Mulberry enzyme residue tablet and preparation method thereof

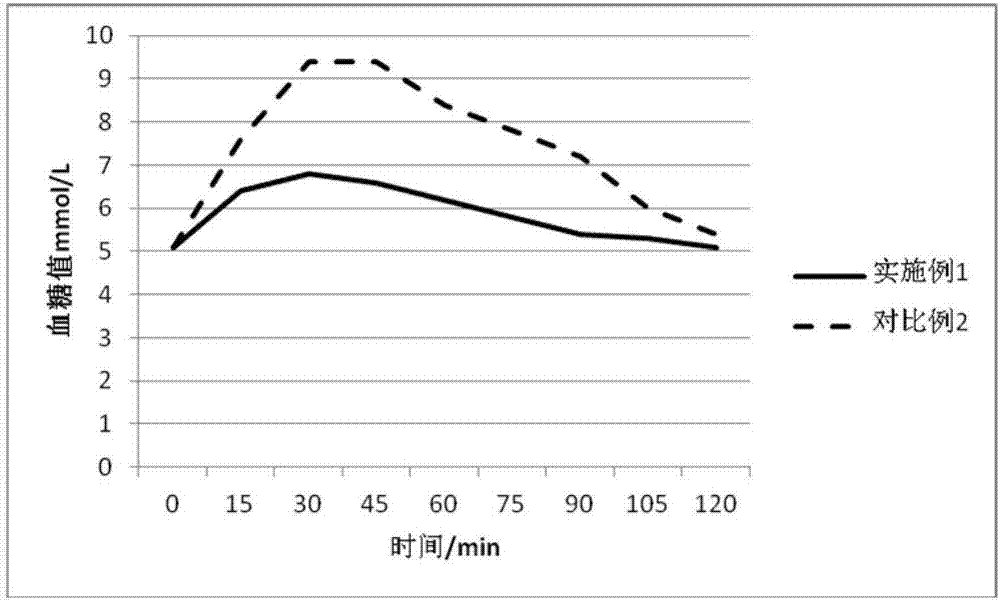

A technology of mulberry enzyme and slag tablets, applied in the field of food, can solve problems such as waste of mulberry seeds, achieve bright skin, improve human metabolism, prevent and skin diseases.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

