Clamp system special for electroplating of fixing bolts

A technology for fixing bolts and special fixtures, applied in electrolysis process, electrolysis components, etc., can solve problems affecting product quality, low production efficiency, large manpower and material resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

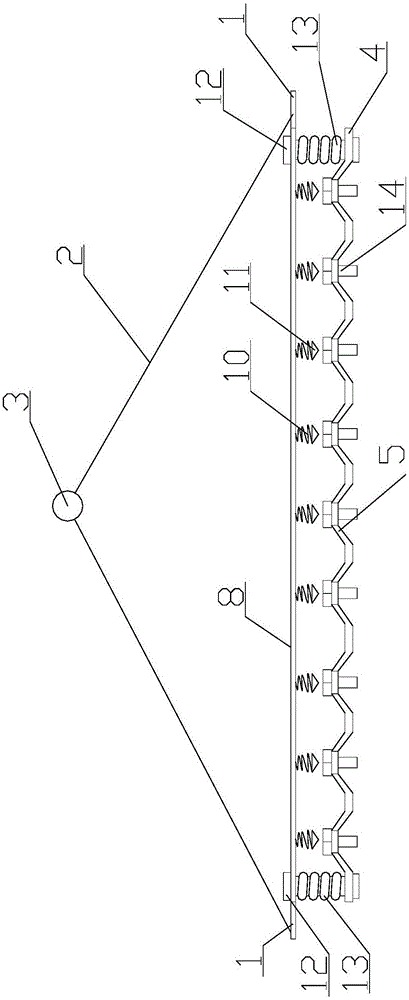

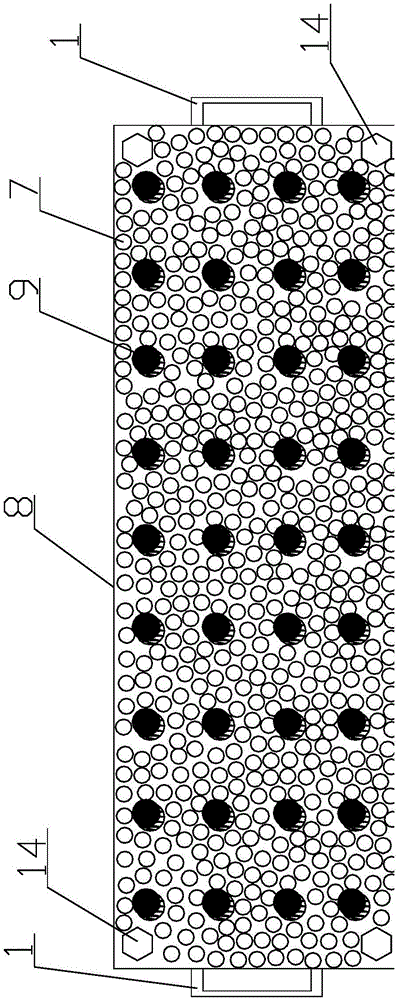

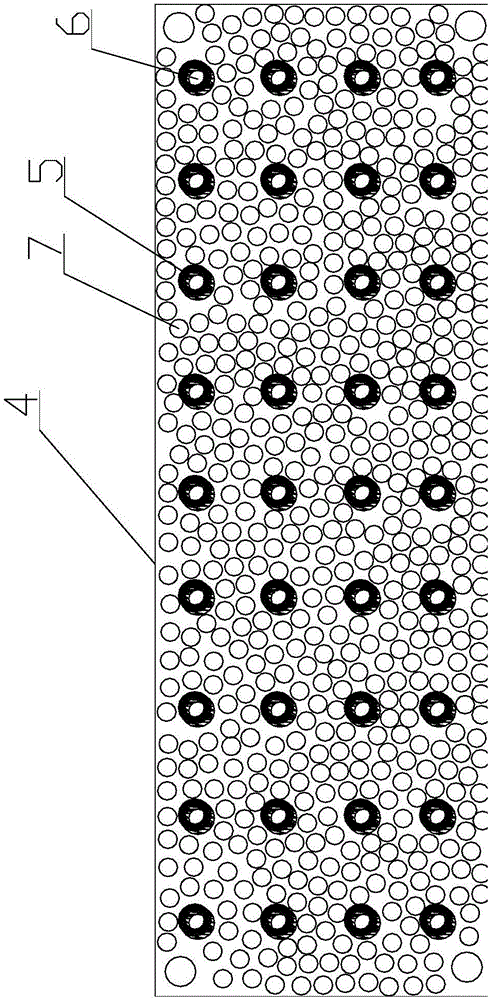

[0016] Such as Figure 1~4 Shown is a special fixture system for fixed bolt electroplating, including a pressure plate assembly, a base plate assembly, a handle 1, a steel wire rope 2 and a pull ring 3, the upper end of the base plate assembly is arranged in parallel with the pressure plate assembly, the handle 1 is arranged at both ends of the pressure plate assembly, and the handle 1 are connected by a steel wire rope 2, and the pull ring 3 is arranged in the middle of the steel wire rope 2; the base plate assembly includes a base plate 4, a round table protrusion 5, a placement hole 6 and a through hole 7, and a plurality of round table protrusions 5 are evenly arranged on the base plate 4. The hole 6 is arranged on the top of the round platform protrusion 5, and a plurality of through holes 7 are uniformly arranged on the base plate 4; A plurality of fixed blocks 9 are embedded in the position of the round platform protrusion 5 on the base plate 4, and the lower ends of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com