Patents

Literature

33results about How to "Avoid black spots" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

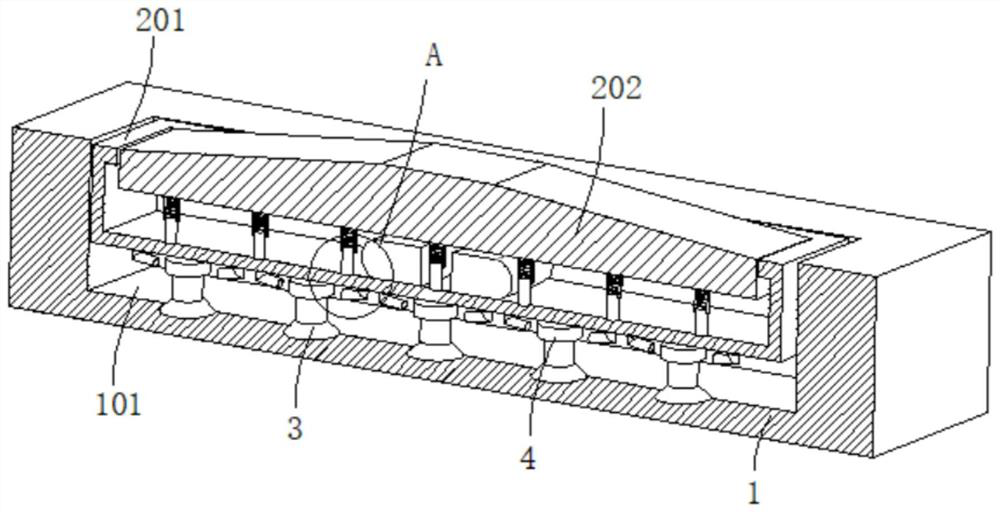

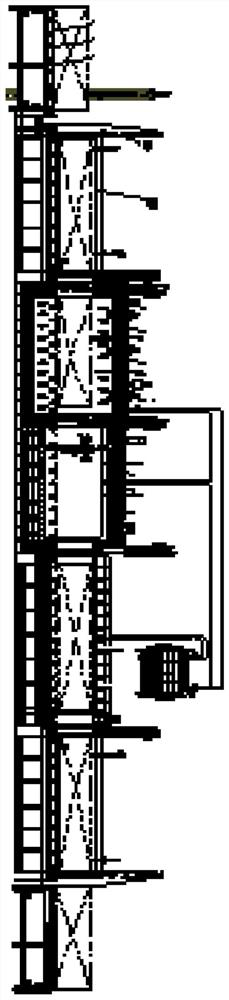

Multi-element gas co-infiltration strengthening system and process thereof

The invention discloses a multi-element gas co-infiltration strengthening system and a process thereof, and belongs to the technical field of workpiece heat treatment. According to the multi-element gas co-infiltration strengthening system and the process thereof, the problems of poor environmental protection, poor infiltration effect and single infiltration layer of traditional heat treatment aresolved. The multi-element gas co-infiltration strengthening system comprises a feeding unit, an air exchange unit, a heating pre-infiltration unit, a multi-element gas co-infiltration strengthening unit, a cooling protection unit and a discharge unit connected in sequence. By means of the multi-element gas co-infiltration strengthening system and a process thereof the, through the cooperation ofeach unit, a traditional acid anticorrosion process is replaced, so that the environmental protection is improved; through the air exchange unit, the air participation is avoided, so that the sufficiency of polyatomic infiltration is improved; through the combination of the heating pre-infiltration unit and microwave radiation, the structure of the surface of a lamp post is changed, so that the infiltration speed and depth of subsequent nitrogen, sulfur and chromium elements are improved; and in the strengthening treatment of multi-element gas co-infiltration, firstly, ammonia atmosphere nitriding treatment is adopted, and then gaseous carbon sulfur chromium complex is released by an accelerating infiltration ball B, so that the carburizing, sulphurizing and chromizing co-infiltration treatment is achieved, the structure of the infiltration layer is complex and diversified, and the hardness of the lamp post is improved.

Owner:江苏良川科技发展有限公司

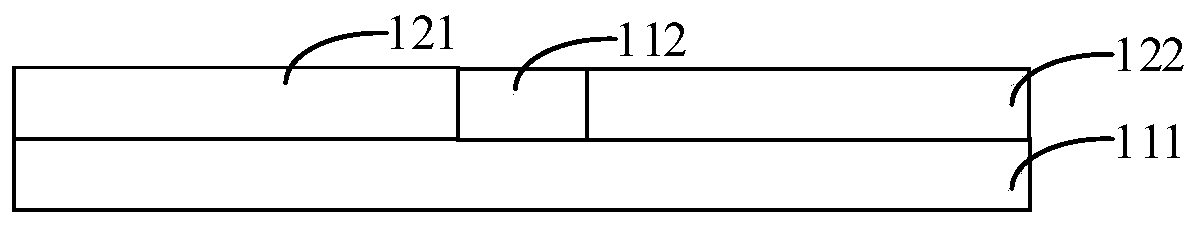

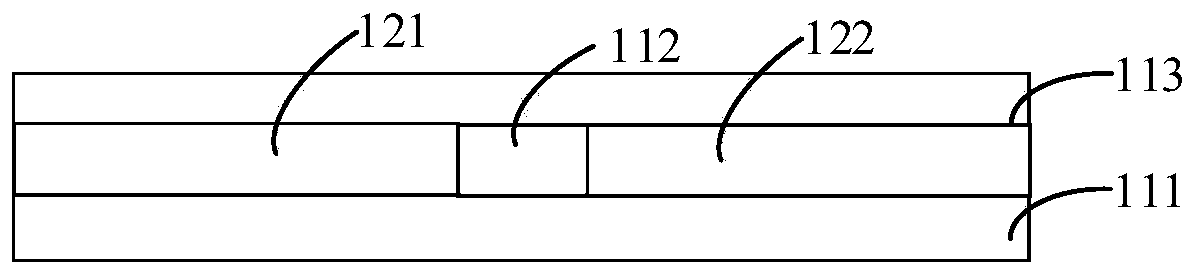

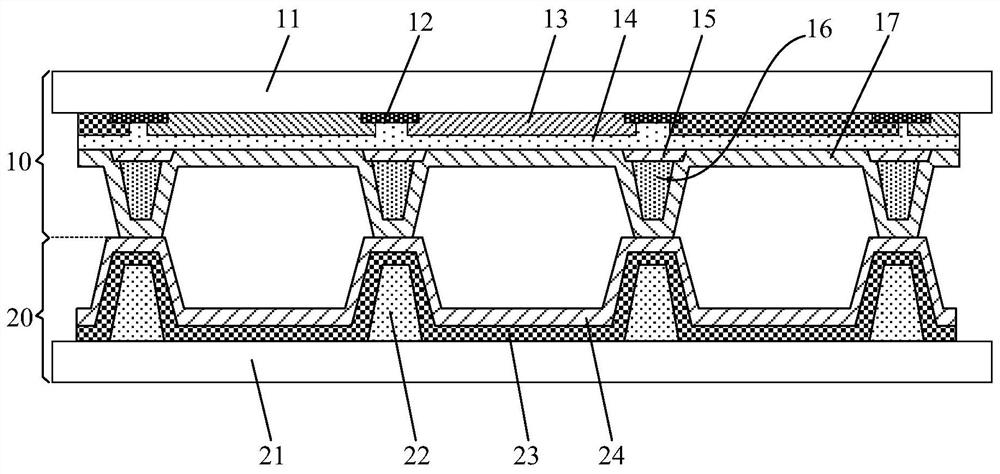

Flexible substrate, display back plate and flexible display screen

InactiveCN109860206AImprove impact resistanceAvoid dark spotsSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringShock resistance

The present invention discloses a flexible substrate, a display back plate and a flexible display screen. The flexible substrate comprises a flexible material layer and a skeleton layer, the flexiblematerial layer comprises a support surface, and the skeleton layer is arranged at the support surface of the flexible material layer, or is arranged at one side far away from the support surface of the flexible material layer, or is arranged at the internal portion of the flexible material layer, and is connected with the flexible material layer; and the elasticity modulus of the skeleton layer islarger than the elasticity modulus of the flexible material layer. The flexible substrate is high in shock resistance capacity, and can effectively avoid the technical problem that the wires in the flexible substrate are damaged due to large impact force.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

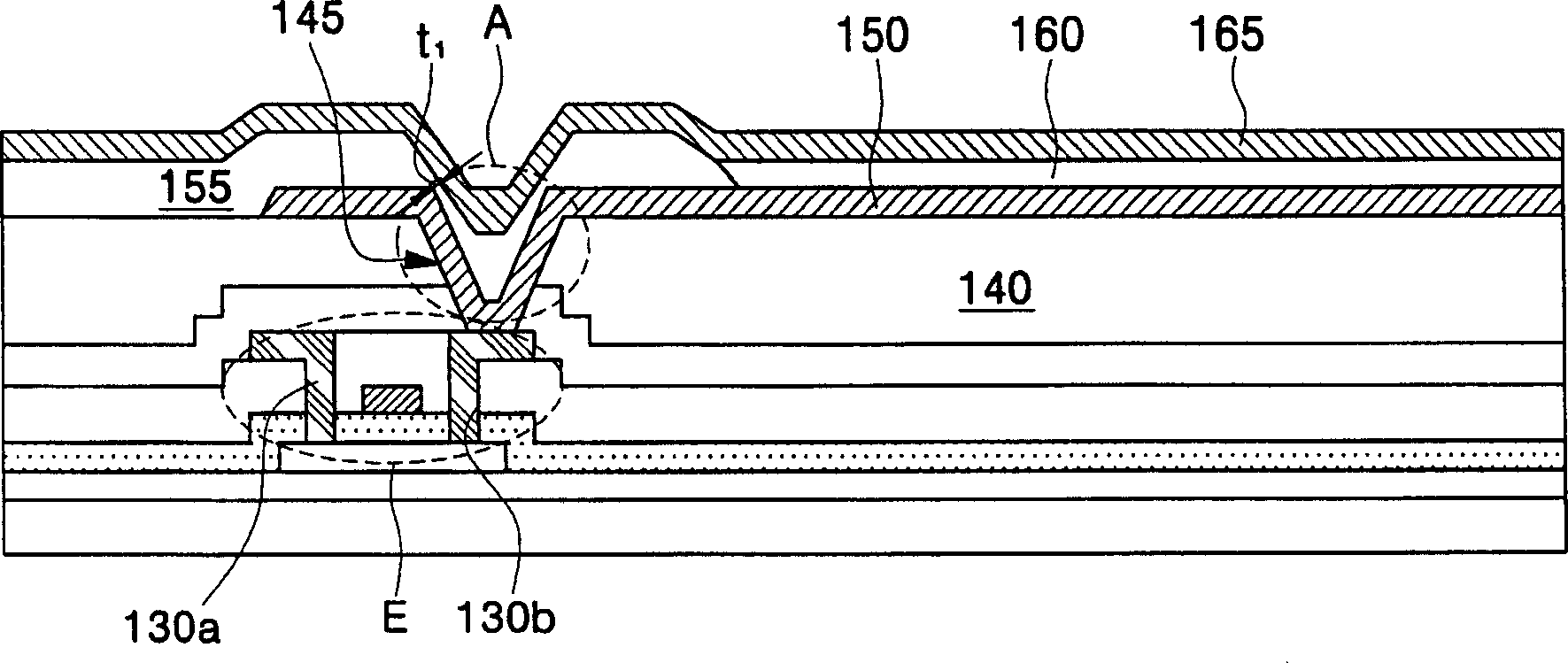

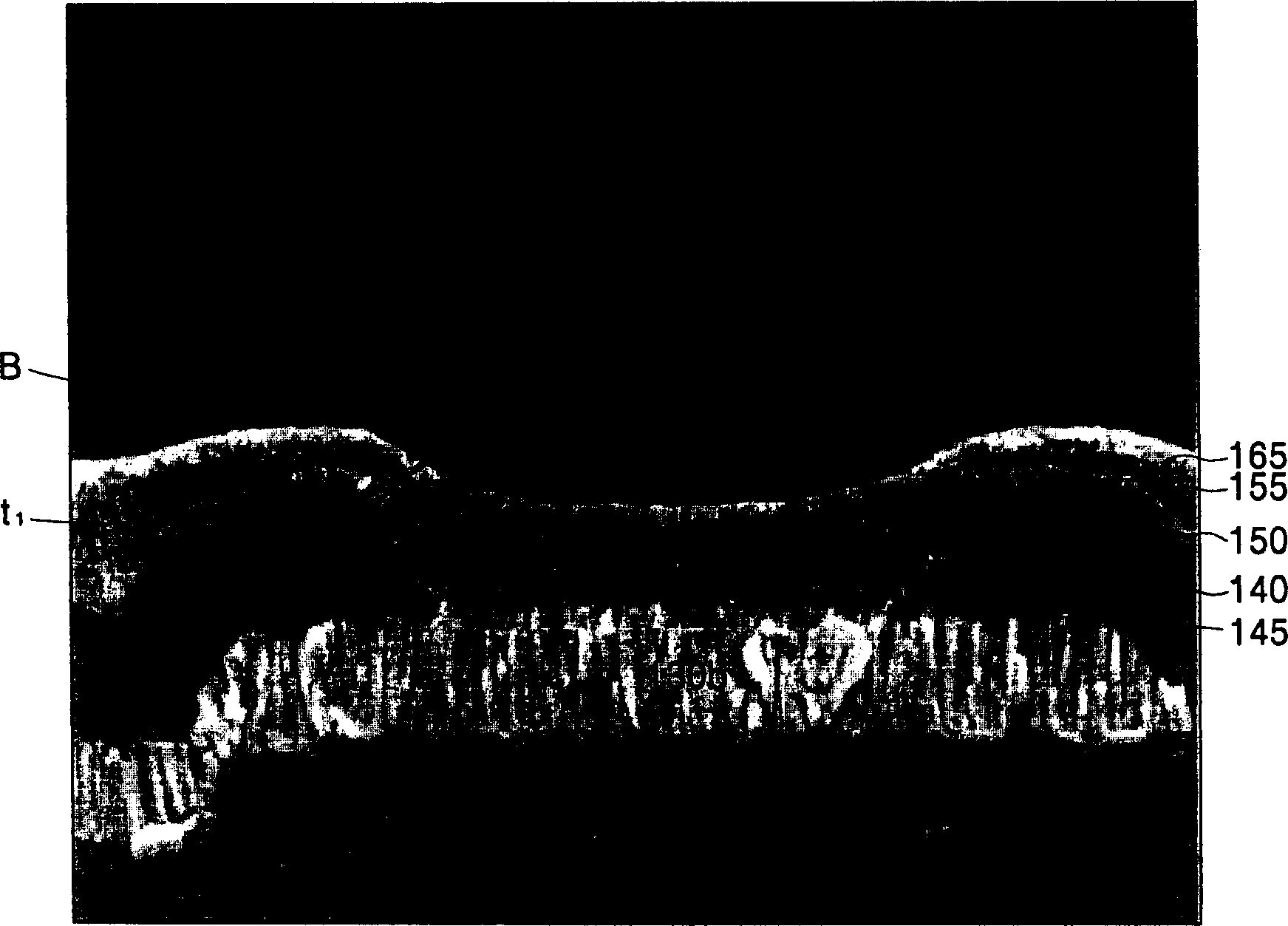

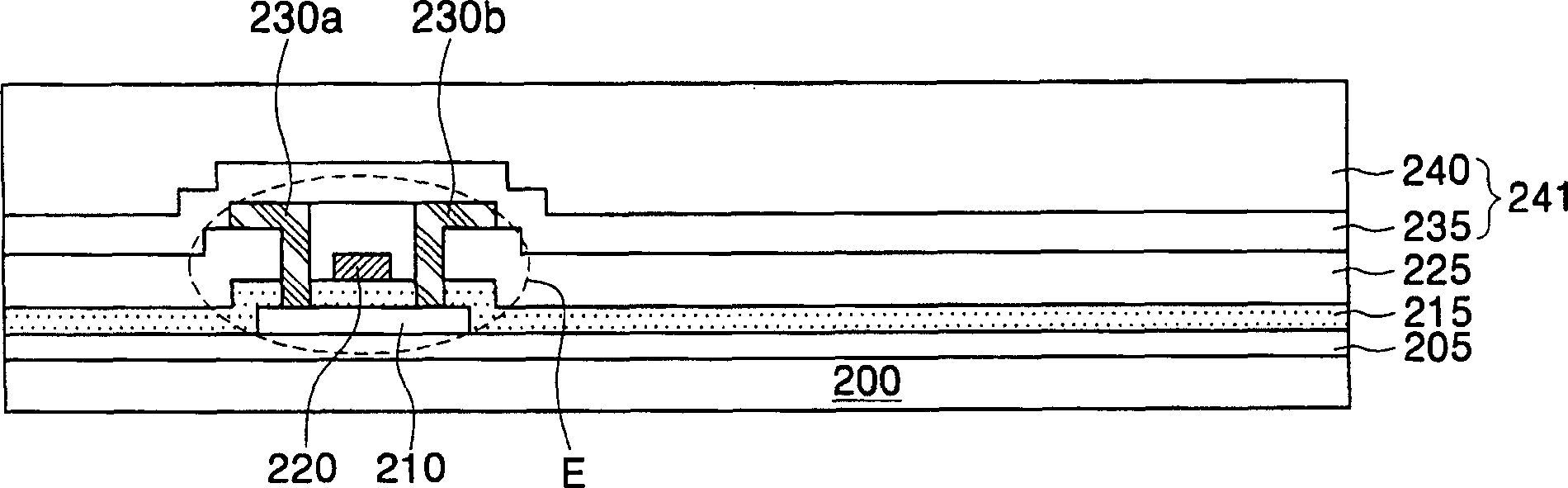

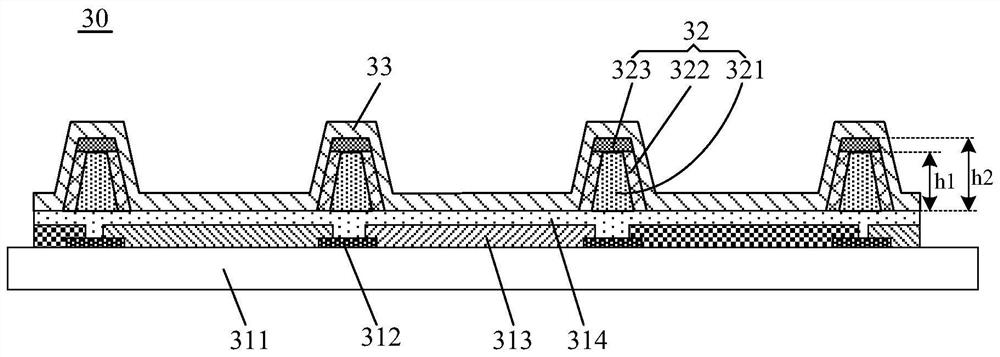

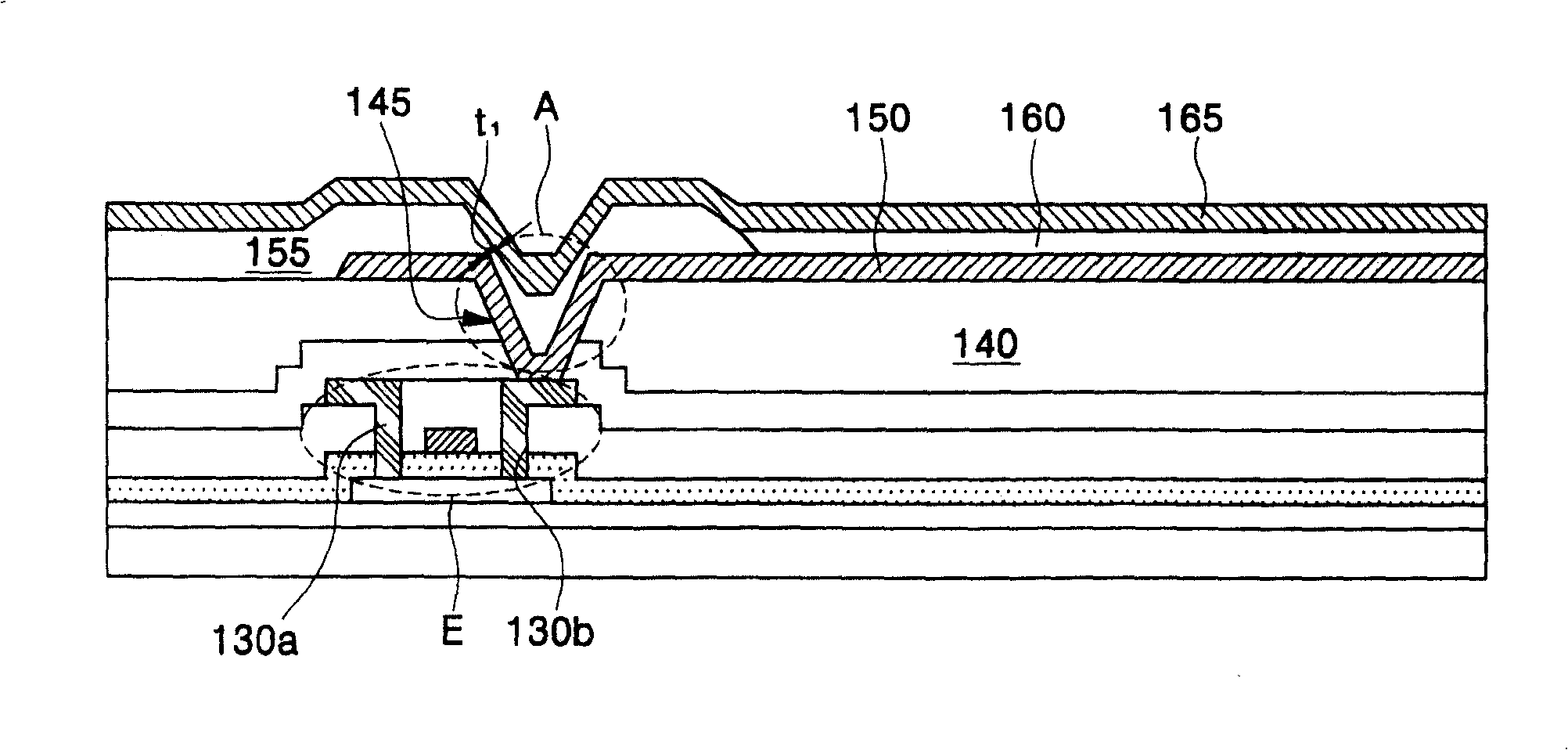

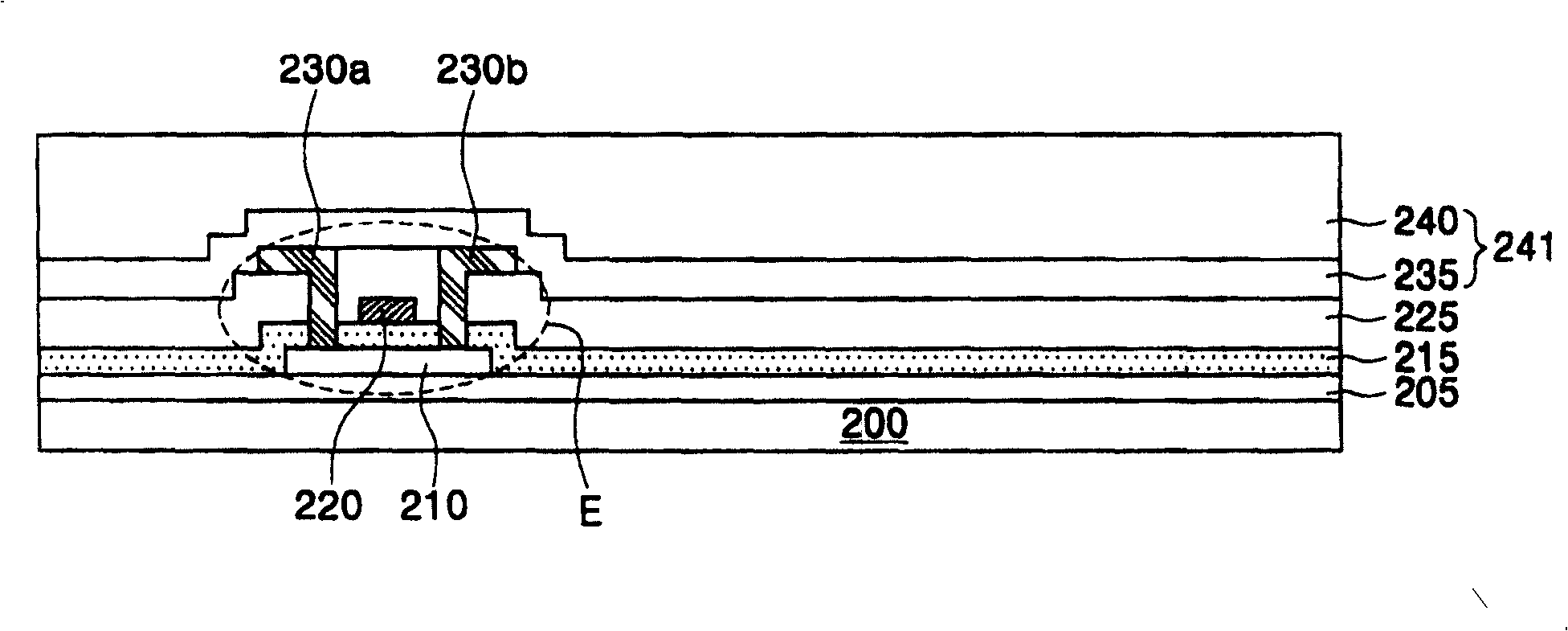

Organic light emitting display and method of fabricating the same

ActiveCN1773721AReduce electrical short circuitAvoid black spotsElectroluminescent light sourcesSolid-state devicesOptoelectronicsElectrode

In one embodiment, the present invention provides an organic light-emitting display (OLED), which includes: a TFT disposed on a substrate; an insulating layer disposed on the TFT and having a through hole; disposed on the insulating layer and connected through the through hole a pixel electrode to a drain electrode of the TFT; an emission layer disposed on the pixel electrode; and a counter electrode pattern disposed on the emission layer and exposing at least an upper portion of the through hole. This avoids the close structural proximity between the counter electrode and the pixel layer, thereby reducing the possibility of short circuits.

