High-hardness domestic ceramic and production process thereof

A high-hardness, daily-use technology, applied in the field of ceramic production, can solve problems such as affecting the appearance and even use of ceramic products, insufficient ceramic hardness, and easily damaged products, etc., to achieve strong plasticity, improve quality and hardness, and prevent cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

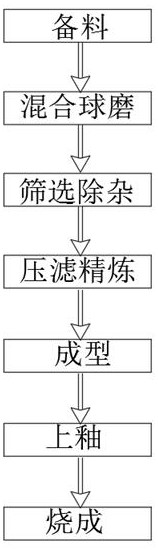

[0032] refer to figure 1 , a high-hardness daily-use ceramics, including a body and a glaze layer, the body formula includes the following components in parts by mass: 20-100 parts of kaolin, 30-50 parts of alumina, 10-18 parts of zirconia 12-18 parts of bentonite, 15-24 parts of waste porcelain slag, 15-30 parts of quartz, 20-50 parts of feldspar, the glaze layer includes the following components in parts by mass: 15-80 parts of kaolin, 6-12 parts of magnetic powder, 12-16 parts of talcum powder, 10-15 parts of spodumene, 6-12 parts of lithium china stone, 10-15 parts of quartz, 7-20 parts of calcite, among which kaolin is preferably Gaotang kaolin or Yunnan Kaolin, quartz is preferably enamel quartz, and feldspar is preferably Yanfeng potassium feldspar or Conghua albite.

[0033] The present invention also proposes a production process of high-hardness ceramics for daily use, comprising the following steps:

[0034] S1: Prepare materials, take each raw material according ...

Embodiment 2

[0044] refer to figure 1 , a kind of high-hardness daily-use ceramics, comprising a green body and a glaze layer, the green body includes the following components in parts by mass: 20-100 parts of kaolin, 30-50 parts of alumina, 10-18 parts of zirconia , 12-18 parts of bentonite, 15-24 parts of waste porcelain slag, 15-30 parts of quartz, 20-50 parts of feldspar, the glaze layer includes the following components in parts by mass: 15-80 parts of kaolin, magnetic powder 6-12 parts, 12-16 parts of talcum powder, 10-15 parts of spodumene, 6-12 parts of lithium china stone, 10-15 parts of quartz, 7-20 parts of calcite, among which kaolin is preferably Gaotang kaolin or Yunnan kaolin , the quartz is preferably enamel quartz, and the feldspar is preferably Yanfeng potassium feldspar or albite feldspar.

[0045] The present invention also proposes a production process of high-hardness ceramics for daily use, comprising the following steps:

[0046]S1: Prepare materials, take each ra...

Embodiment 3

[0056] refer to figure 1 , a kind of high-hardness daily-use ceramics, comprising a green body and a glaze layer, the green body includes the following components in parts by mass: 20-100 parts of kaolin, 30-50 parts of alumina, 10-18 parts of zirconia , 12-18 parts of bentonite, 15-24 parts of waste porcelain slag, 15-30 parts of quartz, 20-50 parts of feldspar, the glaze layer includes the following components in parts by mass: 15-80 parts of kaolin, magnetic powder 6-12 parts, 12-16 parts of talcum powder, 10-15 parts of spodumene, 6-12 parts of lithium china stone, 10-15 parts of quartz, 7-20 parts of calcite, among which kaolin is preferably Gaotang kaolin or Yunnan kaolin , the quartz is preferably enamel quartz, and the feldspar is preferably Yanfeng potassium feldspar or albite feldspar.

[0057] The present invention also proposes a production process of high-hardness ceramics for daily use, comprising the following steps:

[0058] S1: Prepare materials, take each r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com