Substrate for photosensitive drum

A photosensitive drum and substrate technology, applied in optics, thin material processing, instruments, etc., can solve problems such as adverse effects on image quality, and achieve the effect of reducing driving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~13、 comparative example 1~3)

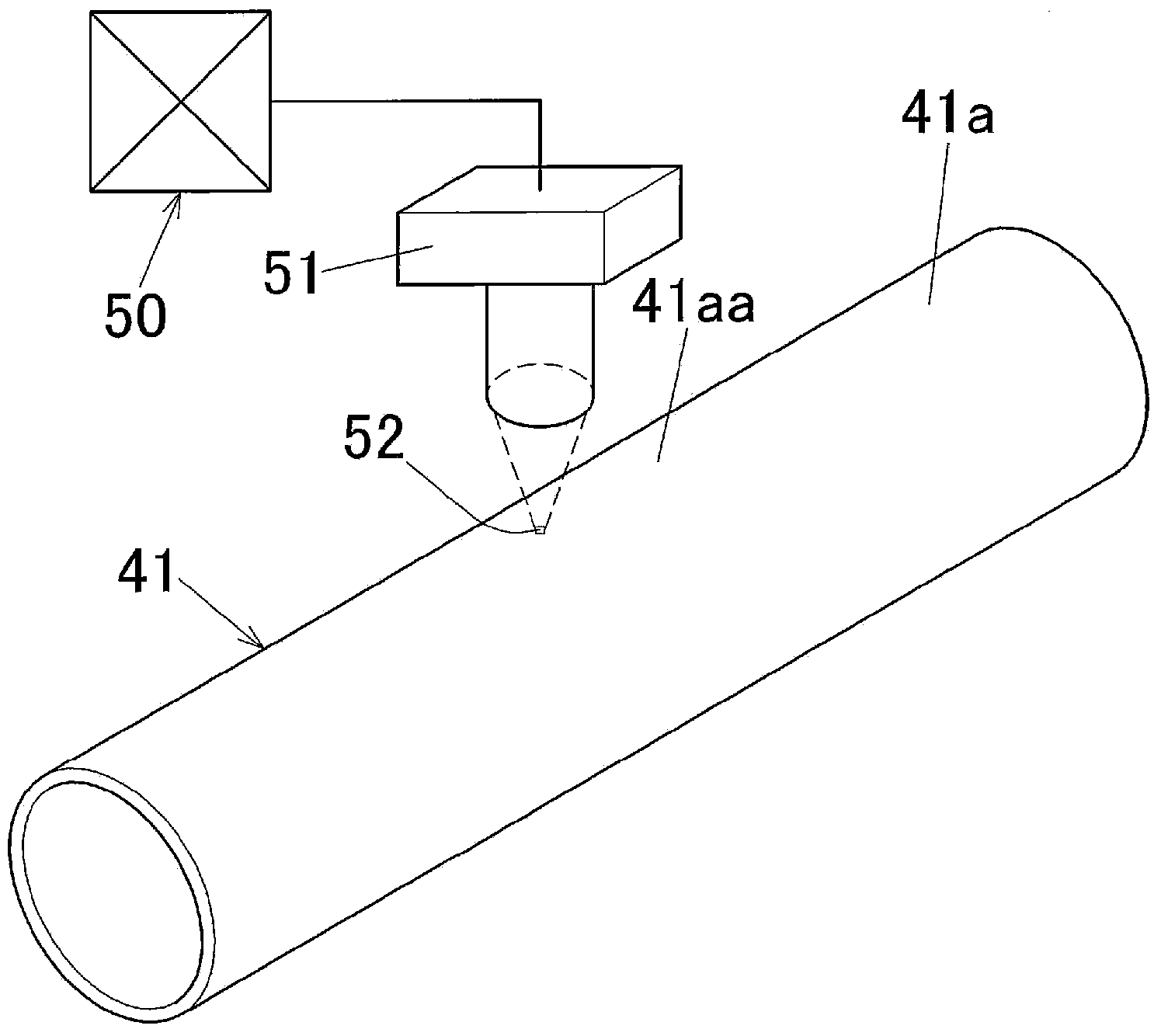

[0163] Used in Examples 1-7 and Comparative Examples 1-3 Figures 4A-4C The drawing apparatus 10 of the above-mentioned embodiment shown was used in Examples 8-13 Figure 5A and Figure 5B The drawing processing apparatus 110 shown performs a drawing process on the extruded aluminum tube 40 to obtain an extruded-drawn tube which is a non-cutting aluminum tube. Then, the extruded-drawn tube is sequentially cut to a predetermined length, chamfered at the cut end, and cleaned, thereby producing a base 41 for a photosensitive drum. The length of the base body 41 is 260 mm.