Owner:SAMSUNG DISPLAY CO LTD

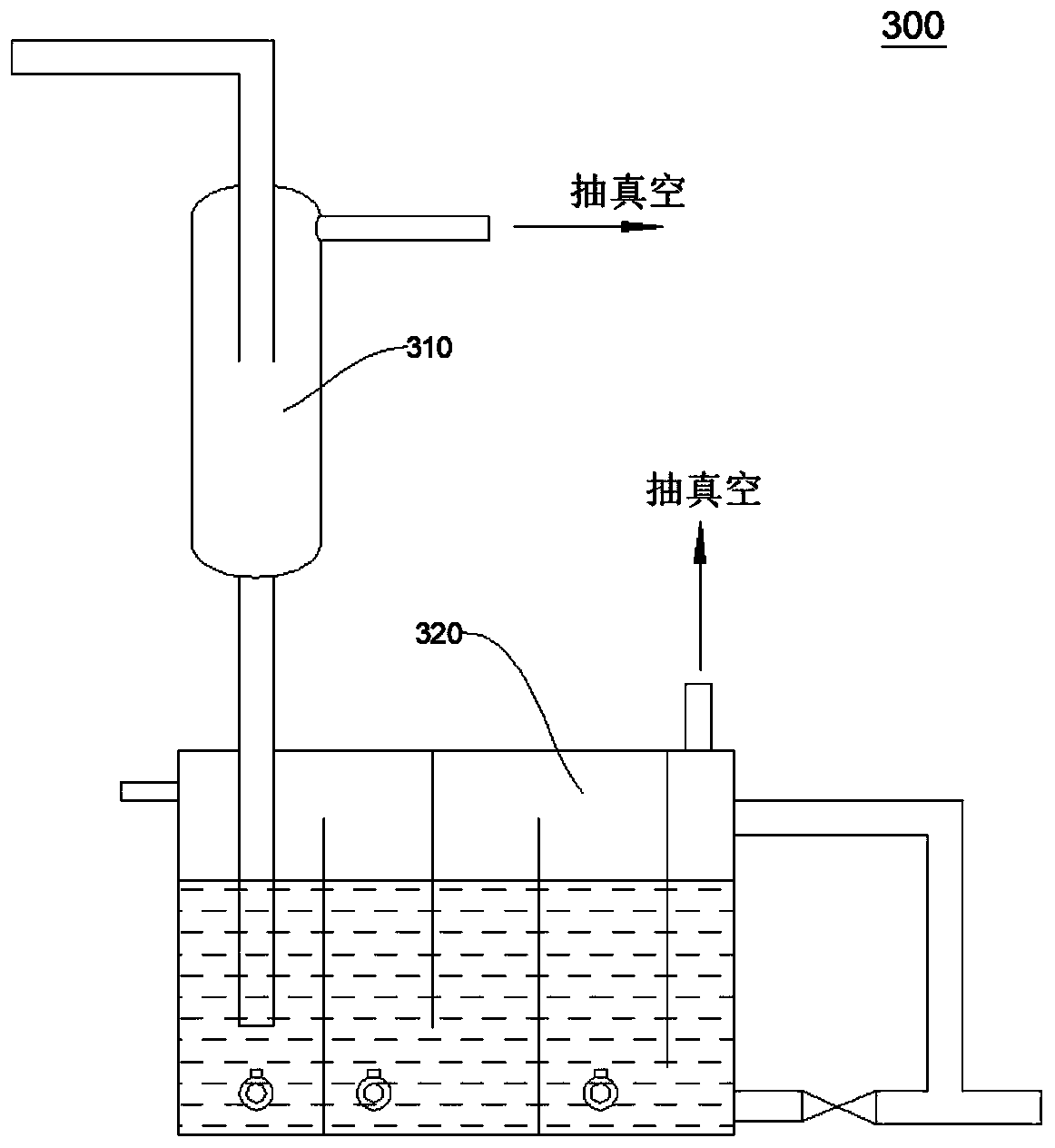

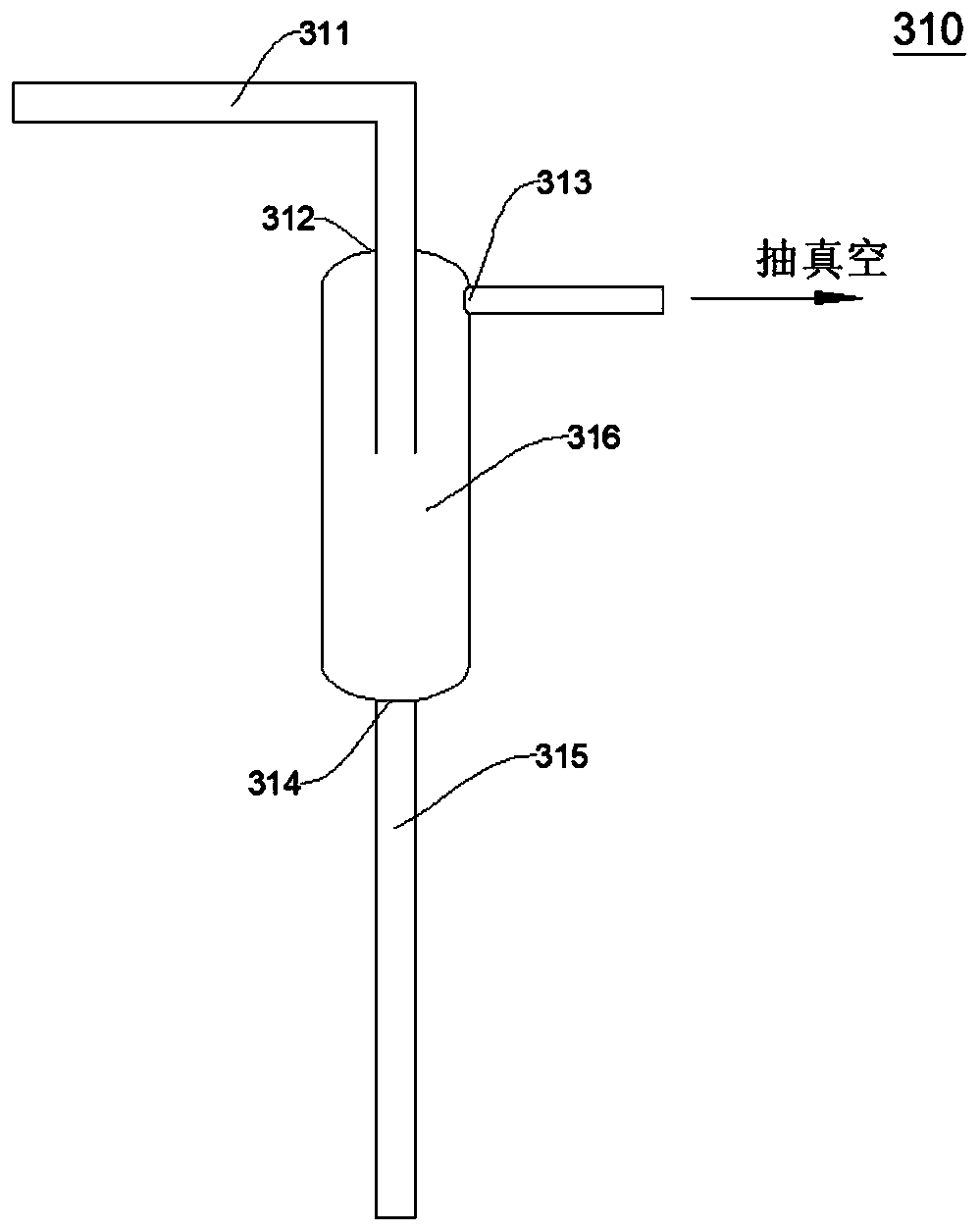

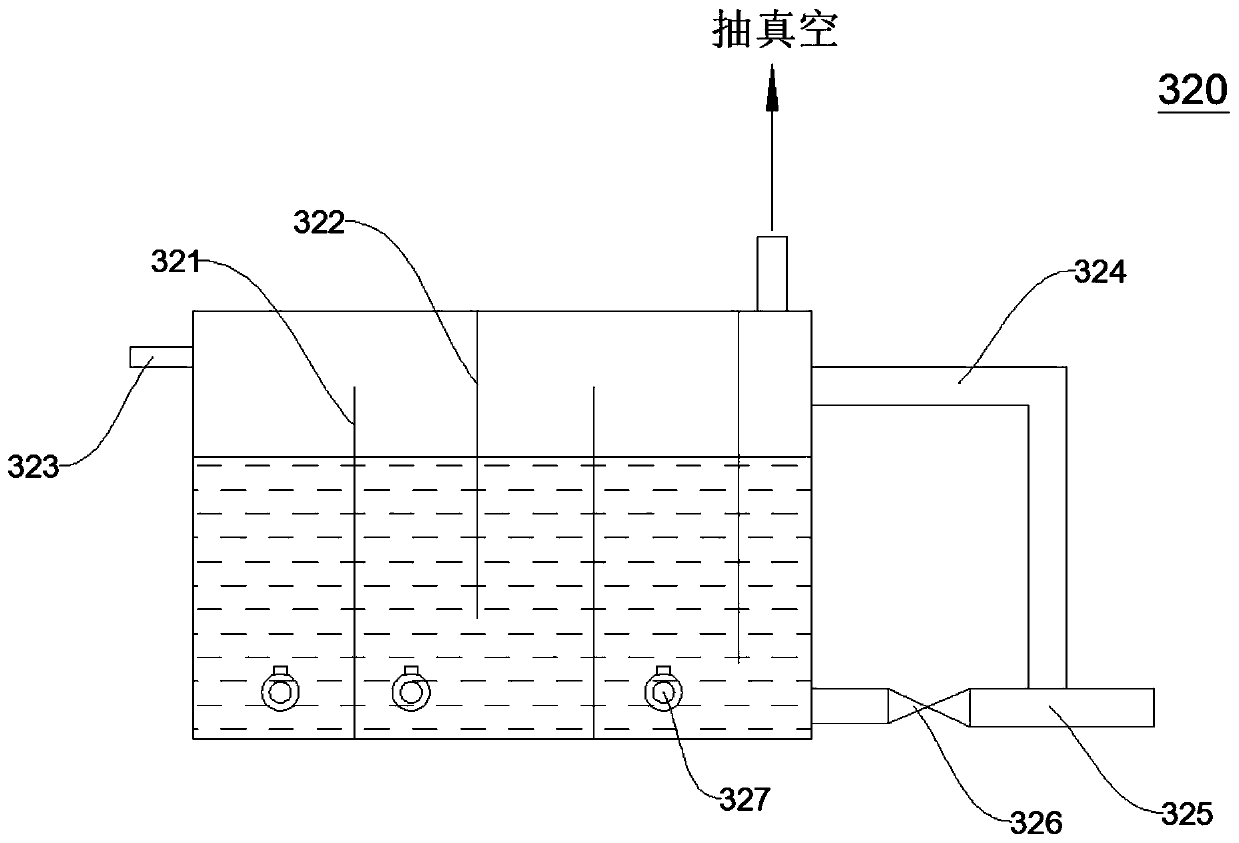

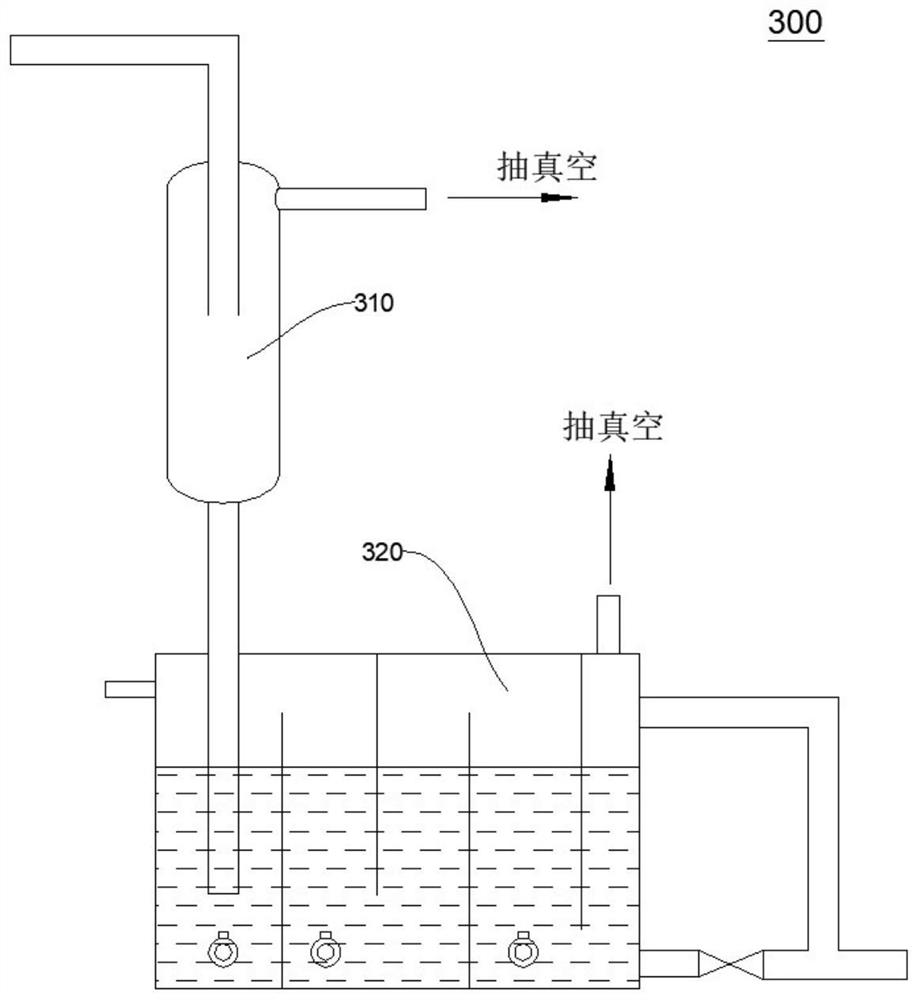

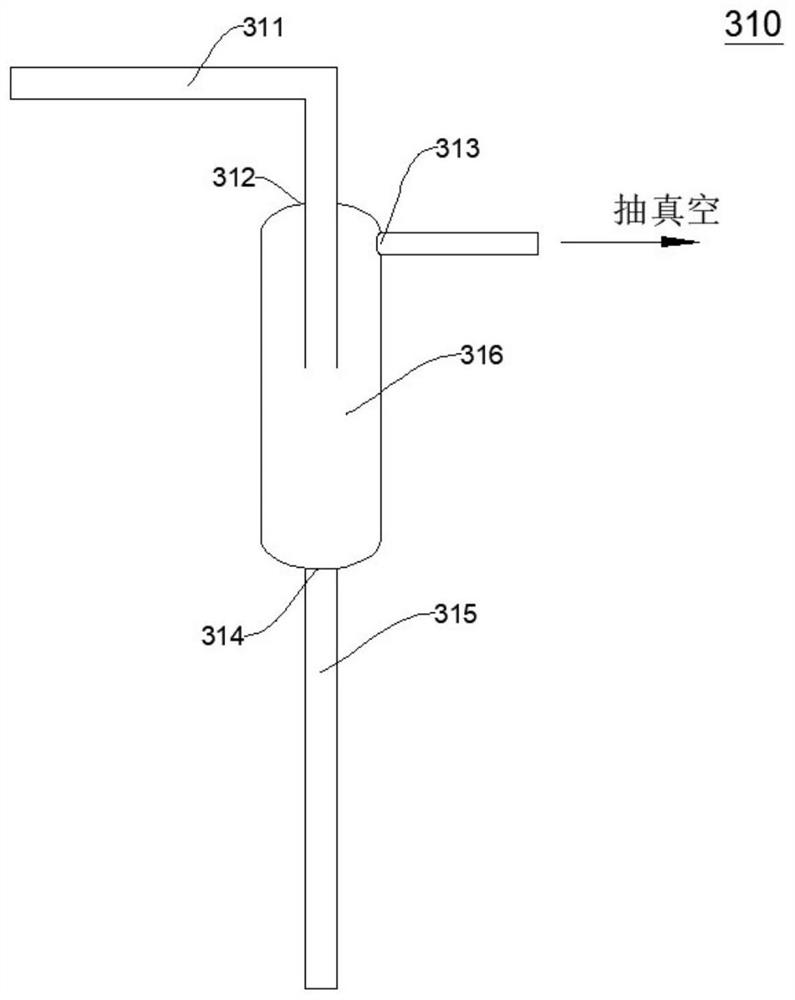

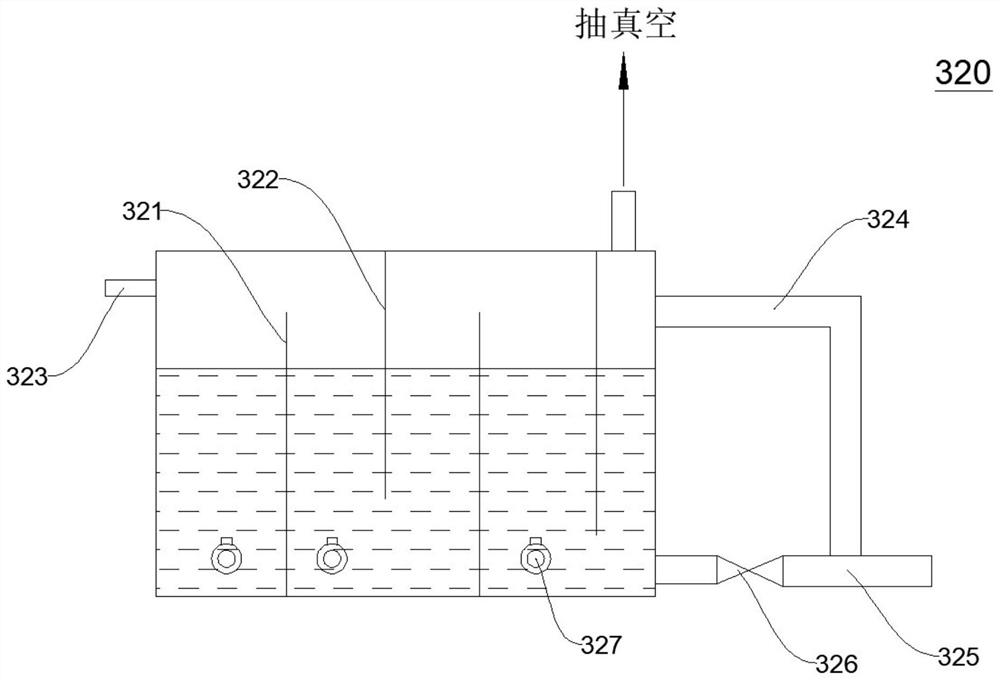

Phenol continuous extraction system, polycarbonate resin production system including same and production method

ActiveCN110538481ARealize sedimentation separationRealize continuous recovery at room temperatureOrganic chemistryOrganic compound preparationPolycarbonatePhenol

The invention provides a phenol continuous extraction system, a polycarbonate resin production system including the same and production method. A phenol continuous extraction apparatus comprises a gas-liquid separation apparatus and a phenol collection apparatus which are in communication, wherein the gas-liquid separation apparatus is used to adjust a flow rate of a gas-liquid mixture entering the gas-liquid separation apparatus, and at least one baffle plate is arranged longitudinally in the phenol collection apparatus. The provided phenol continuous extraction system can ensure vacuum degree and tightness of the polycarbonate resin production system, and simultaneously realizes continuous extraction of phenol as a by-product, and at the same time, the extracted phenol is effectively recycled.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

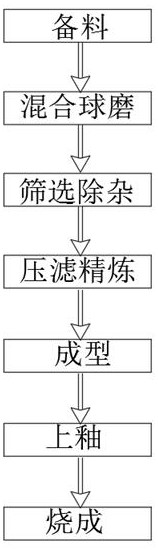

High-hardness domestic ceramic and production process thereof

The invention relates to the technical field of ceramic production, and discloses a high-hardness domestic ceramic and a production method thereof. The high-hardness domestic ceramic comprises a green body and a glaze layer, wherein the green body comprises kaolin, aluminum oxide, zirconium oxide, bentonite, waste porcelain slag, quartz and feldspar, and the glaze layer comprises kaolin, magnetic powder, talcum powder, spodumene, lithium chinastone, quartz and calcite. The invention further provides a production method of the high-hardness domestic ceramic. The production method comprises the following steps: S1, preparing materials; and S2, mixing and ball-milling. Through the formula combined, the hardness of a green body can be improved, a refined mud cake is uniform in structure and higher in plasticity, the hardness of a finished product is improved, black spots can be prevented from being generated on a sintered product, inert gas is filled, the stability is improved, and cracks are prevented from being generated on the product.

