Hipyramid type optical fiber fade down wave temperature sensor and method for manufacturing its bipyramid optical fiber probe

A technology of temperature sensor and optical fiber probe, applied in thermometers, thermometers with physical/chemical changes, instruments, etc., can solve the problems of complex structure, high cost, and difficult production of optical fiber temperature sensors, and achieve fast and effective acquisition and low cost , The effect of simple manufacturing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A preferred embodiment of the present invention is described as follows in conjunction with accompanying drawing:

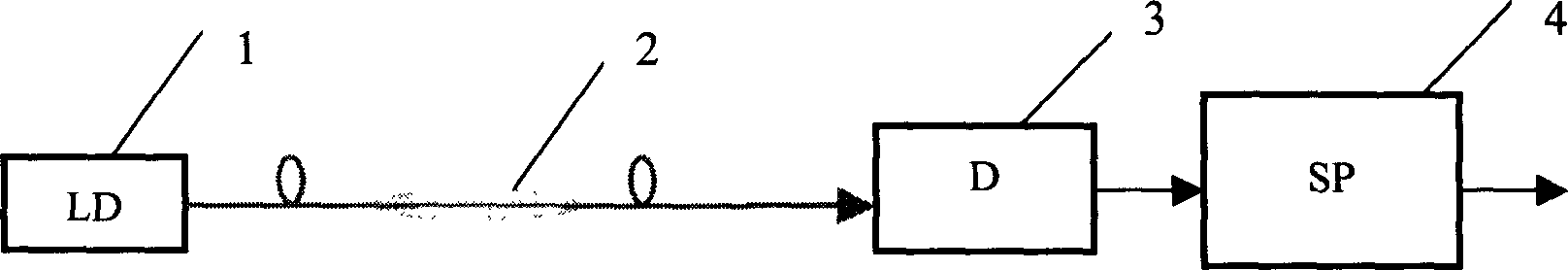

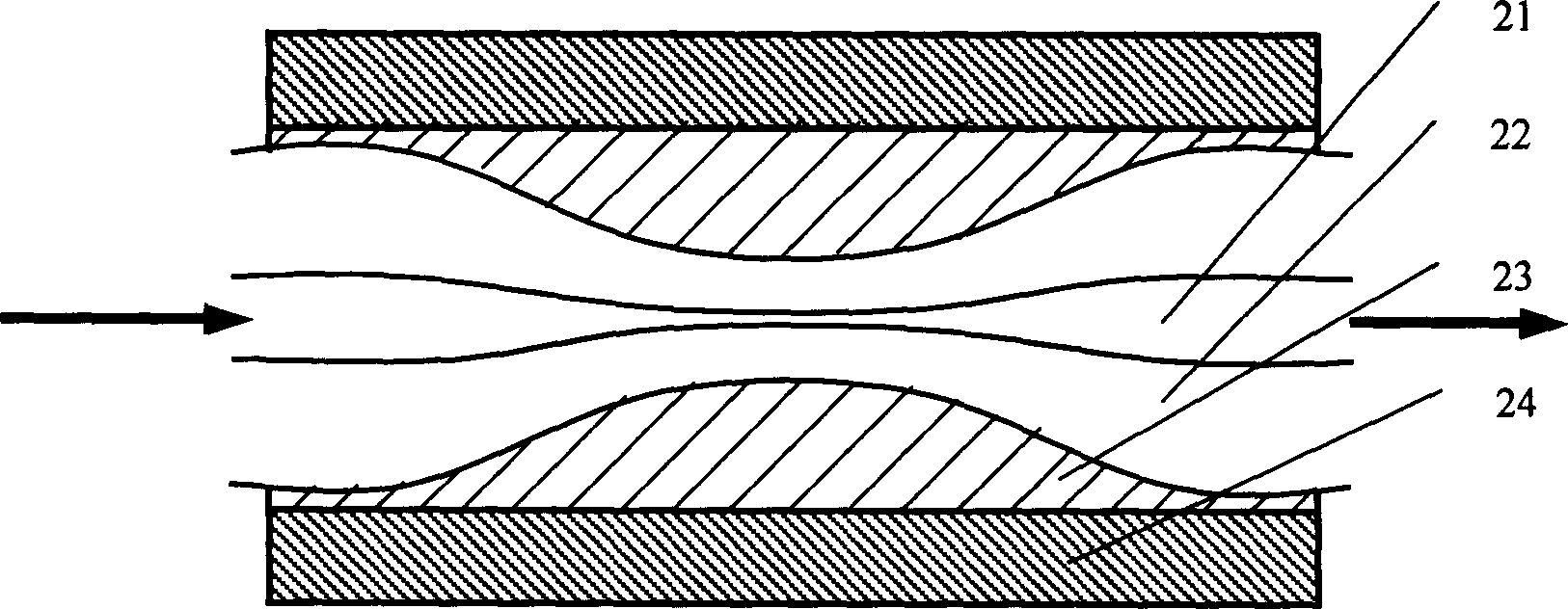

[0015] see figure 1 with figure 2 , the biconical optical fiber evanescent wave temperature sensor is composed of a light source 1 connected to a detector 3 through an optical fiber through a probe 2, and then the detector 3 is connected to a signal processing unit 4. It is characterized in that the probe 2 is a biconical optical fiber probe. When in the temperature change field, the temperature change is sensed by its bicone section, and the evanescent field of the bicone section changes accordingly, resulting in a change in the transmission energy of the sensing fiber; the depth detector 3 converts the optical signal into an electrical signal Then input the signal processing unit 4; the signal processing unit obtains the temperature information after processing the electrical signal. The structure of the above-mentioned double-tapered optical fiber pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com