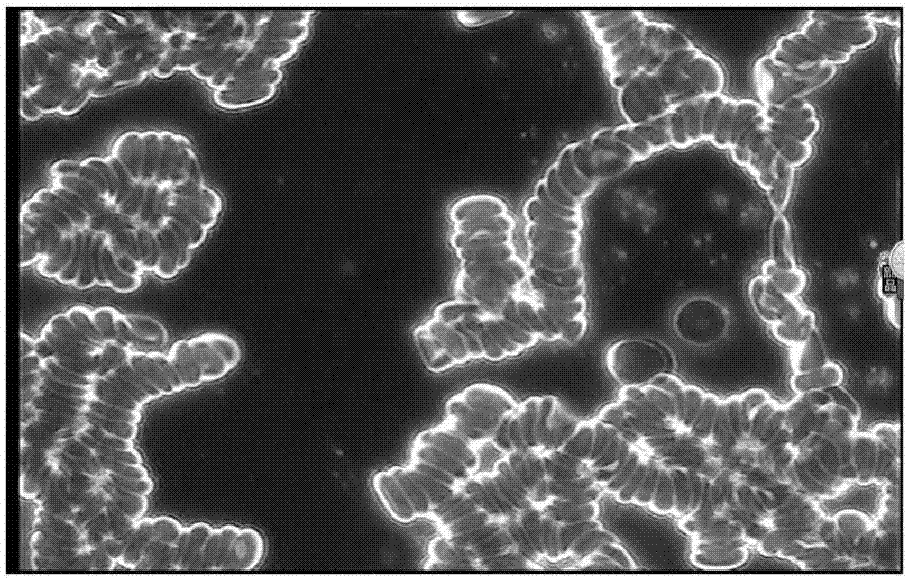

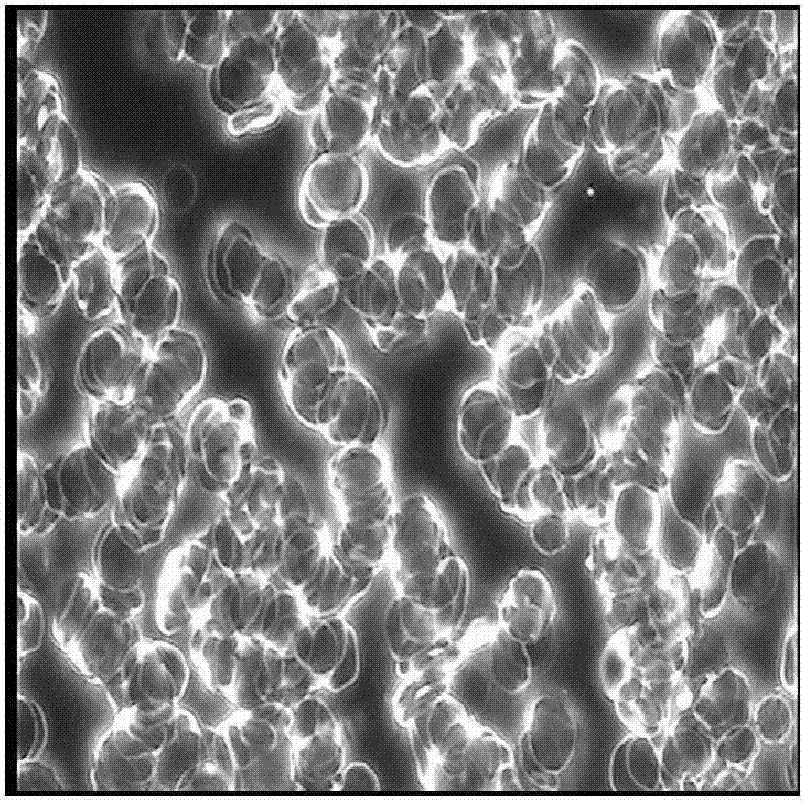

Method used

Image

Examples

Embodiment 1

[0043] (1) Add mulberries to yeast and carry out anaerobic fermentation for one year, the mass ratio of yeast to mulberry is 1:1000, then separate the obtained mulberry enzyme liquid from the slag liquid, dry the obtained mulberry enzyme slag and pulverize to 100 mesh to obtain mulberry enzyme residue powder, and then bake at 65°C for 20 hours to ensure that the mulberry enzyme residue can be completely dried;

[0044] (2) pulverize the dried mulberry enzyme residue and cross a 100-mesh sieve;

[0045] (3) Fully mix the mulberry enzyme slag powder with other ingredients, and the specific quality of other ingredients is as follows:

[0046] Mulberry enzyme residue powder 55.0g, xylitol 28.0g, maltodextrin 8.0g, erythritol 6.0g, fructo-oligosaccharide 1.0g, CMC (sodium carboxymethylcellulose) 1.0g.

[0047] (4) Spray the mixture obtained in step (3) into 30.0g edible alcohol with a spray bottle and stir evenly, so that each component of the mixture can be fully adhered together...

Embodiment 2

[0051] (1) Add mulberry to yeast and carry out anaerobic fermentation for one year. The mass ratio of yeast to mulberry is 2.5:2000. Then the obtained mulberry enzyme liquid is separated from the slag liquid, and the obtained mulberry enzyme slag is dried and crushed to 150 mesh to obtain mulberry enzyme residue powder, and then bake at 55°C for 22 hours to ensure that the mulberry enzyme residue can be completely dried;

[0052] (2) pulverize the dried mulberry enzyme residue and cross a 100-mesh sieve;

[0053] (3) Fully mix the mulberry enzyme slag powder with other ingredients, and the specific quality of other ingredients is as follows:

[0054] Mulberry enzyme residue powder 53.0g, xylitol 29.0g, maltodextrin 12.0g, erythritol 2.0g, fructo-oligosaccharide 2.2g, CMC (sodium carboxymethylcellulose) 0.8g.

[0055] (4) The mixture obtained in step (3) is sprayed into 35.0g alcohol with a spray bottle and stirred evenly, so that each component of the mixture can be fully adh...

Embodiment 3

[0058] (1) Add mulberry to yeast and carry out anaerobic fermentation for one year. The mass ratio of yeast to mulberry is 3:2000, and then the obtained mulberry enzyme liquid is separated from the slag liquid, and the obtained mulberry enzyme slag is dried and crushed to 120 mesh to obtain mulberry enzyme residue powder, and then bake at 60°C for 24 hours to ensure that the mulberry enzyme residue can be completely dried;

[0059] (2) pulverize the dried mulberry enzyme residue and cross a 100-mesh sieve;

[0060] (3) Fully mix the mulberry enzyme slag powder with other ingredients, and the specific quality of other ingredients is as follows:

[0061] Mulberry enzyme residue powder 57.0g, xylitol 25.0g, maltodextrin 9.3g, erythritol 4.0g, fructo-oligosaccharide 3.0g, CMC (sodium carboxymethylcellulose) 0.9g.

[0062] (4) The mixture obtained in step (3) is sprayed into 40.0g alcohol with a spray bottle and stirred evenly, so that each component of the mixture can be fully ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com