Patents

Literature

104results about How to "Avoid dark spots" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

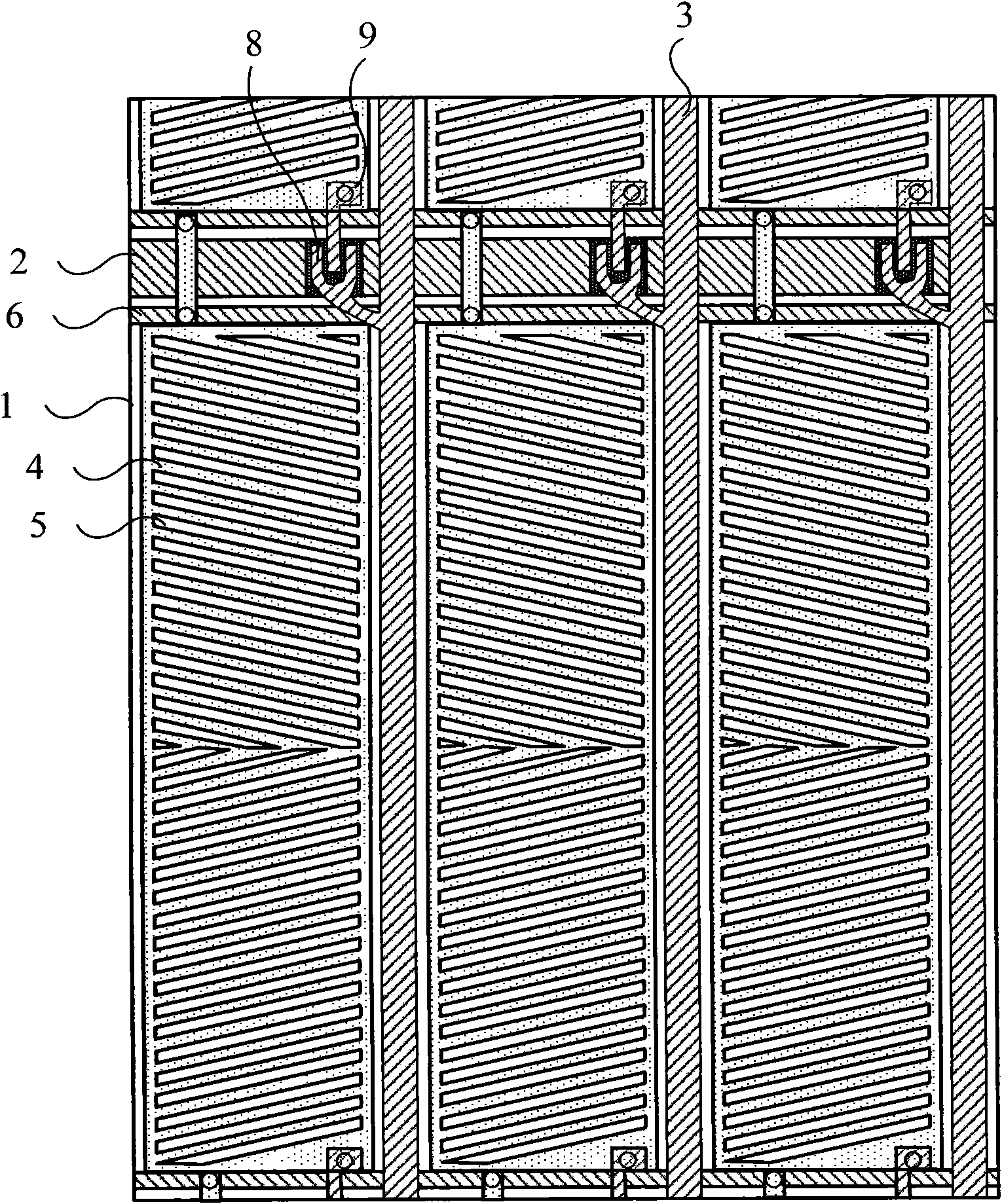

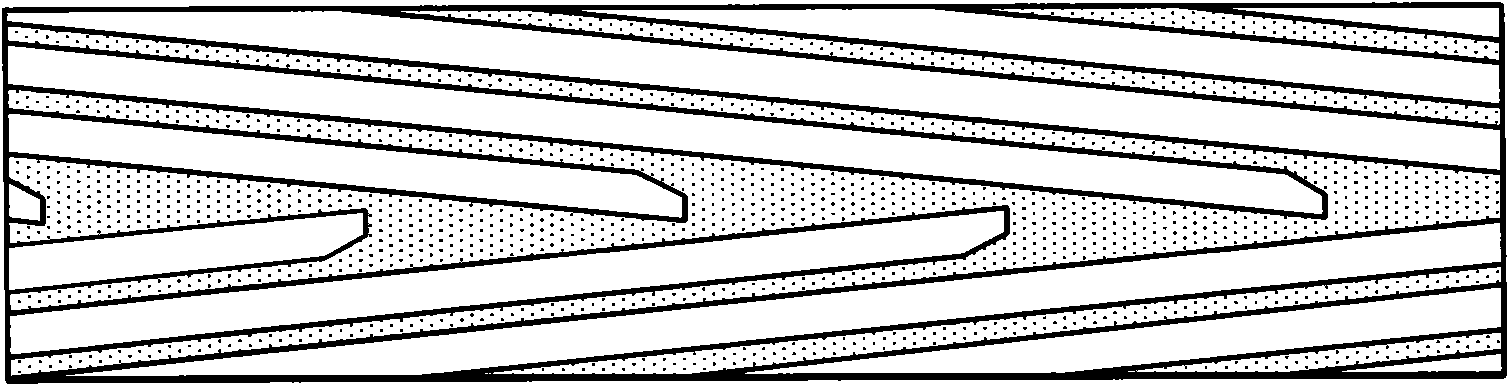

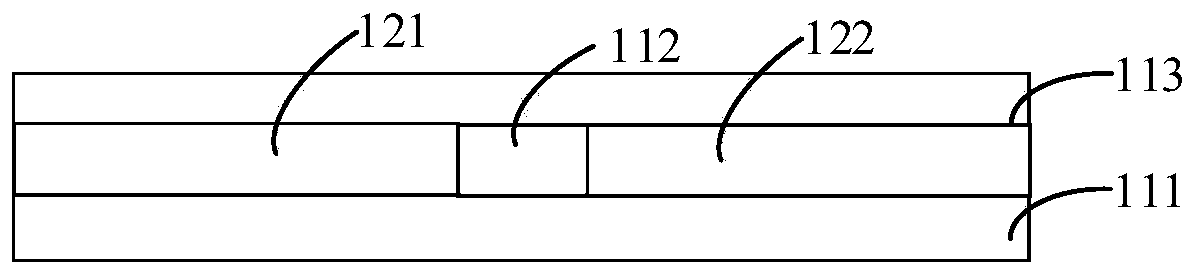

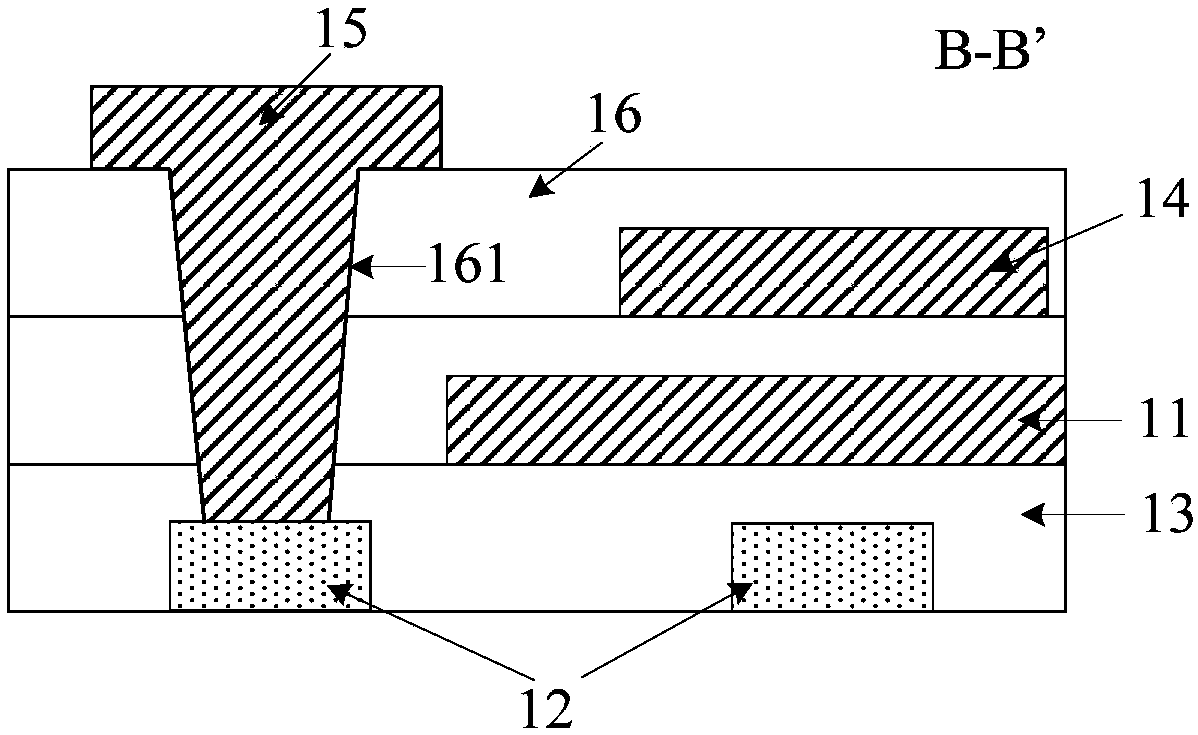

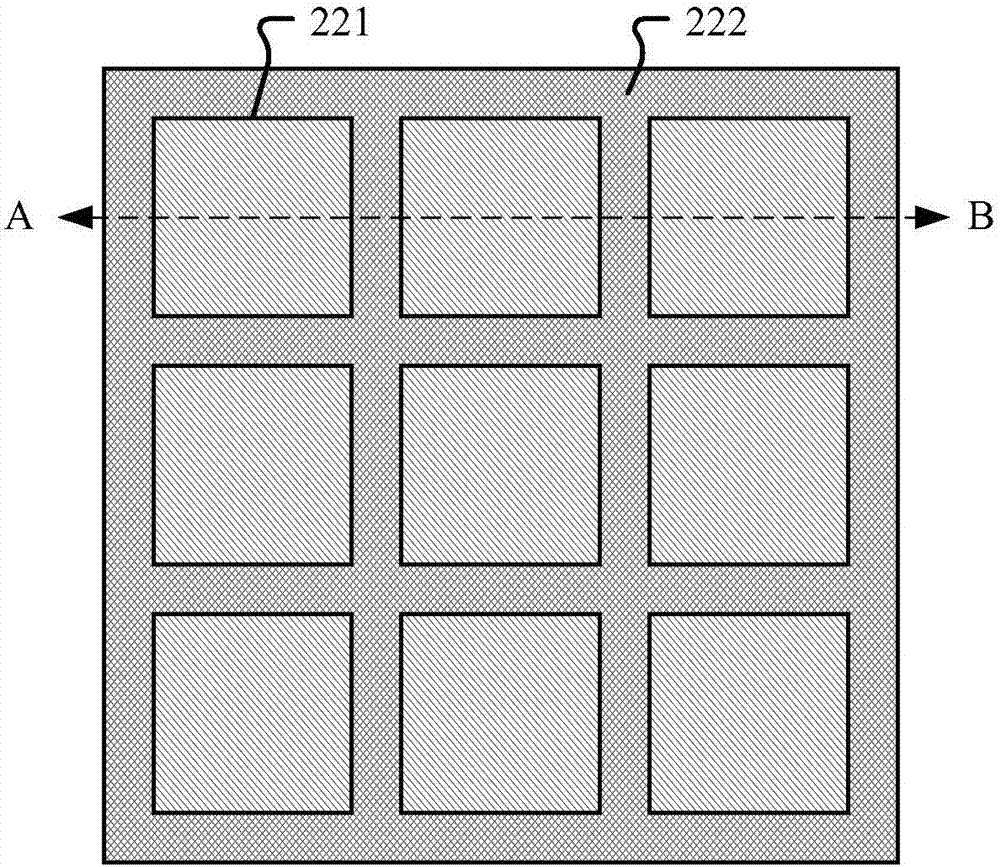

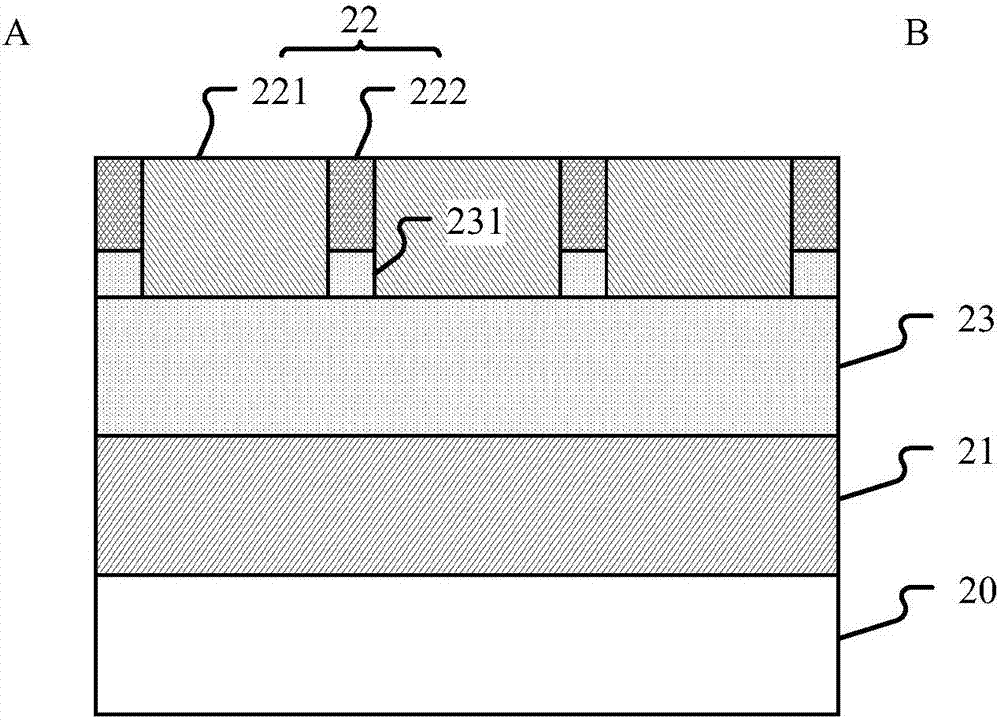

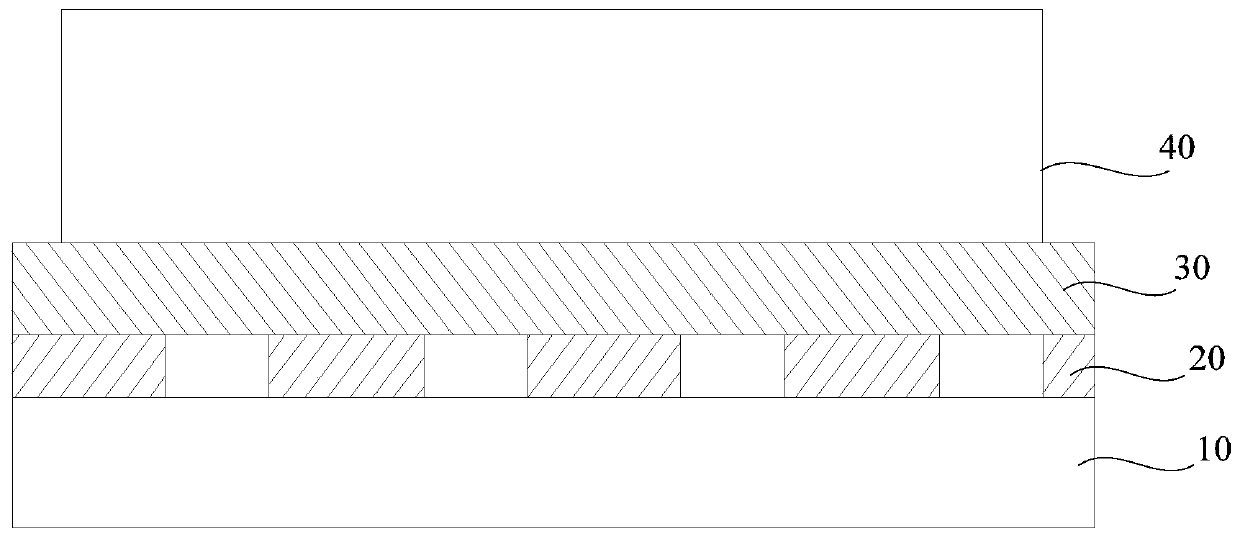

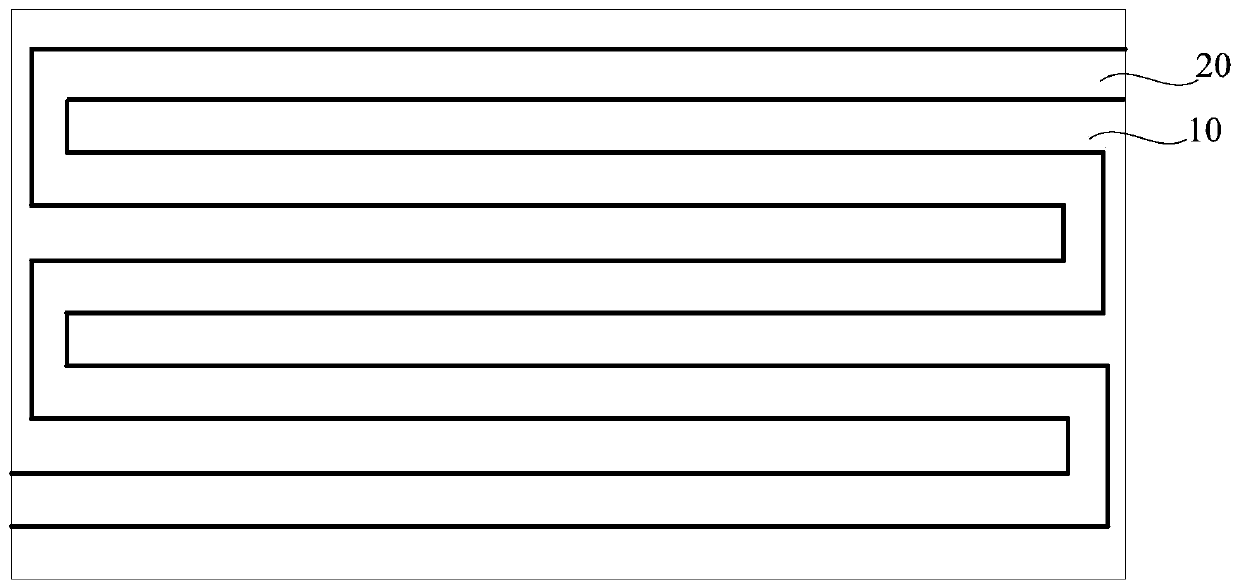

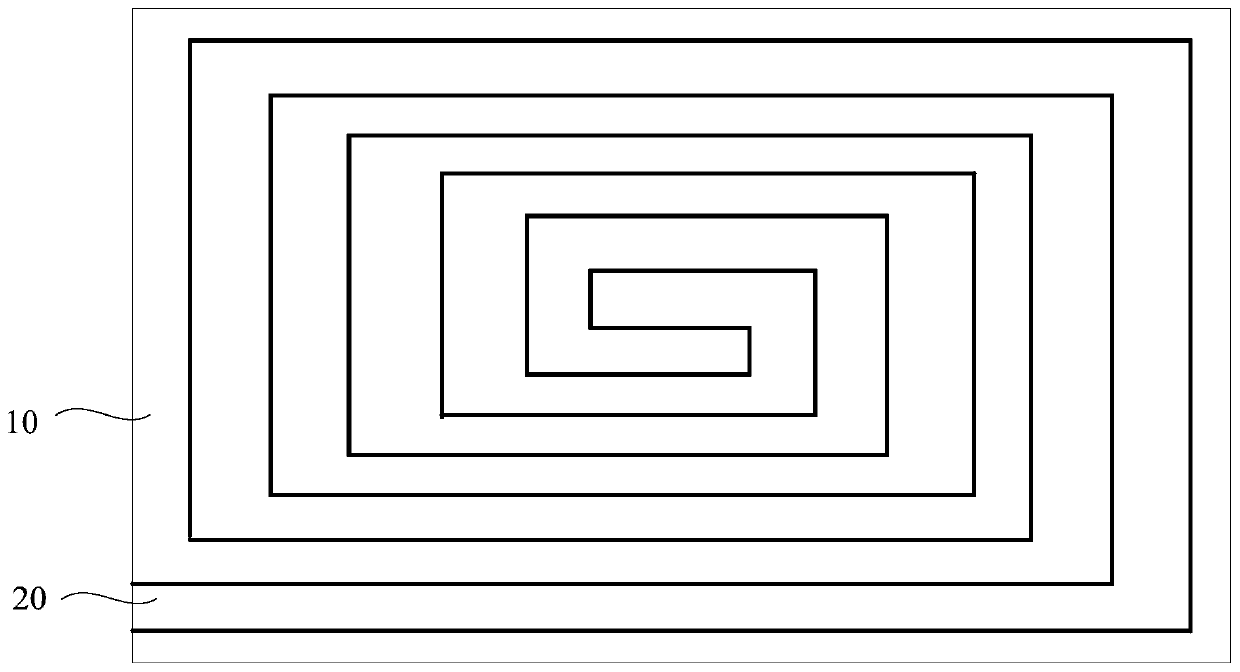

Array substrate, liquid crystal panel and liquid crystal displayer

ActiveCN102156367AAvoid dark spotsDoes not affect aperture ratioSolid-state devicesNon-linear opticsGratingEngineering

The invention discloses an array substrate, a liquid crystal panel and a liquid crystal displayer, wherein the array substrate comprises a first lining substrate, and grating lines and data wires that form a plurality of pixel units in a surrounding way; each pixel unit comprises a first electrode with a narrow seam, a second electrode and a thin-film transistor switch; the first electrode and the second electrode are used for forming electric field that can drive the liquid crystal molecules, wherein the first electrode comprises more than two independent regions; the grating lines and the thin-film transistor switch are arranged among the patterns in all regions of the first electrode; the thin-film transistor switch comprises a grid electrode, a source electrode and a drain electrode; the grid electrode is connected with the grating lines; the source electrode is connected with the data wires; and the drain electrode is connected with all regions respectively. In the invention, theregions of the first electrode with different inclination direction of narrow seams can be divided by the grating lines and the thin-film transistor switch, so that the liquid crystal molecule regions with disorganized deflection can be blocked by the black matrix and the displaying quality of wide visual angle can be improved.