Owner:福建省德化新吉利工艺有限公司

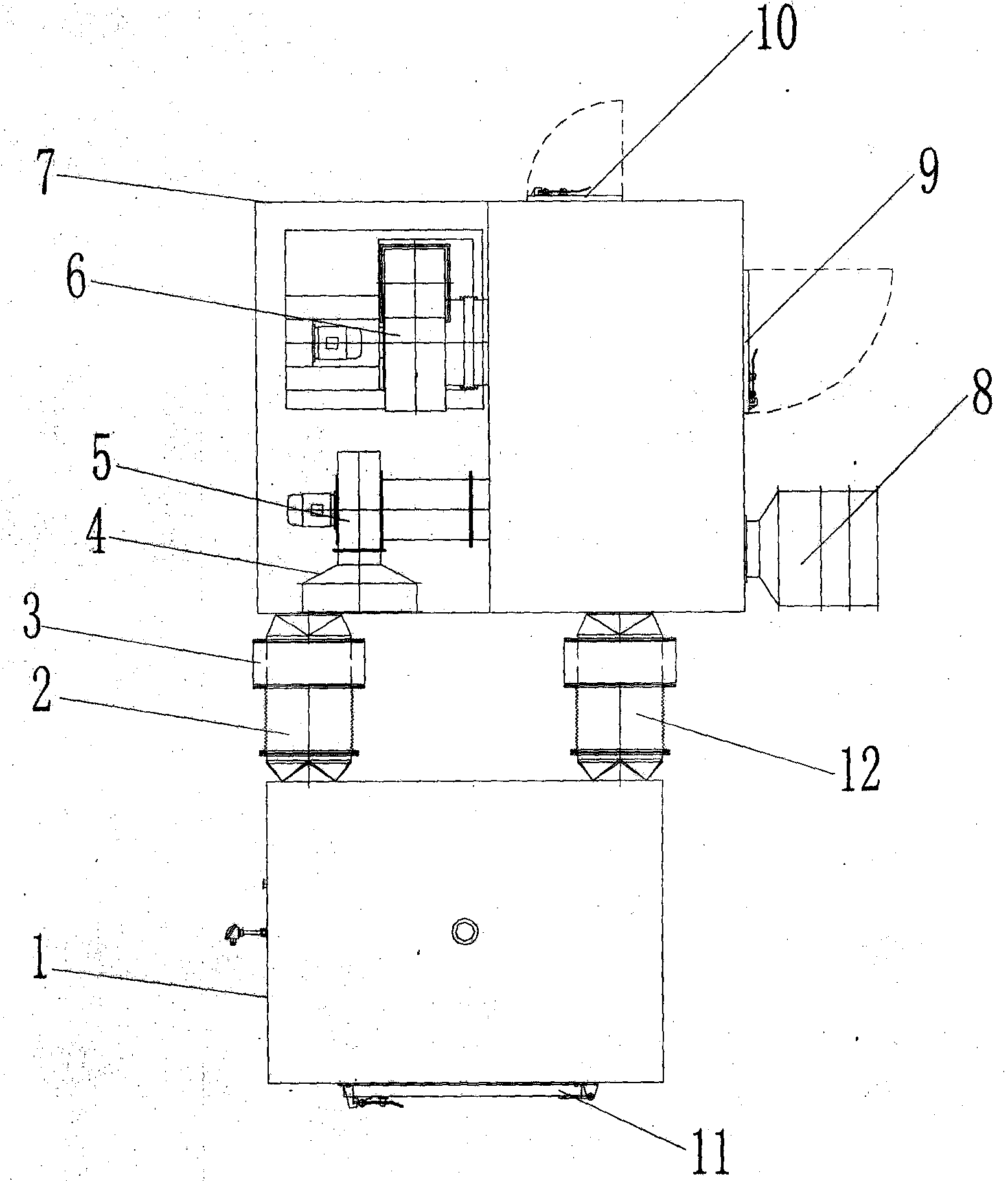

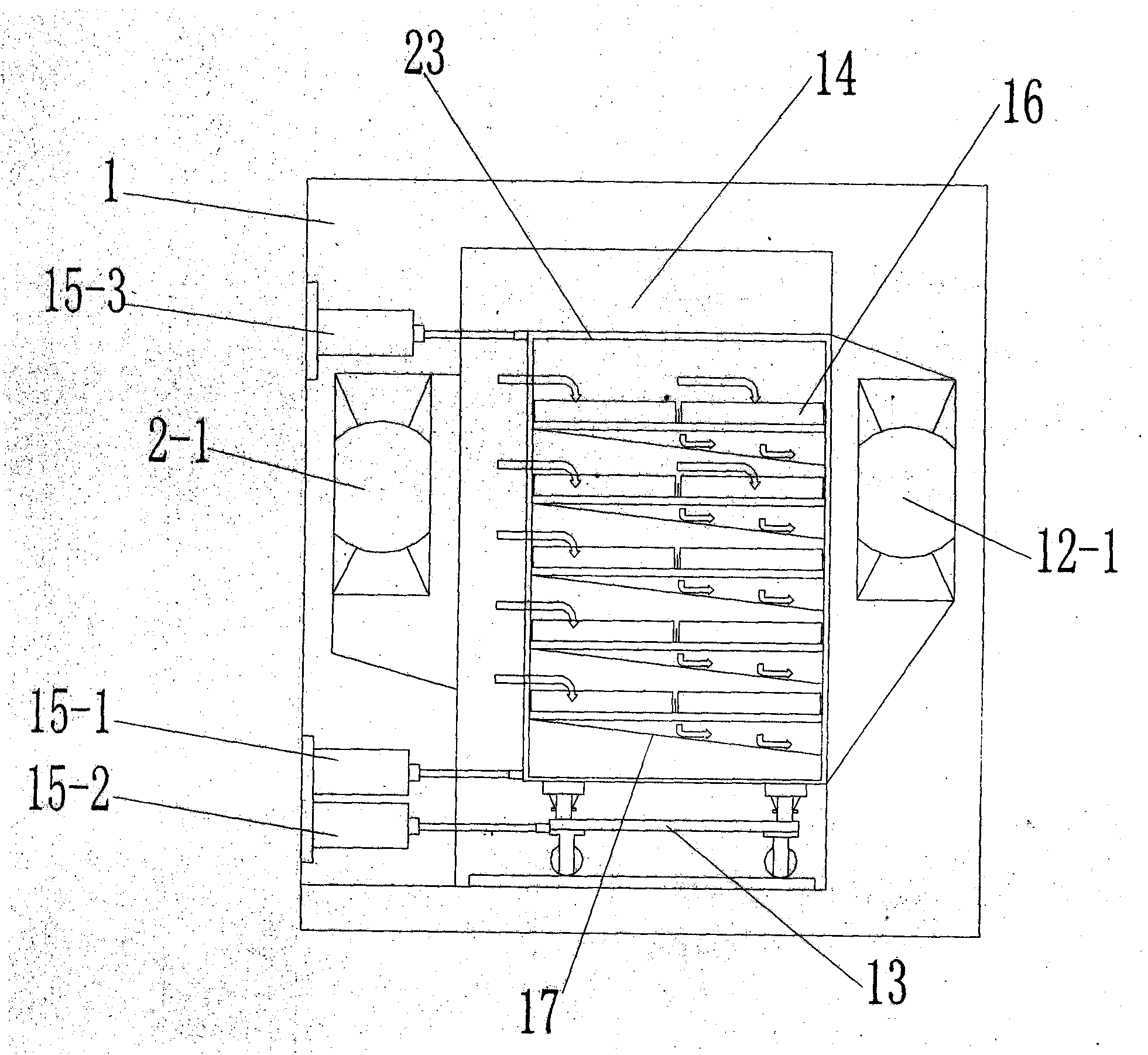

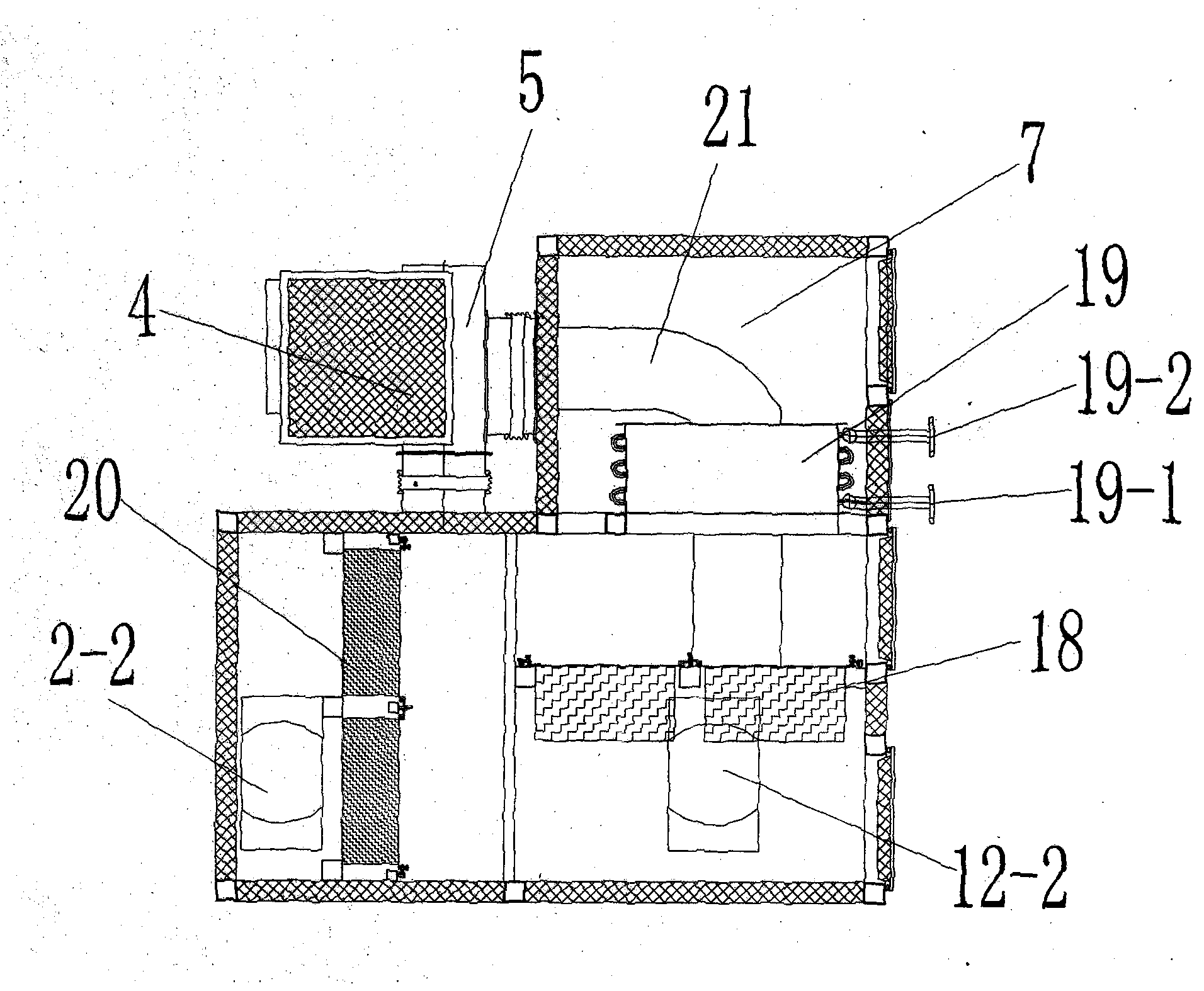

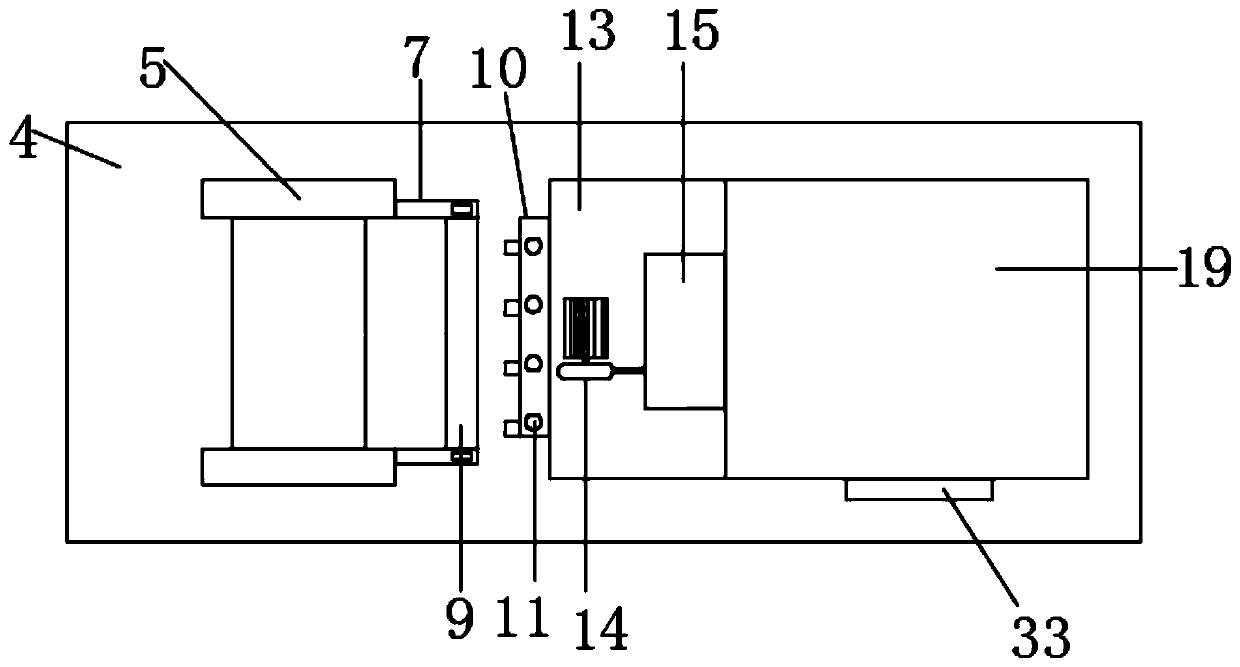

Convection type clean oven

InactiveCN103913047AImprove drying efficiencyAvoid flyingDrying gas arrangementsDrying chambers/containersEngineeringConvection

The invention relates to the technical field of drying medicines, chemicals, foods and pharmaceutical raw materials, and in particular to a convection type clean oven comprising an oven main unit (1) and an oven auxiliary unit (2). The left and right sides of the oven main unit (1) are respectively provided with a main unit air inlet (2-1) and a main unit air returning port (12-1). The interior of the oven auxiliary unit (2) is divided into three independent spaces through partitions, a first space is provided with a high-efficient filter (20) on the perpendicular direction, two sides of the high-efficient filter (20) are respectively provided with na oven auxiliary unit air outlet (2-2) and a circulating fan air outlet, a second space is provided with a medium-efficient filter (18) on the horizontal direction, the lower end of the medium-efficient filter (18) on the side wall of the oven auxiliary unit is provided with an oven auxiliary unit air returning port (12-2), the lower horizontal plane of a third space is provided with a heat exchanger (19), and the side wall of the oven auxiliary unit in the third space is provided with a circulating fan air inlet; the outer walls of the oven auxiliary unit (2) are provided with a wet exhaust fan (5), a circulating fan (6) and a fresh air inlet (8).

Owner:CHANGZHOU AOKAI DRYING EQUIP

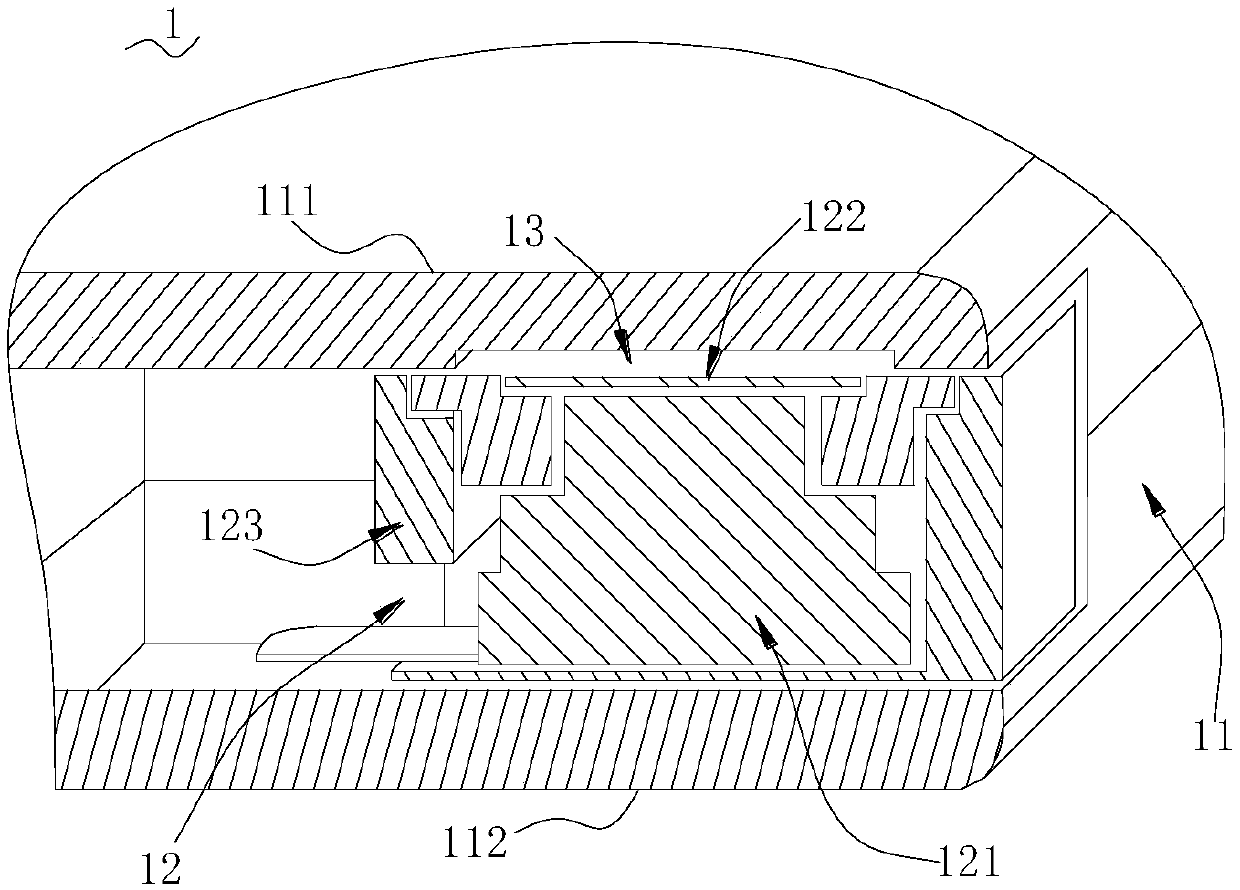

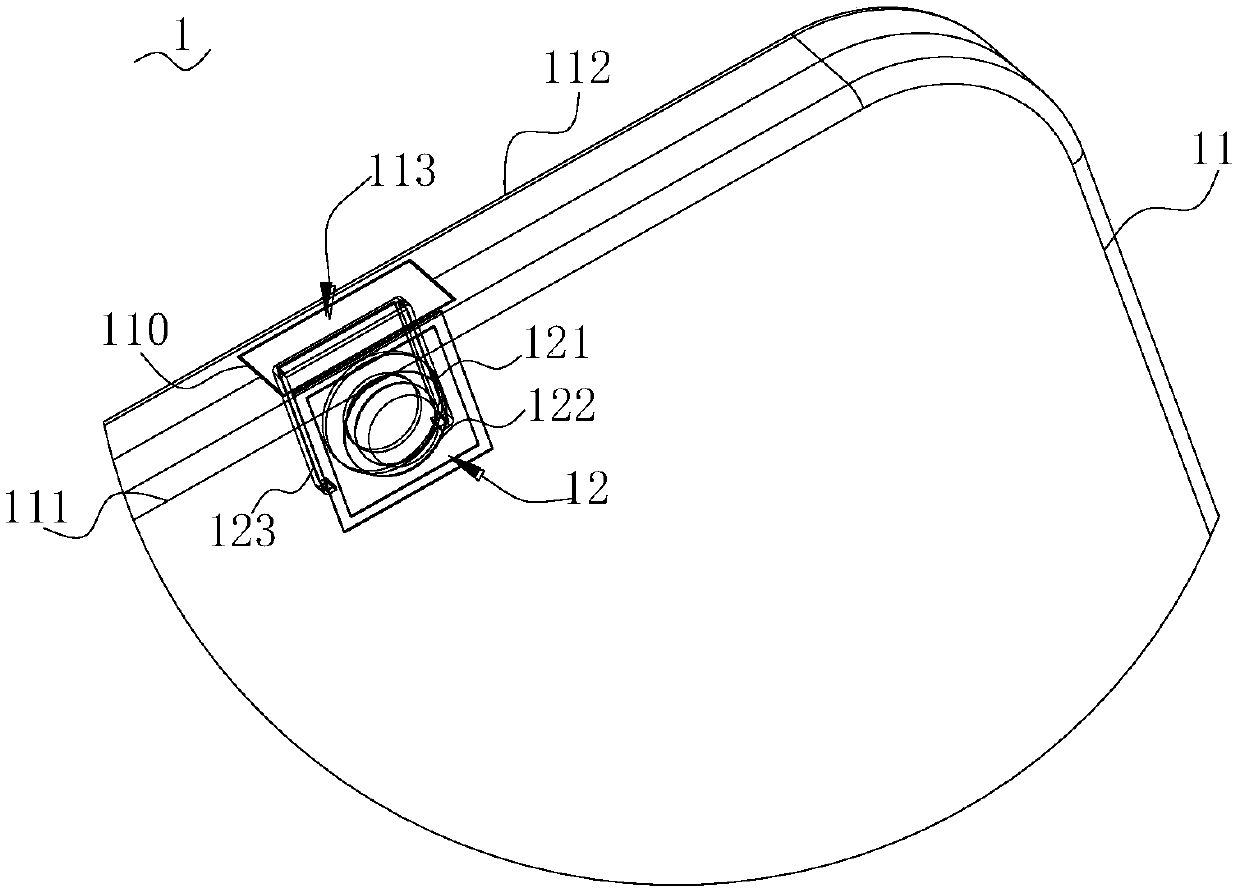

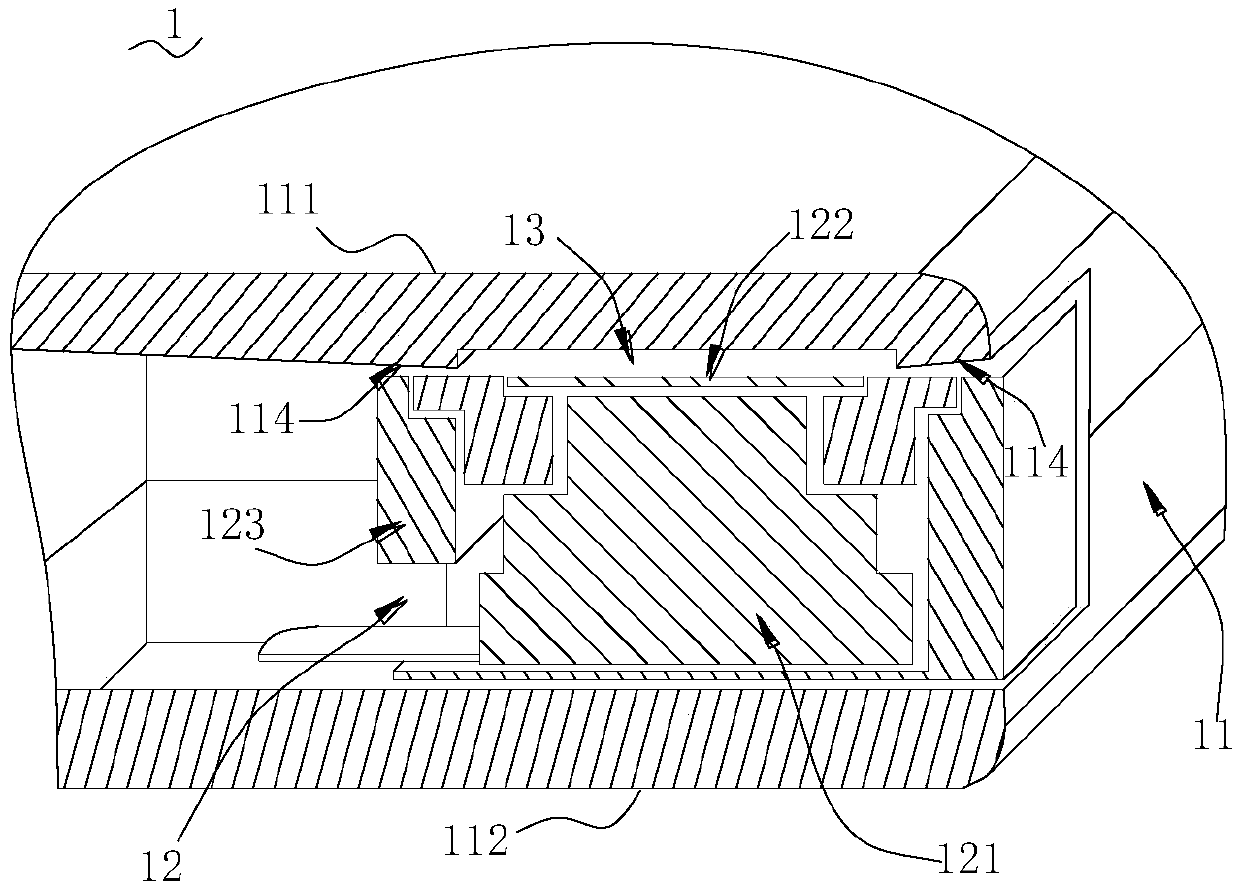

Mobile terminal

ActiveCN109525693AHigh-quality shooting effectImprove cleanlinessCleaning using toolsTelephone set constructionsBlack spotComputer terminal

