Patents

Literature

237 results about "Carnosic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carnosic acid is a natural benzenediol abietane diterpene found in rosemary (Rosmarinus officinalis) and common sage (Salvia officinalis). Dried leaves of rosemary or sage contain 1.5 to 2.5% carnosic acid.

Method for extracting carnosic acid

InactiveCN101113133ATo achieve the purpose of purificationNo need to crystallizeCarboxylic compound separation/purificationChemistryCarnosic acid

The invention discloses a preparation method of extracting carnosin, that is, dry rosemary is immersed in organic solvent, and extracted for 10-60 min in 20-55 DEG C ultrasonic, and filtered to acquire the extract of dry rosemary, and acticarbon is added into the extract of dry rosemary, the quality ratio of the acticarbon and dried rosemary extract is 1: 15- 1: 25; the extract is decolored for 5- 20 min in 25-45 DEG C ultrasonic, and the extract liquid is acquired before being filtering for 1-2 times; the extract liquid is distilled to dryness to acquire the solid. Ethylenediamine tetraacetic disodium is added into the solid to dissolve the solid, then alkali is added to adjust PH to 8.0-9.5 before getting the colature.liquid finally, and acid is added to adjust PH to 2.3-3.0 till precipitation is produced in the colature liquid, and then carnosin is acquired after the precipitation is dried. Without any crystallization, the purity of carnosin can reaches as high as 99.42%, and the extraction process is simple and can be easily operated in short time.

Owner:中科检测技术服务(广州)股份有限公司

Compound antioxidant and grease containing same

InactiveCN106675780AImprove stabilityCharacteristic flavor retentionEdible oils/fats ingredientsFatty substance preservation using additivesPalmitatesPolyphenol

