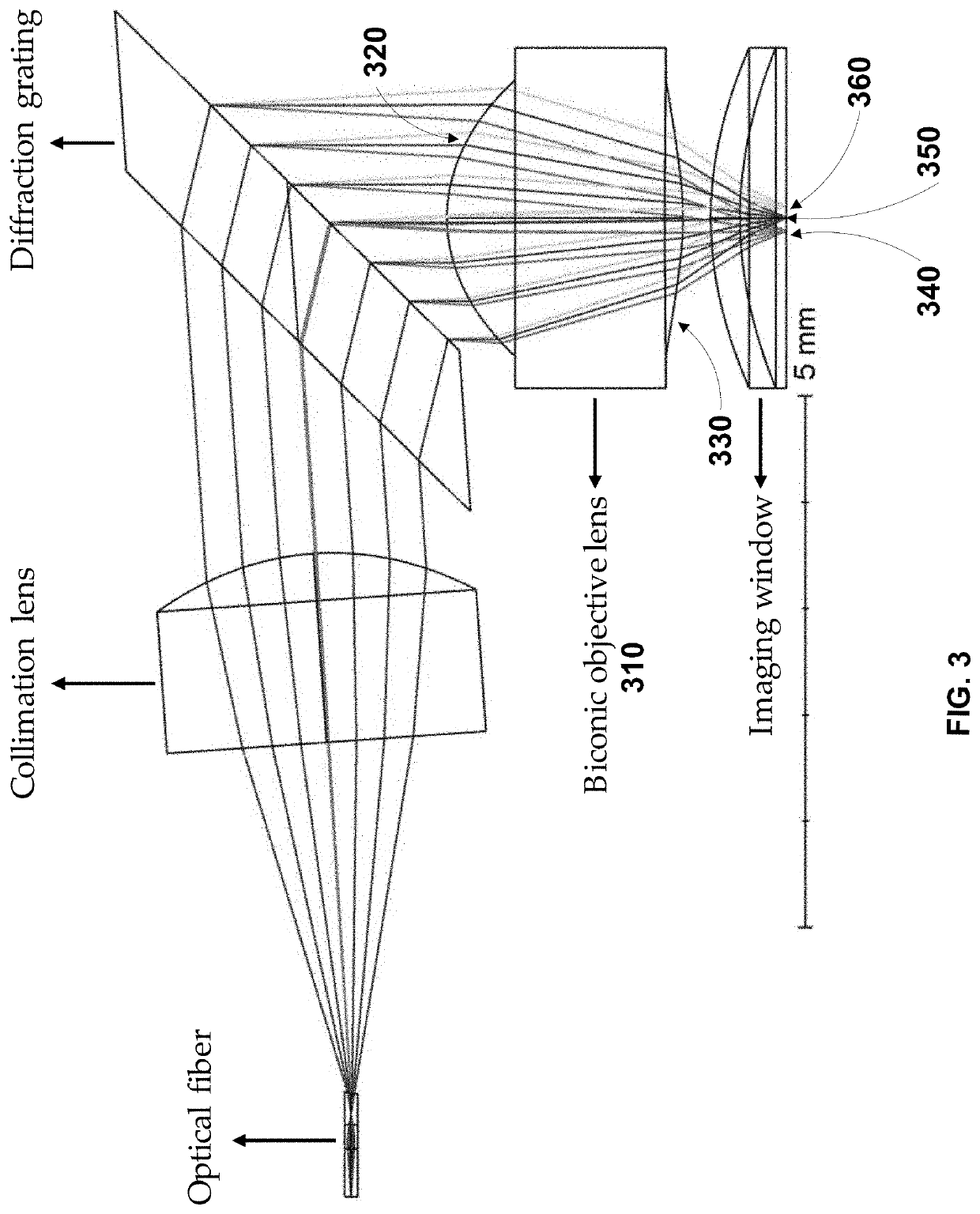

System and method for high-resolution, high-speed capsule endomicroscopy

A probe for performing endomicroscopy, including: a light source; a waveguide coupled to the light source; a diffraction grating, the waveguide directing light from the light source to the diffraction grating; and a lens having a first aspheric surface and a second biconic surface, diffracted light from the diffraction grating being directed into the aspheric surface of the lens and being emitted from the biconic surface of the lens towards a transparent cylindrical surface of the probe.

