A multi-component gas co-infiltration strengthening system and its process

A co-infiltration and gas technology, applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of inability to realize heat treatment of large and super-large objects, single infiltrating elements, and shallow infiltration layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below in conjunction with accompanying drawing and specific embodiment, the present invention is further described:

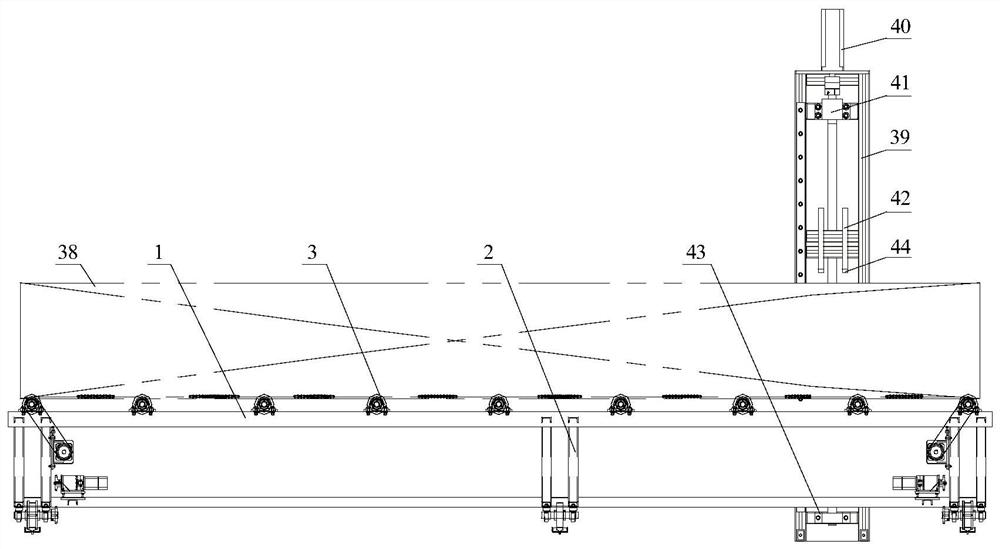

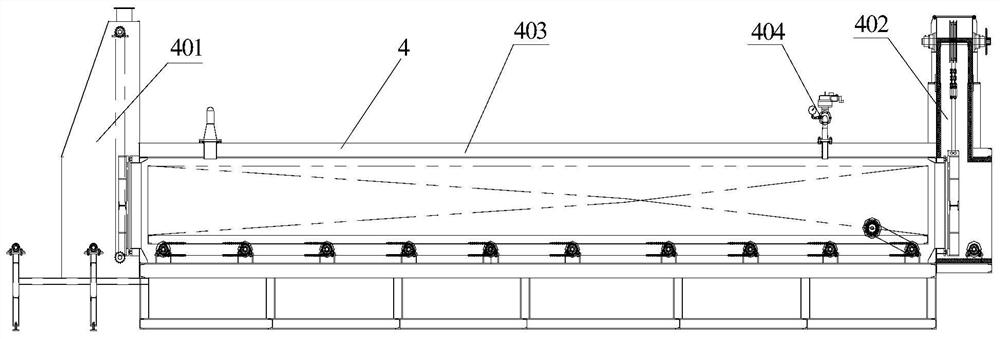

[0043] like figure 1 — Figure 8 As shown, a multi-component gas co-infiltration strengthening system includes a sequentially connected feeding unit, a ventilation unit, a heating pre-infiltration unit, a multi-component gas co-infiltration strengthening unit, a cooling protection unit, and a discharge unit;

[0044] The feeding unit includes a feeding vehicle frame 1, a feeding vehicle traveling mechanism 2 arranged below the feeding vehicle frame 1, and a plurality of conveying rollers 3 that run along the surface of the feeding vehicle frame 1 and run through each unit;

[0045] The ventilation unit includes a front ventilation chamber 4 placed at the front of the heating pre-infiltration unit and a rear ventilation chamber 5 placed at the rear of the cooling protection unit;

[0046] The heating pre-infiltration unit includes a heating furnace, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com