Owner:BOE TECH GRP CO LTD +1

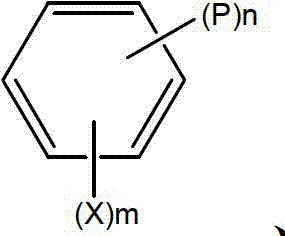

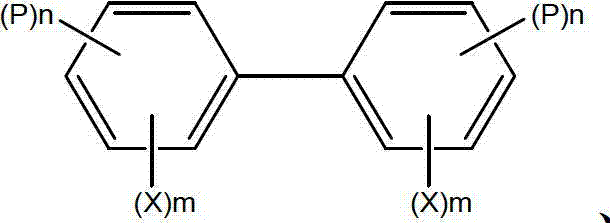

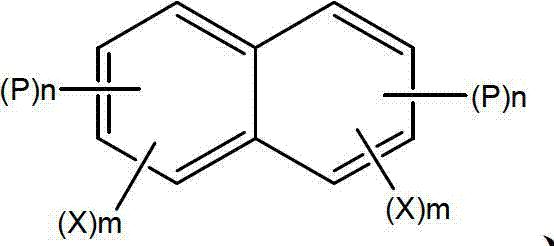

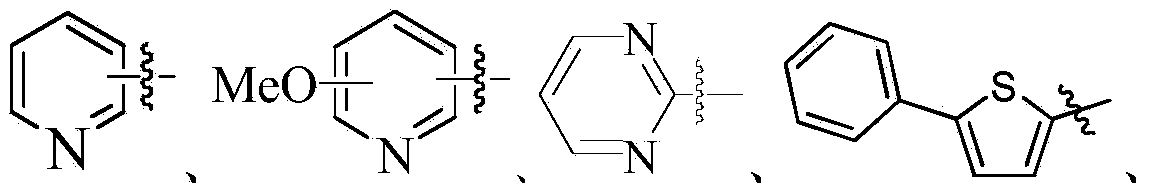

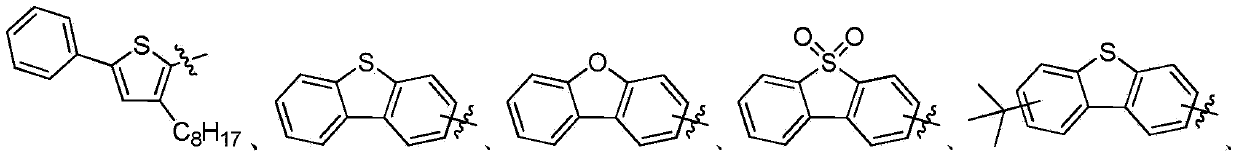

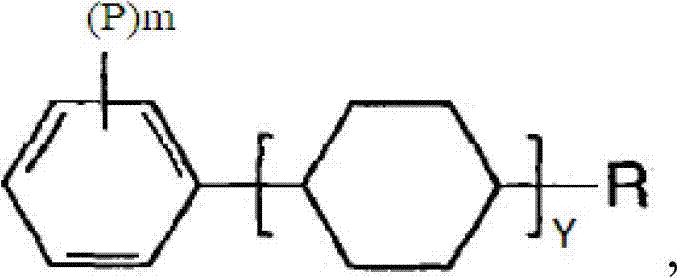

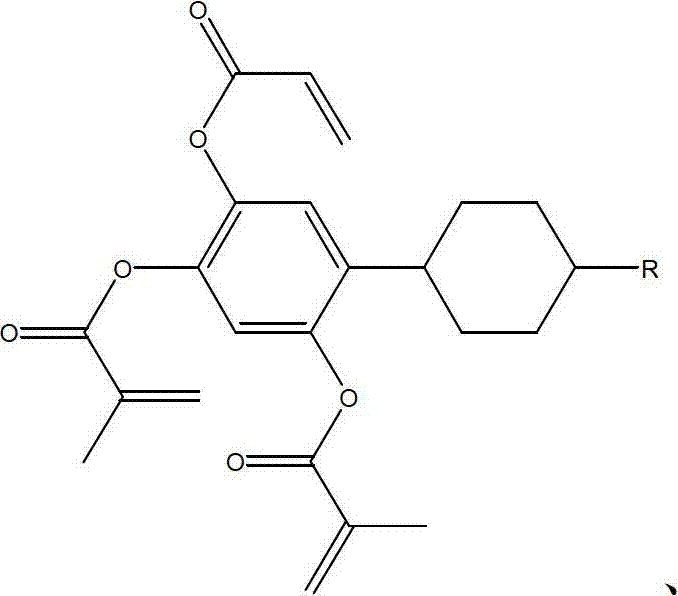

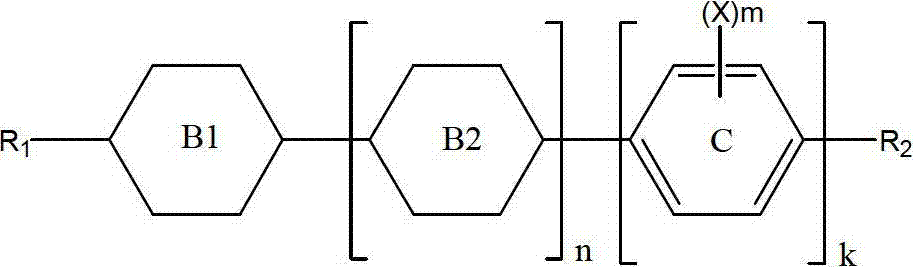

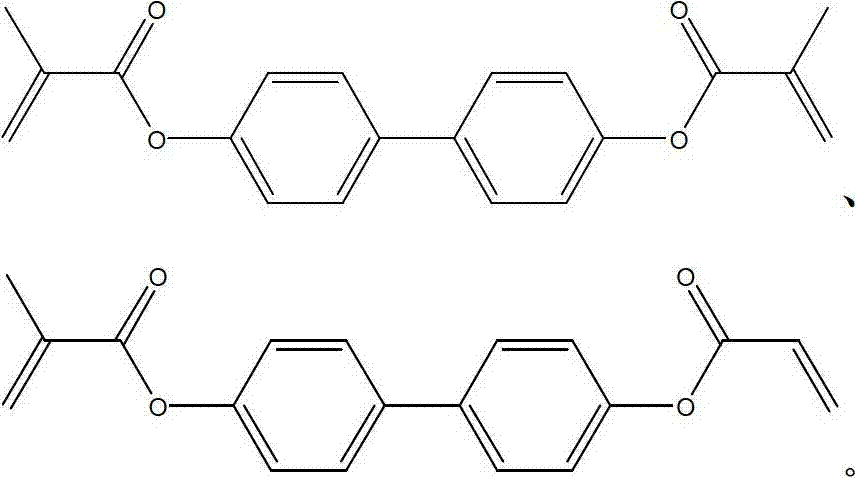

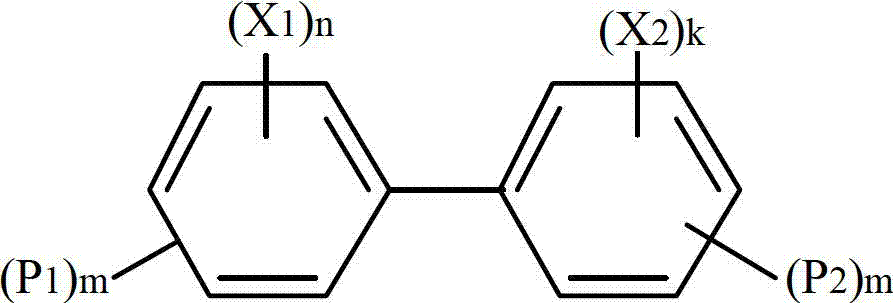

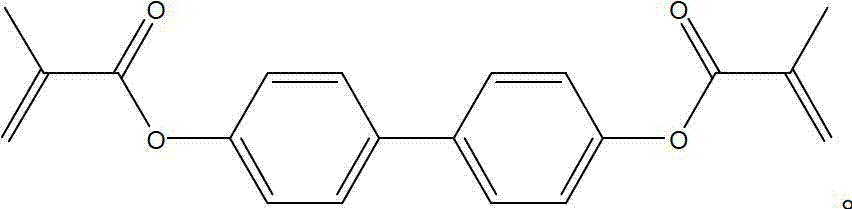

Liquid crystal medium composition

ActiveCN102786936AIncrease contrastAvoid dark spotsLiquid crystal compositionsNegative typeLiquid-crystal display

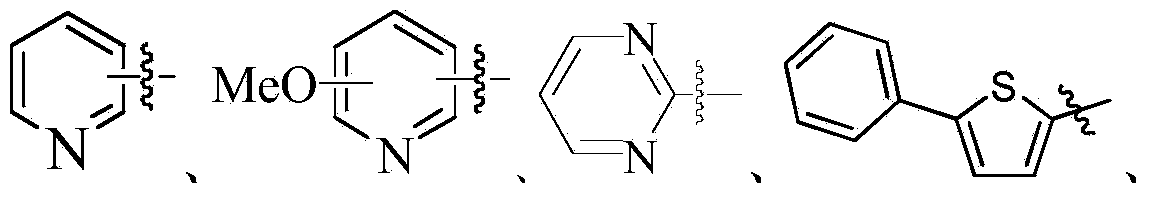

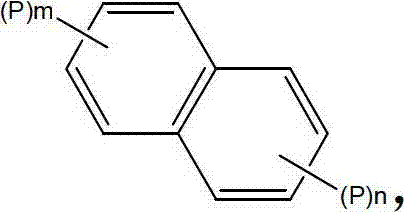

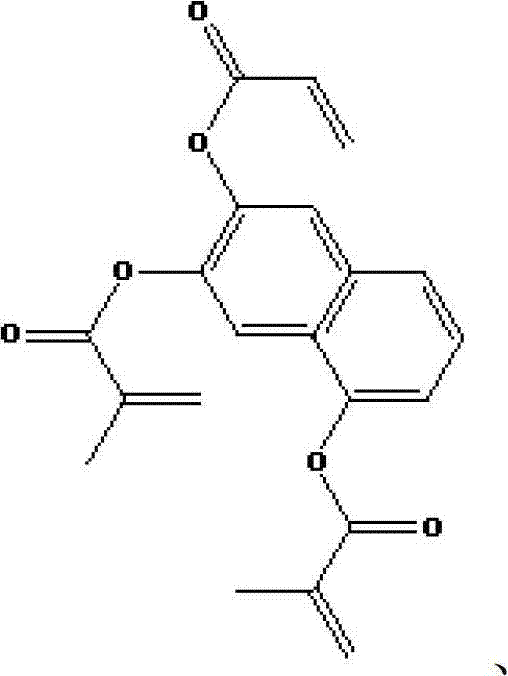

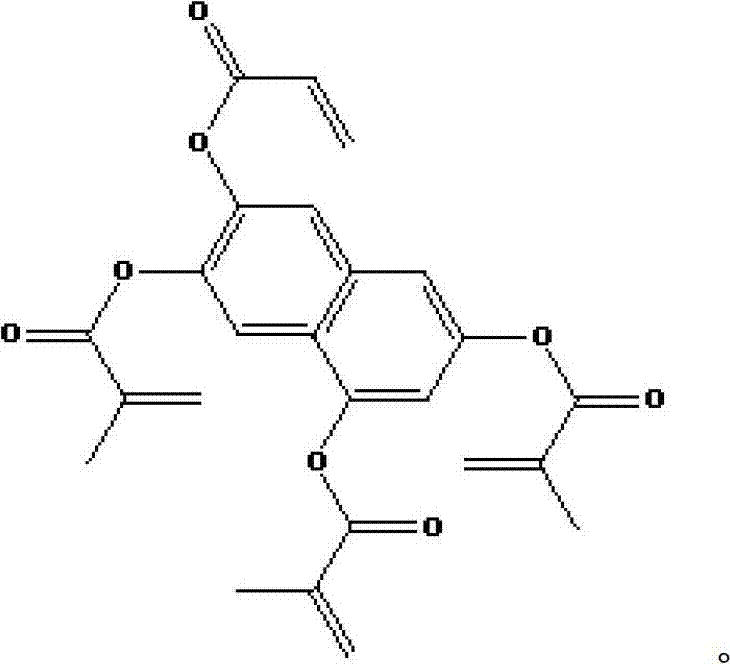

The invention discloses a liquid crystal medium composition, which comprises a negative type liquid crystal material, a stabilizing agent and a reactive monomer capable of performing polymerization under ultraviolet irradiation, wherein the reactive monomer accounts for 0.1%-1% of liquid crystal medium composition according to weight. The reactive monomer at least comprises a reactive monomer descried as a general formula (1) and a reactive monomer descried as a general formula (2), the reactive monomer descried as a general formula (1) accounts for 5%-85% of total amount of the responsive monomer according to mole ratio, a single polymer monomer and a poly polymer monomer in the liquid crystal medium composition can form a polymer under the ultraviolet irradiation, the reaction speed is moderate, the oversized volume of polymer granules can be avoided, loose accumulation can be avoided, the generation of adverse orientation of the liquid crystal and dark state light point phenomenon of a liquid crystal panel can be avoided, and the contrast and optical effect of a liquid crystal display apparatus can be increased. P-L1-X-L2-M_(1).

