Double cone rotating vacuum drier

A vacuum dryer and double-cone cylinder technology, which is applied to non-progressive dryers, dryers, and drying solid materials, can solve the problems of easy wear and tear of gasket materials and large material waste, and achieve improved yield and easy drying. Disassembly and cleaning, avoiding the effect of cross-contamination sources and black spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

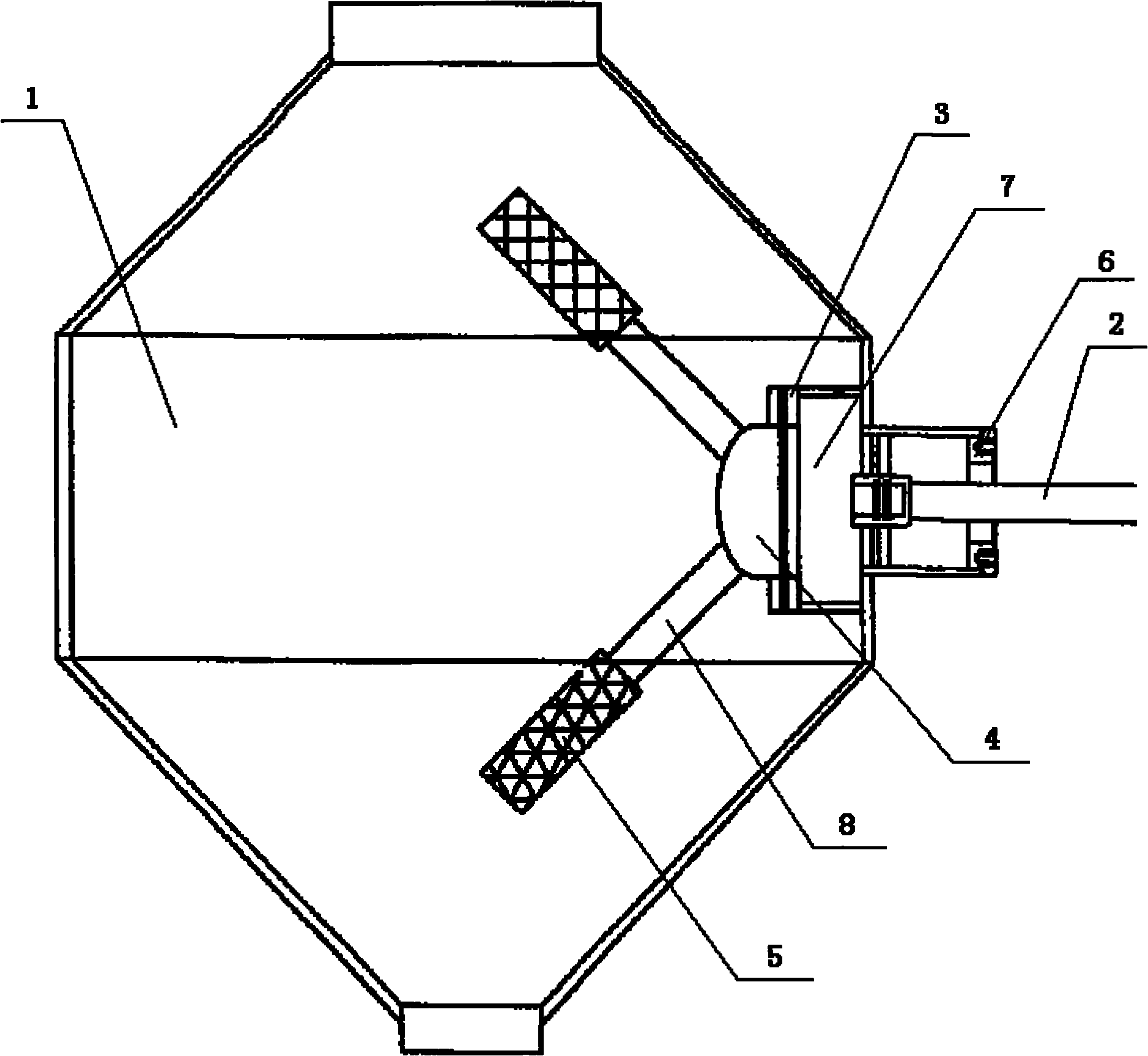

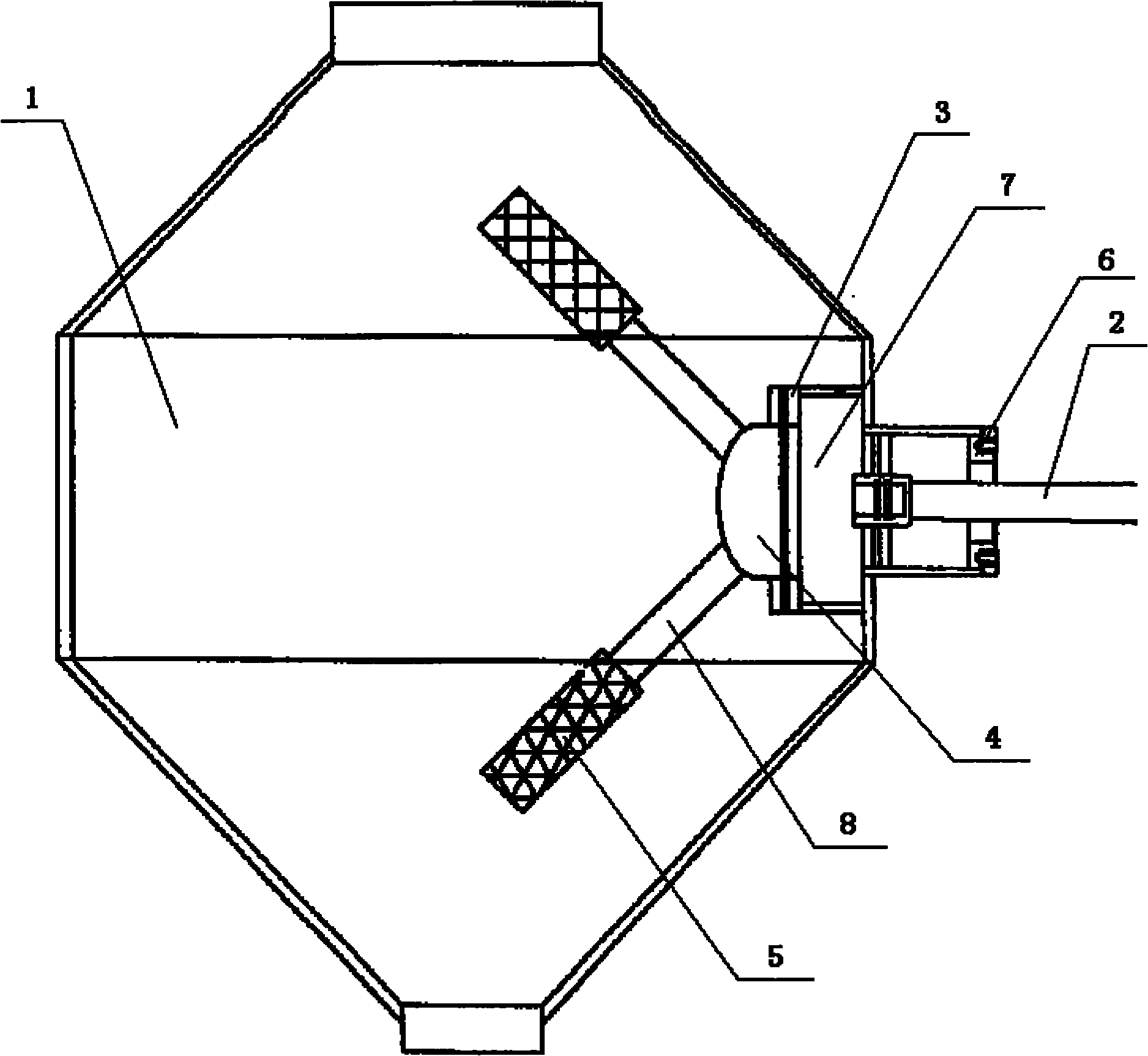

[0009] Such as figure 1 As shown, a double-cone rotary vacuum dryer is composed of a body, a double-cone cylinder 1, a transmission mechanism, a heating device and a vacuum sealing device. The vacuum sealing device includes a vacuum tube 2, a connecting part 3, a circular sealing head 4 and filter vacuum head 5, the outside of the vacuum tube 2 is provided with a bracket 6, the vacuum tube 2 is connected to the double-cone cylinder 1, one end of the connecting part 3 is welded to the double-cone cylinder 1, and the The end face of the vacuum tube 2 is set in the cavity 7 formed by the connecting part 3 and the double-cone cylinder 1, the other end of the connecting part 3 is connected with a circular head 4, and the connecting part 3 and the circular head 4 The connection section 8 with the filter vacuum head 5 is provided on the circular arc surface of the circular head 4 through respective flange surface bolt connections.

[0010] The connection part 3 described in the embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com