The invention provides a mobile terminal comprising a housing and an imaging assembly disposed inside the housing. The surface of the housing is provided with a through hole. The imaging assembly canbe extended or retracted into the housing by the through hole. The imaging assembly comprises a camera and a lens that faces the camera. The inner wall of the housing facing the lens is provided witha dust removing structure, so that the area of the housing facing the moving path of the lens forms an uneven surface. When the imaging assembly is stretched, the more prominent portion of the unevensurface scrapes off the dust adhering to the lens. In the mobile terminal of the invention, when the imaging assembly is extended or retracted into the housing, the more prominent portion of the uneven surface removes the dust adhering to the lens, so that the dust is separated from the surface of the lens, which ensures that the lens surface is clean when the imaging assembly is extended. The user does not need to wipe the lens by hand or by lens wiping cloth, and the dust removing structure scrapes off the dust on the lens surface, which can effectively avoid the generation of black groups and black spots on the shooting imaging, and ensure the high quality shooting effect of the mobile terminal.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

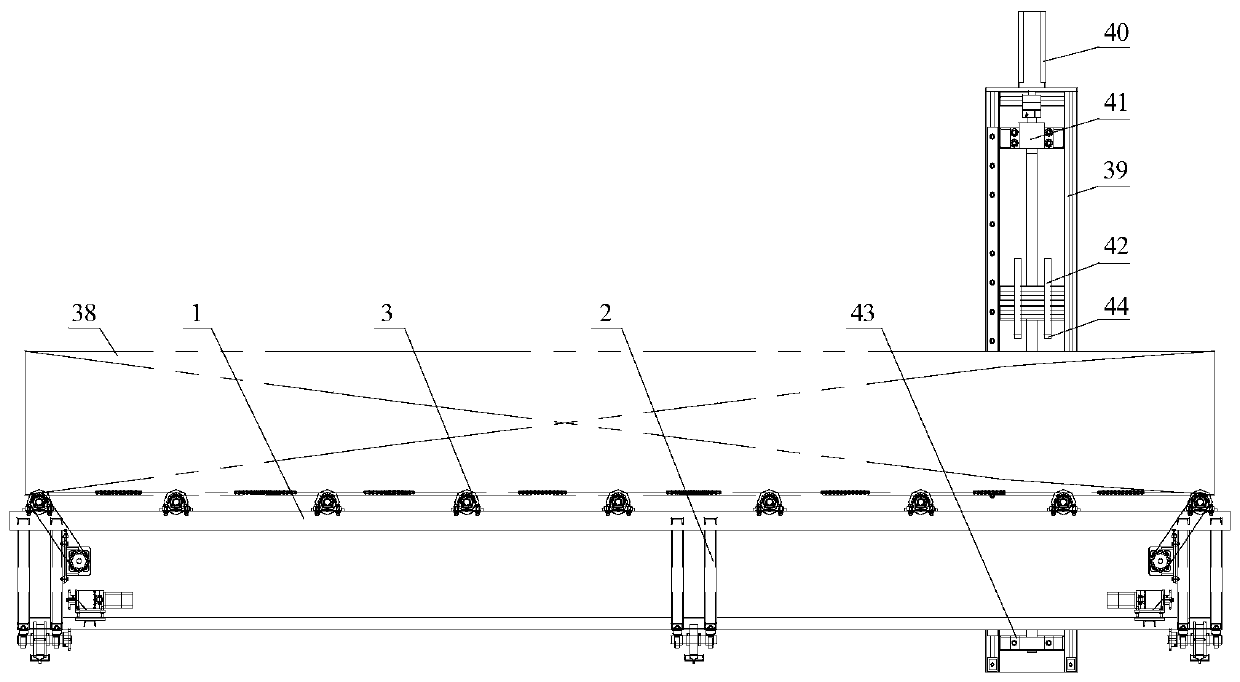

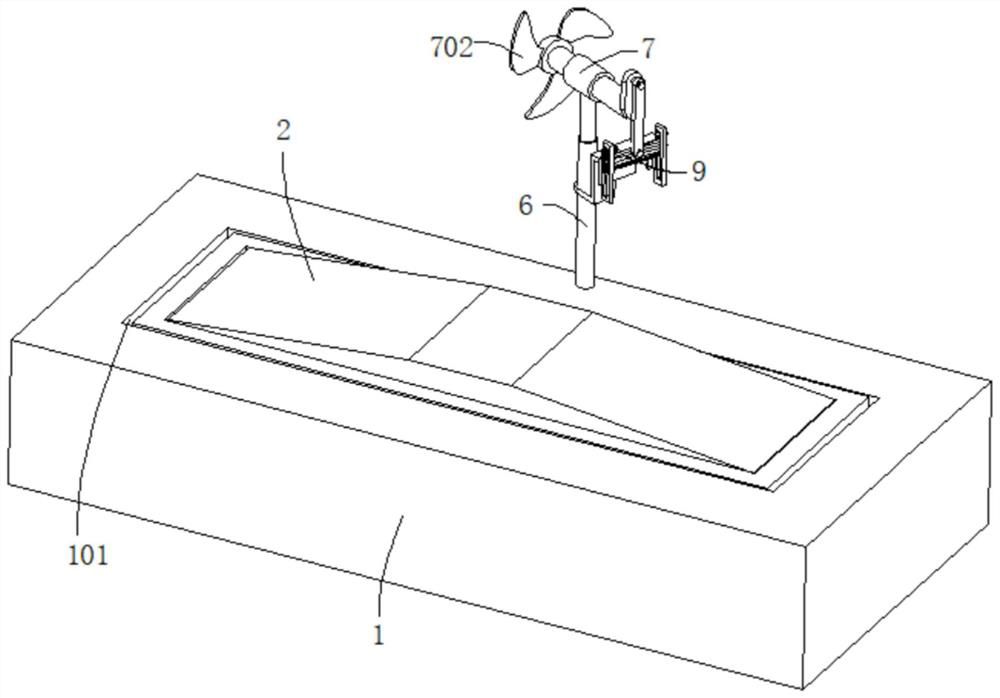

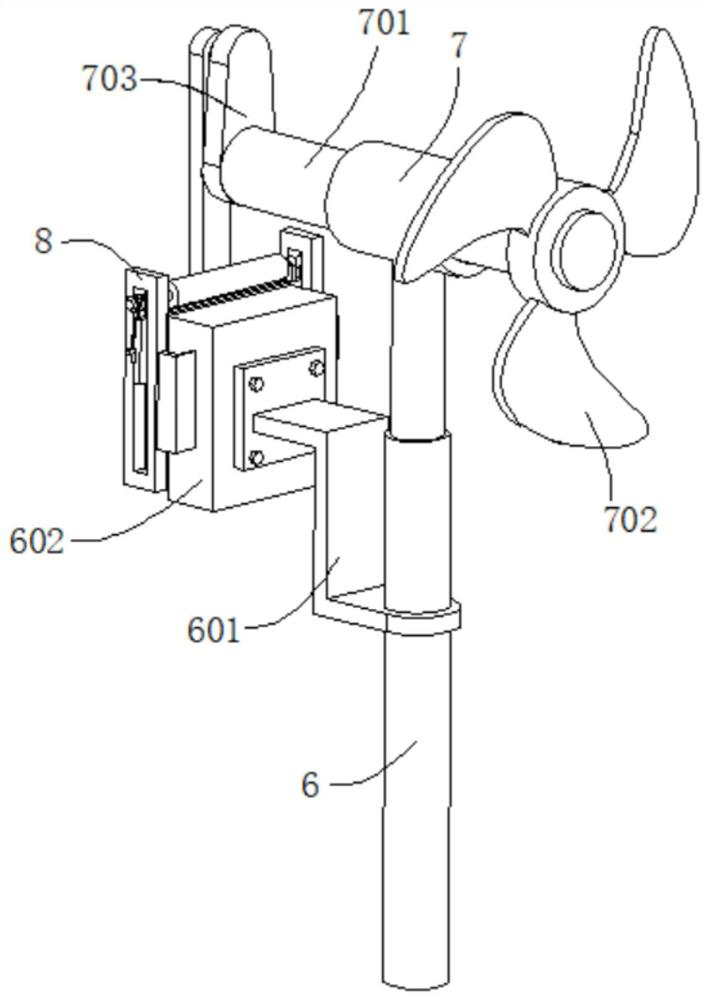

Data acquisition device for dynamic weighing of vehicle and use method thereof

PendingCN113847978AAssurance of Accuracy and CompletenessSpeed up the drying rateWeighing apparatus detailsCleaning using toolsCamera lensStructural engineering

The invention discloses a data acquisition device for dynamic weighing of a vehicle and a use method thereof, and belongs to the technical field of dynamic weighing. The data acquisition device for dynamic weighing of the vehicle comprises a pavement foundation and a groove formed in the pavement foundation and used for placing a weighing assembly, and further comprises a base connected to the inner wall of the groove, wherein a pressure sensor is arranged between the base and the weighing assembly and used for dynamically weighing a running vehicle; an exhaust pipe arranged below the weighing assembly and used for removing dust from the pressure sensor; a camera device which comprises a supporting column connected to a pavement foundation, wherein the outer wall of the supporting column is connected with a connecting frame, and the end, away from the supporting column, of the connecting frame is connected with a camera lens; and a wind power dust removal mechanism arranged on the outer side of the supporting column and used for conducting dust removal operation on the camera lens. According to the invention, dust on the outer sides of the camera lens and the pressure sensor is cleaned, so that the accuracy of weighing data acquisition is ensured.

Owner:浙江东鼎电子股份有限公司

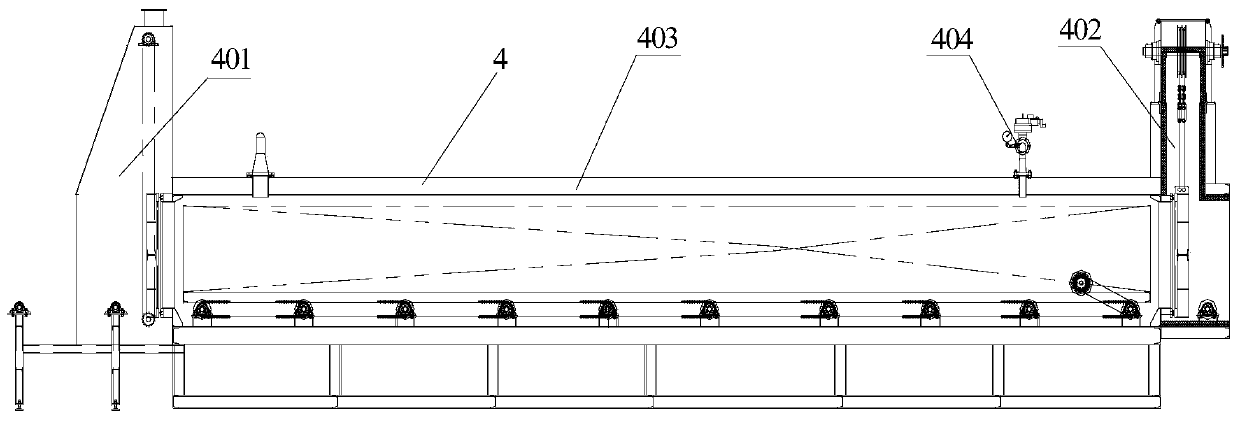

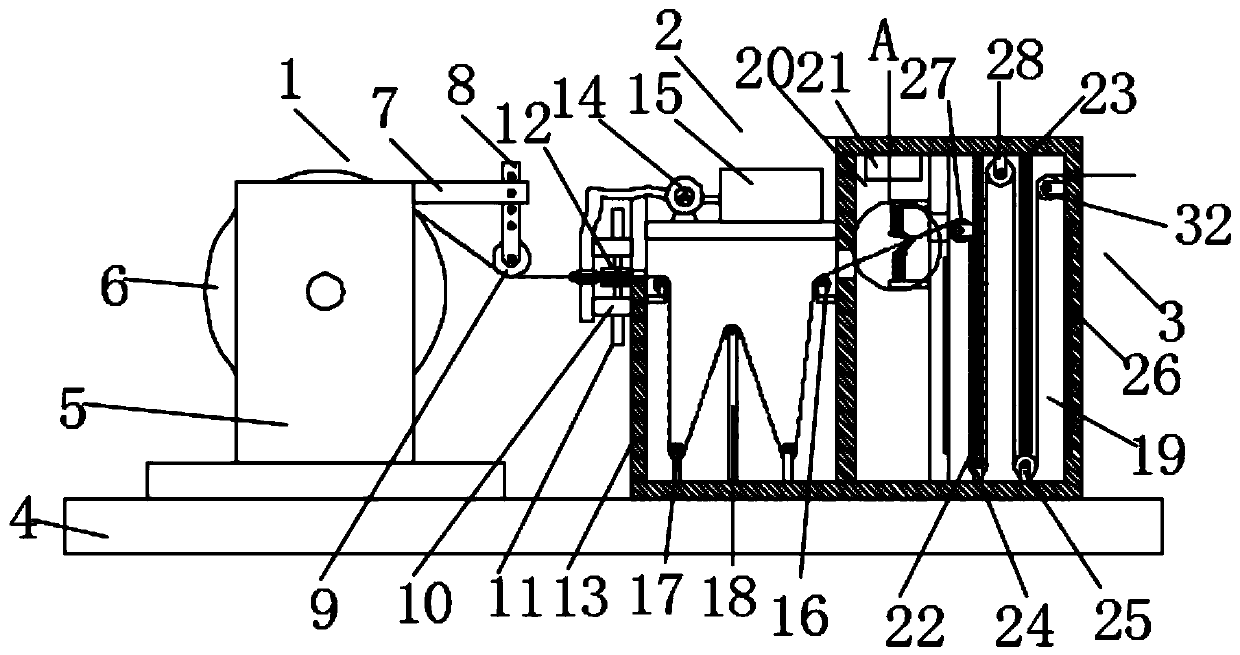

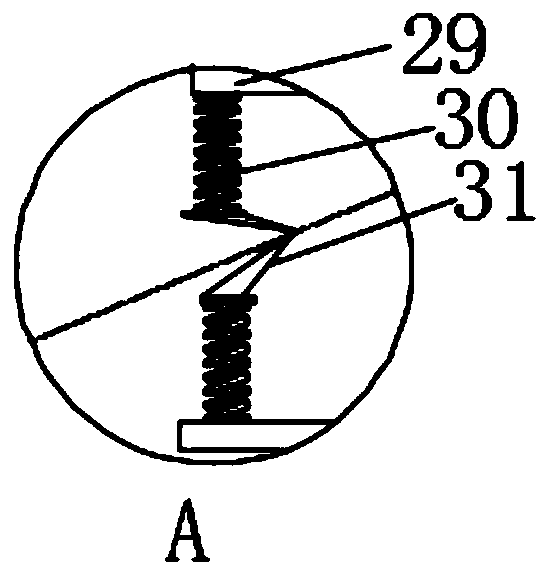

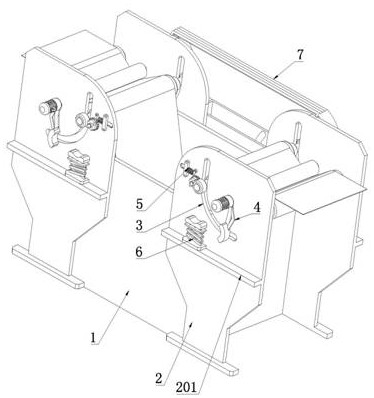

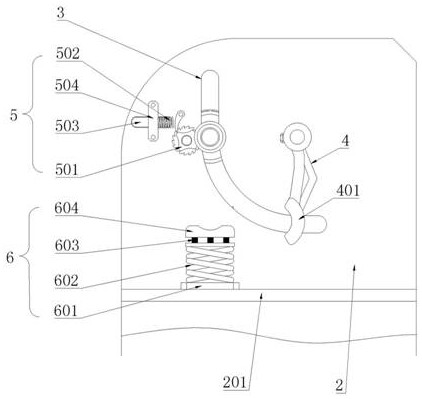

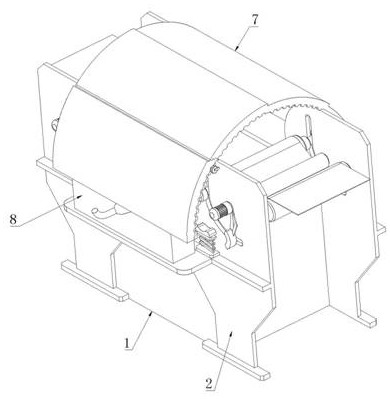

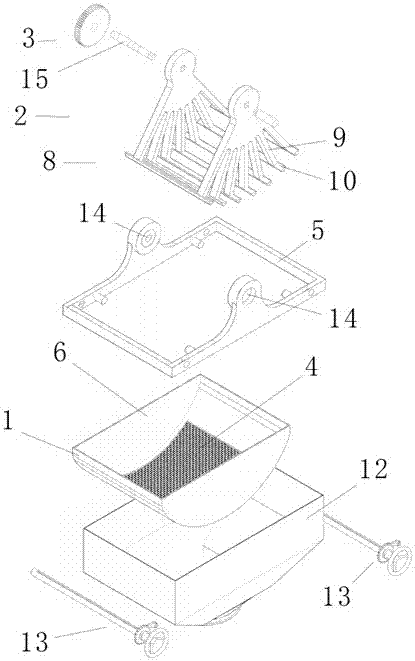

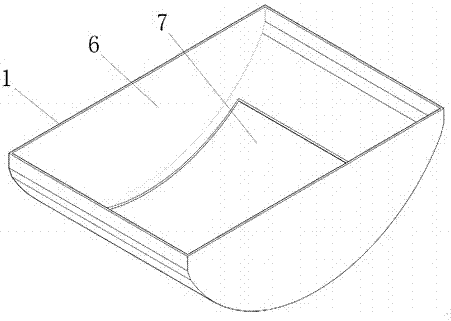

Paper impregnating device for producing glue film paper

InactiveCN110777564AAvoid black spotsAvoid wastingPaper/cardboardApplied substance rearrangementAdhesive glueDust control

The invention discloses a paper impregnating device for producing glue film paper. The paper impregnating device comprises a cleaning mechanism, an impregnating mechanism and a drying mechanism; the cleaning mechanism is composed of a bottom support plate, support plates, a material roller, a balance support rod, a height regulating rod, a first conveying roller, a fixed support seat, a controllable pitch cylinder, a cleaning brush, an impregnating box, a cleaning fan and a dust collection box. Through arrangement of the cleaning fan and the cleaning brush, paper is cleaned through the cleaning brush in work, and dust on the outer side of the paper is sucked by the cleaning fan through a dust suction nozzle; impurities or the dust is prevented from being attached to the outer side paper, and black points of the paper after impregnation are avoided; through arrangement of a glue filtering box and drying box, glue can be filtered for the paper, and the situation that the glue is uneven and wasted is avoided; a first separating plate and a second separating plate are added, and the both sides of the paper are processed through ceramic heating plates simultaneously and uniformly, so that the drying efficiency of the paper is improved; and the production efficiency of the glue film paper is improved.

Owner:池韬略

Packaging cover plate and preparation method thereof, display panel and display device

PendingCN112993192AAvoid conductionAvoid erosionSolid-state devicesSemiconductor/solid-state device manufacturingWater vaporDisplay device

The embodiment of the invention provides a packaging cover plate, a preparation method thereof, a display panel and a display device. The packaging cover plate comprises: a cover plate structure layer; a spacing column structure located on one side of the cover plate structure layer, wherein the spacing column structure comprises a first spacing column located on one side of the cover plate structure layer, and the first spacing column comprises a water absorption structure; and an auxiliary electrode layer located on the side, away from the cover plate structure layer, of the spacing column structure, wherein the spacing column structure is configured to prevent water vapor from diffusing towards the auxiliary electrode layer along the spacing column structure. According to the technical scheme, the spacing column structure can prevent water vapor from diffusing towards the auxiliary electrode layer along the spacing column structure, so that the water vapor is prevented from diffusing to the top electrode and the organic functional layer of the display substrate, black spots can be avoided, the display effect of the display panel is improved, and the service life of the display panel is prolonged.

