White material mold insert

A technology of inserts and white materials, applied in the field of injection mold parts, can solve the problems of black spots and defective products, and achieve the effect of avoiding black spots and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

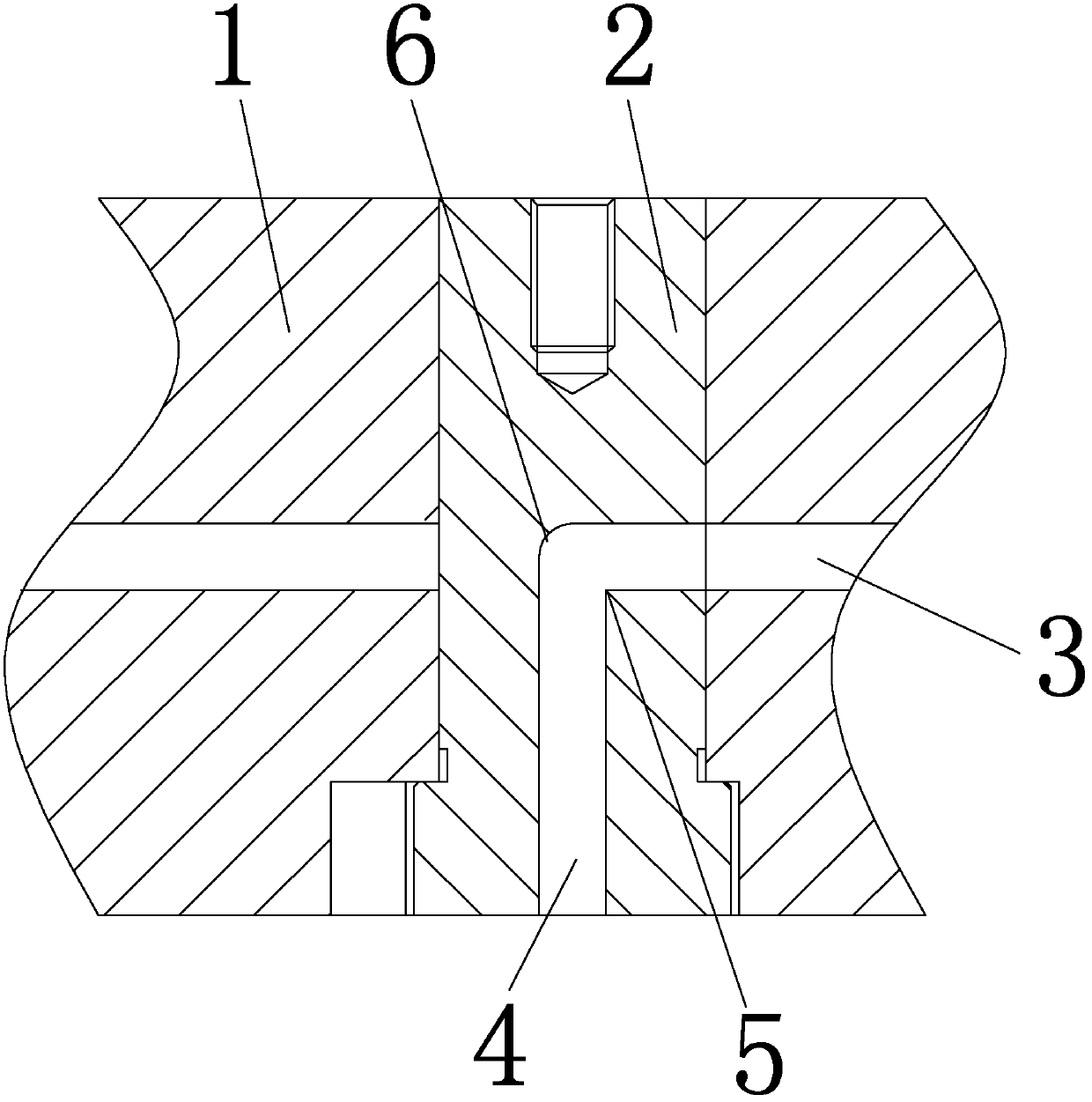

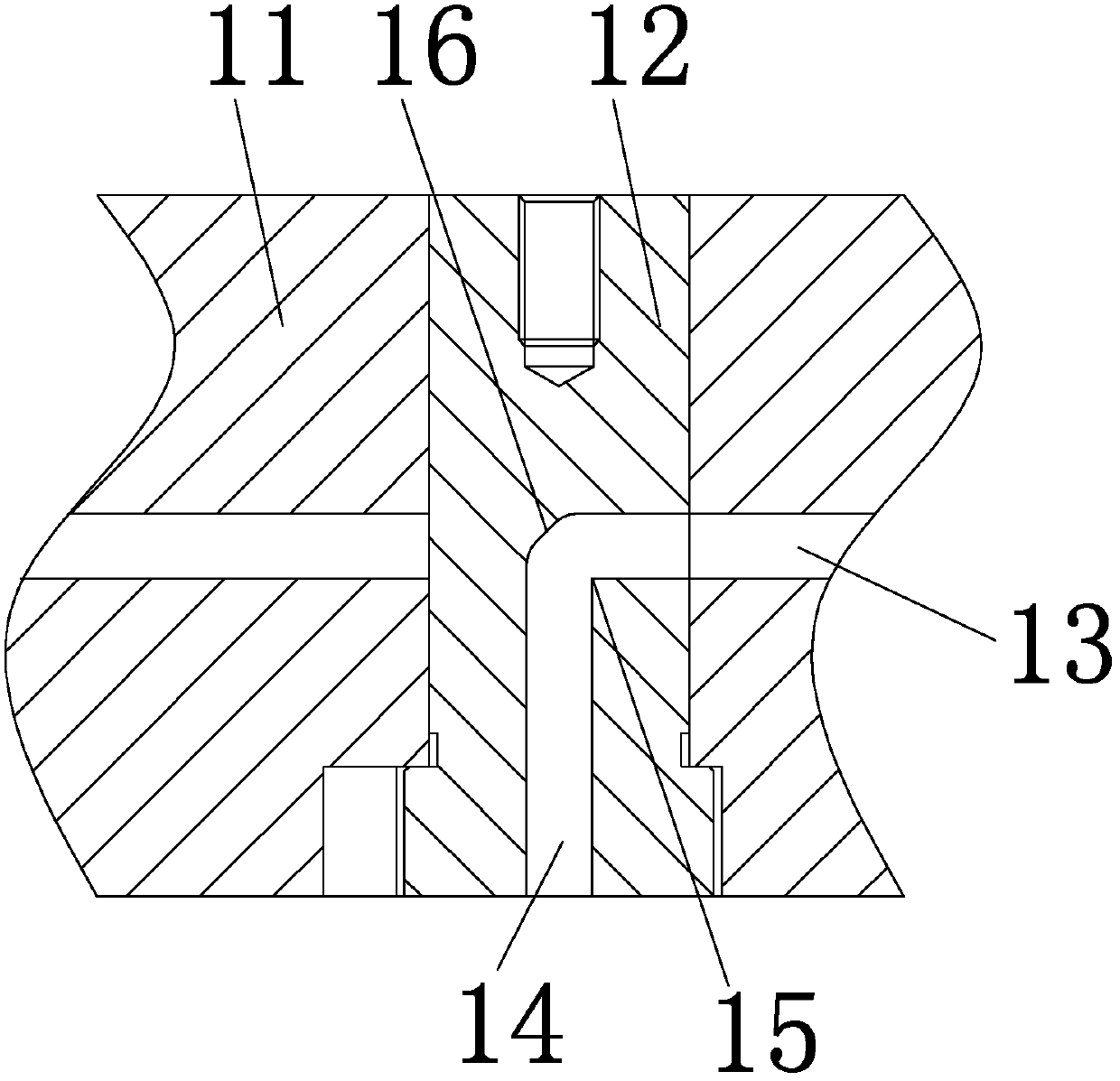

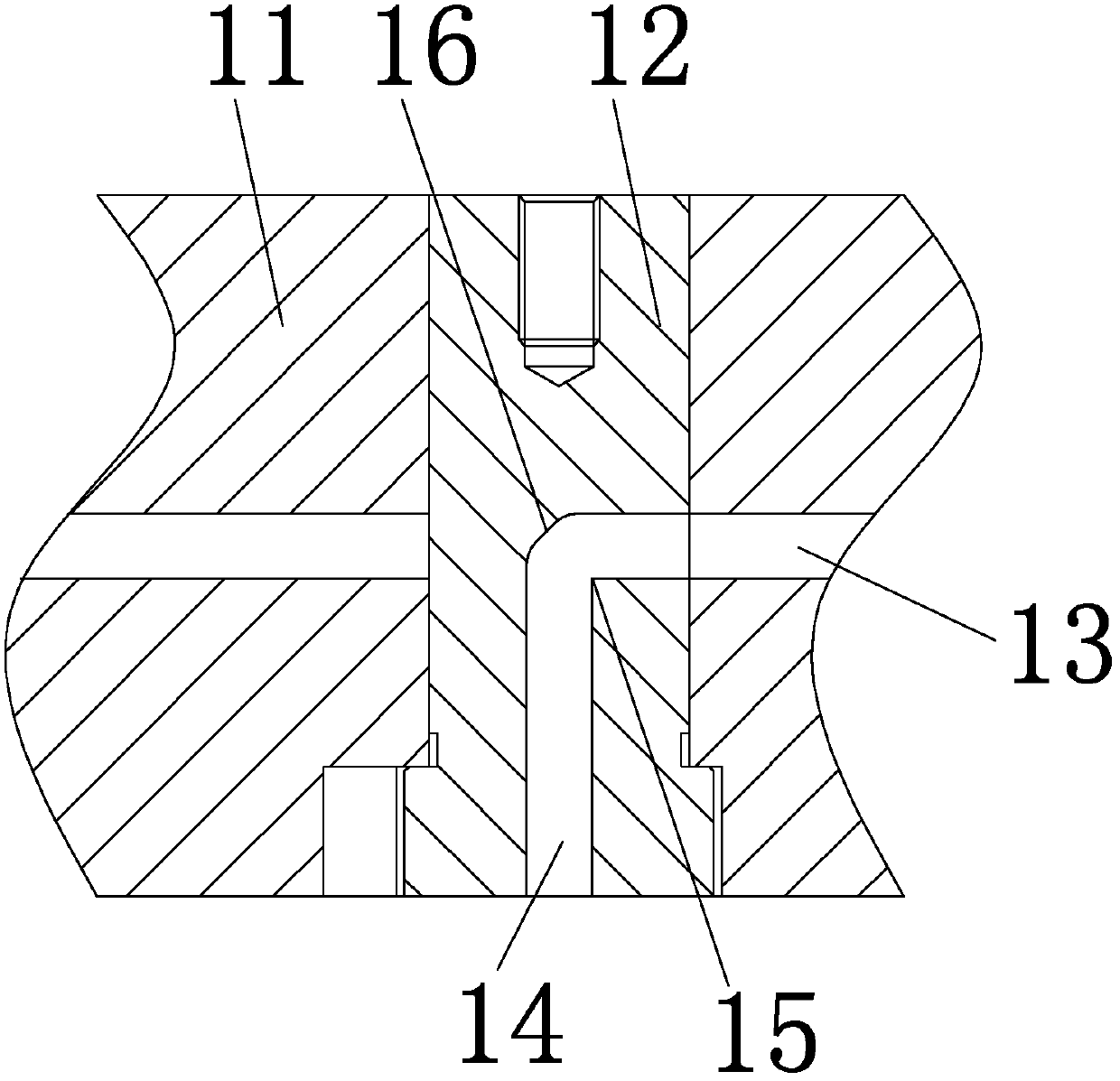

[0011] as attached figure 2 The shown white material insert of the present invention includes an insert body 12 and a fluid channel 14; the fluid channel 14 is arranged inside the insert body 12 in an L shape; when the insert is installed in the diverter plate 11 , the outlet of the fluid channel 14 communicates with the flow channel 13 on the splitter plate 11; the inner corner 15 of the fluid channel 14 is arranged at a right angle; the outer corner 16 of the fluid channel 14 adopts a bevel chamfer, and the The maximum width at the corners of the fluid channel 14 is the same as the width of the straight section of the fluid channel 14 .

[0012] The beneficial effects of the present invention are mainly reflected in: the maximum width at the corner of the fluid passage in the white material insert of the present invention is the same as the width of the straight line section of the fluid passage; Remaining plastic solution can avoid defects such as black spots in the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com