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

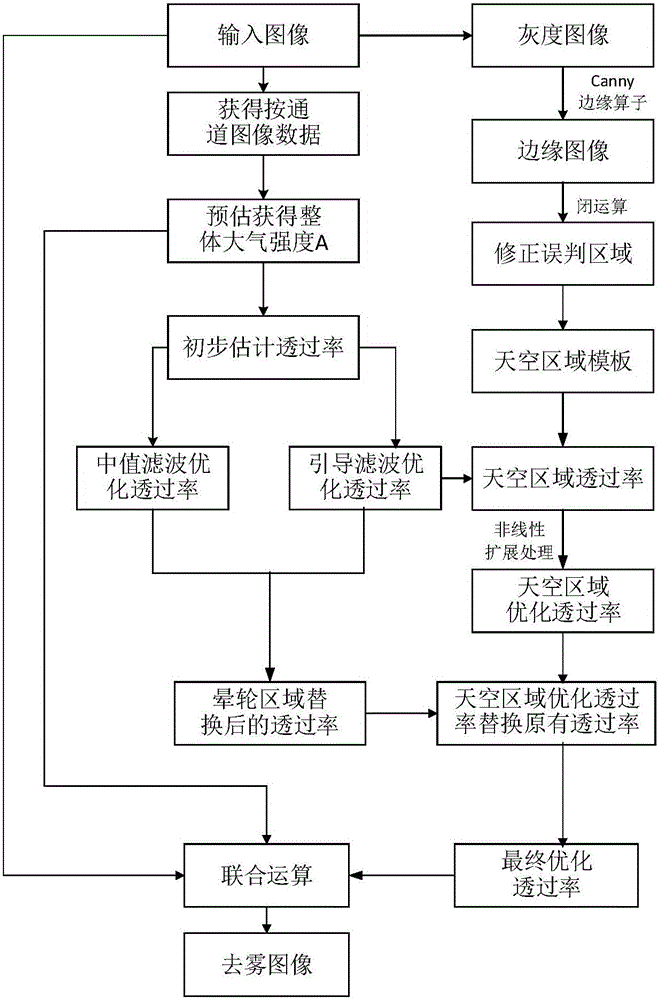

Single image defogging method based on sky region segmentation processing

ActiveCN105761230AAvoid improving deficienciesPastel colorImage enhancementImage analysisDistortionTransmittance

The invention discloses a single image defogging method based on sky region segmentation processing, comprising the steps of: calculating the preliminary estimation transmittance of an input image according to a dark channel prior theory, optimizing the preliminary estimation transmittance respectively through median filtering and guide filtering, combining two results, and replacing the transmittance optimized by halo region guide filtering with the transmittance optimized by median filtering; employing a Canny boundary operator to calculate the boundary images of original images, correcting miscalculated regions, dividing the images into sky and ground regions to be used as binary template to extract the sky region transmittance after guide filtering optimization, and performing non-linear expansion processing on the extracted sky region transmittance; combining the transmittance respectively obtained through the two steps, and performing guide filtering smooth processing; and utilizing obtained optimization transmittance to perform filtering processing. The single image defogging method can better improve halo effects and sky region color distortion, and greatly improve defogging effects of fog-degraded images.

Owner:XIDIAN UNIV

Liquid crystal medium mixture and liquid crystal display using same

InactiveCN102876338AAvoid misalignmentQuick responseLiquid crystal compositionsNon-linear opticsCrystallographyLiquid-crystal display

The invention provides a liquid crystal medium mixture and liquid crystal display using the same. The liquid crystal medium mixture comprises the following components: at least one anisotropic liquid crystal material, and two or more polymerizable monomers which can be polymerized under UV (ultraviolet) irradiation, wherein the liquid crystal material comprises an alkenyl compound which is stable to a polymerization reaction during polymerization of the polymerizable monomers; and the polymerizable monomers account for 0.1-1% of the total amount of the liquid crystal medium mixture in part by weight. The liquid crystal medium mixture can be polymerized into polymer bulge with relatively small size and good uniformity by adopting the two or more polymerizable monomers which can be polymerized under the UV irradiation according to a proper ratio, so that poor liquid crystal alignment, and a light spot phenomenon of a liquid crystal panel in the dark state are avoided, thus increasing the response speed of the liquid crystal panel and achieving high contrast and stable massive productivity.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

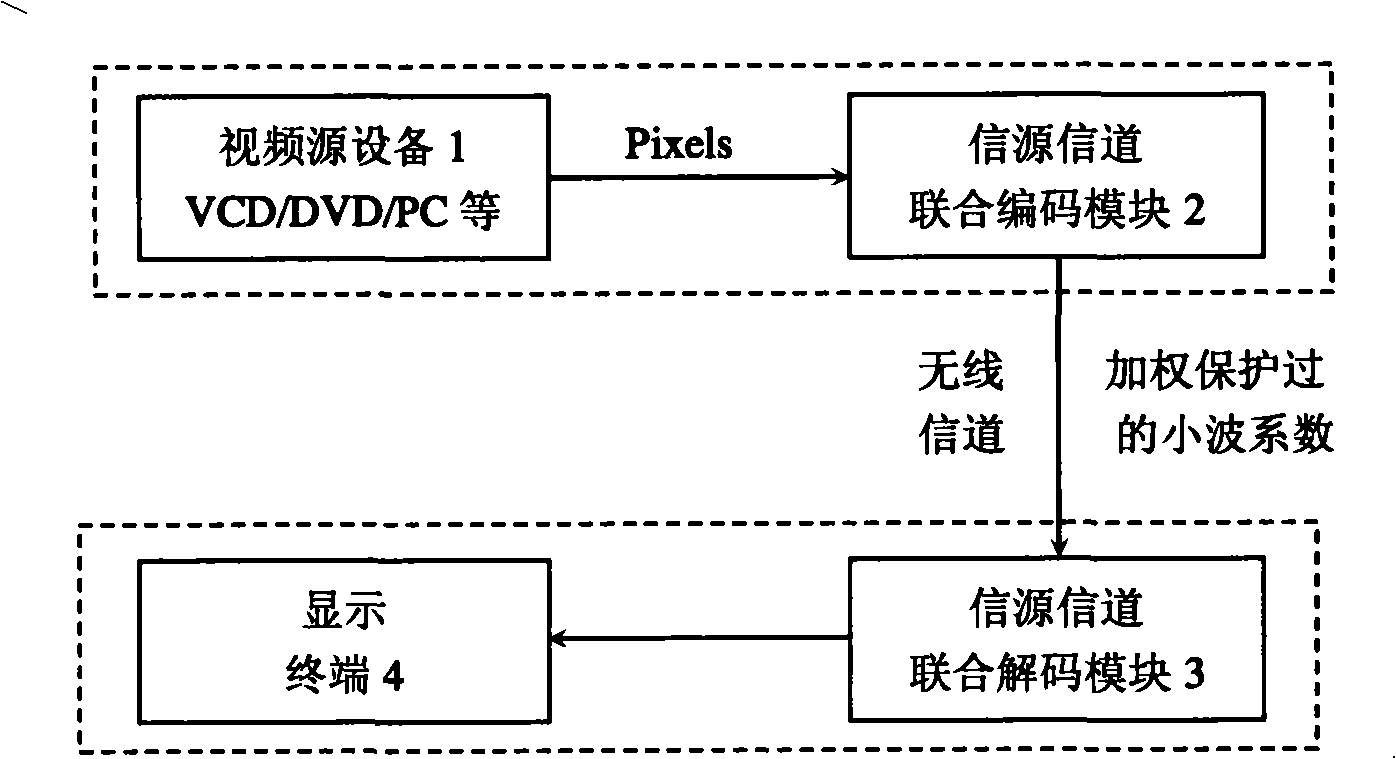

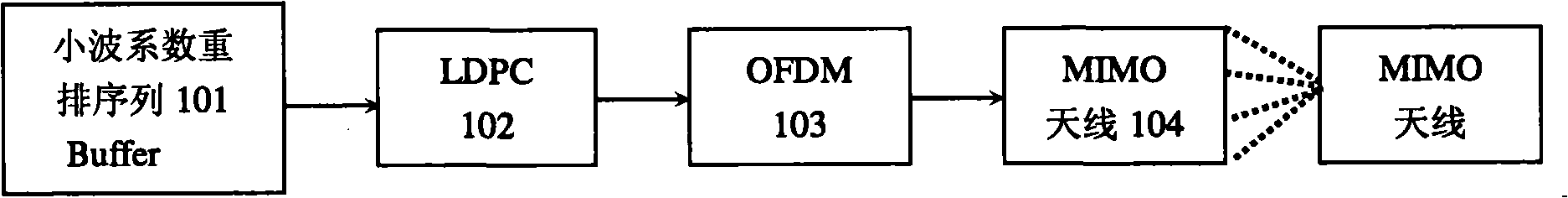

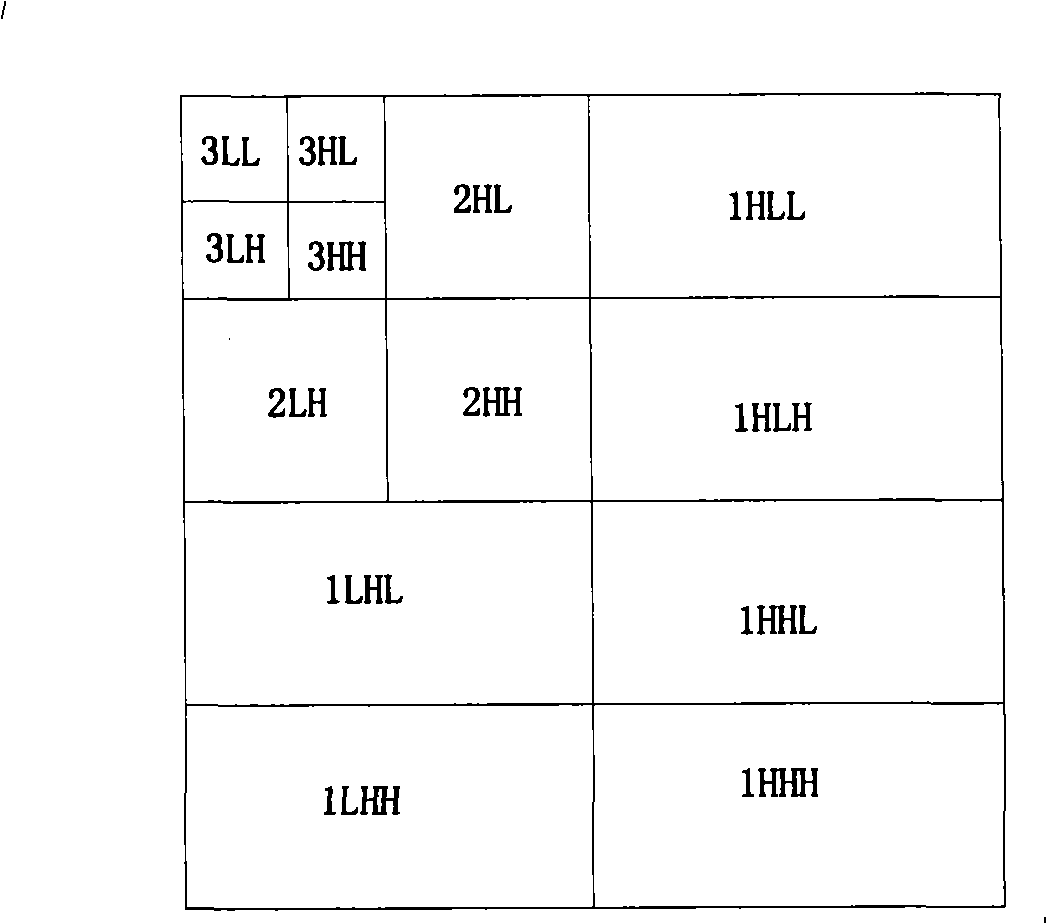

Non-compression high definition video signal wireless transmission method based on wavelet conversion characteristics

InactiveCN101494774AProtect image qualityEasy to useColor television with pulse code modulationPulse modulation television signal transmissionImaging qualityTelevision equipment

The invention discloses a non-compressed high-definition video signal wireless transmission method based on wavelet transform characteristics, which adds a source-channel combined decoding module of images on the wireless channel between the video source equipment and the television, wherein, the transmitting end reads the original image frame in the external buffer through the source-channel combined decoding module, performs coding protection processing according to the image characteristic and based on wavelet transform, and uses the MIMO channel to expand the transmission band-width for transmitting high-definition video signals; the flow path of the receiving end is reverse. Using the method of the present invention not only eliminates the signal line so that the television equipment is more simple, but also can greatly protect the image quality even in poor channel conditions (such as airports, bus stations and other public environments), showing superiority of supporting the high-definition picture quality of the high-definition digital television.