[0164] Next, if figure 1 The image forming surface 41aa of the outer surface 41a of the substrate 41 was evaluated as shown.

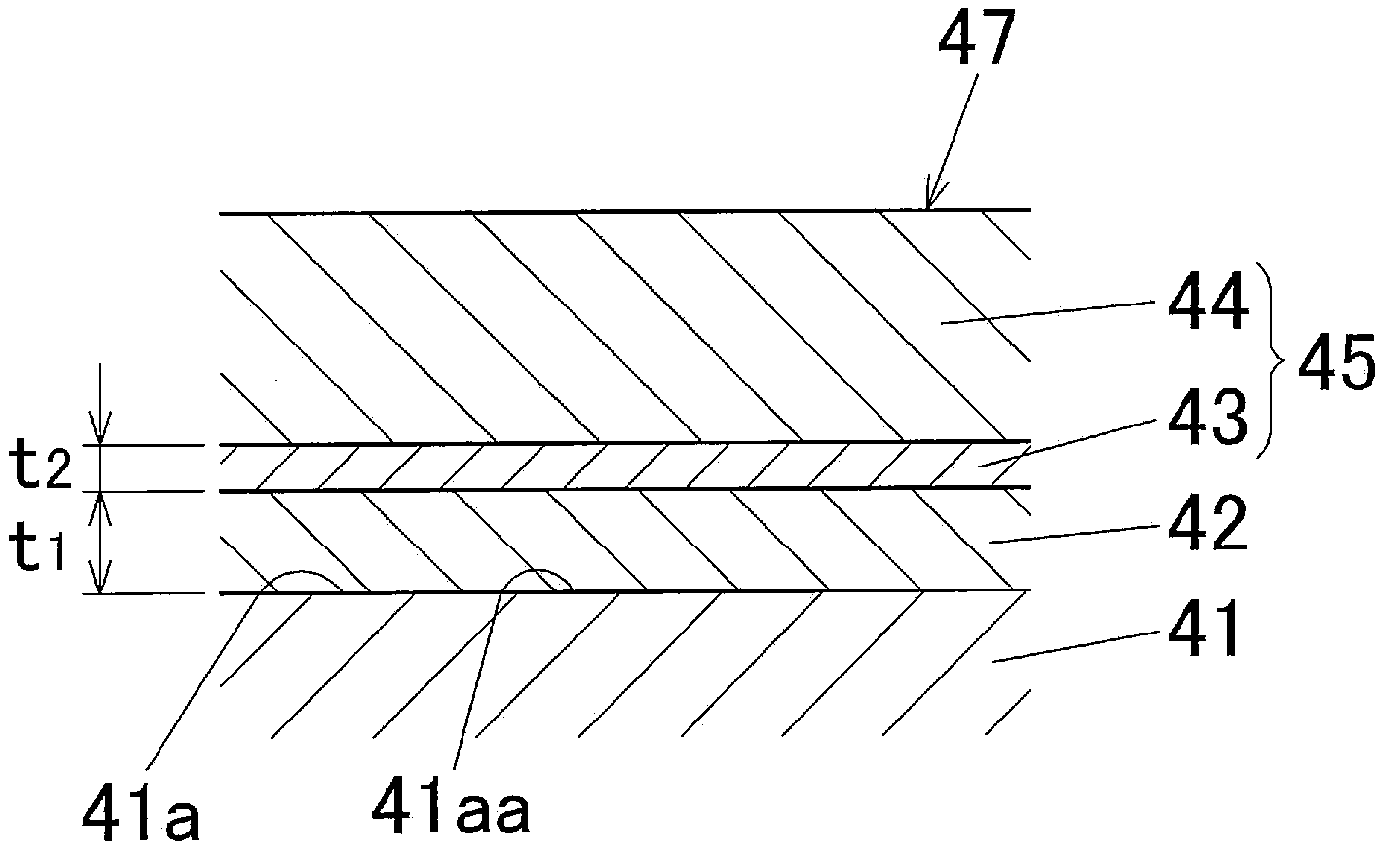

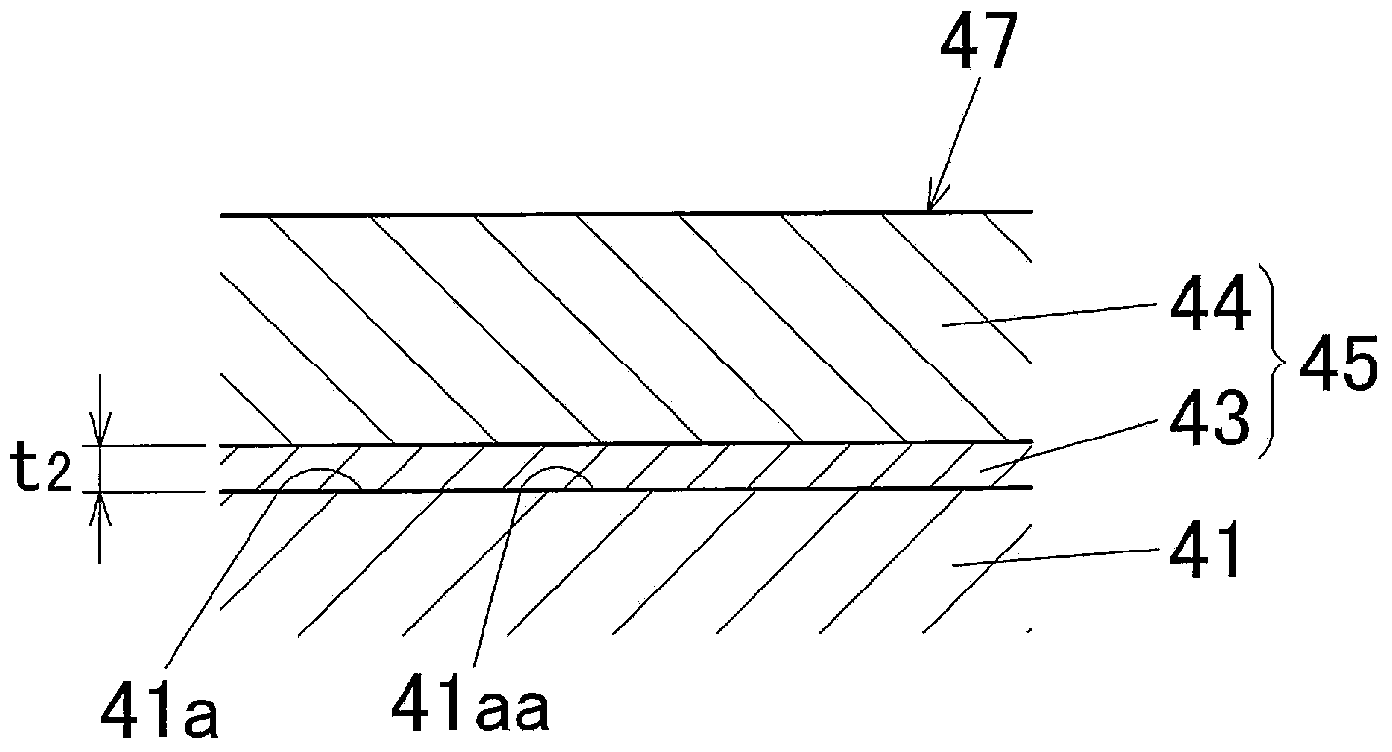

[0165] Next, if figure 2 As shown, a functionally separated organic photoreceptor layer 45 (that is, a charge generating layer 43 and a charge transporting layer 44 ) is coated on an image forming surface 41 aa of a substrate 41 via an overcoat layer 42 , thereby producing a pho...

Embodiment 1~13)

[0197] As shown in Table 1, when the area is greater than or equal to 1 μm 2 The first point that the total area ratio of the pits relative to the observation field area is greater than 2% and each area is greater than or equal to 1 μm 2 The average area of the pits is less than 8μm 2 In the case where both of the second points are greater (that is, Examples 1 to 13), the occurrence of interference fringes can be prevented.

[0198] Furthermore, when the area is greater than or equal to 1 μm in all 2 The third point is that the total occupied area ratio of pits relative to the viewing field area is less than or equal to 15%, and each area is greater than or equal to 1 μm 2 The average area of the pits is 20 μm or less 2 This fourth point and no area greater than or equal to 300μm 2 In the case of the fifth point (that is, Examples 1 to 7), which is a coarse pit, the generation of black spots can also be prevented.

[0199] Therefore, it can be confirmed that these poi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com