Ceramic thread processing tool and ceramic thread processing method

A technology for thread processing and ceramics, applied in the field of ceramic manufacturing, can solve the problems of metal powder embedded in ceramics, scrapped ceramic products, and difficult to clean black spots, so as to achieve the effects of low manufacturing cost, reduced use, and avoidance of black spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

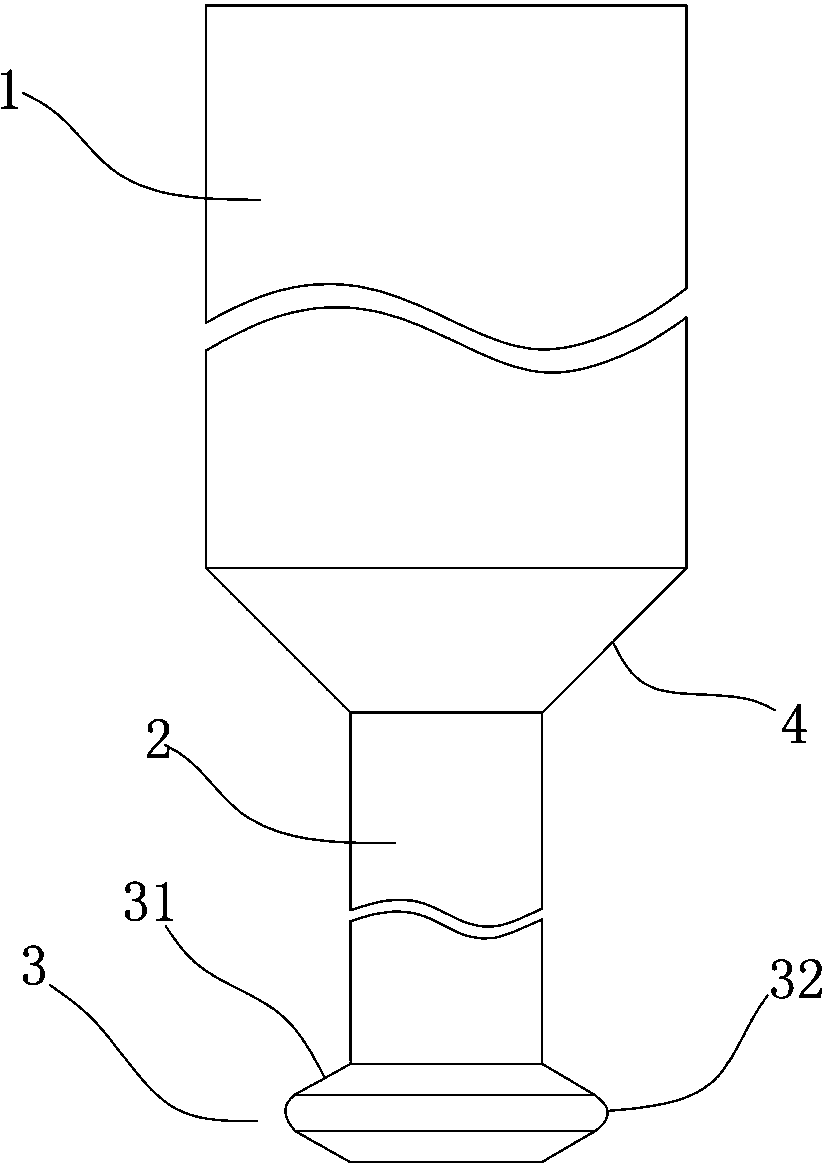

[0024] Example: such as figure 1 As shown, a ceramic threading tool of the present invention comprises a body, the body is integrally formed, the body includes a rod-shaped fixed section 1, and one end of the fixed section 1 is provided with a working section with a diameter smaller than the fixed section 1 2. A tooth-shaped protrusion 3 is provided on the peripheral surface of the end of the working section 2 towards the outer ring, and the top of the tooth-shaped protrusion 3 is provided with a rounded corner 32. The bottom surface of the tooth-shaped protrusion 3 is attached to the surface of the diamond grit.

[0025] A conical surface 4 is provided at the joint between the fixed end and the working section 2 .

[0026] The length of the main body is 60 mm, and the diameter of the fixing section 1 is 6 mm.

[0027] The length of the working section 2 is 8mm, the diameter of the working section 2 is 2.4mm, and the diameter of the tooth-shaped protrusion is 4mm.

[0028] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com