Owner:XIAMEN OVERSEAS CHINESE ELECTRONICS ENTERPRISE

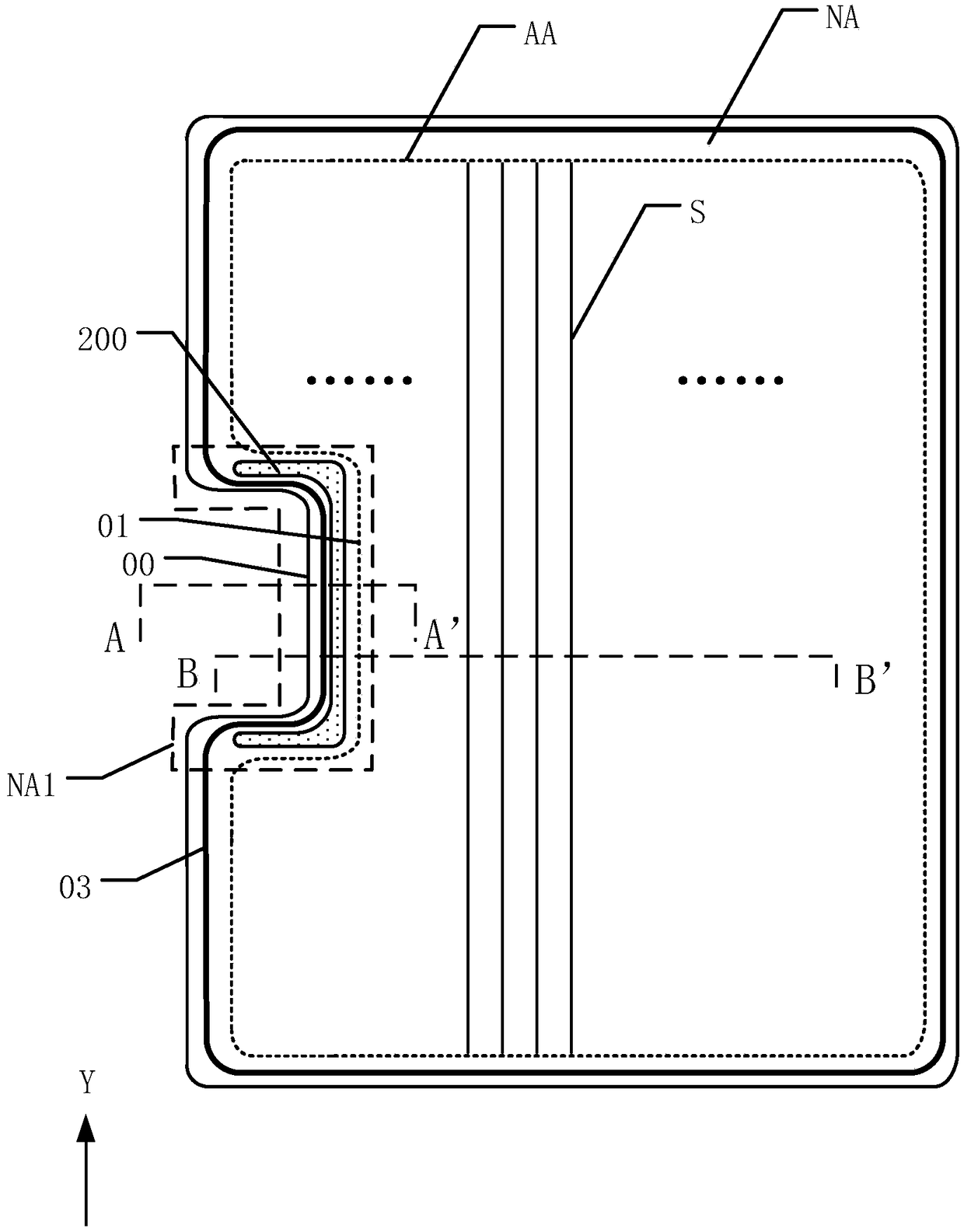

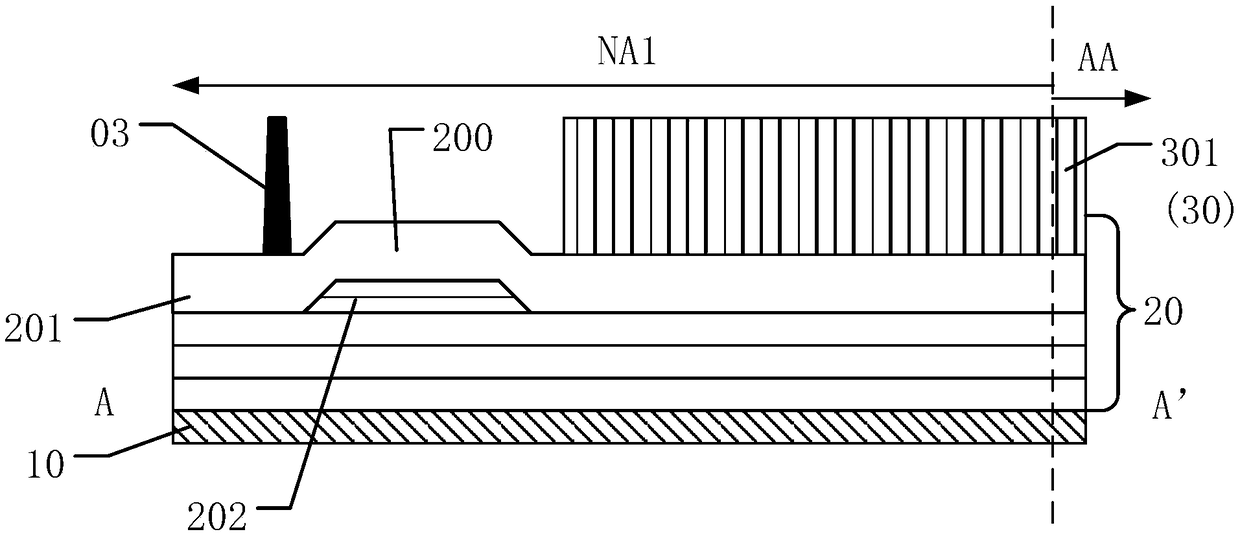

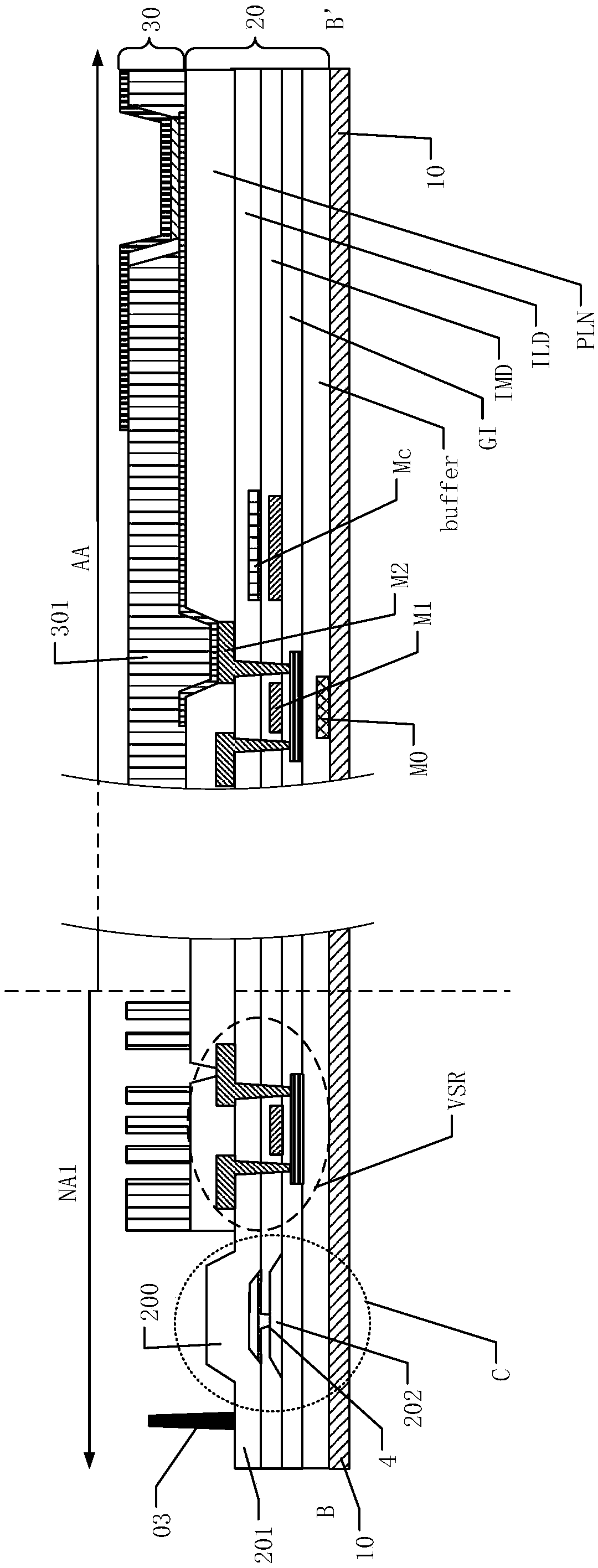

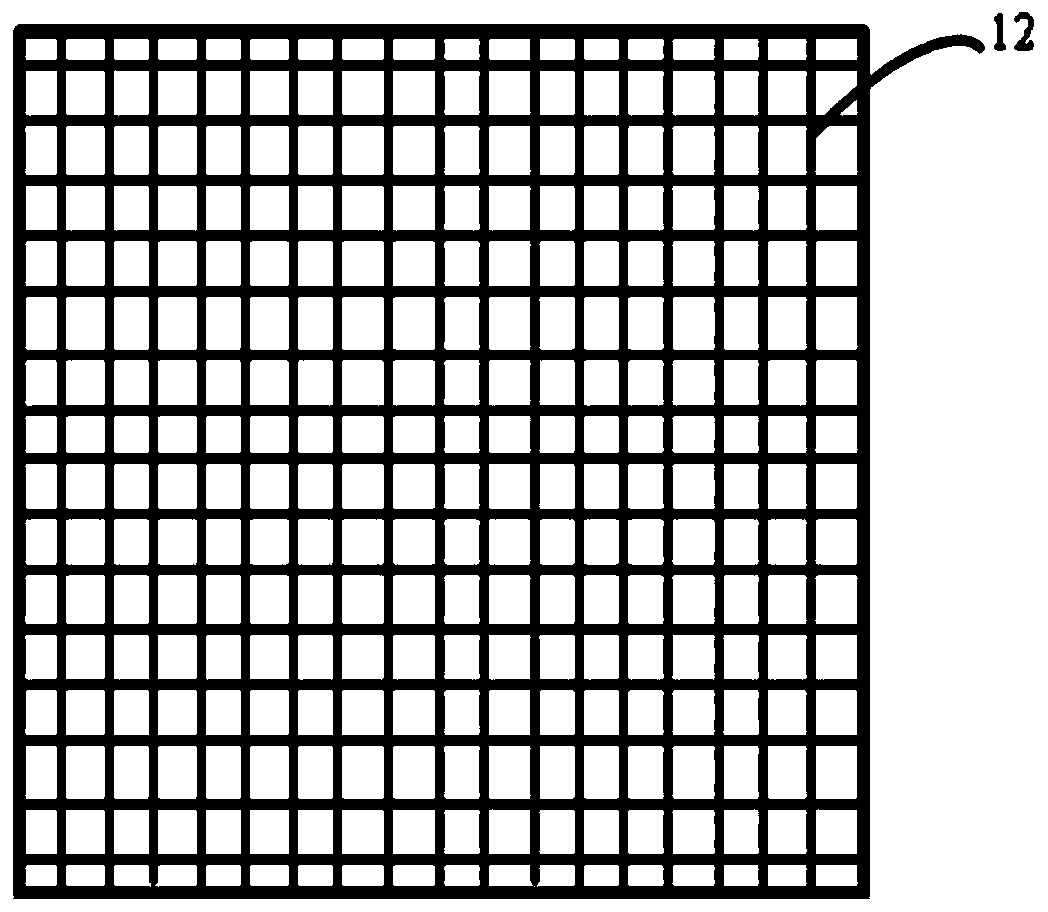

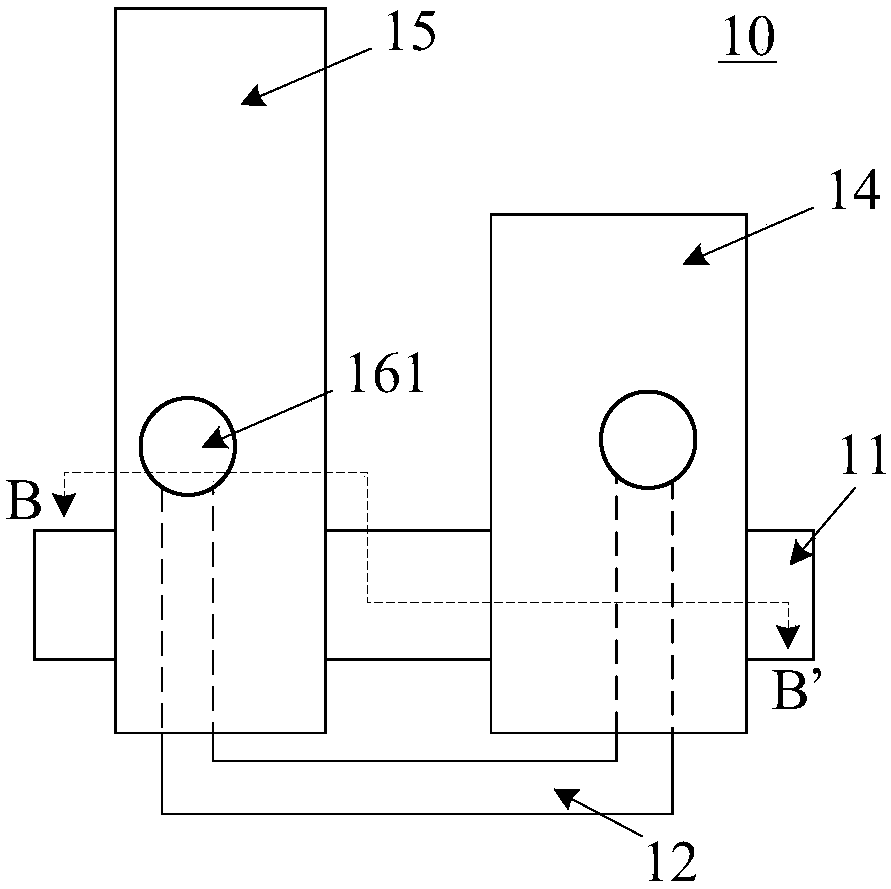

Display panel and display device

ActiveCN109300970AShorten speedAvoid dark spotsSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceDark spot

The invention discloses a display panel and a display device. The display panel comprises a display area, a non-display area arranged around the display area, and at least one notch. The display areaincludes a plurality of data lines and specially-shaped edges, wherein the data lines and the specially-shaped edges extend along a column direction. The non-display area includes a first non-displayarea. In addition, the display panel also includes a substrate, an array layer, and a display function layer. The array layer at least includes one inorganic layer at least extending to the first non-display area; the inorganic layer includes at least one protrusion portion. The display function layer includes a light emitting device and a pixel defining layer. The non-display area at least includes one blocking portion. The display device includes the display panel. According to the invention, the possibility of extension of the crack caused by the external impact to the display area is reduced as much as possible, the speed of the extension of the crack caused by the external impact to the display area is reduced, and generation of dark spots in the display area is avoided, so that the display effect and display quality of the display panel are not affected.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

Health-care bitter gourd tea bag

The invention discloses a health-care bitter gourd tea bag, which is prepared by using bitter gourds, shelled Chinese waxgourd seeds, orange peel, peach blossom and honey as raw materials and by drying, crushing, mixing, disinfecting and sterilizing and packaging. The health-care bitter gourd tea bag has the effects of losing weight, removing toxins, beautifying the skin, activating blood and benefiting vital energy, and can prevent the dryness and ageing of the skin, improve the vitality and elasticity of the skin, and effectively prevent yellow brown spots, freckles and black spots; and when a user drinks the health-care bitter gourd tea regularly, the effect of making appearance red and bright, skin delicate and soft and hair dark and bright is achieved.

Owner:蒋涛

Tea oil shampoo and preparation method thereof

InactiveCN103860428AEffective Balanced CarePrevent agingCosmetic preparationsHair cosmeticsCamellia oleiferaHair care

The invention discloses a tea oil shampoo. The tea oil shampoo is prepared from tea oil and a surface activity treating agent. The invention also discloses a preparation method of the tea oil shampoo. The preparation method comprises the steps: 1) preparing camellia oil; 2) preparing the surface activity treating agent; 3) blending the tea oil shampoo; and 4) cooling to obtain a finished product. By utilizing natural tea oil, the tea oil shampoo can be used for resisting bacteria and viruses, killing microbes, preventing tinea capitis, alopecia, scurf, cell senescence, black spots and freckles and relieving itching, has unique fresh scent of oil tea, is strong in the detergency, has certain efficacy on growing black hairs, and can be effectively used for carrying out previous balance nursing on the hairs. With the adoption of the finished product, the market needs that the modern pursues a natural and health hair care article can be satisfied, and the economic benefits of the tea oil can also be increased.

Owner:ANHUI YIHONG BIOTECH

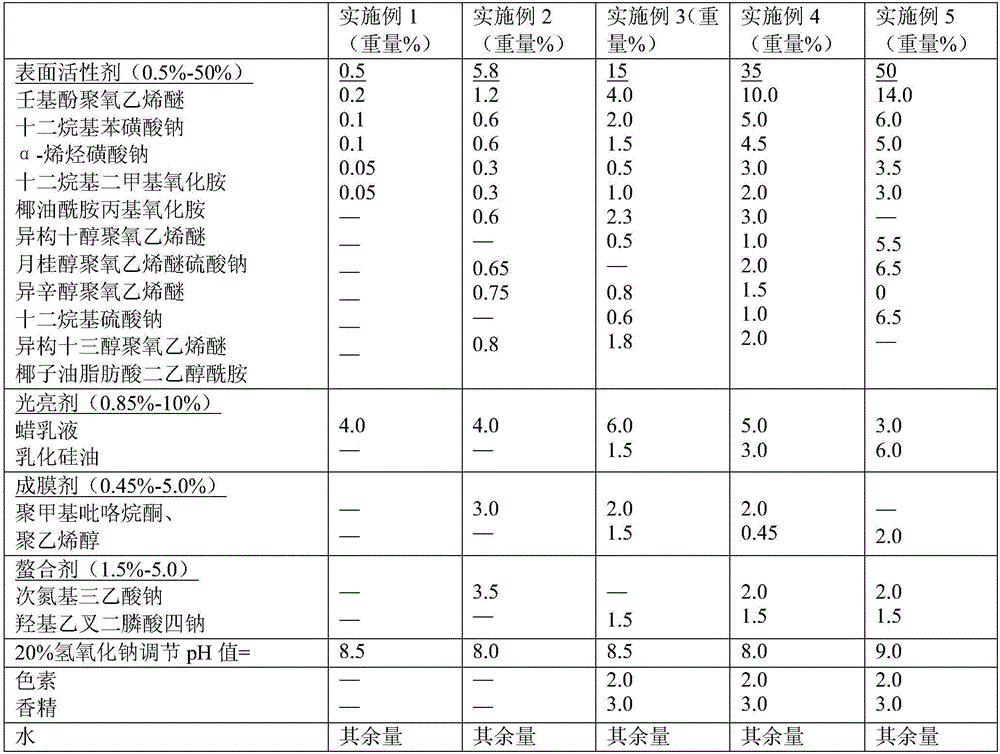

Cleaning agent for automotive body and preparation method of cleaning agent

InactiveCN105950309AProtect from being scratchedEfficient removalInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsCocamidopropyl dimethylamineCleansing Agents

The invention relates to a cleaning agent for an automotive body and a preparation method of the cleaning agent. The cleaning agent aims to solve the technical problems to improve the cleaning effect, reduce water consumption, improve a sunlight exposure preventing effect and the like. The cleaning agent is prepared from at least the following components in percentage by weight: 0.5%-50% of a surfactant, 0.85%-10% of a brightening agent, 0.5%-8.0% of a pH conditioning agent and the balance of water through mixing, wherein the surfactant comprises at least five substances as follows: nonylphenol polyoxyethylene ether, sodium dodecylbenzene sulfonate, alpha-sodium olefinsulfonate, dimethyl dodecyl amine oxide and cocamidopropyl dimethylamine oxide. The preparation method comprises steps as follows: all the surfactants are dissolved in part of water firstly at the room temperature under normal pressure, the brightening agent is added, the mixture is stirred uniformly, the pH value of the mixture is adjusted to range from 8.0 to 8.5 with a 20% sodium hydroxide aqueous solution, the balance of water is added, the mixture is mixed uniformly, and the cleaning agent is obtained.