Owner:BOE TECH GRP CO LTD

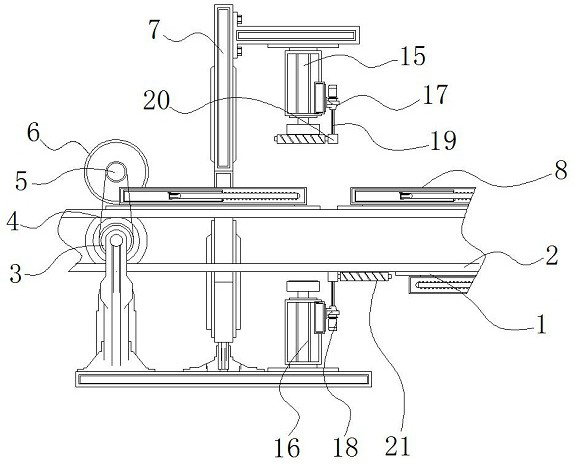

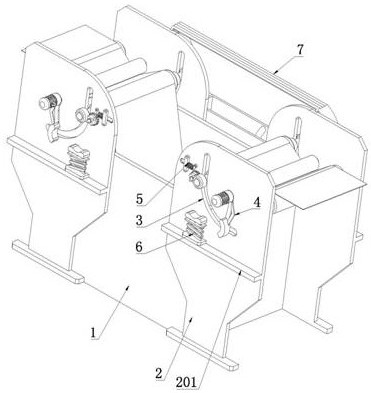

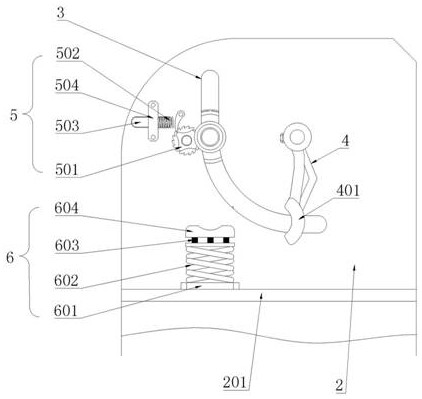

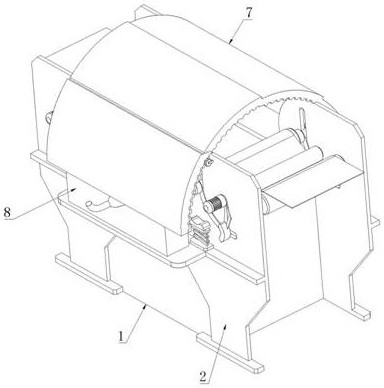

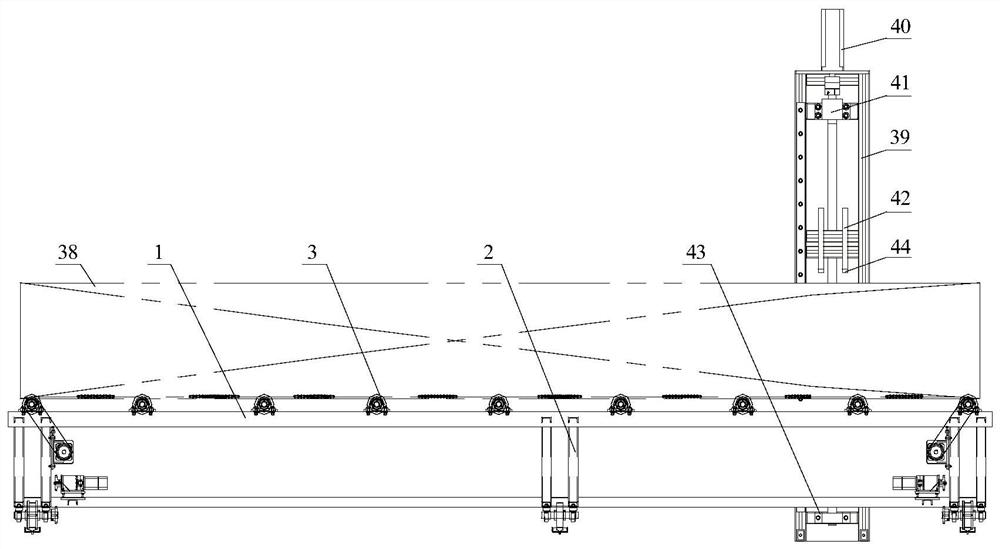

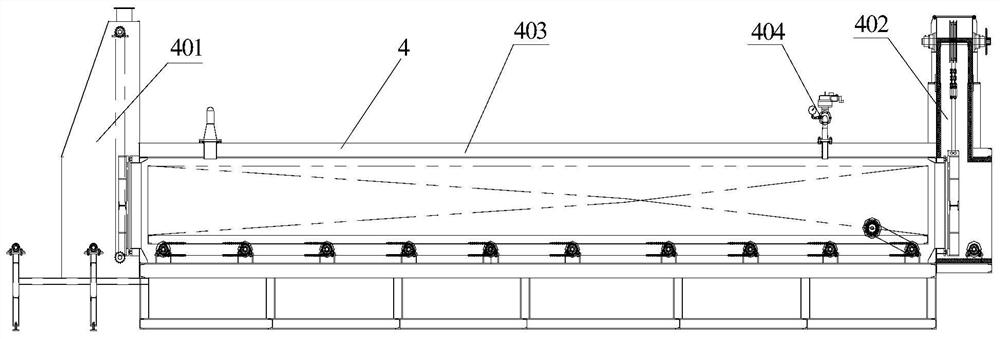

Self-adaptive tension copper foil surface treatment machine

The invention discloses a self-adaptive tension copper foil surface treatment machine, and relates to the field of copper foil processing. The self-adaptive tension copper foil surface treatment machine is characterized in that clamping shaft seats are rotatably arranged on two inner side walls of a pickling tank in a sealing mode, brackets are fixedly arranged on two outer sides of the pickling tank, arc grooves are formed in the brackets, a push rod is rotatably arranged on a support plate, and a free end of the push rod is fixedly connected with a first top block; a ratchet mechanism fixed to the support is arranged on the side, away from the push rod, of the arc groove; a lifting mechanism is further arranged on each bracket, an elastic piece is fixedly arranged on the lifting mechanism, and a second ejector block is fixedly connected to the elastic piece; a folding fan cover is further arranged on the outer side of the pickling tank, and an alkaline water tank is arranged in the folding fan cover. According to the technical scheme, a submerged roller is arranged to be in a hanging and clamping mode, the process of discharging acid liquor is omitted, the arc grooves are formed to change the position of a tensioning roller to avoid hanging work of the submerged roller, the lifting mechanism is used for controlling the height of the tensioning roller, and the elastic piece is arranged to achieve the effect of automatically and finely adjusting the tension of copper foil.

Owner:江西省江铜铜箔科技股份有限公司

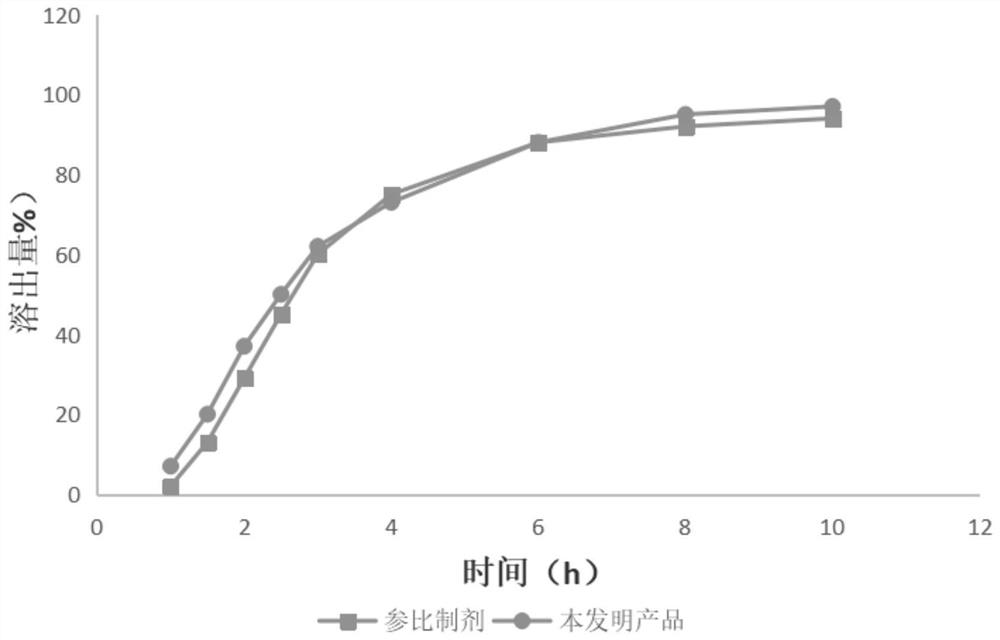

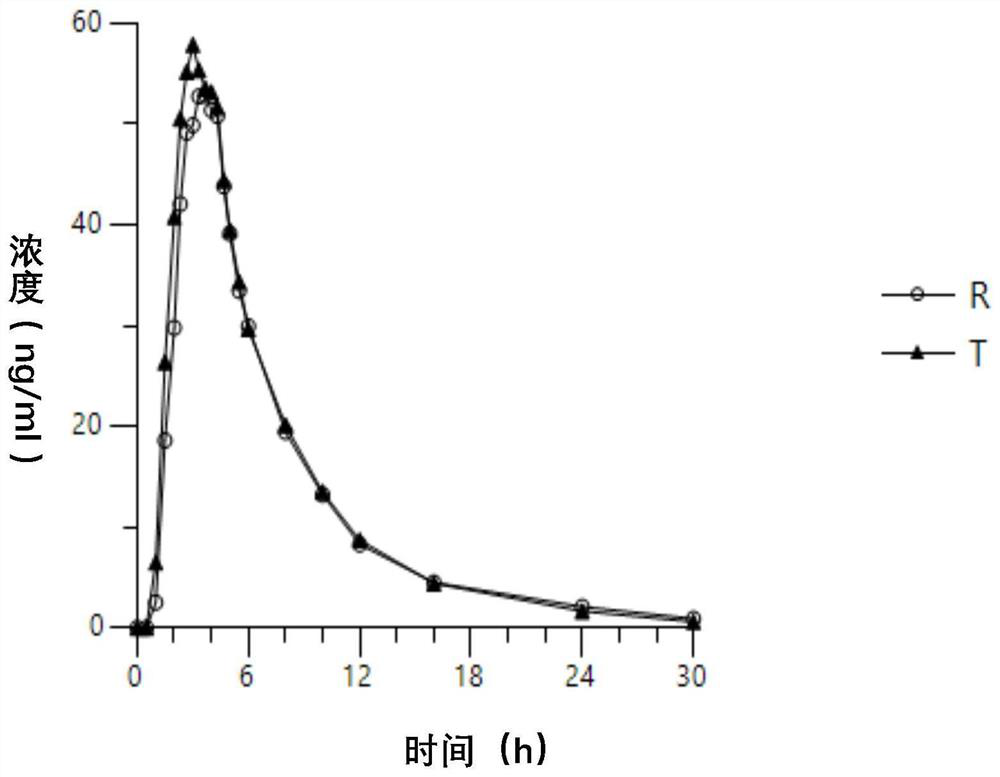

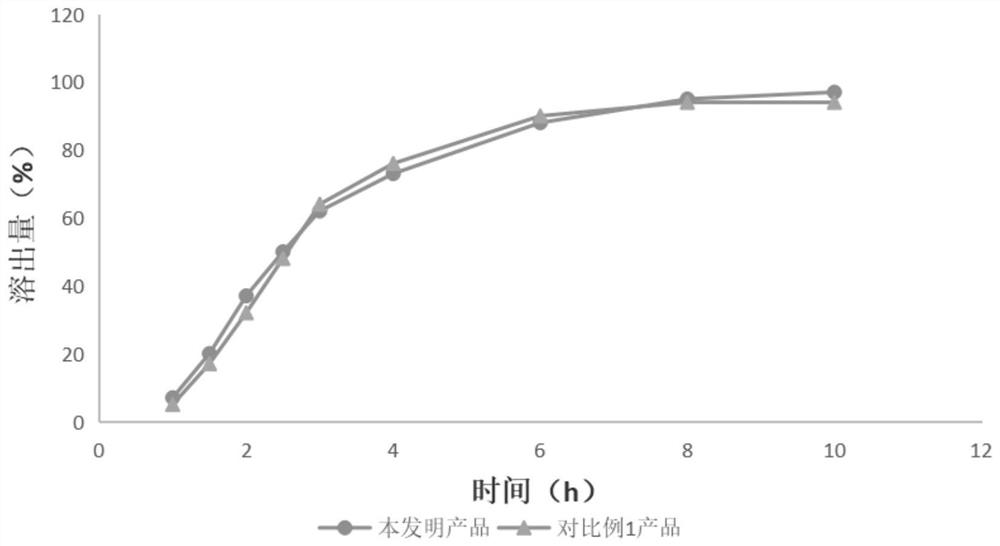

Tofacitinib citrate sustained release tablet

PendingCN112755000AImprove pass rateAvoid black spotsOrganic active ingredientsAntipyreticClinical efficacyProlonged-release tablet

The invention provides a tofacitinib citrate sustained release tablet. The tofacitinib citrate sustained release tablet is composed of a tablet core, a sustained release layer coating and a color layer coating, wherein drug release pores are formed in the sustained release layer coating. According to the tofacitinib citrate sustained release tablet, the composition of an osmotic pressure forming agent and the dosage ratio of the osmotic pressure forming agent to a sustained release agent are adjusted, and the composition of the sustained release layer coating and the weight increment of the coating are further optimized, so that the defect that the dissolution speed is reduced after long-term storage when sorbitol is singly used as the osmotic pressure forming agent is avoided, the initial release speed of the tofacitinib citrate sustained release tablet is increased, the tofacitinib citrate sustained release tablet can be slowly and continuously released after being kept for 6 hours, the drug release is relatively complete, the blood concentration is kept at a uniform and stable level for a long time, the fluctuation of the blood concentration during the administration interval is reduced, the bioavailability is further improved, the adverse reaction is reduced, and the clinical curative effect and safety are guaranteed.

Owner:CSPC OUYI PHARM CO LTD

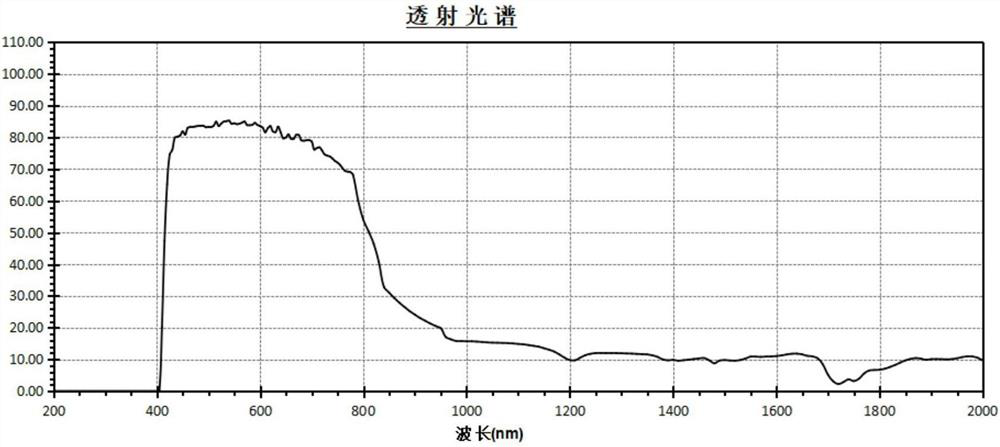

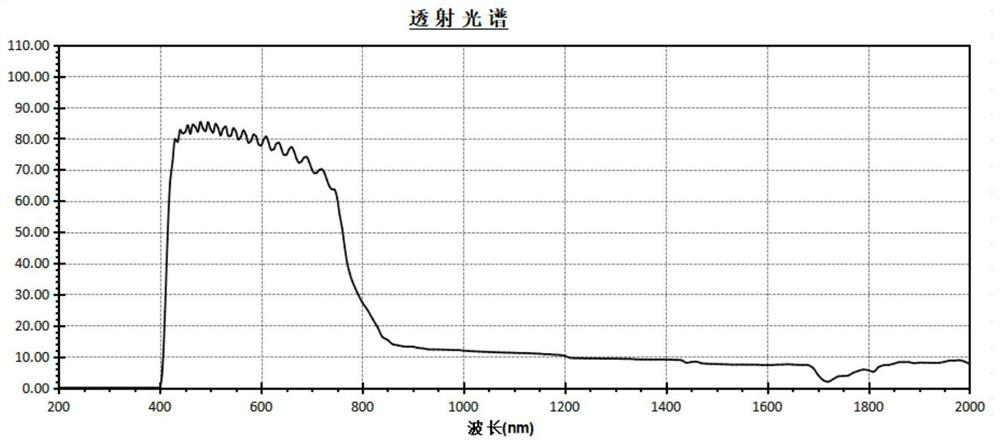

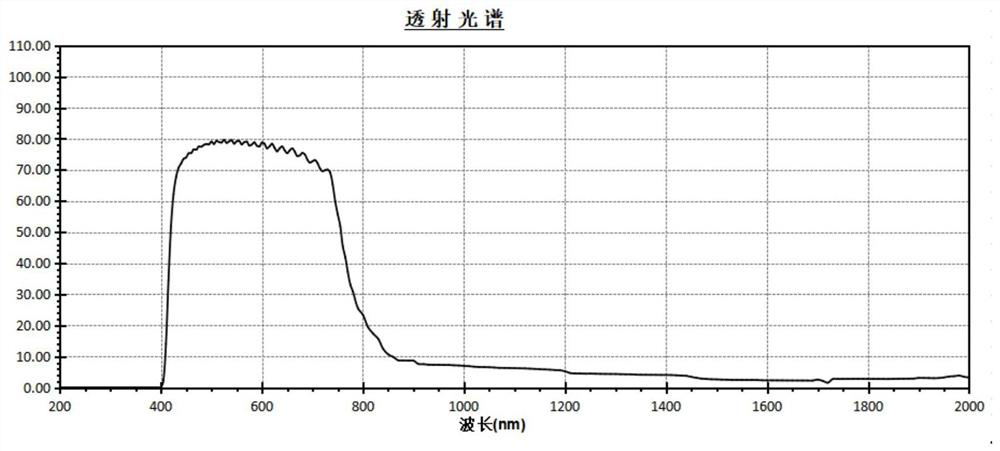

Manufacturing method of anti-infrared high-energy heat-insulation goggle lens

The invention discloses a manufacturing method of an anti-infrared high-energy heat-insulation goggles lens. The manufacturing method comprises the following steps: firstly, drying PC or PA; uniformly mixing 8-15 kg of PC or PA with 8-13 g of nano-scale metal oxide and 2-7 g of a dispersing agent; forming a strip-shaped material from the mixed material; forming a cylindrical anti-infrared master batch from the strip-shaped material; drying PC or PA plastic grains; matching the prepared anti-infrared master batch and dried PC or PA plastic grains according to the proportion that 0.1-0.5 kg of master batch corresponds to 1 kg of plastic grains, and uniformly stirring; and forming the anti-infrared high-energy heat-insulation goggle lens from the stirred mixed material. According to the invention, the manufacturing method is simple, the cost is lower, the color is more stable and uniform, and the product quality is improved; and detection results show that the light transmittance of a 780-2000 nm infrared region reaches 8.69%, namely, the blocking rate is 91.31%, the visible light perspective rate reaches 78.43%, the haze reaches 0.8%, and the product has the advantages of preventing near infrared rays from irradiating eyes, insulating heat, protecting the skin around the eyes, slowing down aging and reducing the occurrence probability of cataract.

Owner:EYEPOL POLARIZING TECH XIAMEN

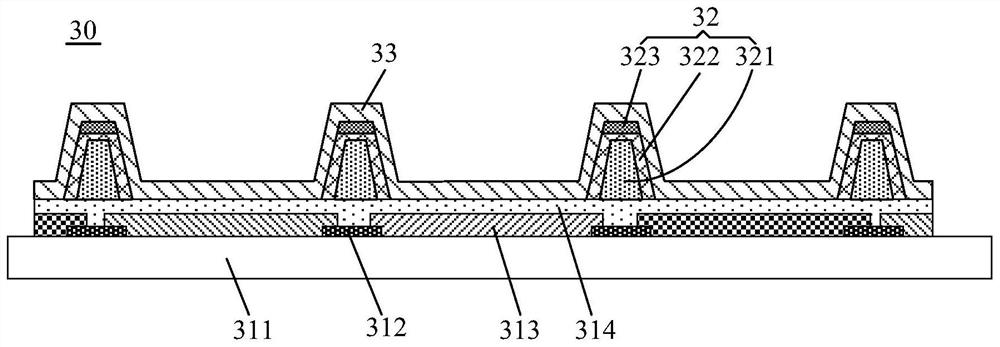

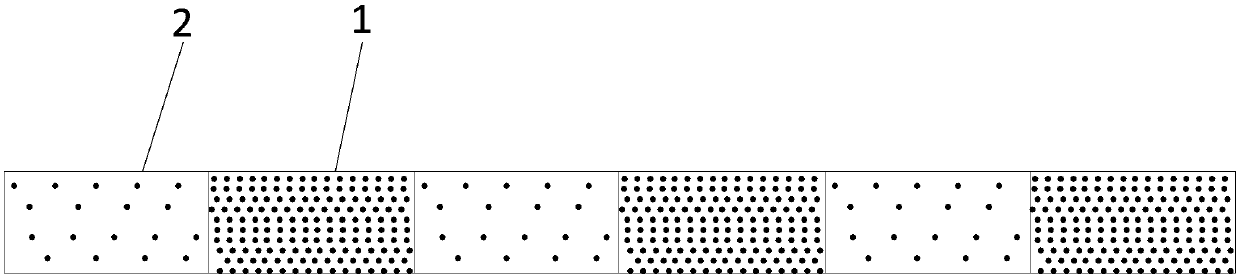

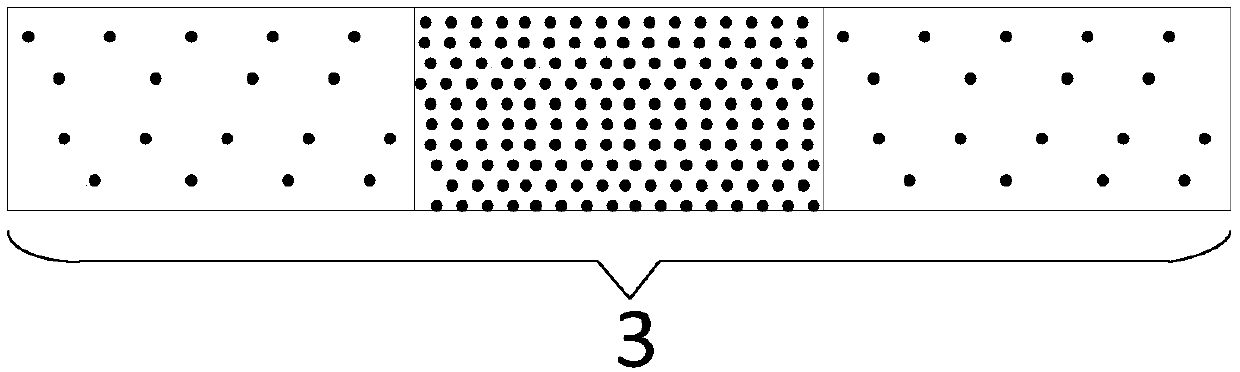

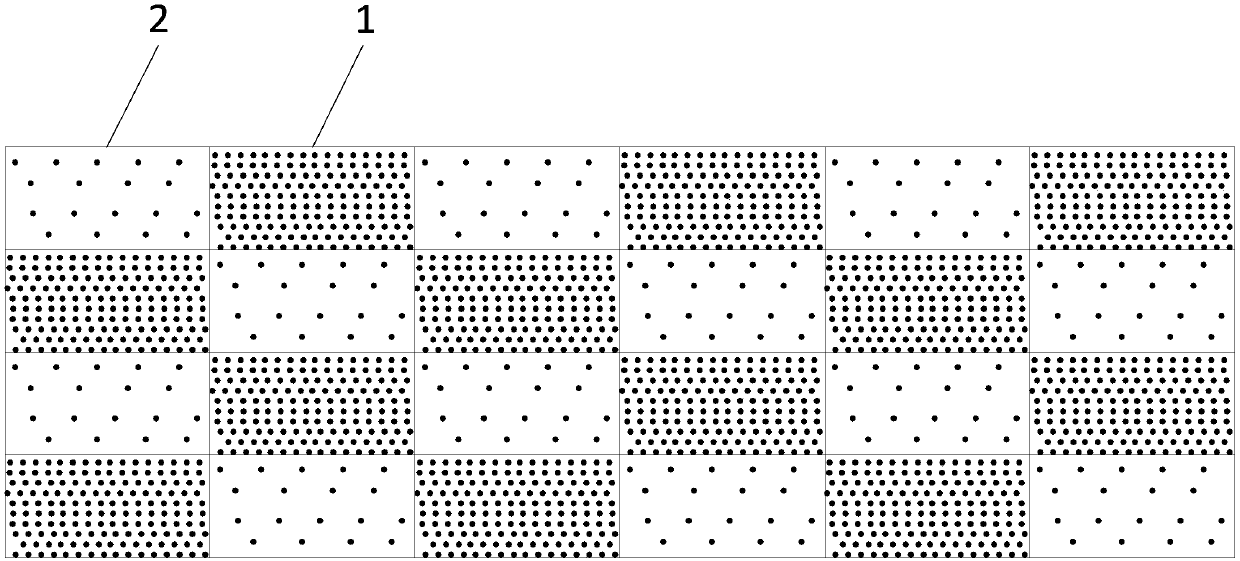

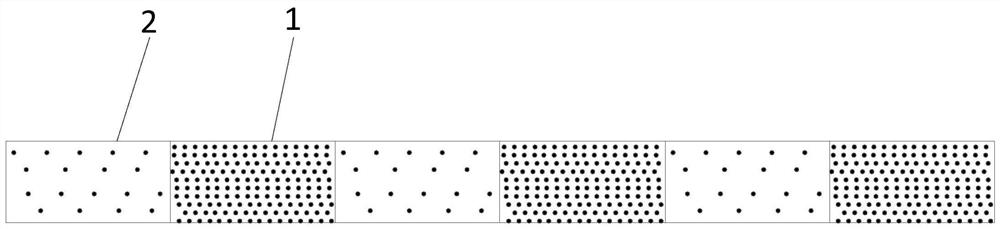

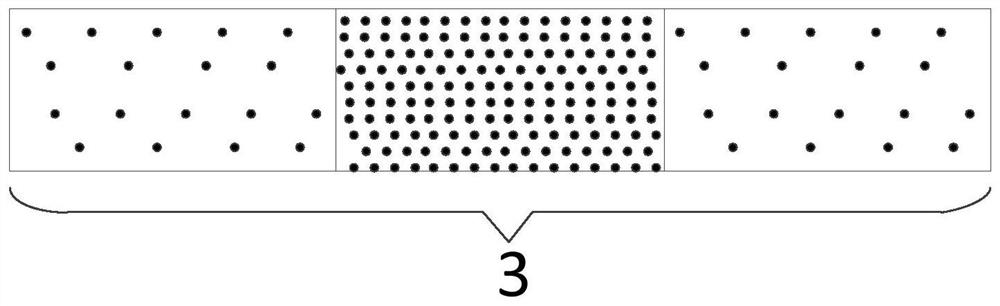

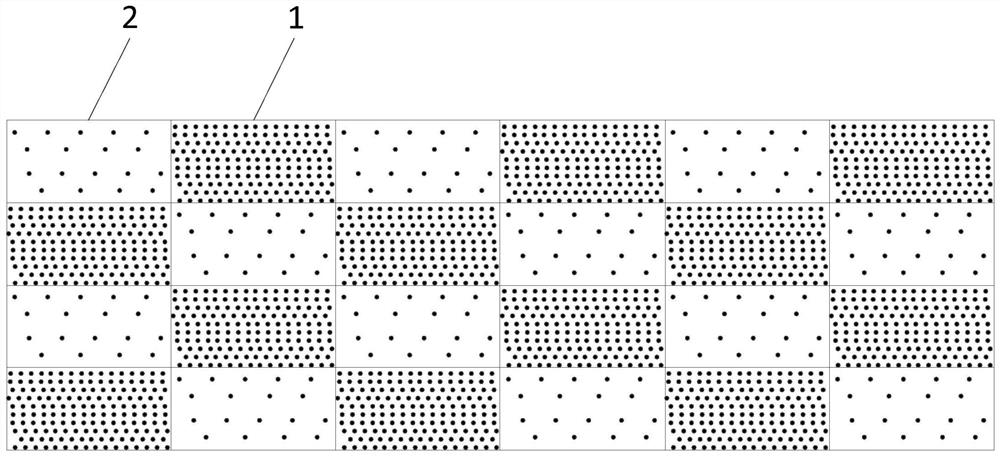

Display panel as well as preparation method and preparation equipment of display panel

