Liquid crystal medium mixture and liquid crystal display using same

A liquid crystal display and liquid crystal medium technology, which is applied in liquid crystal materials, instruments, chemical instruments and methods, etc., can solve the problems of insufficient alignment force, affecting the alignment of liquid crystal media, and affecting the reaction and polymerization of polymerizable monomers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0097] The liquid crystal medium mixture adopts negative type liquid crystal material and two kinds of polymerizable monomers, specifically as follows:

[0098] The structural formula of the negative type liquid crystal material is

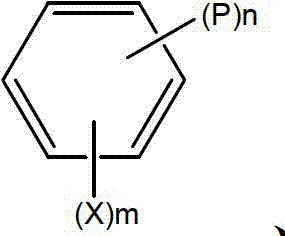

[0099] The two polymerizable monomers are RM-A1 and RM-B1 respectively. The structural formula of RM-A1 is as follows:

[0100]

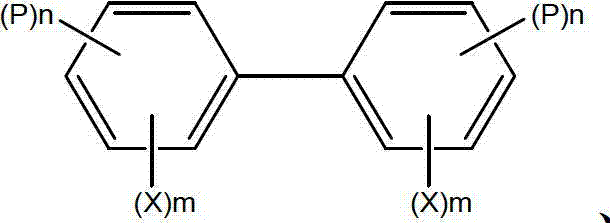

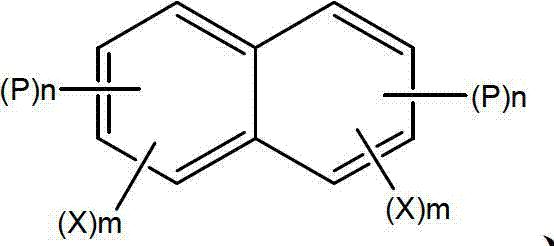

[0101] The structural formula of RM-B1 is as follows:

[0102]

[0103] The molar ratio of RM-A1 to RM-B1 is 1:5, and the total content of the two accounts for 3000ppm of the liquid crystal medium layer. In the mixture of liquid crystal media, RM-A1 and RM-B1 are used in combination, and the size of the polymer bump generated by ultraviolet irradiation is small and uniform, and there is no phenomenon of bright light in the dark state.

Embodiment 2

[0105] The liquid crystal medium mixture adopts negative type liquid crystal material and two kinds of polymerizable monomers, specifically as follows:

[0106] The structural formula of the negative type liquid crystal material is

[0107] The two polymerizable monomers are RM-A1 and RM-B1 respectively. The structural formula of RM-A1 is as follows:

[0108]

[0109] The structural formula of RM-B1 is as follows:

[0110]

[0111] The molar ratio of RM-A1 to RM-B1 is 1:5, and the total content of the two accounts for 1000ppm of the liquid crystal medium layer. In the mixture of liquid crystal media, RM-A1 and RM-B1 are used in combination, and the size of the polymer bump generated by ultraviolet irradiation is small and uniform, and there is no phenomenon of bright light in the dark state.

Embodiment 3

[0113] The liquid crystal medium mixture adopts negative type liquid crystal material and two kinds of polymerizable monomers, specifically as follows:

[0114] The structural formula of the negative type liquid crystal material is

[0115] The two polymerizable monomers are RM-A1 and RM-B1 respectively. The structural formula of RM-A1 is as follows:

[0116]

[0117] The structural formula of RM-B1 is as follows:

[0118]

[0119] The molar ratio of RM-A1 to RM-B1 is 1:5, and the total content of the two accounts for 10000ppm of the liquid crystal medium layer. In the mixture of liquid crystal media, RM-A1 and RM-B1 are mixed, and the size of the polymer bump generated by ultraviolet irradiation is small and uniform, and there is no phenomenon of bright light in the dark state.

[0120] To sum up, the liquid crystal medium mixture for liquid crystal display according to the present invention, through the two or more polymerizable monomers contained in the liquid cryst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com