Owner:宁波市乾东网络科技有限公司

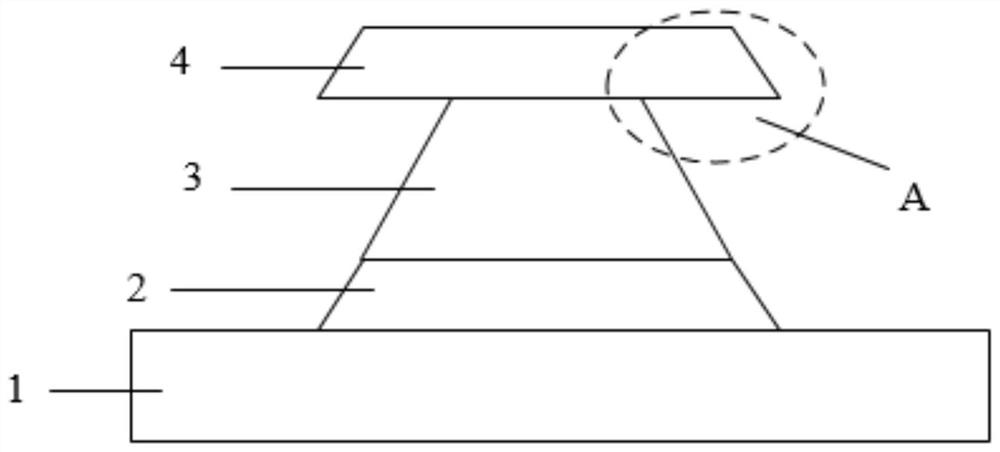

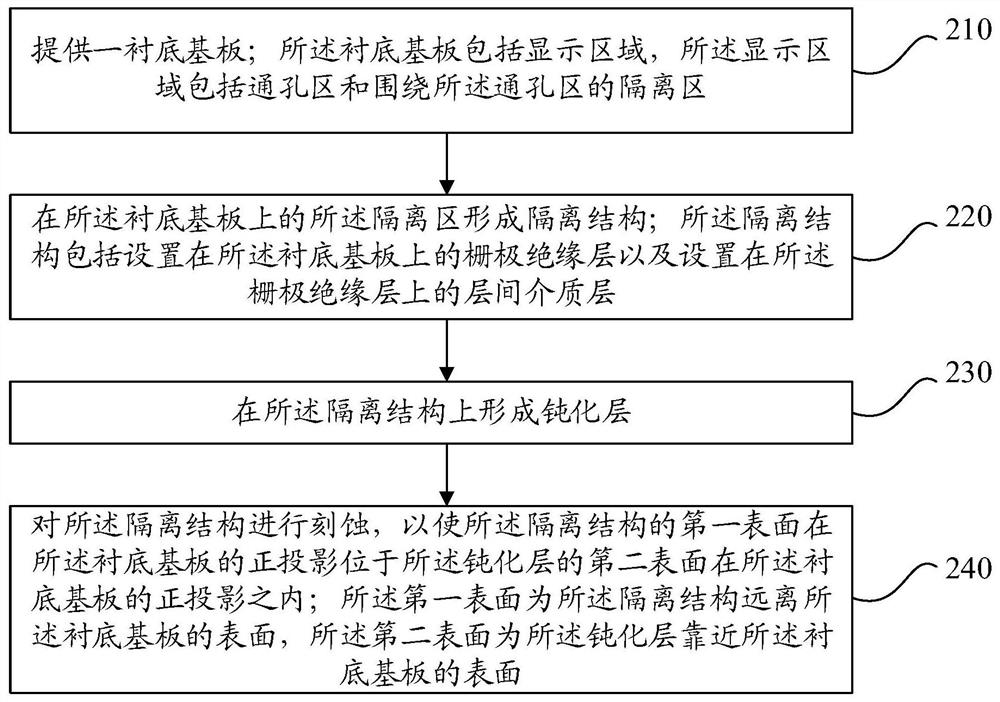

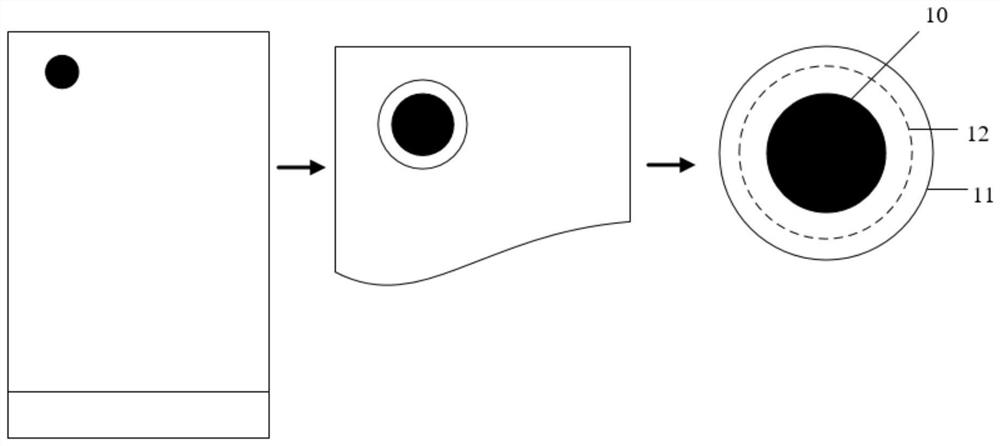

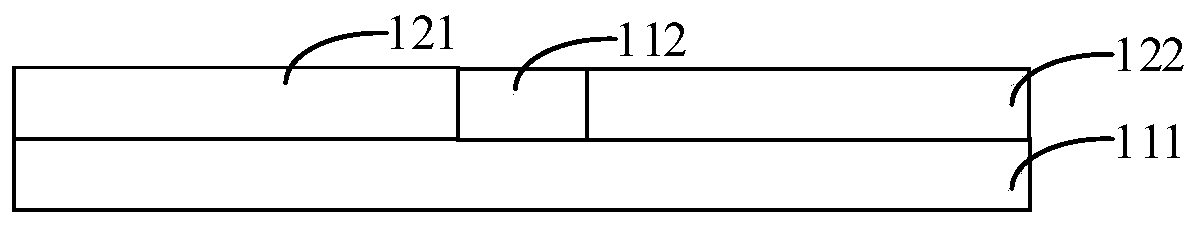

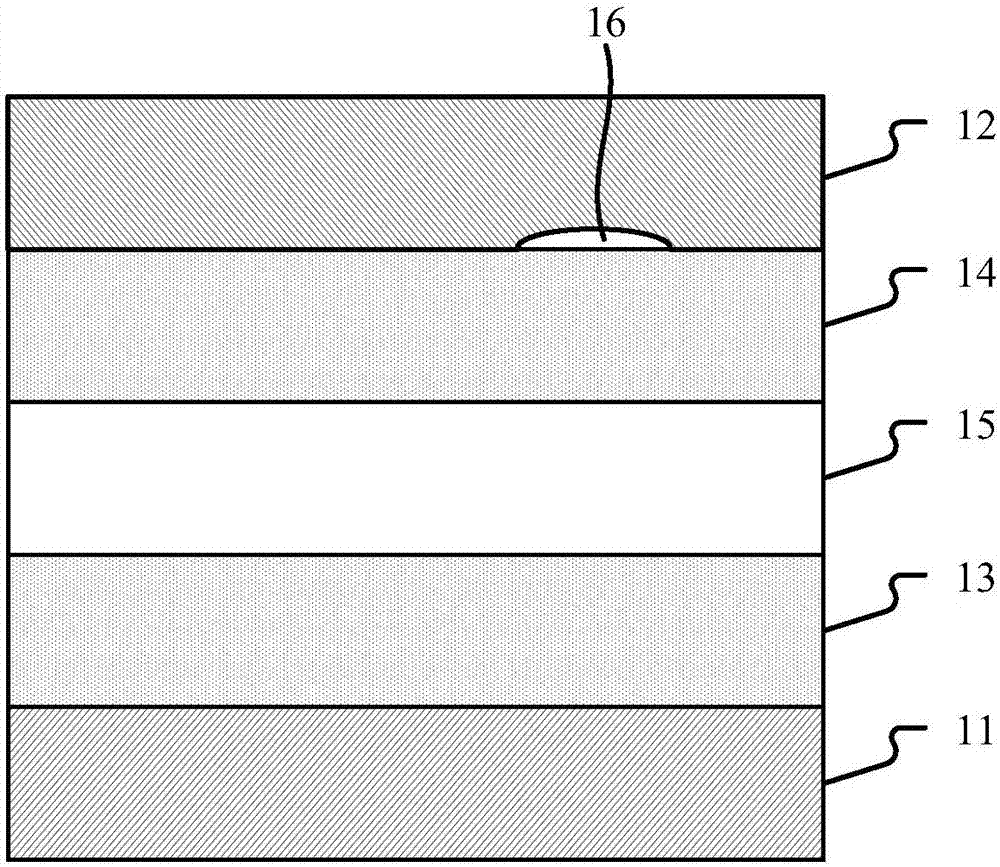

Manufacturing method of display substrate, display substrate and display device

PendingCN111653522AAvoid dark spotsSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceDielectric layer

The invention provides a manufacturing method of a display substrate, the display substrate and a display device, and relates to the technical field of display. According to the embodiment of the invention, a substrate is provided. The substrate comprises a display area, and the display area comprises a through hole area and an isolation area surrounding the through hole area. An isolation structure is formed on the isolation area on the substrate; the isolation structure comprises a gate insulating layer arranged on the substrate and an interlayer dielectric layer arranged on the gate insulating layer. A passivation layer on the isolation structure; the isolation structure is etched, so that the orthographic projection of the first surface, far away from the substrate, of the isolation structure on the substrate is located in the orthographic projection of the second surface, close to the substrate, of the passivation layer on the substrate; therefore, the contact position of the passivation layer and the isolation structure is disconnected when an organic material is evaporated, water and oxygen in the through hole area are prevented from being transmitted to other areas in the display area through the organic material, and the problem of isolation failure when a metal isolation structure is adopted is also solved.

Owner:BOE TECH GRP CO LTD +1

Flexible substrate, display back plate and flexible display screen

InactiveCN109860206AImprove impact resistanceAvoid dark spotsSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringShock resistance

The present invention discloses a flexible substrate, a display back plate and a flexible display screen. The flexible substrate comprises a flexible material layer and a skeleton layer, the flexiblematerial layer comprises a support surface, and the skeleton layer is arranged at the support surface of the flexible material layer, or is arranged at one side far away from the support surface of the flexible material layer, or is arranged at the internal portion of the flexible material layer, and is connected with the flexible material layer; and the elasticity modulus of the skeleton layer islarger than the elasticity modulus of the flexible material layer. The flexible substrate is high in shock resistance capacity, and can effectively avoid the technical problem that the wires in the flexible substrate are damaged due to large impact force.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

OLED material with carrier transmittability as well as preparation method and application thereof

ActiveCN103468245ALower the HOMO valueImprove stabilitySilicon organic compoundsCarboxylic acid nitrile preparationLow voltageOrganic electroluminescence

The invention discloses an OLED (Organic Light-Emitting Diode) material with carrier transmittability, and the structure of the OLED material is shown in formula I. The OLED material is excellent in performance as the carrier transmittability and the luminous efficiency of a device are improved. The invention further discloses a preparation method and application of the OLED material. A synthetic route of the OLED material is simple and easy to operate, and the reaction yield is higher, so that the OLED material has excellent industrialization prospect; an OLED prepared by using the OLED material can realize high luminance, high efficiency and low voltage, can effectively avoid screen dim spots, and has better performance.

Owner:SHIJIAZHUANG CHENGZHI YONGHUA DISPLAY MATERIALS CO LTD

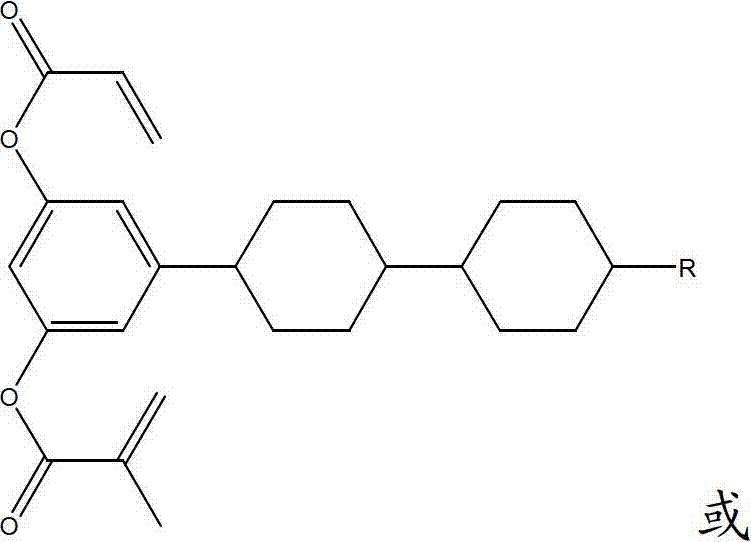

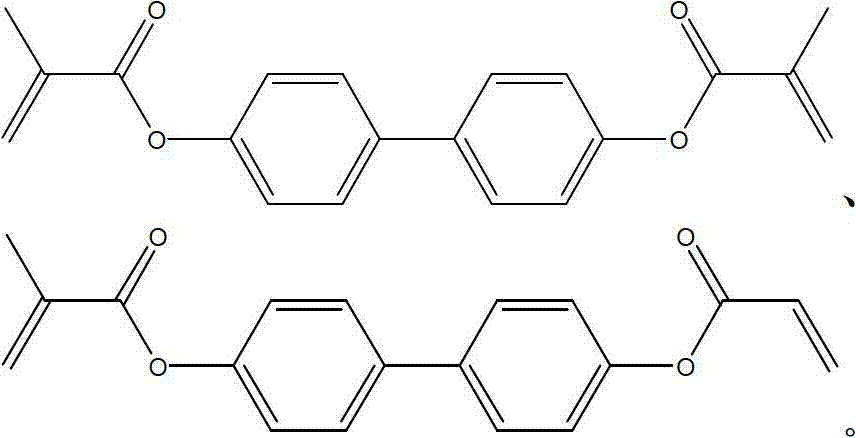

Liquid crystal medium mixture and liquid crystal display using liquid crystal medium mixture

InactiveCN102888231AAvoid misalignmentQuick responseLiquid crystal compositionsNon-linear opticsCrystallographyLiquid-crystal display

The invention provides liquid crystal medium mixture and a liquid crystal display using the liquid crystal medium mixture. The liquid crystal medium mixture comprises at least one kind of anisotropic liquid crystal materials and one kind of polymerizable monomer which can be subjected to polymerization reaction under the irradiation of ultraviolet light; and the polymerizable monomer accounts for 0.1 to 1 percent based on the total weight of the liquid crystal medium mixture. According to the liquid crystal medium mixture and the liquid crystal display using the liquid crystal medium mixture, one kind of the polymerizable monomer which can be subjected to polymerization reaction under the irradiation of ultraviolet light, and an appropriate proportion are adopted, so that polymer prominence which is small in size and high in uniformity can be obtained through polymerization reaction, and the phenomena of poor liquid crystal alignment effect and dark-state bright point of a liquid crystal panel can be avoided; and therefore, the liquid crystal panel is high in response speed, high contrast ratio can be guaranteed, and the stable mass production can be realized.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Liquid crystal medium mixture and liquid crystal display using same

ActiveCN102888229AGood uniformityAvoid liquid crystal misalignmentLiquid crystal compositionsNon-linear opticsHigh contrastLiquid-crystal display

The invention provides a liquid crystal medium mixture and a liquid crystal display using the liquid crystal medium mixture. The liquid crystal medium mixture comprises at least one anisotropic liquid crystal material and a polymerizable monomer which can be polymerized under ultraviolet irradiation; and the polymerizable monomer is 0.1-1% of the total weight of the liquid crystal medium mixture in part by weight. According to the liquid crytal medium mixture and the liquid crystal display using the liquid crystal medium mixture provided by the invention, the liquid medium mixture can be polymerized to obtain polymer prominence which is relatively small in size and high in uniformity by adopting the polymerizable monomer which can be polymerized under ultraviolet irradiation based on proper mixture ratio, so that the phenomena that poor liquid crystal alignment is obtained, and bright spot is generated on a liquid crystal panel under dark state are avoided, and as a result, fast response speed of the liquid crystal panel is obtained as well as high contrast ratio, and stable volume production is achieved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Production method of fireproof and flame-retardant type medium-density fiber wood floor

InactiveCN109366680AAlleviate the contradiction between supply and demandImprove fire and flame retardant performanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesFiberMedium density

The invention discloses a production method of a fireproof and flame-retardant type medium-density fiber wood floor. The production method comprises the steps of (1) pretreatment of raw materials; (2)screening; (3) stewing softening operation; (4) grinding operation; (5) glue application and drying; (6) pre-pressing operation; (7) hot-pressing operation; (8) sawing and sanding; (9) glue coating and veneering hot-pressing operation; and (10) preservation and grooving, so that the finished product is obtained. According to the production method, the eucalyptus bark, branches and waste leftovermaterials which remain after board manufacturing is accomplished are used as main raw materials, then other miscellaneous trees are added, the waste is turned into the wealth, and therefore the sufficient and effective utilization of timber resources can be achieved; and due to the fact that modified paraffin and flame-retardant urea-formaldehyde resin adhesives are added, the fireproof and flame-retardant performance of the wood floor can be greatly improved, and the produced medium-density fiber wood floor is excellent in fireproof and flame-retardant performance, good in water resistance and low in formaldehyde content, and is a safe, environmentally friendly and durable wood floor.