ActiveCN109671750AReduces oxygen and moisture infiltrationAvoid black spotsSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringSurface plate

The embodiment of the invention provides a display panel, as well as the preparation method and the preparation equipment of the display panel. The invention solves the following problems in the priorart that: a packaging film layer of a flexible display device is too high in density and easily causes the fracture of a packaging inorganic layer in the bending process, the packaging film layer istoo low in density and causes the oxygen and the water vapor to permeate into a flexible OLED display panel, so that the service life of the flexible display panel is shortened. The display panel comprises a packaging structure and a water and oxygen barrier layer in the packaging structure. The water and oxygen barrier layer comprises at least one inorganic material layer. The inorganic materiallayer comprises at least one high-density region and at least one low-density region. The high-density region and the low-density region are arranged at intervals.

Owner:YUNGU GUAN TECH CO LTD

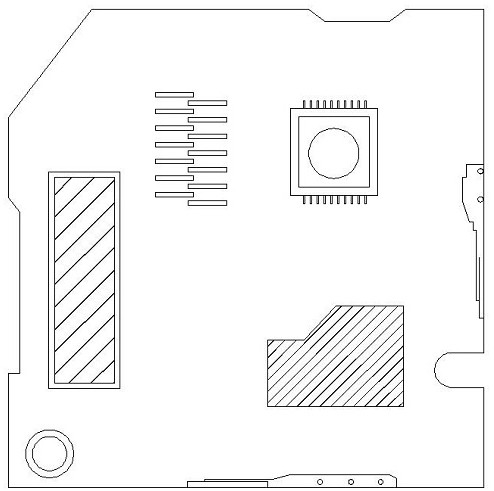

Size detection equipment capable of positioning and correcting and for mobile phone electronic part detection

PendingCN112033976AGood for appearance defect detectionRealize external dimension detectionMaterial analysis by optical meansEyepieceConveyor belt

The invention discloses size detection equipment capable of positioning and correcting and for mobile phone electronic part detection, and relates to the technical field of mobile phone electronic part detection. The size detection equipment specifically comprises a transparent glass substrate, positioning and correcting mechanisms and an eyepiece cleaning mechanism, two sides of the lower surfaceof the transparent glass substrate are connected with a conveyor belt, the positioning and correcting mechanisms are placed at two sides of the upper surface of the transparent glass substrate, and the eyepiece cleaning mechanism is placed on the surfaces of the right sides of an upper shooting eyepiece and a lower shooting eyepiece. According to the size detection equipment capable of positioning and correcting and for mobile phone electronic part detection, the upper shooting eyepiece shoots the front surface of a circuit board, and the lower shooting eyepiece shoots the back surface of thecircuit board, and comparison software can be used for comparing with a circuit board standard part in a database while the detection of the profile and size is achieved, so that appearance defect detection on the circuit board in detection is facilitated, and the definition of an image shot by the lower shooting eyepiece can be improved through the arrangement of the transparent glass substrate.

Owner:深圳市凤舞科技有限公司

Organic light emitting display and method of fabricating the same

ActiveCN100426518CReduce electrical short circuitAvoid black spotsElectroluminescent light sourcesSolid-state devicesOptoelectronicsThin-film transistor

In one embodiment, an organic light emitting display (OLED) includes a thin film transistor (TFT) disposed on a substrate. In additiona, the display includes: an insulating layer disposed on the TFT and having a via hole; a pixel electrode disposed on the insulating layer and connected to a drain electrode of the TFT through the via hole; an emission layer disposed on the pixel electrode; and an opposite electrode pattern disposed on the emission layer and exposing at least an upper region of the via hole. This avoids close configuration proximity between the opposite electrode and the pixel layer thus reducing the possibility of a short circuit.

Owner:SAMSUNG DISPLAY CO LTD

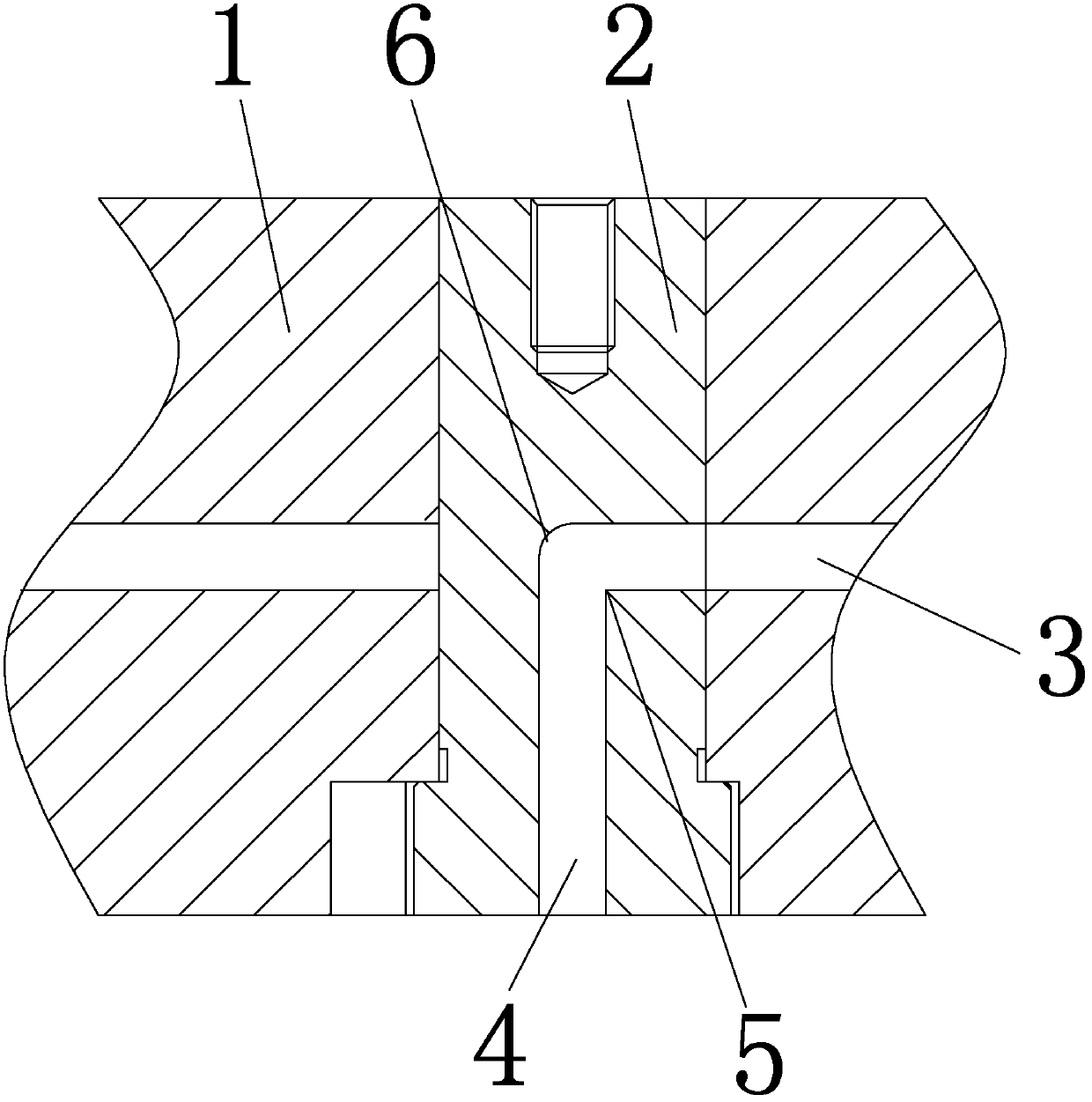

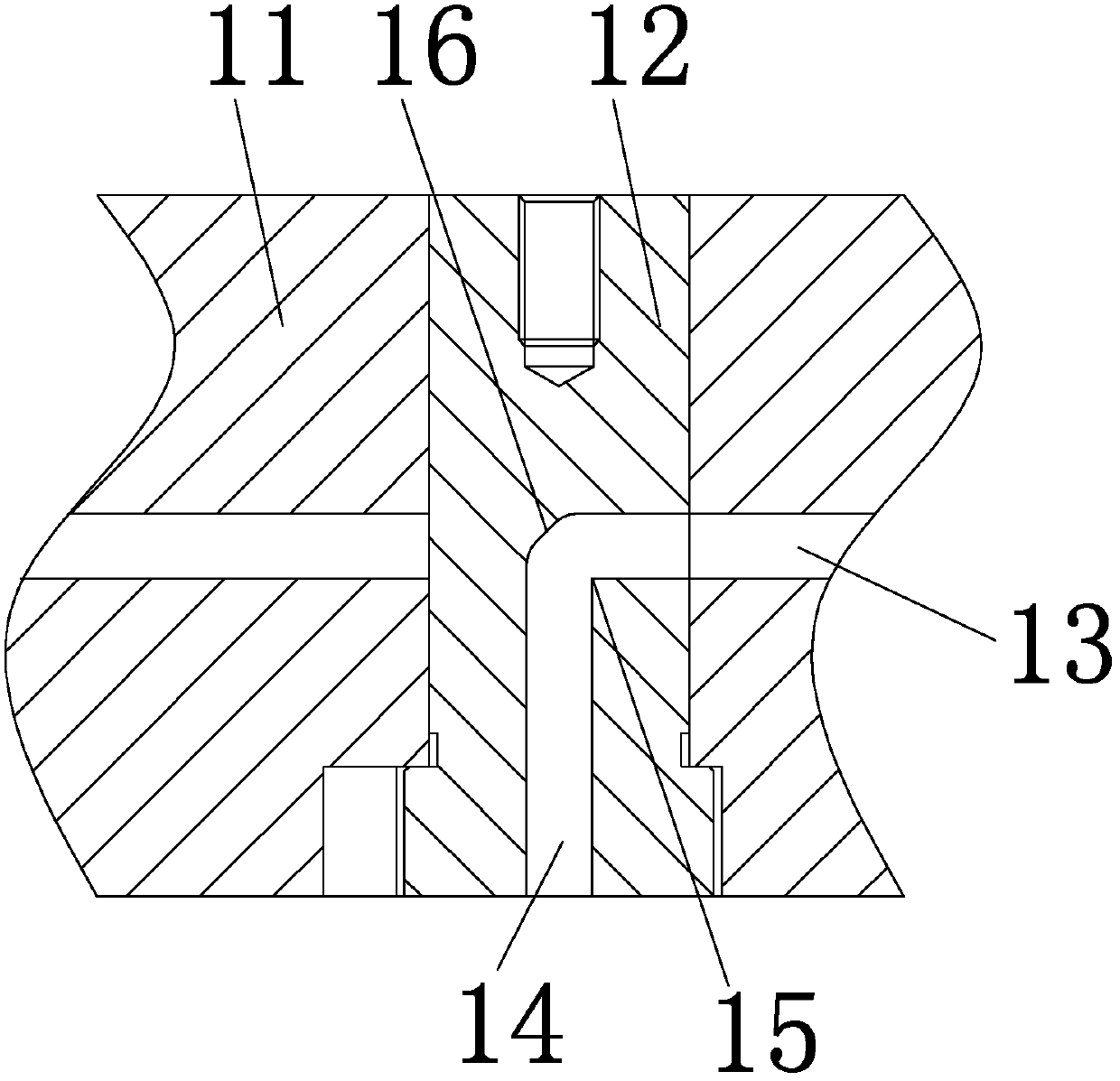

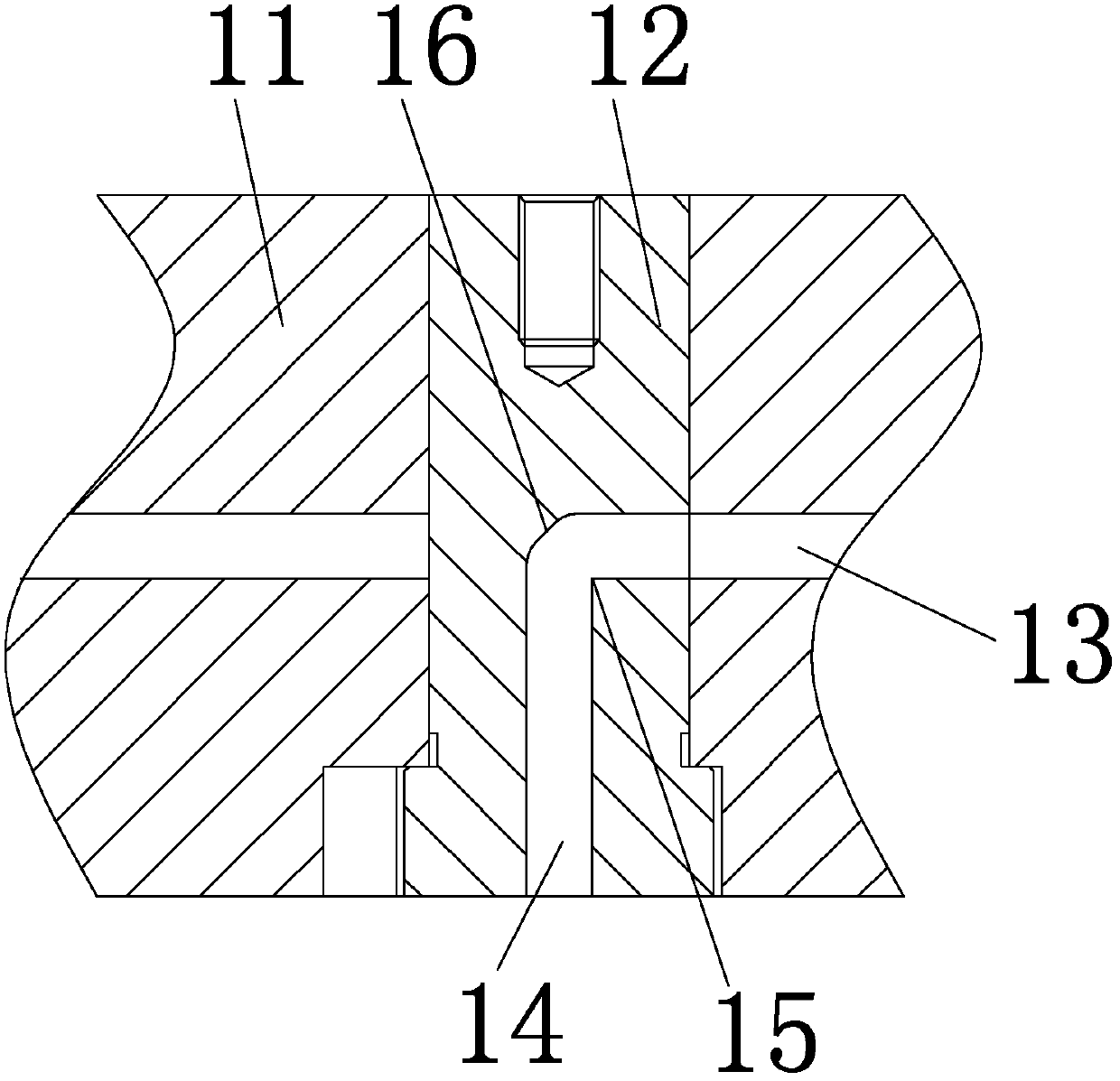

White material mold insert

The invention discloses a white material mold insert, which comprises a mold insert body and a fluid flow passage; the fluid flow passage is arranged in the mold insert body and is of an L shape; an outlet of the fluid flow passage is communicated with a branch flow passage on a splitter plate when the mold insert is installed in the splitter plate; an inner corner of the fluid flow passage is configured as a right angle; an outer corner of the fluid flow passage adopts a bevel edge; and the maximum width of the corner of the fluid flow passage is equal to the width of the straight-line segment of the fluid flow passage. According to the invention, the maximum width of the corner of the fluid flow passage is equal to the width of the straight-line segment of the fluid flow passage, in this way no residual plastic solution exists in the fluid flow passage during the injection molding, so that flaws such as black points and the like produced in the secondary injection molding by the white material mold insert can be avoided; and the white material mold insert provided by the invention is simple in structure and is practical.

Owner:SUZHOU HTS MOLD

Preparation process of lithium battery negative electrode plate formula

The invention discloses a preparation process of a lithium battery negative electrode plate formula. The preparation process is characterized by including steps: (1) pouring NMP into an emulsifying machine, adding a certain quantity of H2O into the emulsifying machine, and stirring for 5-10min to well mixing NMP with H2O; (2) adding needed SP into the emulsifying machine, and stirring for 5-10min;(3) standing for 8-10min to enable complete mixing and wetting of SP, wherein NMP refers to N-methyl pyrrolidone, H2O refers to water, and SP refers to a conductive agent. The preparation process ofthe lithium battery negative electrode plate formula has advantages that dark spots and pock marks in a coating process can be eliminated, and splattering of SP in a preparation process of the lithiumbattery negative electrode plate formula is avoided.

Owner:JIAN UTILITY TECH CO LTD

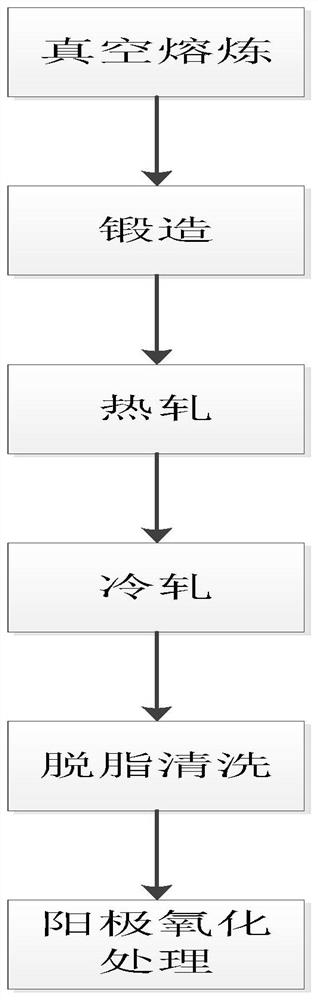

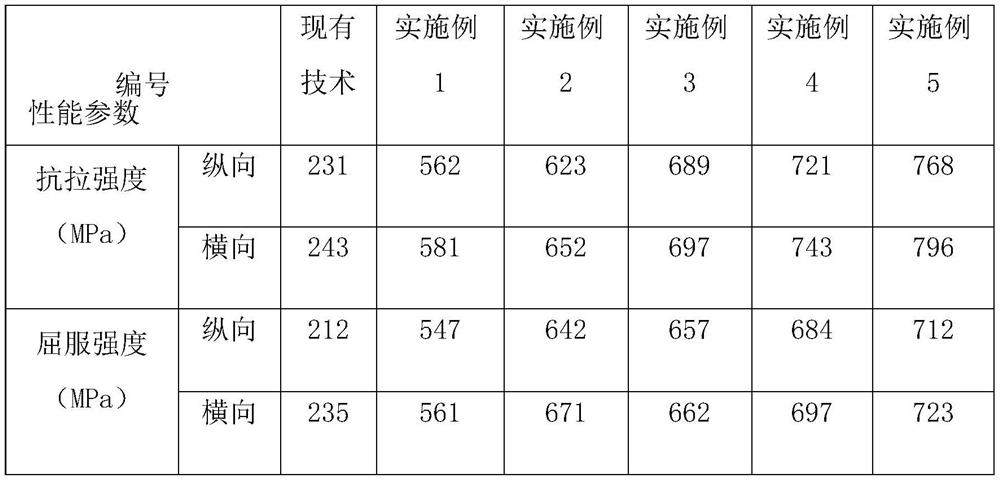

Preparation method of wide pure titanium foil coiled tape

PendingCN114405995ALow content of impurity elementsHigh puritySurface reaction electrolytic coatingFurnace typesNumerical controlMaterials processing

The invention provides a preparation method of a wide pure titanium foil coiled tape, and belongs to the technical field of titanium material processing. 0A-grade sponge titanium is adopted as a raw material, two times of vacuum consumable electrode furnace smelting are carried out, oxide skin on the surface of a plate blank is removed through a numerical control milling machine, and micro cracks on the surface of the plate blank are polished through grinding equipment, so that the produced plate blank is uniform in tissue size and few in internal defect, and a solid foundation is laid for obtaining high-quality and high-yield plates; next, the plate blank is subjected to hot rolling, annealing shot blasting acid pickling, cold rolling acid pickling, secondary acid pickling annealing, surface rolling oil stain removal on a degreasing line and whole roll annealing in a vacuum bell-type furnace, and after the process treatment is conducted, the prepared titanium foil coiled material is more uniform in structure, the forming width is increased, the mechanical property is tested, the titanium foil coiled material is rolled into the (0.1-0.3) * 1530 * Cmm cold rolling titanium foil material through a 20-roller rolling mill; the mechanical property consistent with that of a finished product generated by a narrow rolling mill is kept, the production efficiency and the yield of the coiled tape are improved, and the production cost is reduced.

