Vacuum pump

A vacuum machine and vacuum hood technology, applied in vacuum evaporation coating, ion implantation coating, coating and other directions, can solve the problems of unstable coating adhesion, black spots, easy to be contaminated with dust on the surface, etc., to eliminate black spots , The effect of improving adhesion and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

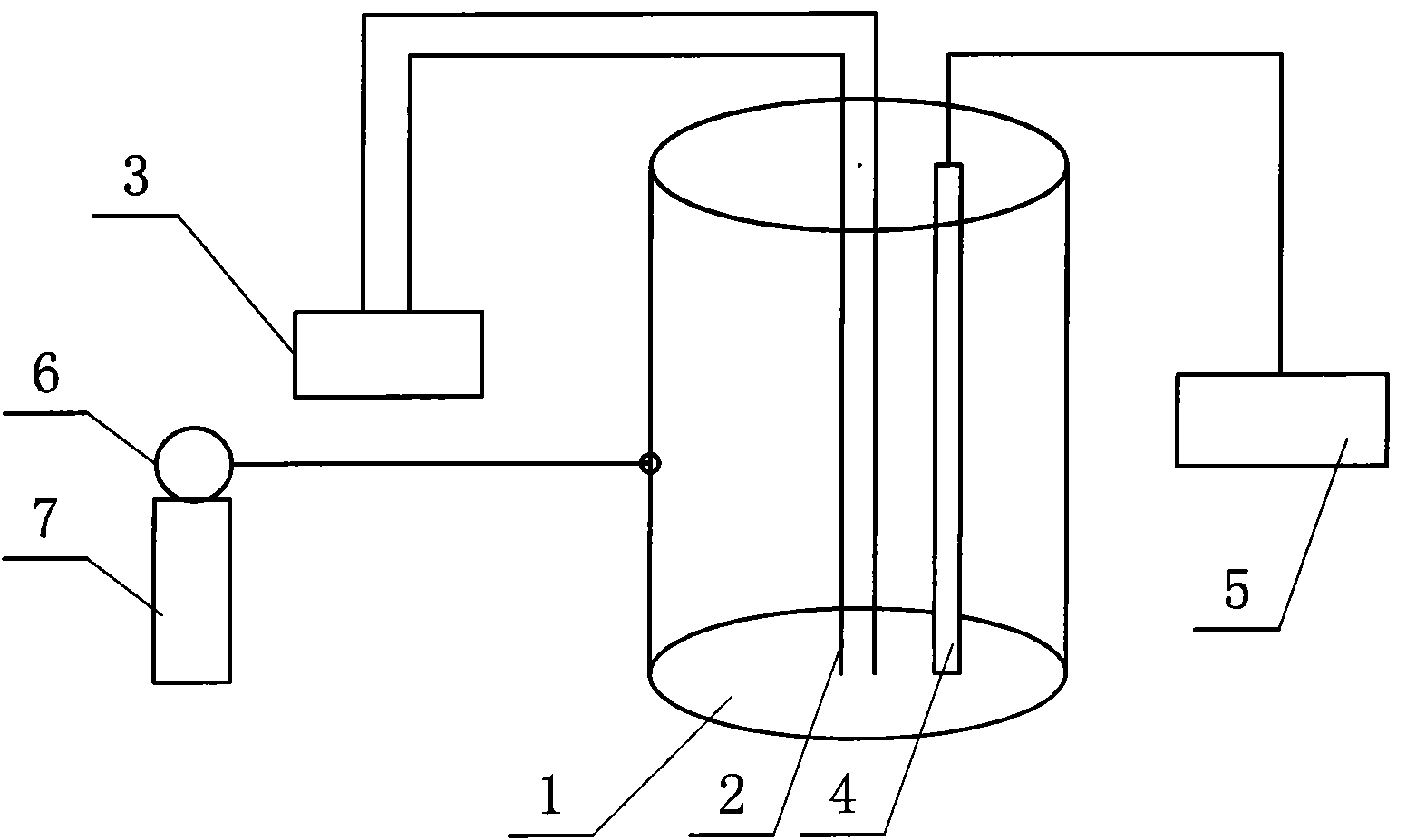

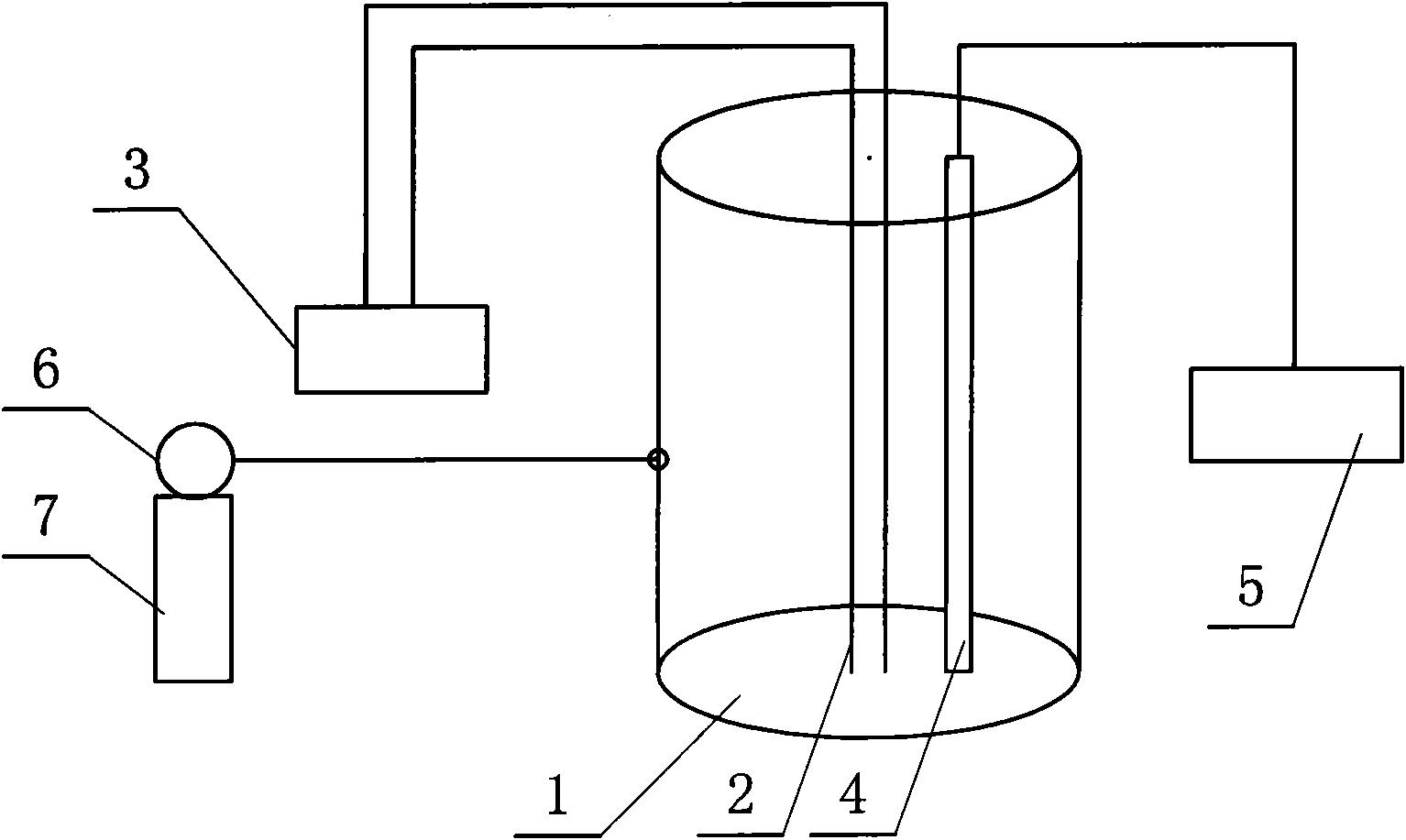

[0010] refer to figure 1 It is an embodiment of a vacuum machine of the present invention, a vacuum machine, comprising a vacuum cover 1, an evaporation electrode 2 and an evaporation current controller 3, the evaporation electrode 2 is arranged in the vacuum cover 1, and the evaporation electrode 2 is also connected with The evaporation current controller 3 outside the vacuum cover 1 is connected, and also includes an ion generator 4 and an ion generation controller 5, the ion generator 4 is arranged in the vacuum cover 1, and the ion generator 4 is connected with the external vacuum cover 1 The ion generation controller 5 is connected, and the ion generator 4 is an aluminum rod; when passing through with high voltage and low current, the ion wind can be better generated, and the vacuum cover 1 is connected to the argon gas tank 7 through the gas volume control valve 6 .

[0011] Described ion generator 4 also can adopt copper rod. Using high voltage and low current, a stabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com