Owner:广西横州丽冠环保材料有限公司

Vacuum microwave drying method for yellow gingers

InactiveCN109869986AMaintain colorUniform colorDrying solid materials with heatDrying solid materials without heatHeating timeEconomic benefits

The invention discloses a vacuum microwave drying method for yellow gingers. The vacuum microwave drying method comprises the following steps of: selecting the yellow gingers; pre-treating the yellowgingers and drying the yellow gingers; the pretreatment step comprises the following steps of: removing mud from the selected yellow gingers; removing the peels of the yellow gingers; washing the yellow gingers; draining the yellow gingers; slicing the yellow gingers by using a slicing machine to make sure that the thickness of the yellow ginger slices is 4+ / -0.25 mm, and weighing a certain amountof yellow ginger slices; in the drying step, the yellow ginger slices are dried in two stages by adopting vacuum microwave drying; the vacuum degree in each stage is -0.090+ / -0.05 Mpa; the microwavepower in the first stage is 1500 W; the continuous heating time of the microwave is controlled to be within 0-60 min; the microwave power in the second stage is 1000 W; the continuous heating time ofthe microwave is controlled to be within 0-90 min so that the final water content of the yellow ginger slices is reduced to 12% or lower, and yellow ginger slices which are relatively good in color, appearance and quality can be obtained. The method disclosed by the invention can keep the original color of the yellow ginger slices, effectively reduces nutrient losses of the yellow ginger slices, is also high in production efficiency and low in cost, realizes deep processing and comprehensive utilization of yellow ginger raw materials and achieves good economic benefits.

Owner:HEZHOU UNIV

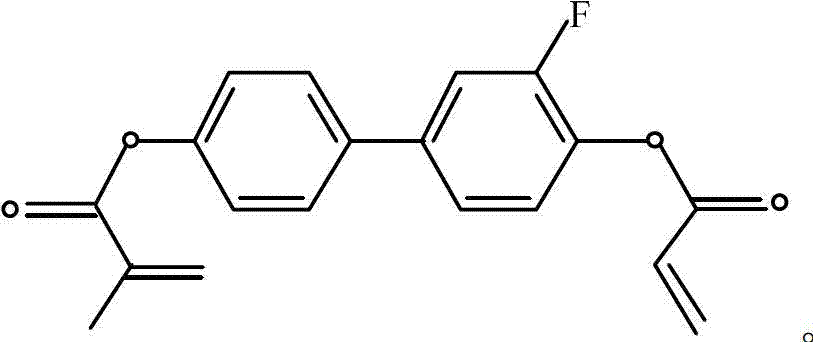

Liquid crystal medium mixture and liquid crystal display using liquid crystal medium mixture

InactiveCN102863968AAvoid misalignmentQuick responseLiquid crystal compositionsNon-linear opticsLiquid-crystal displayUltraviolet irradiation

The invention provides a liquid crystal medium mixture and a liquid crystal display using the liquid crystal medium mixture. The liquid crystal medium mixture comprises components of at least one anisotropy liquid crystal material and two polymerizable monomers which can generate polymerization reaction under ultraviolet irradiation. The polymerizable monomers in part by weight occupy 0.1%-1% of a total quantity of the liquid crystal medium mixture. By means of the liquid crystal medium mixture and the liquid crystal display, the liquid crystal medium mixture can be subjected to the polymerization reaction by adopting two or more than two polymerizable monomers which can generate polymerization reaction under ultraviolet irradiation and appropriate cooperation, polymer prominences in small size and good uniformity can be obtained, and poor alignment of liquid crystal and dark state bright spots of a liquid crystal display panel are avoided, thereby a response speed of the liquid crystal display panel is quickened to obtain a high contrast ratio, and stable volume production performance is achieved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

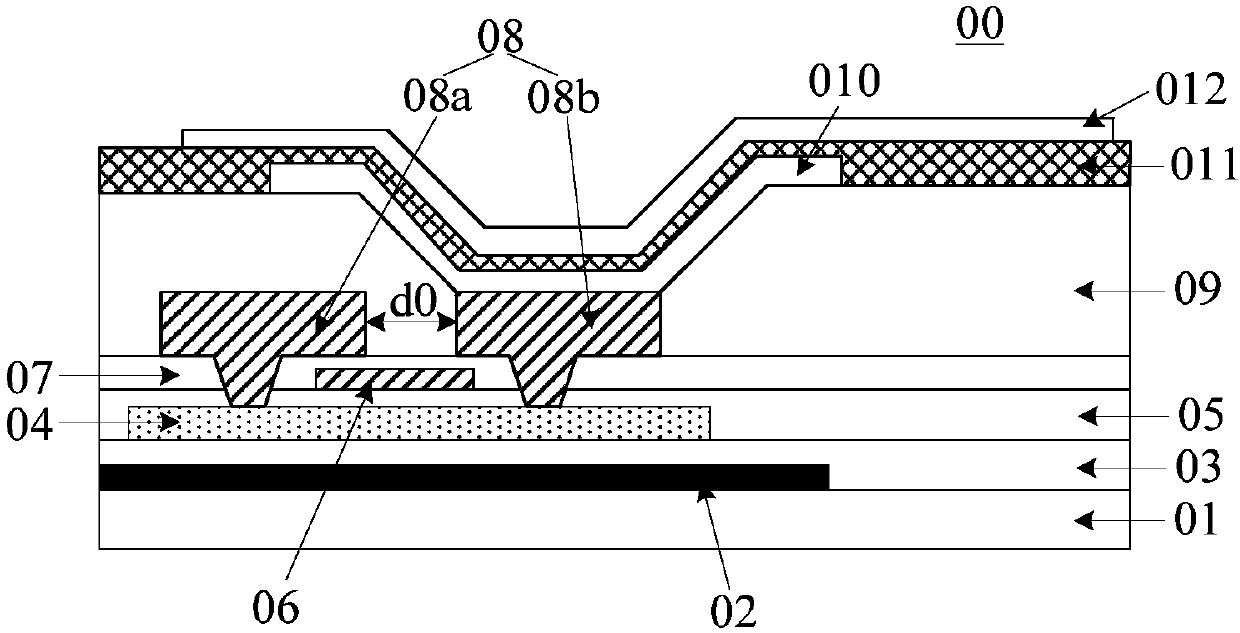

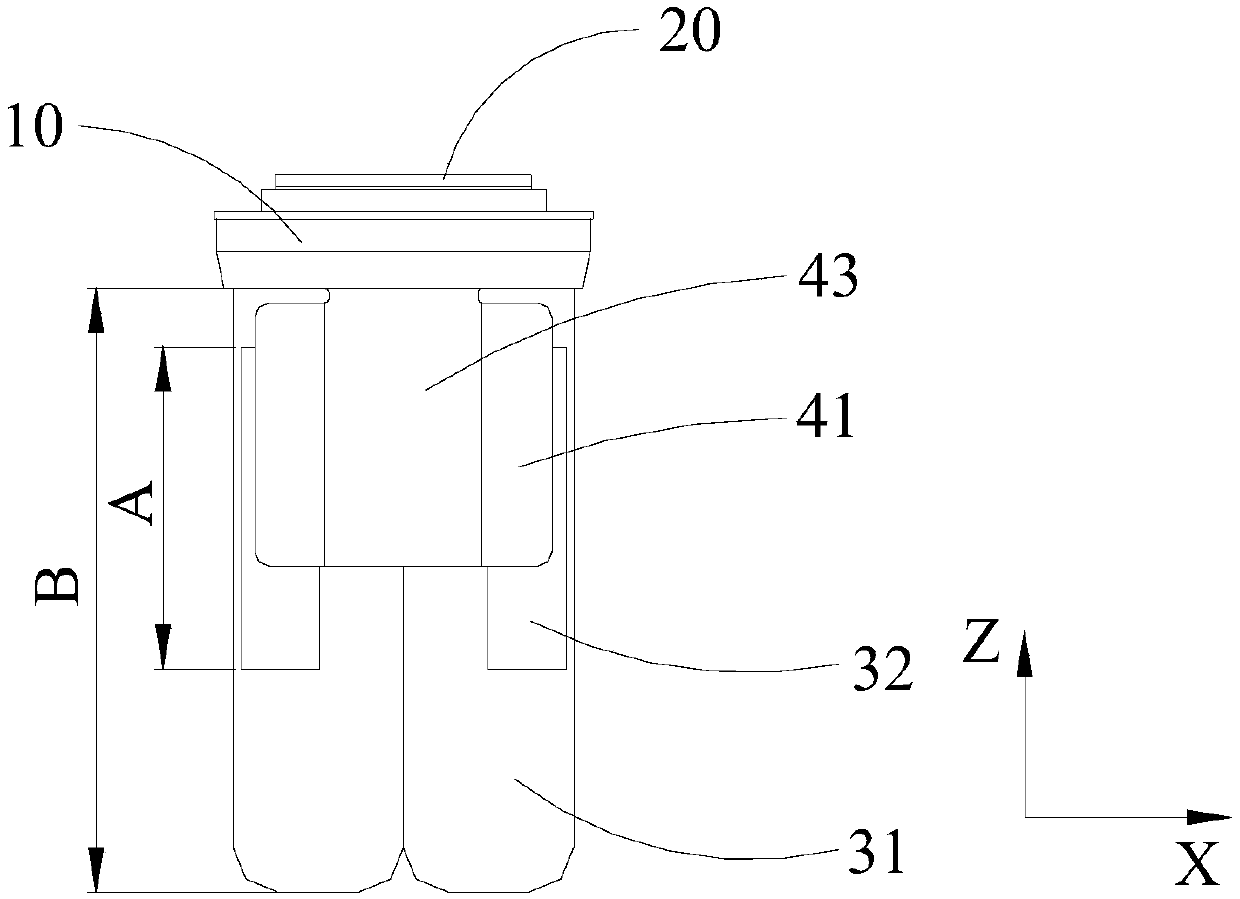

Thin film transistor, array substrate, manufacturing method of array substrate and display device

PendingCN107611181AAvoid dark spotsAvoid short circuitTransistorSolid-state devicesDisplay deviceOptoelectronics

The invention discloses a thin film transistor, an array substrate, a manufacturing method of the array substrate and a display device, and belongs to the technical field of display. The thin film transistor comprises a gate pattern, an active layer pattern, a gate insulating layer, a first conductive pattern, a second conductive pattern and a first middle insulating layer, the gate insulating layer is positioned between the gate pattern and the active layer pattern, the first middle insulating layer is positioned between the first conductive pattern and the second conductive pattern, the first conductive pattern and the second conductive pattern are a source pattern and a drain pattern, a first via hole is formed in the first middle insulating layer, and the second conductive pattern is connected with the active layer pattern through the first via hole. As the first middle insulating layer is arranged between the source pattern and the drain pattern, short connection of a source and adrain is effectively avoided, and the thin film transistor is used for the display device.

Owner:BOE TECH GRP CO LTD +1

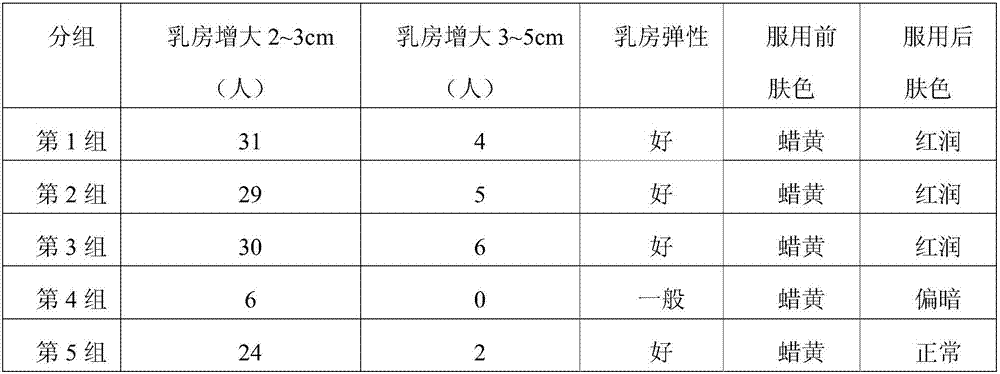

Skin-nourishing and breast-enlarging tea and preparation method thereof

The invention relates to the technical field of tea processing and specifically relates to a skin-nourishing and breast-enlarging tea and a preparation method thereof. The skin-nourishing and breast-enlarging tea provided by the invention belongs to the field of tea processing technology. The skin-nourishing and breast-enlarging tea is prepared from the following raw materials: puerarin, pig trotter grease, sealwort, mulberry, grapefruit, walnut, avocado, red date slice, wolfberry, yam, longan, ligusticum wallichii, kiwi fruit, green papaya, goat milk, ginseng, calendula, jasmine flower, rosemary, carnation, roselle, rose, dandelion roots and burdock. The preparation method for the skin-nourishing and breast-enlarging tea comprises the following steps: (1) pre-treating raw materials; (2) mixing and frying till drying; (3) bagging and sterilizing. The skin-nourishing and breast-enlarging tea can achieve an excellent effect of nourishing skin and enlarging breasts.

Owner:陆川县米场镇合美种养专业合作社联合社

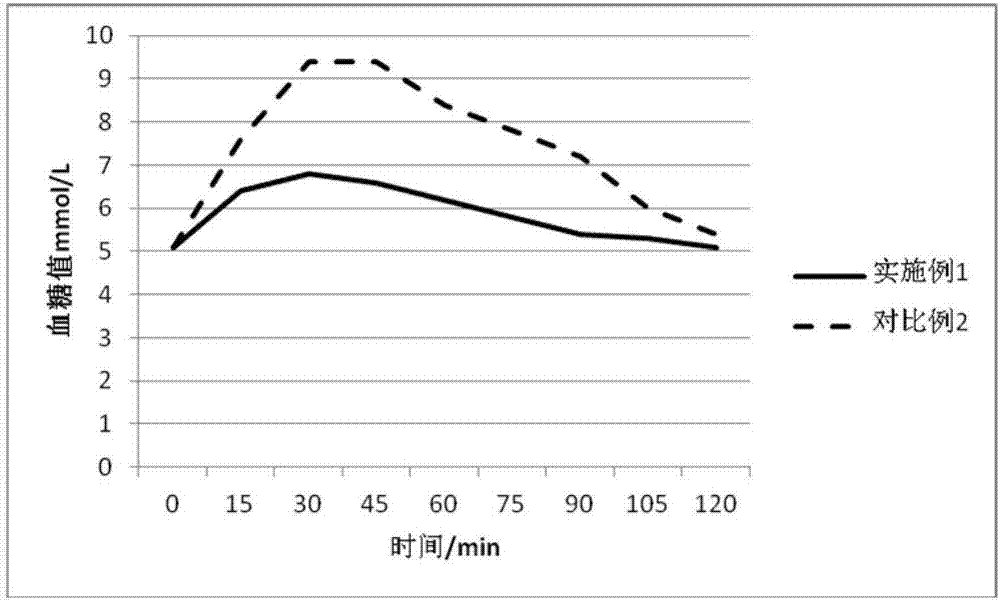

Mulberry enzyme residue tablet and preparation method thereof

InactiveCN106962936AMaintain pure sweetness propertiesTo promote metabolismFood ingredient functionsSweetnessErythritol

The invention discloses a mulberry enzyme residue tablet and a preparation method thereof, and relates to the technical field of food. Based on the total mass of the mulberry enzyme residue tablet, the mulberry enzyme residue tablet comprises, by mass, 53.0-57.0% of mulberry enzyme residue powder, 25.0-29.0% of xylitol, 8.0-12.0% of maltodextrin, 2.0-6.0% of erythritol, 1.0-3.0% of fructo-oligosaccharide, 0.8-1.0% of sodium carboxymethylcellulose and 0.8-1.0% of magnesium stearate. The mulberry enzyme residue tablet and the preparation method thereof have the advantages that after drying and smashing, mulberry seeds are made into the mulberry enzyme residue tablet which people can eat easily; the appropriate fructo-oligosaccharide is added to promote absorption of mineral substances in the mulberry seeds, and nutritional elements in the mulberry enzyme residue tablet can be absorbed and utilized by human bodies to the greatest extent; the sweetness of the mulberry enzyme residue tablet is adjusted by the xylitol with high sweetness, and the erythritol is used for covering up the bitterness of the mulberry seeds, so that the obtained mulberry enzyme residue tablet is suitable for people's taste.