Owner:新疆湘润新材料科技有限公司

A continuous phenol extraction system, a polycarbonate resin production system including the same, and a production method

ActiveCN110538481BRealize sedimentation separationRealize continuous recovery at room temperatureOrganic chemistryOrganic compound preparationEngineeringPolycarbonate

The invention provides a continuous phenol extraction system, a polycarbonate resin production system including the same and a production method. The phenol continuous extraction device includes a connected gas-liquid separation device and a phenol collection device. The gas-liquid The separation device is used to adjust the flow rate of the gas-liquid mixture entering the gas-liquid separation device, and at least one baffle is longitudinally arranged in the phenol collection device. The continuous phenol extraction system provided by the invention can ensure the vacuum degree and tightness inside the polycarbonate resin production system, realize continuous extraction of by-product phenol, and effectively recycle the extracted phenol.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

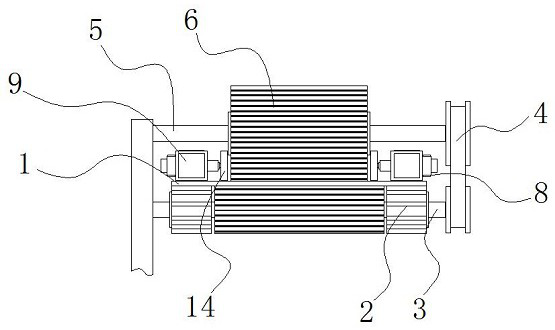

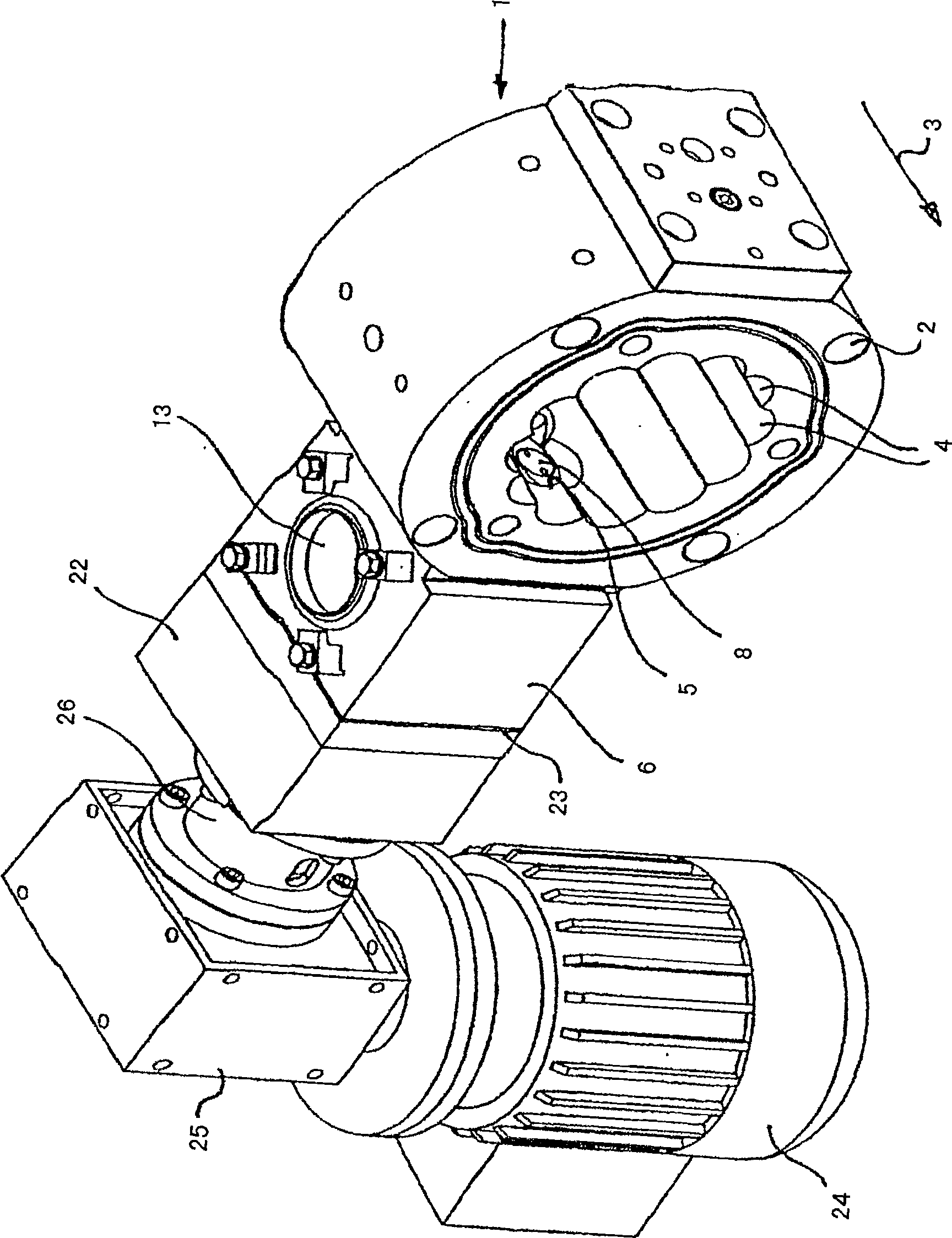

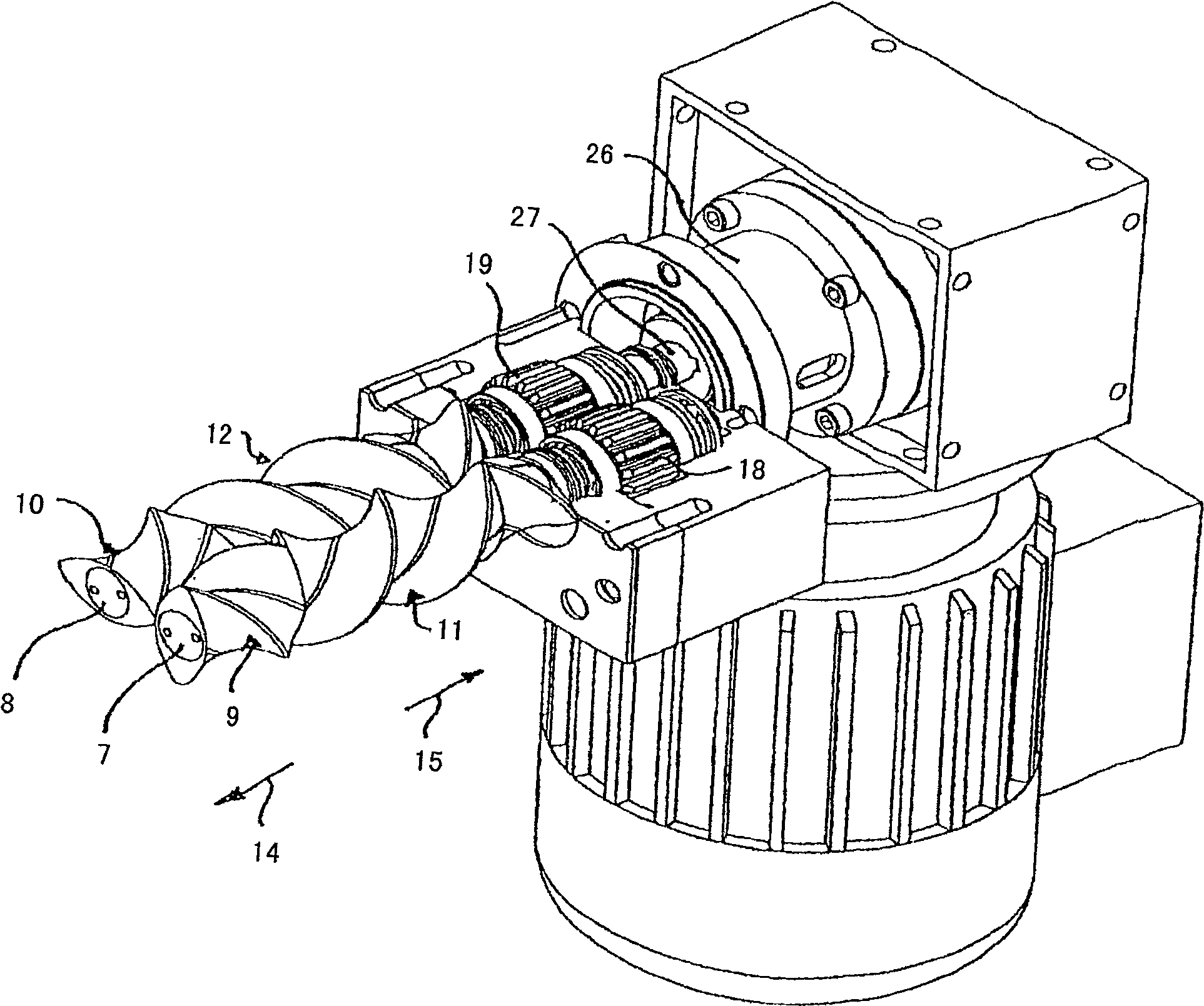

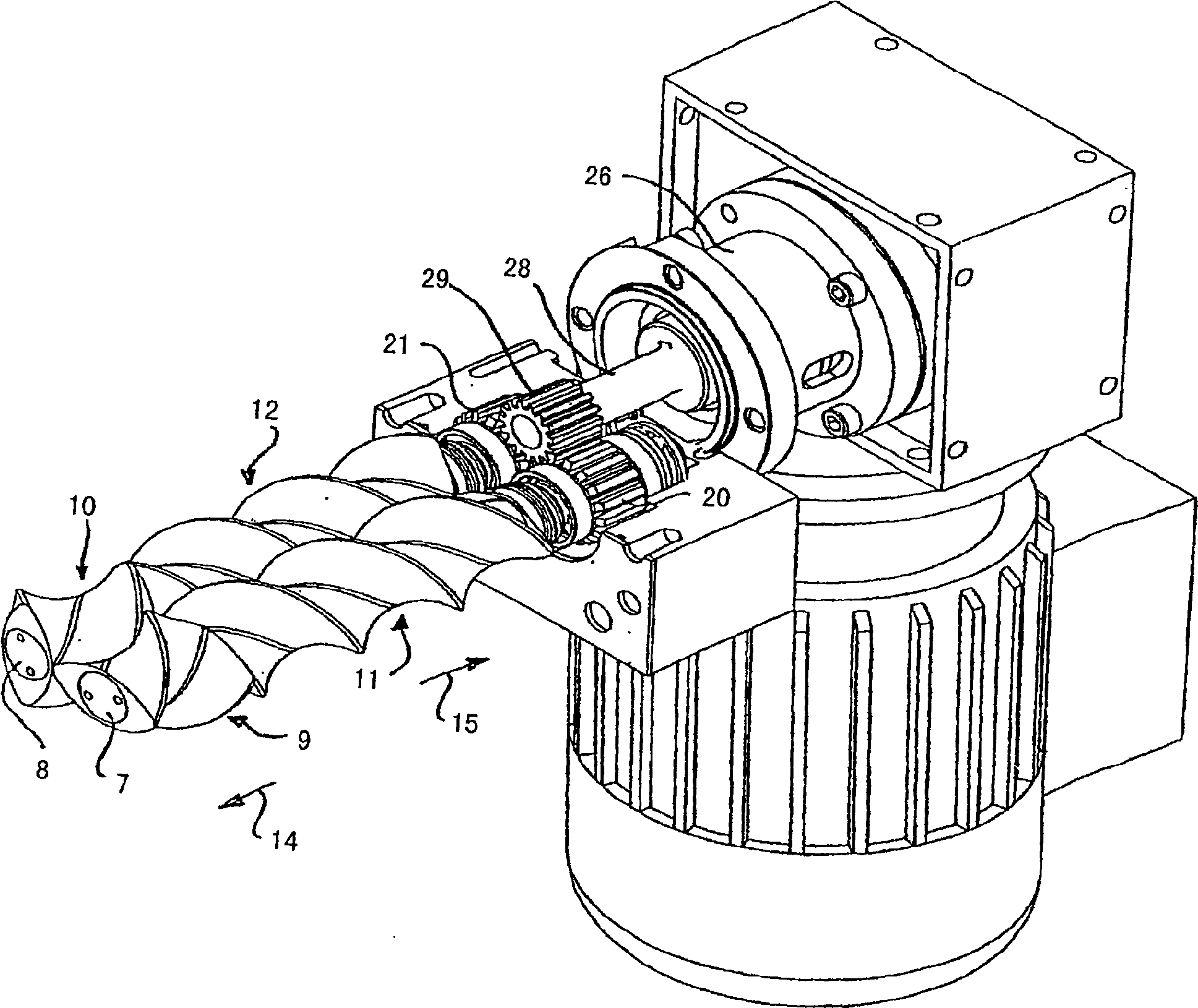

Extruder

The extruder has a processing section with a housing in which at least one screw shaft is arranged, the housing being provided at one end with a material inlet orifice for the material to be processed, On the other end there is a material discharge orifice for the processed material and an intermediate orifice is provided between the material inlet orifice and the material discharge orifice for the discharge of gases from the treatment section (5), a material blocking device is connected to the middle orifice, the material blocking device has at least one screw shaft (7, 8) in an intermediate housing (6), and the screw shaft is connected from the middle orifice ( 5) A gas discharge orifice (13) extending into the intermediate housing (6) and feeding material squeezed into the intermediate housing (6) back into the treatment section. In this case, the screw section (9, 10) of the screw shaft (7, 8) facing the treatment section has a direction of pitch which feeds back into the treatment section and the screw shaft (7, 8) faces away from the treatment section. The screw segments (11, 12) of the processing section have opposite lead angle directions.

Owner:BLACH VERWALTUNGS GMBH

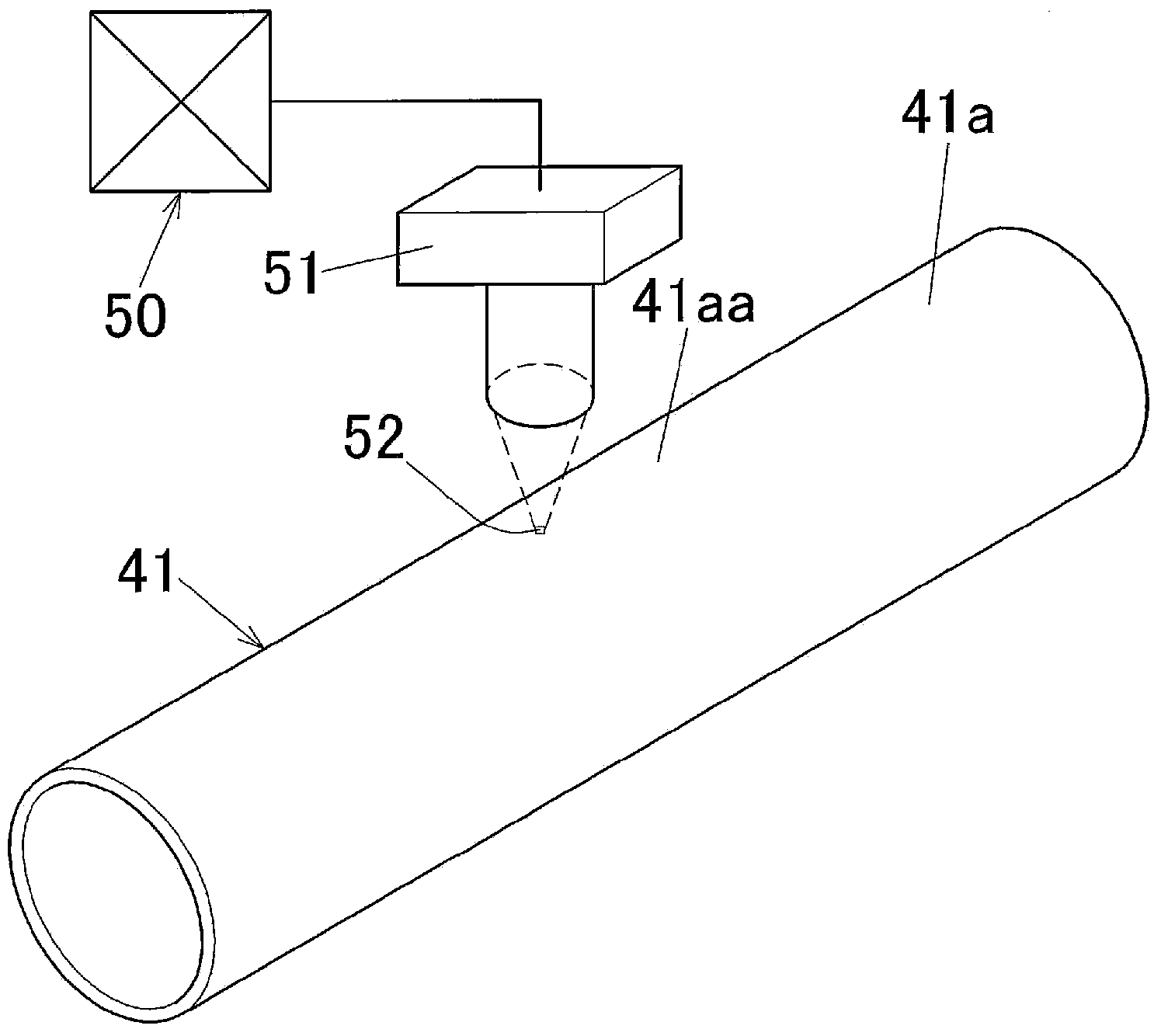

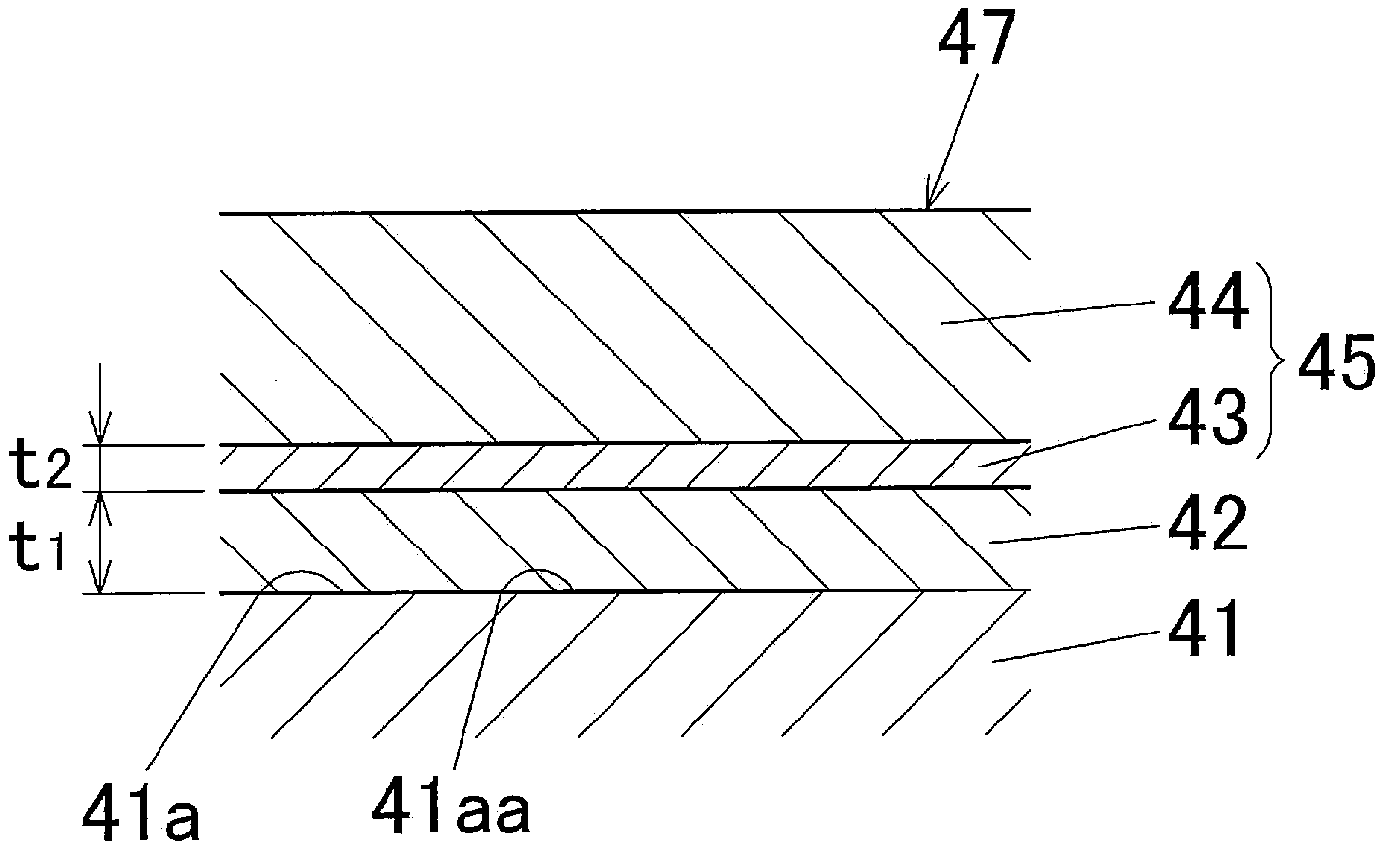

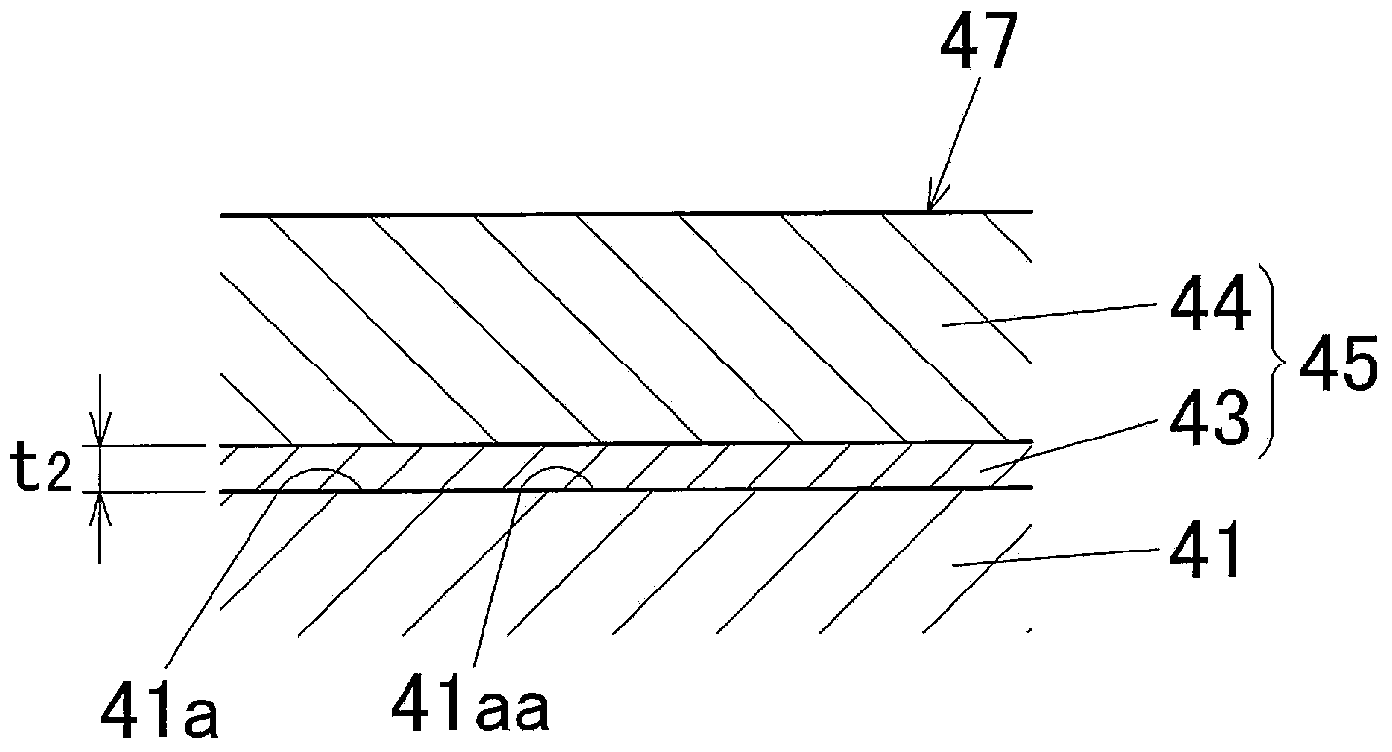

Substrate for photosensitive drum

InactiveCN103748520AImprove qualityAvoid it happening againElectrography/magnetographyThin material handlingVisual field lossEngineering

A substrate (41) for a photosensitive drum is formed from an uncut metal pipe. In an observation visual field (52) in which an image-forming surface (41aa) of a surface (41a) of the substrate (41) is observed in a visual field having an arbitrary size, the total occupancy area ratio of pits having an area of 1 [mu]m2 or more with respect to the area of the observation visual field is greater than 2%, and the average area per pit having an area of 1 [mu]m2 or more is greater than 8 [mu]m2.

