Oral buccal tablet and preparation method thereof

A production method and oral technology, applied in the field of lozenges, can solve the problems of easy inactivation of active ingredients, residual solvent technology, single variety, etc., and achieve the effects of protecting the stomach, preventing oxidation and escape, and improving the extraction rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

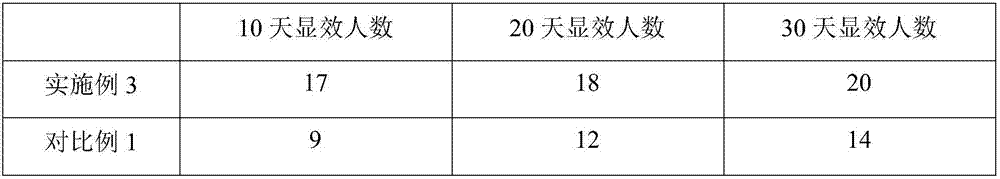

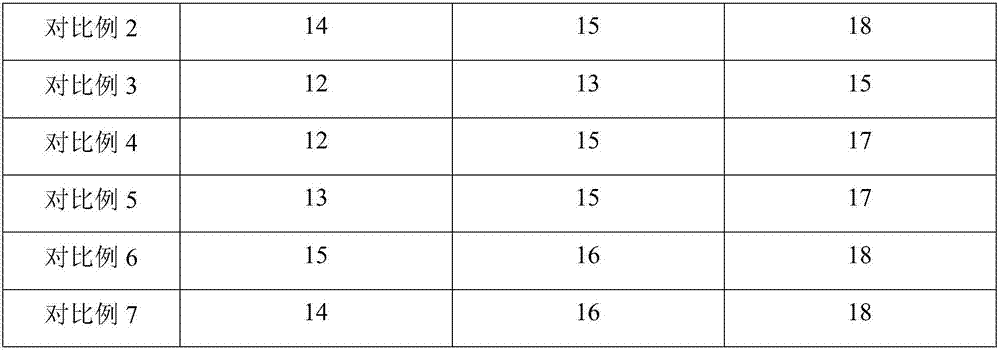

Examples

Embodiment 1

[0027] A kind of buccal lozenge, comprises the raw material of following parts by weight to make:

[0028] 50 parts golden camellia, 20 parts spirulina, 20 parts fructooligosaccharide, 5 parts mung bean, 3 parts black fungus, 2 parts croissant, 3 parts kelp, 2 parts yam, 2 parts chestnut, 4 parts shiitake mushroom, 4 parts sweet potato, lotus root 3 parts, honeysuckle 2 parts, menthol 1.5 parts, vitamin C 2.5 parts, propolis 3 parts.

Embodiment 2

[0030] A kind of buccal lozenge, comprises the raw material of following parts by weight to make:

[0031] 40 parts golden camellia, 18 parts spirulina, 15 parts fructooligosaccharide, 4 parts mung bean, 2 parts black fungus, 1 part croissant, 2 parts kelp, 1.5 parts yam, 1.5 parts chestnut, 3 parts shiitake mushroom, 3 parts sweet potato, lotus root 2 parts, 1.5 parts of honeysuckle, 1.2 parts of menthol, 2 parts of vitamin C, 2.5 parts of propolis.

Embodiment 3

[0033] A kind of preparation method of buccal lozenge, comprises the following steps:

[0034] S1. Wash and mash 40 parts by weight of Camellia japonica, mix with 200 parts by weight of distilled water and 100 parts by weight of ethanol to obtain the first mixture, ultrasonically vibrate the first mixture for 15 minutes at a frequency of 50KHz, and then use ultrasonic waves to disrupt the cells The instrument was used for cell disruption treatment for 10 minutes, then ultrasonically oscillated at 30KHz for 10 minutes, and extracted at 25°C for 48 hours. During the extraction period, sodium bicarbonate was added every 6 hours to adjust the pH of the first mixture to 7.5. After the extraction was completed, The first mixture is filtered, and the obtained filtrate is first subjected to vacuum rotary evaporation to remove ethanol, and then freeze-dried to remove water, so as to obtain Camellia japonica extract;

[0035] S2. After washing 18 parts by weight of spirulina, 4 parts by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com