Owner:FUTASTE PHARM CO LTD

Dragon fruit crisp and making method thereof

ActiveCN104247741AKeep the original tasteBright skin colorDough treatmentBakery productsIcing sugarBlood pressure

The invention discloses a dragon fruit crisp and a making method thereof. The dragon fruit crisp is composed of a crust and filling. The crust is made from solid butter, liquid butter, powdered sugar, milk powder, salt, flour, dragon fruit pigment and dragon fruit pectin. Two kinds of dragon fruit crusts are made through two manners, and the filling is made of the dragon fruits. The dragon fruit crisp has the advantages that the dragon fruit pectin is added to solve that problem that dregs fall when people eats the crisp; with the dragon fruit, human body immunity is increased, blood pressure is decreased, eyesight is improved, and functions such as facial beauty and skin whitening are achieved; by adopting two kinds of crusts, different taste requirements of people are met.

Owner:广西沃田食品开发有限公司

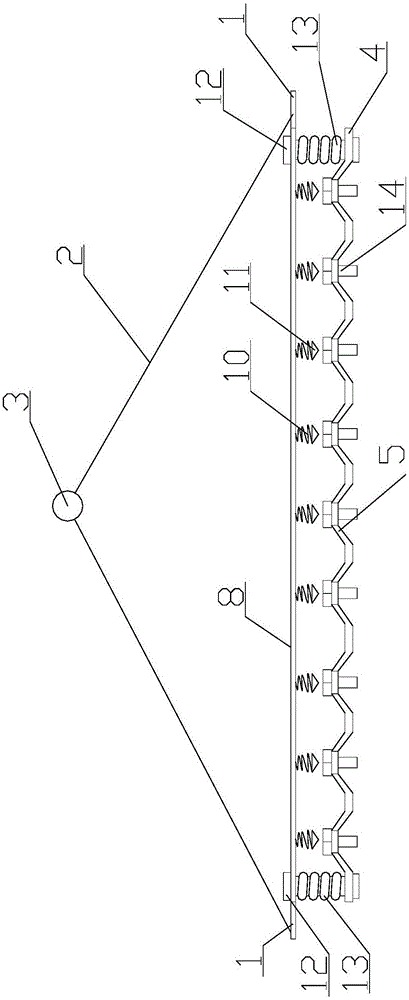

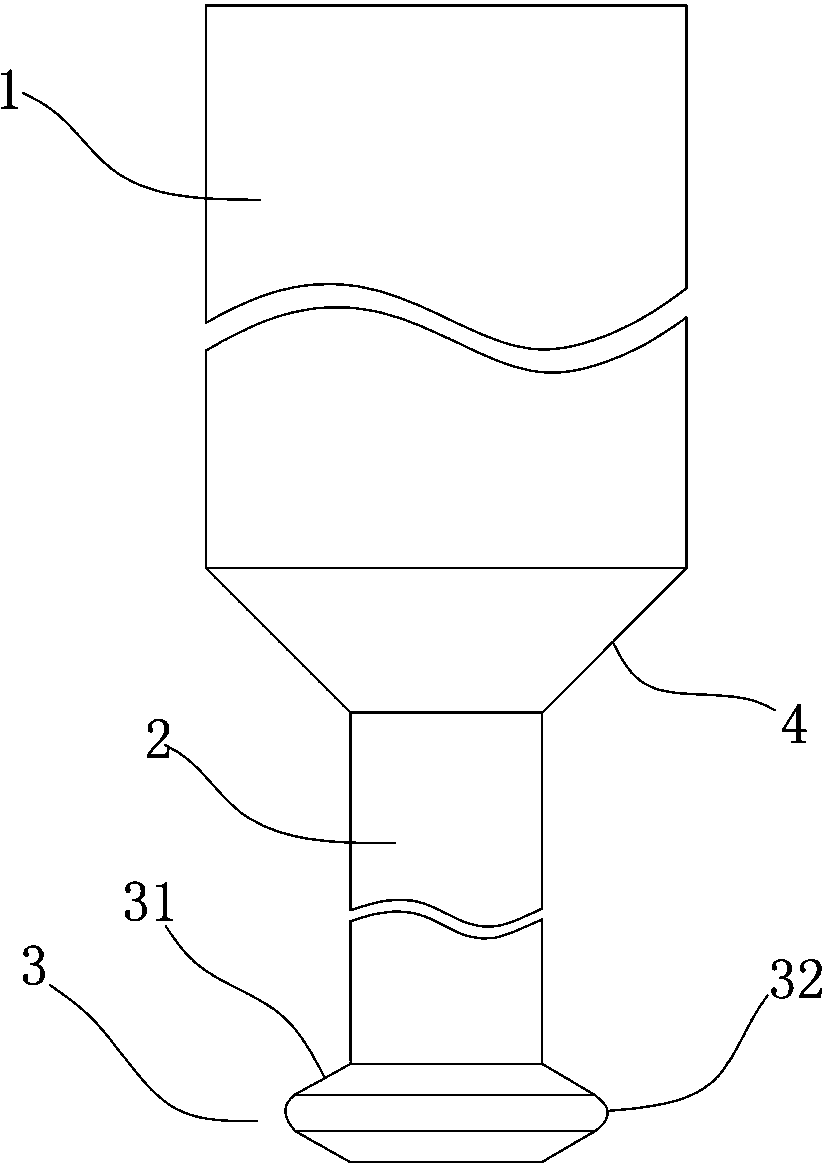

Clamp system special for electroplating of fixing bolts

ActiveCN106367788AAvoid Dark SpotsGuarantee the quality of platingElectrolysis componentsBlack spotEconomic benefits

The invention relates to a clamp system special for electroplating of fixing bolts. The clamp system comprises pressing plate assemblies, a base plate assembly, handles, a steel wire rope and a pull ring. The pressing plate assemblies are arranged at the upper end of the base plate assembly in parallel. The handles are arranged at the two ends of the pressing plate assemblies. The handles are connected through the steel wire rope. The pull ring is arranged in the middle of the steel wire rope. The base plate assembly comprises a base plate, circular truncated cone protrusions, containing holes and through holes. Each pressing plate assembly comprises a pressing plate, through holes, fixing blocks, first compression springs and pressing blocks. By adoption of the clamp system special for electroplating of the fixing bolts, multiple fixing bolts can be placed in clamps to be electroplated at a time, black spots of the fixing bolts are avoided, and the overall production efficiency is improved and the economic benefits are increased while the electroplating quality for the fixing bolts is guaranteed.

Owner:JIANGSU MENGDE NEW MATERIALS TECH CO LTD

Ceramic thread processing tool and ceramic thread processing method

InactiveCN104385466AIngenious designReasonable structureStone-like material working toolsBlack spotStrong acids

The invention discloses a ceramic thread processing tool, comprising a body, wherein the body is formed in an integrated way; the body comprises a rodlike fixing section; one end of the fixing section is provided with a working section of which the diameter is smaller than that of the fixing section; a toothlike bump is annularly arranged towards the outer side on the periphery of the tail end of the working section; the top part of the toothlike bump is provided with a round angle; the root part of the lower end of the toothlike bump is connected with the bottom face of the working section; diamond sand grains are attached to the surface of the toothlike bump. The invention also discloses a ceramic thread processing method. The tool provided by the invention is igneous in design, rational in structure, convenient to produce and manufacture, lower in manufacturing cost, and convenient to use; by applying the tool, threads can be directly processed and formed in a ceramic product, so that a metal piece is not used, and the use of the metal piece is reduced; the formation of black spots, on the ceramic product, of metal dust is avoided; the pollution, caused by the use of the metal piece in a strong acid environment or a strong base environment, to the ceramic product is avoided.

Owner:DONGGUAN XINBO STRUCTURAL CERAMICS CO LTD

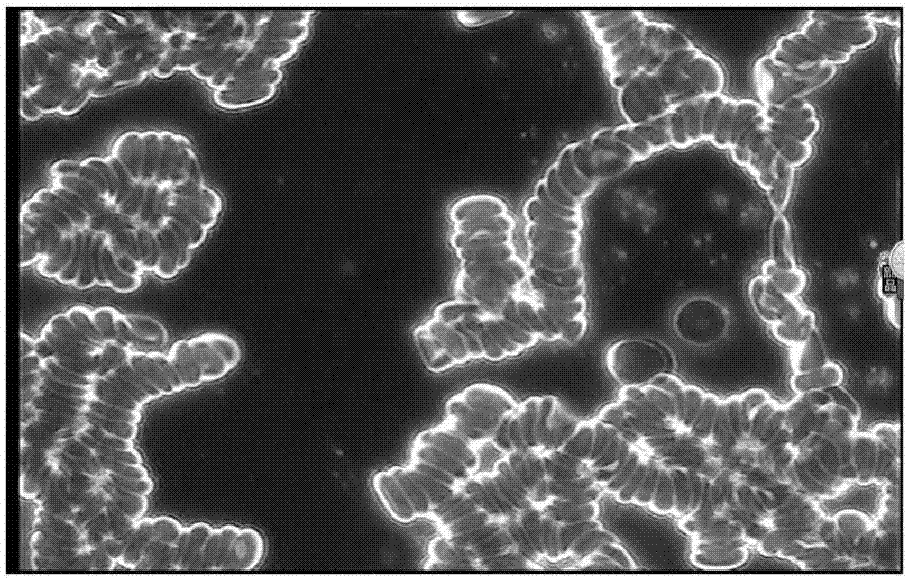

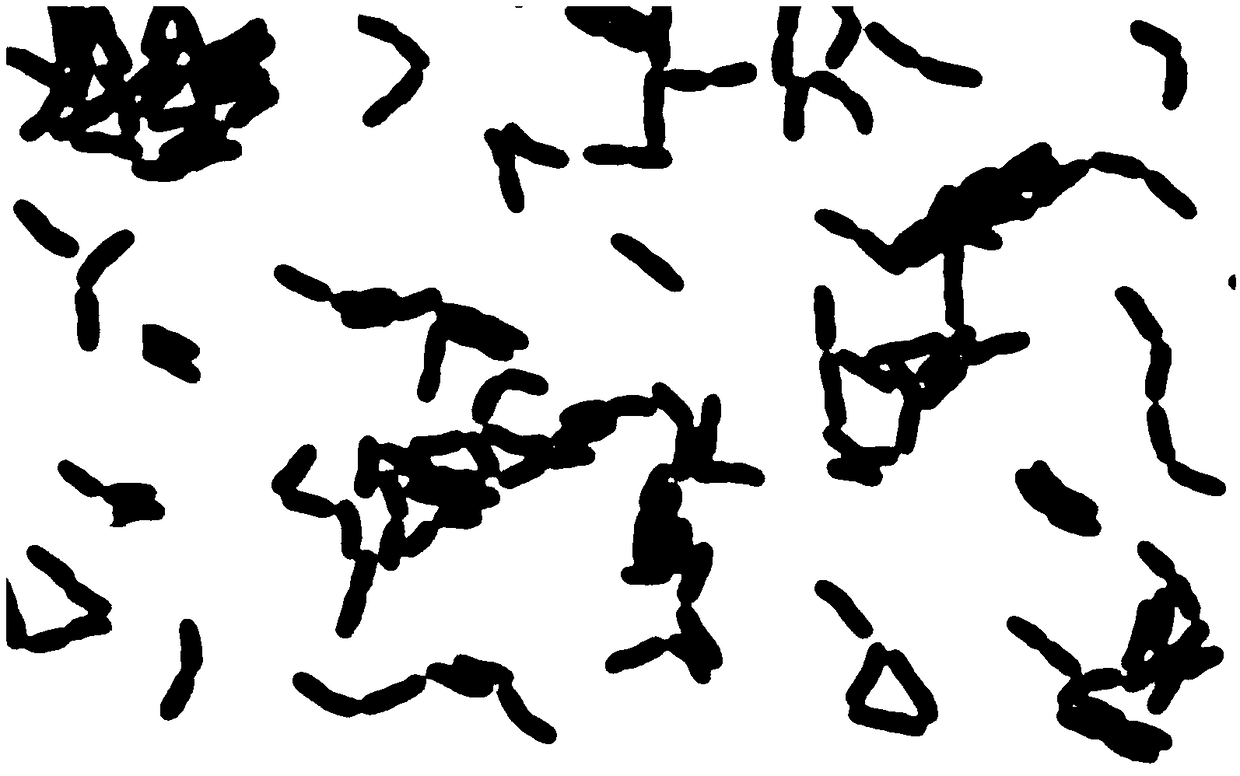

Lactobacillus salivarius SNK-6 and application thereof

ActiveCN108611300AAvoid dark spotsImprove qualityBacteriaAnimal feeding stuffBiotechnologyLactobacillus salivarius

The invention discloses a lactobacillus salivarius SNK-6 and the application thereof, wherein the lactobacillus salivarius SNK-6 has a preservation number of CCTCC NO: M 2018044, has a 16S DNA sequence as shown in SEQ ID NO: 1, and is derived from chicken intestines. The lactobacillus salivarius SNK-6 is used for preventing dark spots on eggs and improving egg quality.

Owner:SHANGHAI ACAD OF AGRI SCI

Organic light-emitting device, manufacturing method thereof, display panel and display device

ActiveCN107123743AIncrease contact areaEnhanced adhesionSolid-state devicesSemiconductor/solid-state device manufacturingBlack spotOrganic light emitting device

The present application discloses an organic light-emitting device, a manufacturing method thereof, a display panel and a display device. The organic light-emitting device comprises a first electrode and a second electrode arranged on a substrate, and an organic light-emitting function layer positioned between the first and second electrodes. The second electrode comprises a plurality of second electrode blocks and second connection electrodes used for electrically connecting the second electrode blocks with one another. The organic light-emitting function layer comprises first organic material blocks configured to protrude towards the second connection electrodes. According to the technical scheme of the invention, organic material blocks configured to protrude towards the second connection electrodes are arranged on the organic light-emitting function layer, so that the contact area of the second electrodes with the organic light-emitting function layer is increased. The adhesive force between the second electrodes and the organic light-emitting function layer is improved, so that the generation of black spots is avoided.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

Peel-off type rhodiola rosea nourishing facial mask and preparation method thereof

InactiveCN103356427ANourishing and effectiveAvoid dark spotsCosmetic preparationsToilet preparationsWrinkle skinGlycerol

The invention discloses a peel-off type rhodiola rosea nourishing facial mask and a preparation method thereof. The peel-off type rhodiola rosea nourishing facial mask is prepared from the following raw materials in parts by weight according to a conventional method: 10-14 parts of polyvinyl alcohol, 8-12 parts of glycerin, 0.8-1.2 parts of hydrolyzed elastin, 4-6 parts of ethanol, 6-8 parts of sodium PEG-8 olive oil carboxylate, 0.8-2 parts of rhodiola rosea extracting solution, 0.03-0.08 part of compound preservative and 100 parts of deionized water, wherein the compound preservative comprises the following components in parts by weight: 1-3 parts of carnosic acid, 3-5 parts of antioxidants of bamboo leaves, 1-3 parts of nisin and 1-3 parts of iodopropynyl butylcarbamate. The peel-off type rhodiola rosea nourishing facial mask disclosed by the invention is capable of cleaning facial skins deeply, reducing facial fine wrinkles, making the skins elastic and firm, nourishing skins effectively, enhancing vital energy and blood and preventing dark specks of the skins.