Owner:RESONAC HOLDINGS CORPORATION

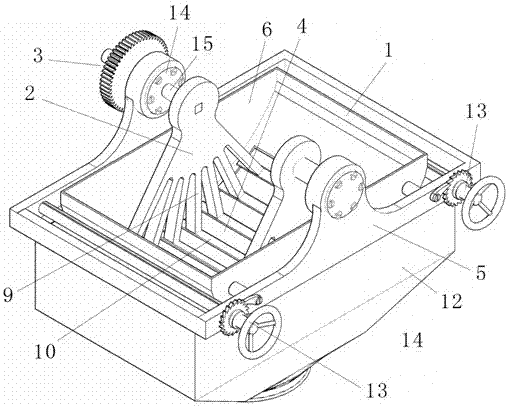

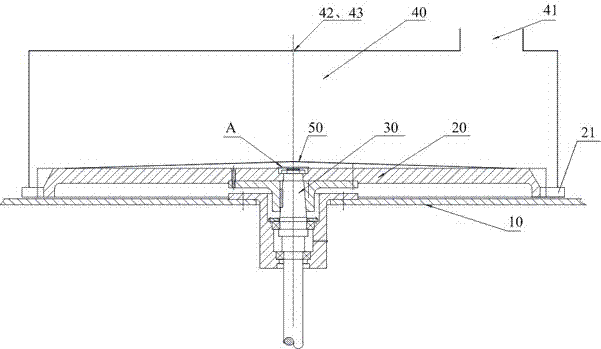

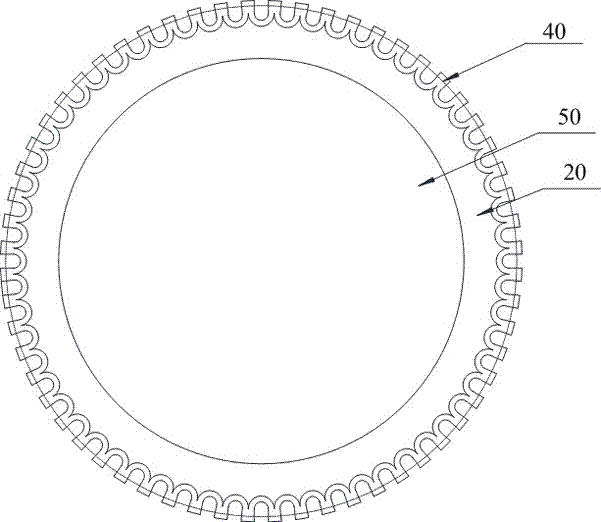

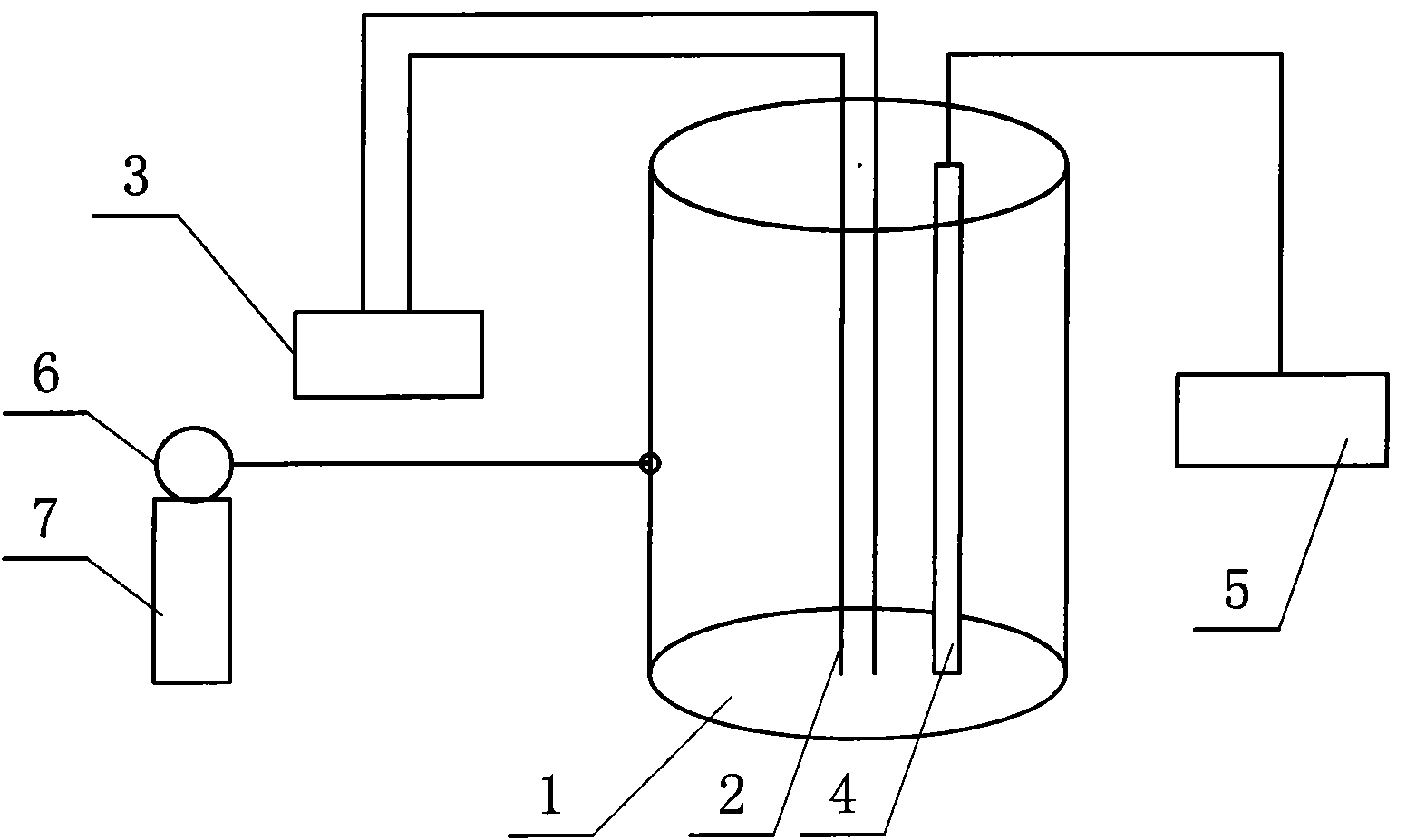

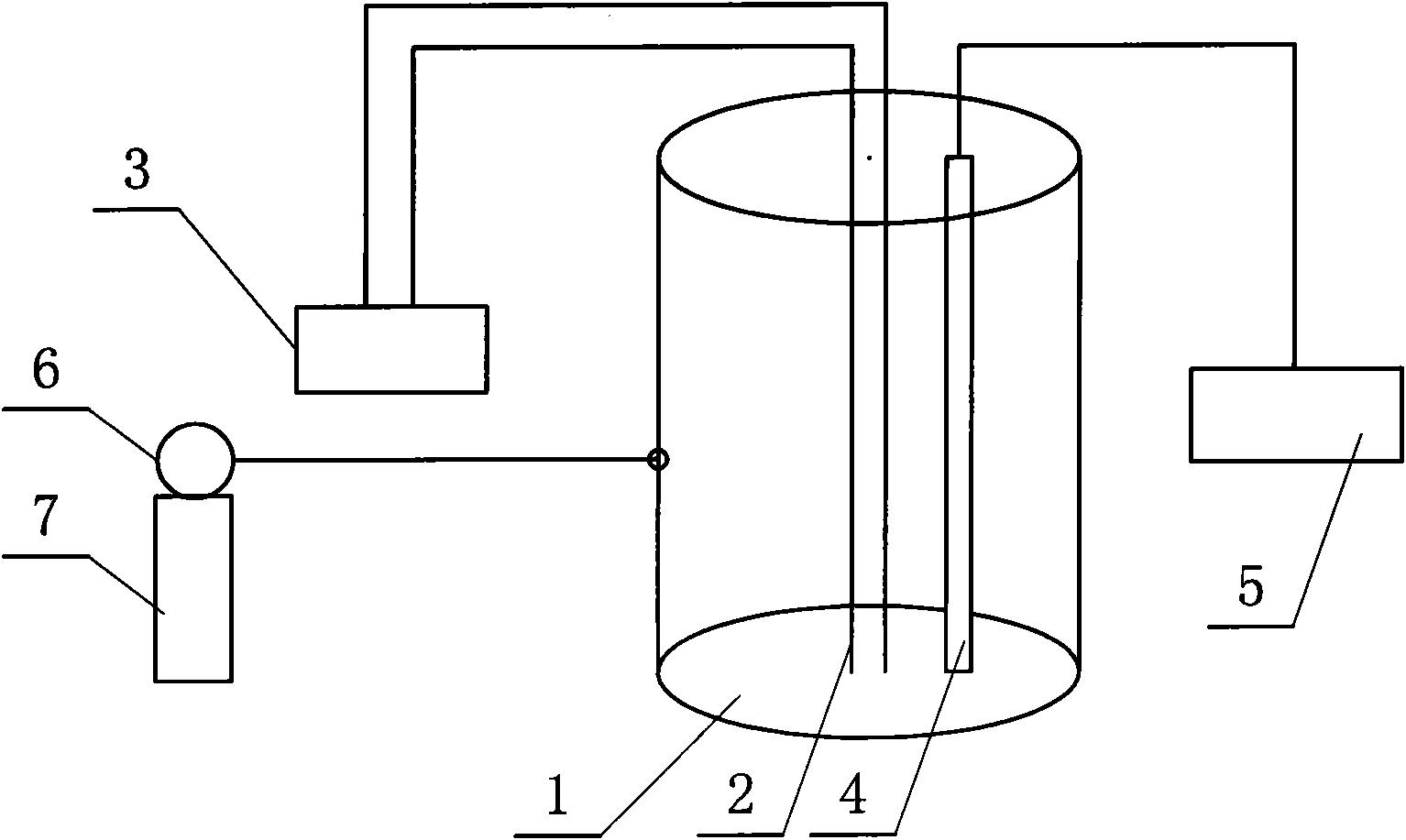

A non-contact swing granulation device for materials and bearings

ActiveCN105498629BAvoid problems with access to the material hopperGuaranteed efficacyGranulation by material expressionBlack spotEngineering

The invention relates to the technical field of pharmaceutical equipment, in particular to a material and bearing non-contact type swing pelletizing device. The device comprises a material hopper used for containing materials, an extruding assembly and a driving part, wherein the material hopper is provided with a material inlet and a material outlet, and a screen plate is arranged on the material outlet; the extruding assembly is matched with the screen plate; the driving part is arranged outside the material hopper and used for driving the extruding assembly, the extruding assembly stretches out of the material hopper and is matched with the driving part, and the portion, for the extruding assembly to stretch out, of the material hopper is spaced from the material containing position in the material hopper. Due to the scheme, on one hand, the black spot phenomenon is avoided, the medicine effect of medicine is guaranteed, and medicine safety is guaranteed; on the other hand, it can also be avoided that materials enter a transmission part, and accordingly the risk that lubricating performance is weakened, and running reliability and safety of the pelletizing device are guaranteed while work efficiency of the pelletizing device is improved.

Owner:SICHUAN KELUN PHARMA CO LTD

Automatic sorting machine

PendingCN106925535AFully distributedEliminate long-term residual problems inside the storage siloSortingDrive shaftSlag

The invention provides an automatic sorting machine. The automatic sorting machine comprises a rack, a round discharging disk, a transmission shaft and a material storing bin which is located above the round discharging disk; a feeding port is formed in one side of the top of the material storing bin; the transmission shaft is connected to the rack; the upper end of the transmission shaft is connected with the round discharging disk, and the round discharging disk is driven to rotate; a plurality of square teeth are arranged on the circumferential circle of the round discharging disk; a conical material distributing cover with a downward opening is fixedly arranged in the middle of the top face of the round discharging disk; and the diameter of the opening of the conical material distributing cover is 0.6-0.8 of the diameter of the round discharging disk. The conical material distributing cover is arranged to make capsules roll to the circumference of the round discharging disk by themselves, gas blowing is added over the round discharging disk to assist in capsule material distributing, and in this way, it is avoided that the capsules stay in the round discharging disk for a long time, and consequently the water loss is caused; and meanwhile, site clearing is convenient, and therefore the capsule waste amount is controlled, the problems of capsule residues and small black slag are reduced, the site clearing quality and efficiency of the automatic sorting machine is substantially improved, and the product quality is guaranteed.

Owner:青岛益青生物科技股份有限公司

A copper foil surface treatment machine with self-adaptive tension

A self-adaptive tensioning force copper foil surface treatment machine, which relates to the field of copper foil processing, the two inner walls of the pickling tank are sealed and rotated to be provided with clamping shaft seats, and the two outer sides of the pickling tank are fixedly provided with brackets. An arc groove is opened on the top, and a push rod is also rotated on the support plate, and the free end of the push rod is fixedly connected with the first top block; the side of the arc groove away from the push rod is provided with a ratchet mechanism fixed on the bracket; The bracket is also provided with a lifting mechanism, the lifting mechanism is fixedly provided with an elastic piece, and the elastic piece is fixedly connected with a second top block; the outside of the pickling tank is also provided with a folding windshield, and the folding windshield is provided with an alkali water tank. In this technical solution, the submerged roller is set in the form of hanging and clamping, which saves the process of discharging acid, and arc grooves are set to change the position of the tension roller to avoid the submerged roller from hanging and working, and the lifting mechanism is used to control the tension roller The height of the copper foil is set, and elastic parts are set to realize the function of automatic fine-tuning of the tension of the copper foil.

Owner:江西省江铜铜箔科技股份有限公司

Display panel, manufacturing method and manufacturing equipment of display panel

ActiveCN109671750BAvoid black spotsExtend your lifeSolid-state devicesSemiconductor/solid-state device manufacturingHigh densityEngineering

Owner:YUNGU GUAN TECH CO LTD

Vacuum pump

InactiveCN101892454AImprove adhesionAvoid black spotsVacuum evaporation coatingSputtering coatingAdhesion forceBlack spot

The invention discloses a vacuum pump, which can solve the problem that the conventional product is likely to stick dust on surface when entering the vacuum pump and to generate black spots during film plating and the problem that the adhesion force of a plated film is unstable. The vacuum pump comprises a vacuum enclosure, an evaporating electrode, an evaporating current controller, an ion generator and an ion generation controller, wherein the evaporating electrode is arranged in the vacuum enclosure; the evaporating electrode is also connected with the evaporating current controller outside the vacuum enclosure; the ion generator is arranged in the vacuum enclosure; and the ion generator is connected with the ion generation controller outside the vacuum enclosure. The vacuum pump has the advantage that ionic wind is generated by the ion generator under a vacuum condition to blow off dust on the surface of the product, eliminate the black spots and improve rate of finished product and the adhesion force of the plating of the product.

Owner:平湖市东洋塑胶真空涂膜厂

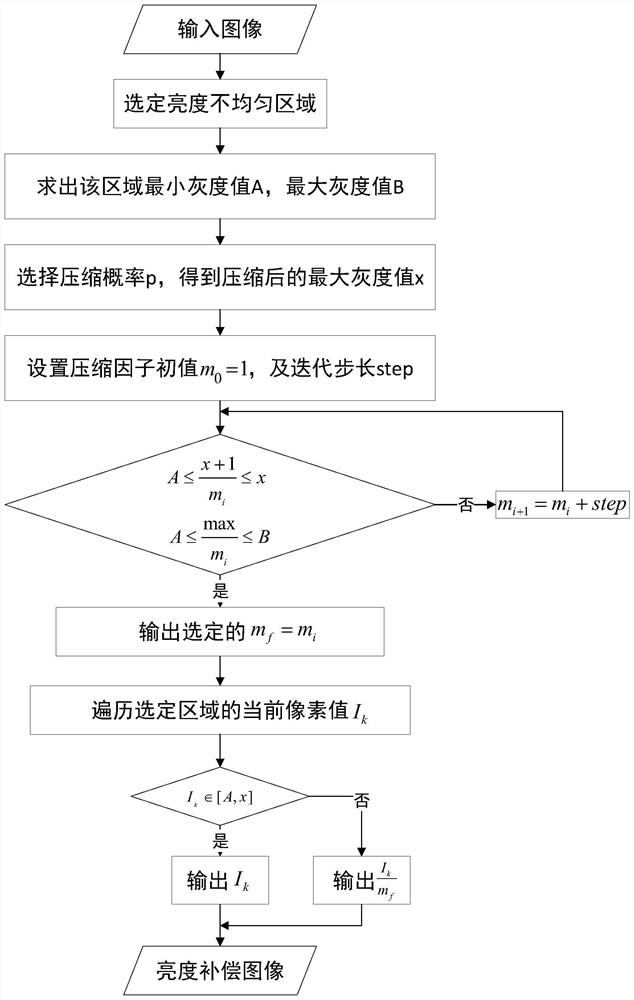

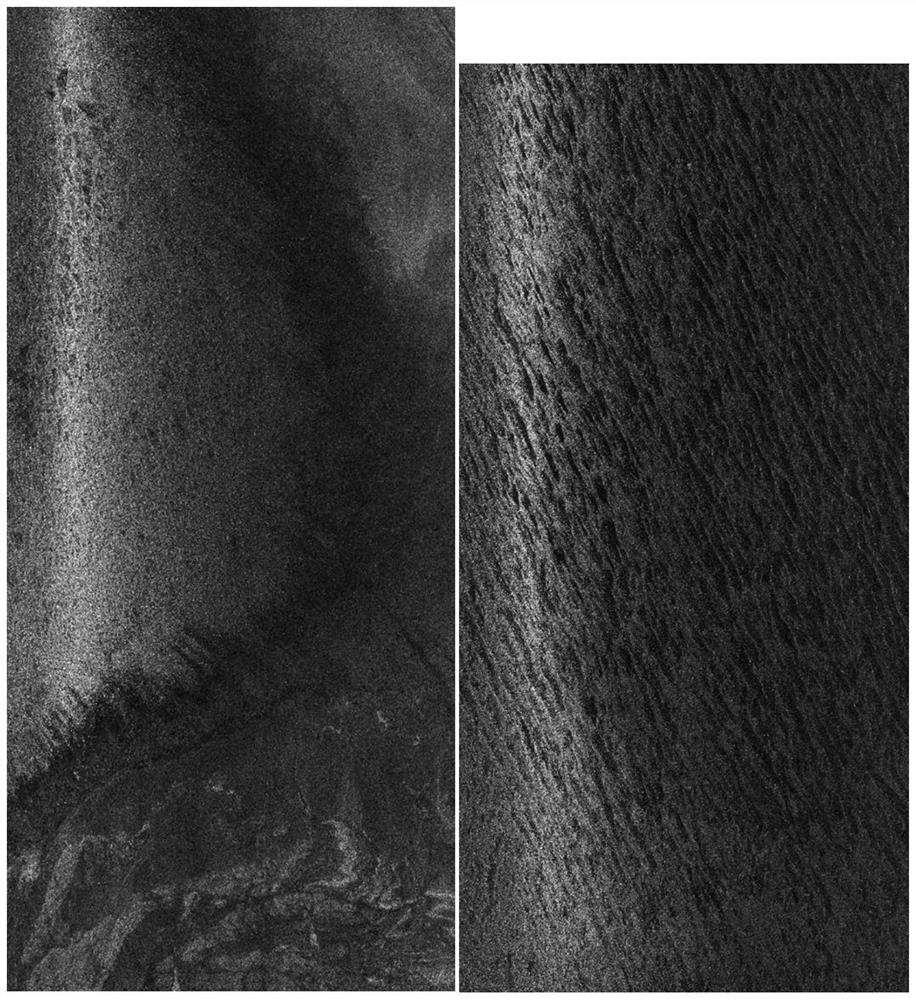

Brightness Compensation Method of SAR Single Scene Image Based on Local Histogram Compression

ActiveCN108961178BAchieve the purpose of compensationAvoid black spotsImage enhancementImage analysisBlack spotComputer graphics (images)

The invention relates to a SAR single scene image brightness compensation method based on local histogram compression, which includes the following steps: S1. For the SAR single scene image to be processed, select an area with uneven brightness as a selected area; S2. Traverse the selected area area, and obtain the lowest pixel gray value and the highest pixel gray value in the selected area; S3. Make a histogram of the selected area, and select the compression probability p of the histogram to obtain the selected area. The maximum grayscale value x after compression, the grayscale range of the selected area is divided into two parts [A,x] and [x+1,B]; S4. Obtain the appropriate compression factor m through the iterative method f , so that the gray level of the selected area is compressed from the initial range [A, B] to [A, x]; S5. Traverse the selected area, for any pixel gray value I k , if I k ∈[A,x], then output I k ; Otherwise, output the image after brightness compensation. The invention can effectively avoid the black spot phenomenon, retain the detailed information of the image, and obtain satisfactory brightness compensation effect.

Owner:陕西宝塔星空航天科技有限公司

A multi-component gas co-infiltration strengthening system and its process

ActiveCN110359009BAvoid pollutionImprove sufficiencySolid state diffusion coatingProcess engineeringEnvironmental engineering

The invention discloses a multi-component gas co-infiltration strengthening system and its technology, which belong to the technical field of workpiece heat treatment, and solve the problems of poor environmental protection, poor penetration effect and single infiltration layer in traditional heat treatment, including sequentially connected feeding units, ventilation unit, heating pre-infiltration unit, multi-component gas co-infiltration strengthening unit, cooling protection unit and discharge unit. The invention replaces the traditional acid anti-corrosion process through the cooperation of each unit, improves environmental protection, uses the ventilation unit to avoid air participation, and improves the sufficiency of polyatomic penetration. The heating pre-infiltration unit combines microwave radiation to change the surface structure of the lamp pole. Accelerate the infiltration speed and depth of subsequent nitrogen, sulfur and chromium elements. During multi-component gas co-infiltration treatment, first use ammonia atmosphere nitriding treatment, and then use infiltration promoting ball B to release gaseous carbon-sulfur-chromium complexes to achieve infiltration. Co-carburizing, sulfurizing and chromizing treatments make the structure of the carburized layer complex and diversified, and improve the surface hardness of the light pole.

Owner:江苏良川科技发展有限公司

Manufacturing process of gradient glass panel and gradient glass panel

PendingCN111908801ARealize the color gradient effectEasy transitionOther printing apparatusIceboxWater purification filter

The invention discloses a manufacturing process of a gradient glass panel, which takes a glass panel as a base material, and comprises the following steps: cleaning, drying, printing, spraying and coloring. In the spraying process, spraying a semitransparent gradient layer with the thickness change of 0-10 [mu]m on the first surface of the base material in the spraying process, and then carrying out ink printing and coloring; therefore, a metallic gradient effect is achieved and gradient lattice points are avoided; the thickness change of the semitransparent gradient layer is easy to control through spraying, compared with whole-face spraying, the requirement for thickness consistency is not high, the cost is low, and the obtained gradient glass panel is high in metal gradient texture, good in transitivity and continuity and good in gradient effect; the gradient glass panel can be widely applied, as decorative panels, to household appliances such as refrigerators, water heaters, rangehoods, water purifiers and the like.

Owner:FUJIAN RICHES ELECTRONICS SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com