Owner:THE GENERAL HOSPITAL CORP

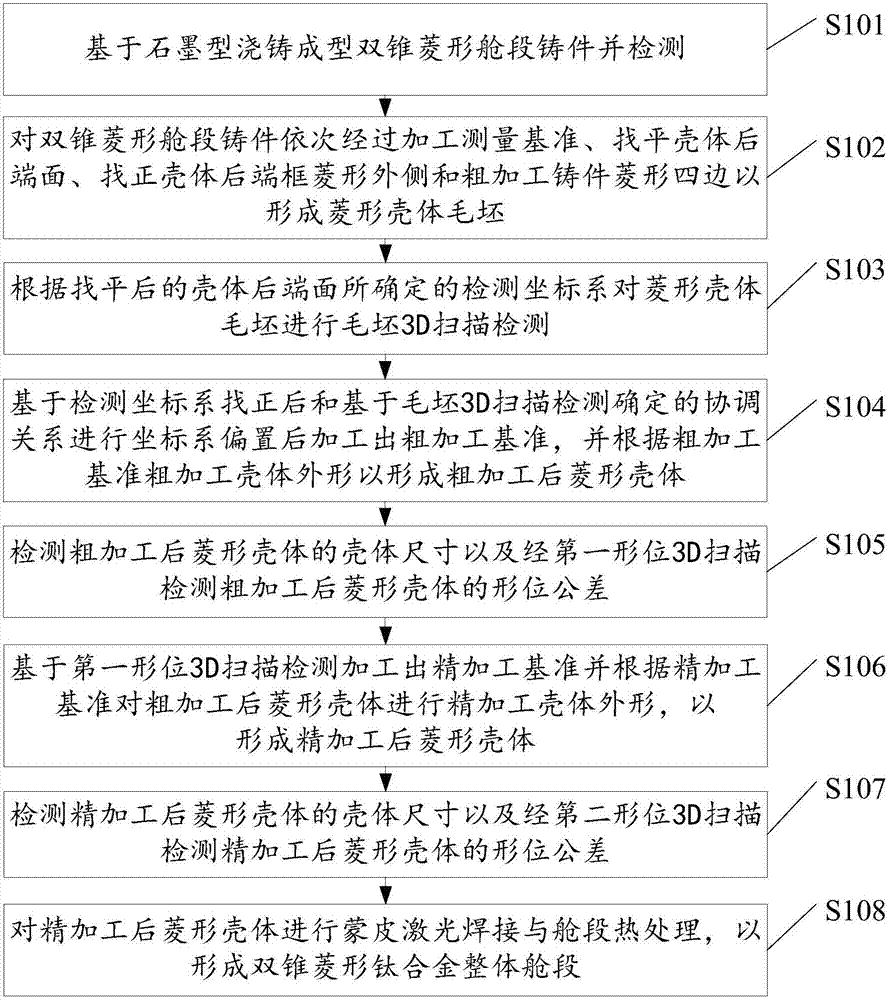

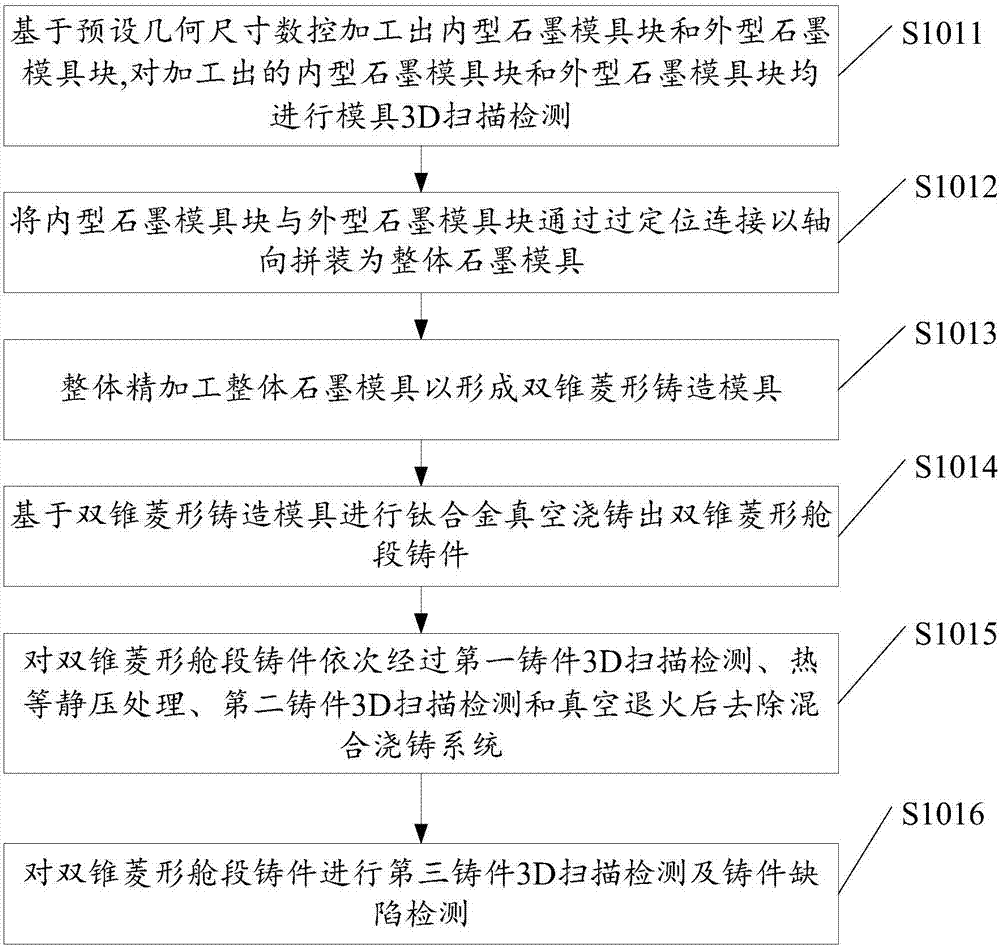

A method for manufacturing a biconical diamond-shaped titanium alloy integral cabin

The invention discloses a method for manufacturing a biconical diamond-shaped titanium alloy integral cabin, which includes: forming a biconical rhomboid cabin casting based on graphite casting and testing; the biconical diamond cabin casting is sequentially processed and measured to form a rhomboid shell Body blank, after the coordinate system is offset, the shell shape is roughly machined according to the rough machining reference to form a rhomboid shell after rough machining; the shell size of the diamond shell after rough machining is detected and the rough machining is detected by the first shape and position 3D scanning Shape and position tolerance of diamond-shaped shells; based on the finishing datum, finish the shape of the rough-machined diamond-shaped shell; detect the shell size of the finished diamond-shaped shell and detect the finished rhombus after the second shape and position 3D scanning The shape and position tolerance of the shell; and then carry out skin laser welding and cabin heat treatment on the diamond-shaped shell after finishing. It effectively solves the technical problem that the mechanical processing of the existing biconical diamond-shaped titanium alloy integral cabin is difficult to control, and ensures the overall quality of the biconical rhomboid titanium alloy integral cabin.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com