Owner:马建欣

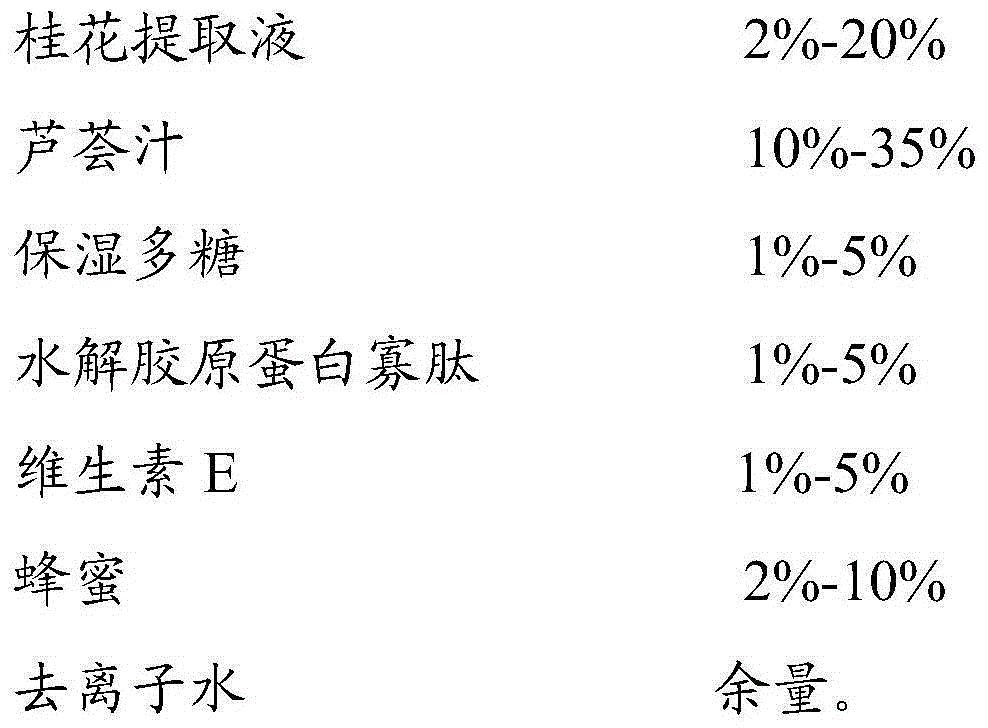

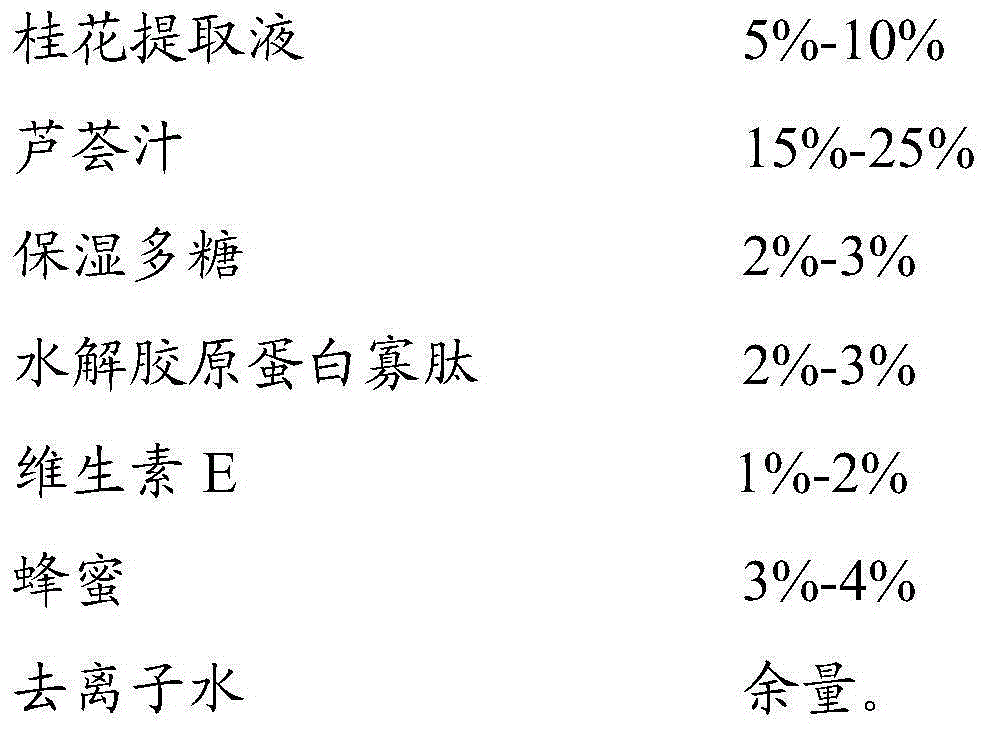

Whitening and moisturizing composition and application thereof and mask

InactiveCN105030646AGood whitening and moisturizing effectNo harsh chemicalsCosmetic preparationsToilet preparationsWrinkle skinIrritation

The invention relates to a whitening and moisturizing composition and application thereof and a mask with the composition as a nutrition solution. The composition is composed of, by weight, 2%-20% of sweet-scented osmanthus extract, 10%-35% of aloe juice, 1%-5% of moisturizing polysaccharide, 1%-5% of hydrolyzed collagen oligopeptide, 1%-5% of vitamin E, 2%-10% of honey and the balance deionized water. According to the whitening and moisturizing composition, pure natural matter is adopted as raw materials, no irritation chemical component is contained, the content and the variety of amino acid are high, and high-quality plant protein and rich mineral nutrition elements are contained. The mask prepared from the composition has the effects that absorption by the skin is easy, the dry and rough phenomena of the skin can be effectively relieved, and wrinkles can be relieved; meanwhile, the effects that the skin is moisturized, the skin is maintained to be moist, and chloasma, freckles and tache noire can be effectively prevented are achieved at the same time. By using the mask for a long time, the skin can be kept moist, smooth and shell pink, and the resistant ability of the skin can be enhanced.

Owner:INST OF IND TECH GUANGZHOU & CHINESE ACADEMY OF SCI

Flexible display motherboard and manufacturing method of flexible display screen

ActiveCN110085127AHigh light transmittanceImprove cleanlinessDigital data processing detailsTransparent/reflecting heating arrangementsChain structureDisplay device

The invention provides a flexible display motherboard and a manufacturing method of a flexible display screen, belonging to the technical field of flexible display screens. The flexible display motherboard comprises a carrier substrate, a flexible substrate, and a display device arranged on the flexible substrate; a plurality of heating resistors are arranged between the carrier substrate and theflexible substrate; a bonding force formed by the heating resistors and the carrier substrate is greater than that formed by the heating resistors and the flexible substrate; the flexible substrate isprovided with extension parts filled between the adjacent heating resistors; a hydrogen bond is formed by molecular chain structures of the extension parts and a molecular chain structure of the carrier substrate; the heating resistors are used for heating the carrier substrate and the flexible substrate, so that the hydrogen bond is destroyed by heat generated by the heating resistors. Accordingto the flexible display motherboard and the manufacturing method of the display screen, the flexible substrate can be stripped from the carrier substrate, and the display effect of the flexible display screen can be also improved.

Owner:YUNGU GUAN TECH CO LTD

Liquid crystal medium mixture and liquid crystal display using same

InactiveCN102876337AAvoid misalignmentAvoid dark spotsLiquid crystal compositionsNon-linear opticsCrystallographyLiquid-crystal display

The invention provides a liquid crystal medium mixture and a liquid crystal display using the same. The liquid crystal medium mixture comprises the following components: at least one anisotropic liquid crystal material, and two or more polymerizable monomers which can be polymerized under UV (ultraviolet) irradiation, wherein the polymerizable monomers account for 0.1-1% of the total amount of the liquid crystal medium mixture in part by weight. The liquid crystal medium mixture can be formed in a way that the two or more polymerizable monomers which can be polymerized under the UV irradiation can be polymerized into polymer bulge with relatively small size and good uniformity according to a proper ratio, so that poor liquid crystal alignment, and a light spot phenomenon of a liquid crystal panel in the dark state is avoided, thus increasing the response speed of the liquid crystal panel and achieving high contrast and stable massive productivity.

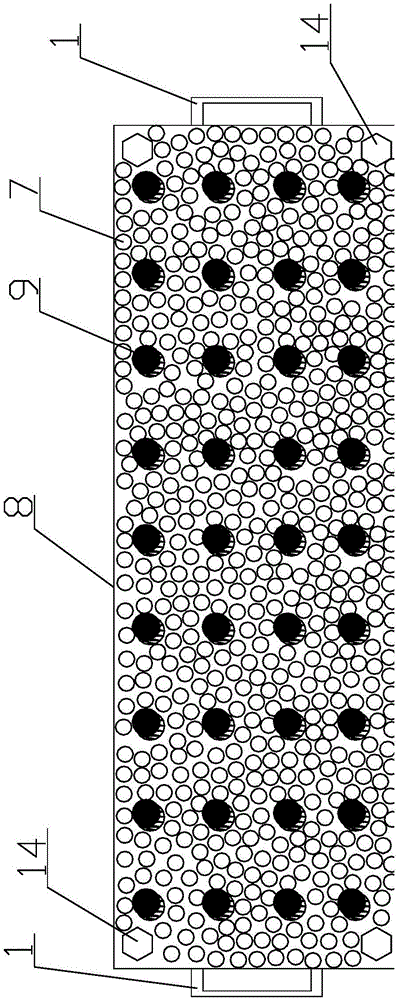

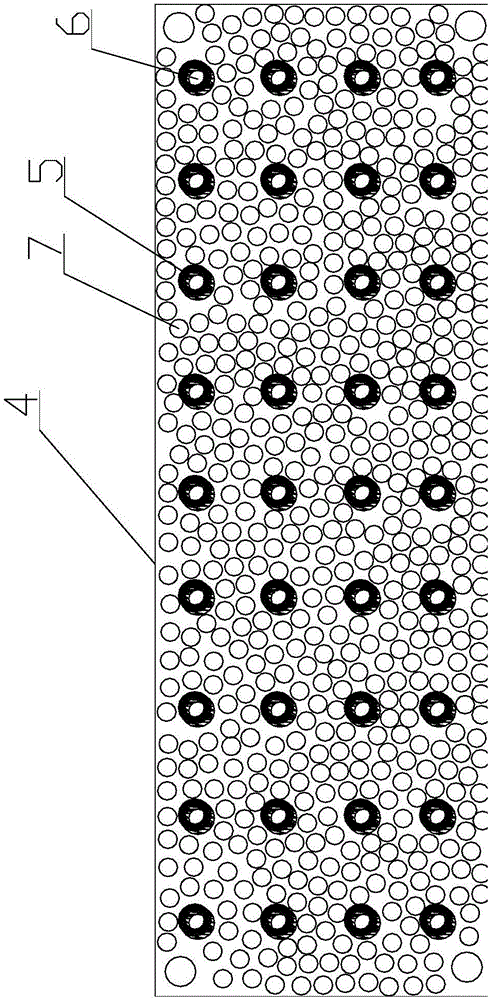

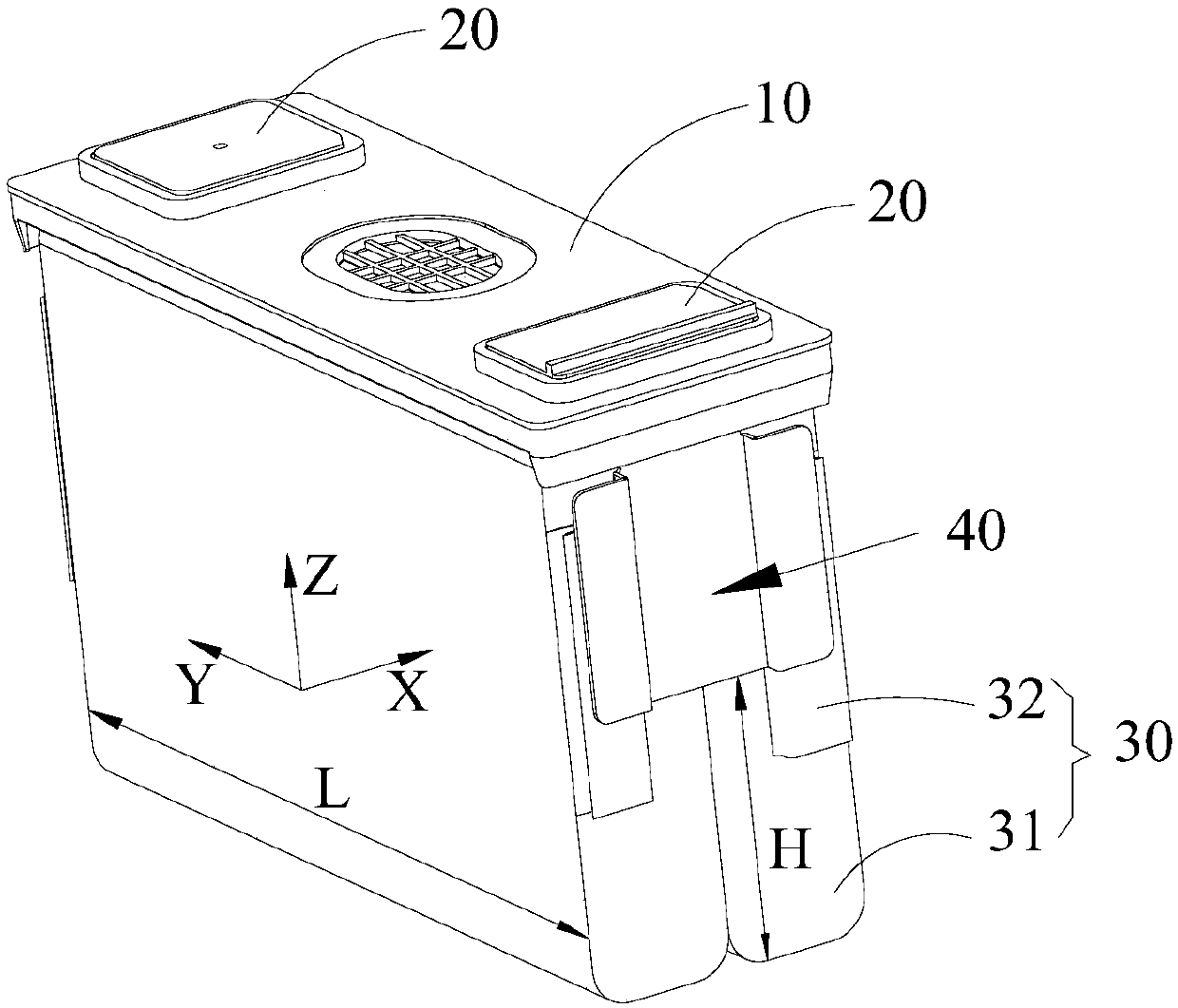

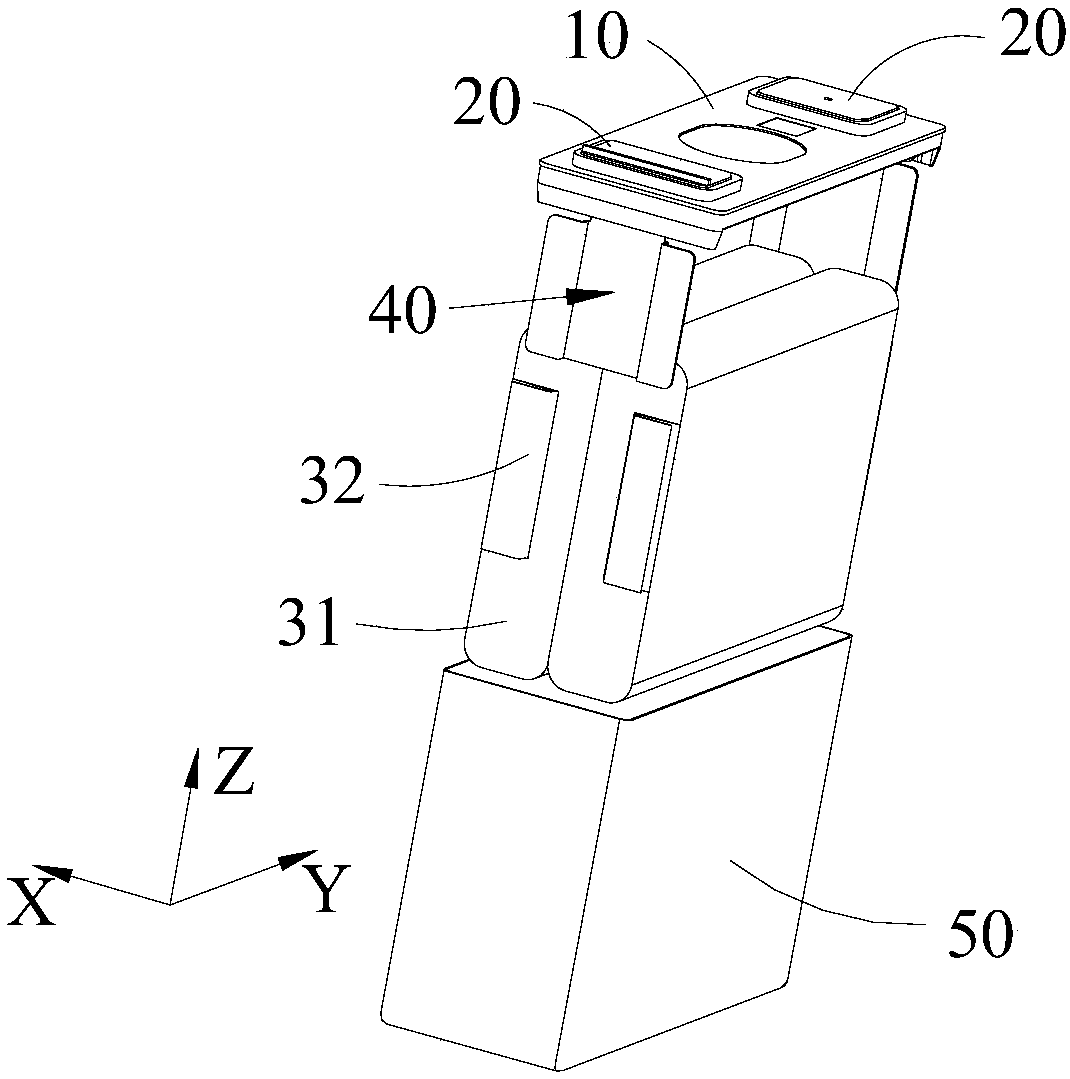

Secondary battery and automobile

ActiveCN110224099AIncrease energy densityImprove cycle lifeCurrent conducting connectionsSecondary cellsBlack spotPole piece

The application relates to the technical field of energy storage devices, in particular to a secondary battery and an automobile. The secondary battery comprises a top cover plate, post terminals, anelectrode assembly and connecting members. Each connecting member includes a first connecting plate connected with a corresponding tab, a second connecting plate and a supporting plate. The supportingplates at least partially protrude towards the side close to a body part relative to the first connecting plates, and the protruding portions of the supporting plates fit the body part. In the heightdirection of the secondary battery, the minimum distance between each supporting plate and the bottom of the electrode assembly is the bare height H of the body part on its side. The dimension of thebody part along the length direction of the secondary battery is the length L of the body part, and the bare height H and the length L of the body part satisfy the following relational expression: 0.1<=H / L<=0.8. Black spots on a first or second pole piece can be avoided as much as possible, the energy density and cycle life of the secondary battery can be improved, and the safety of the secondarybattery can be improved.

Owner:CONTEMPORARY AMPEREX TECH CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com