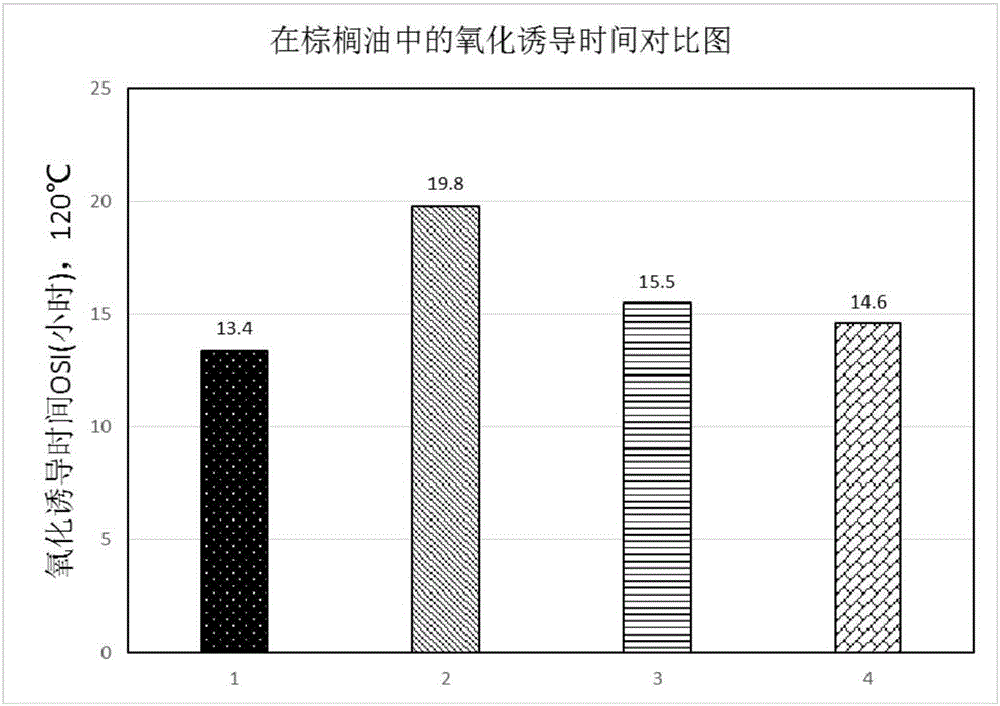

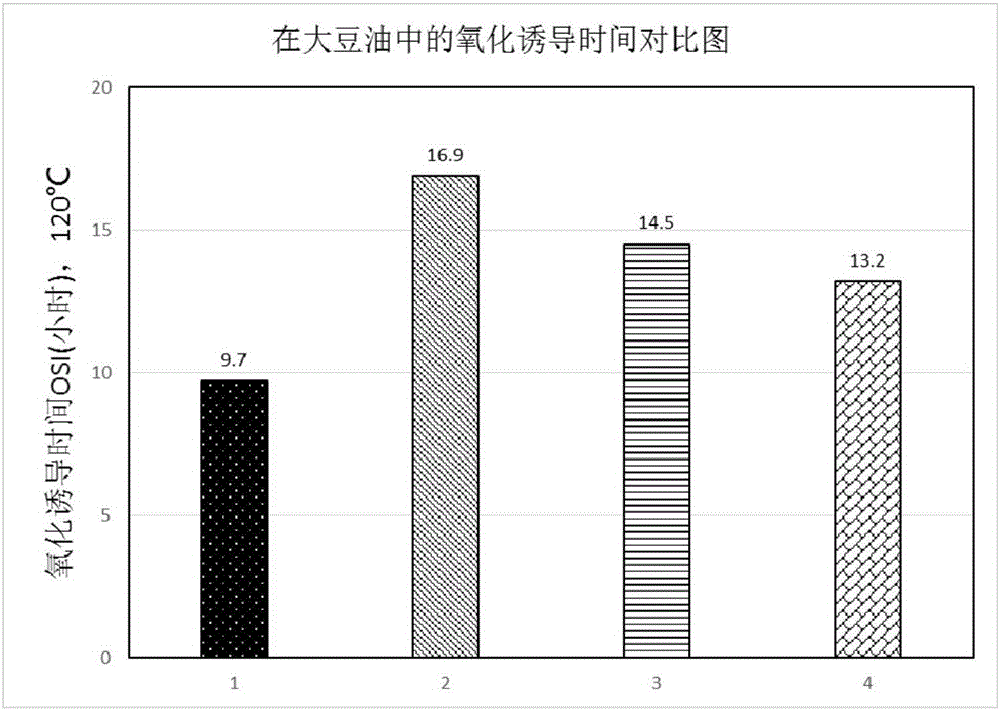

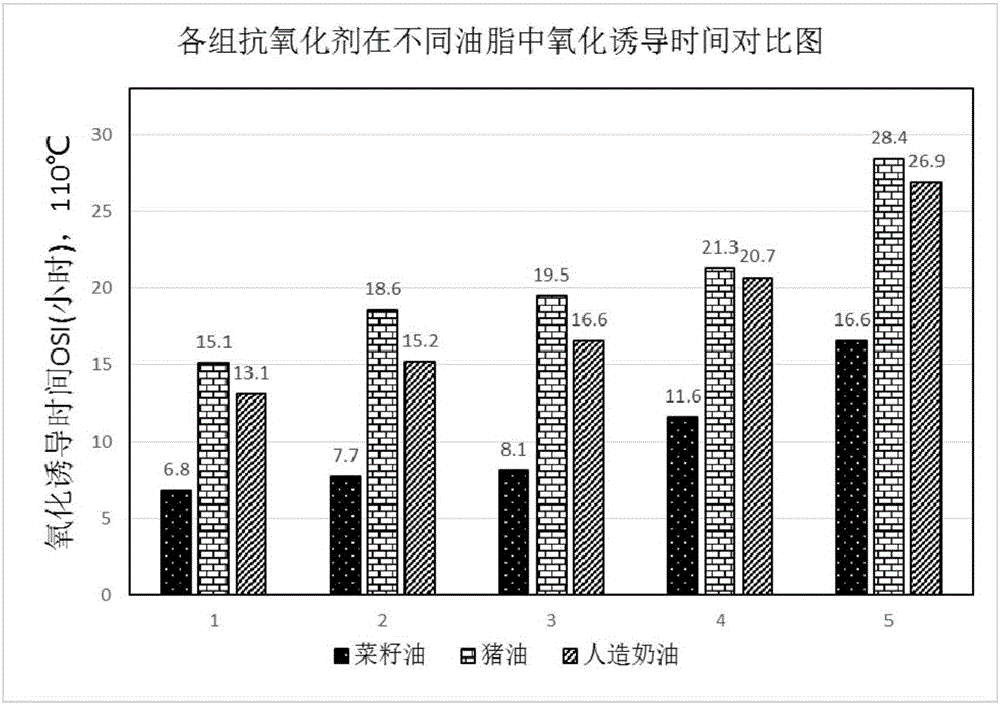

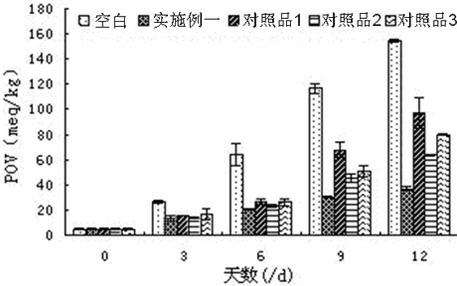

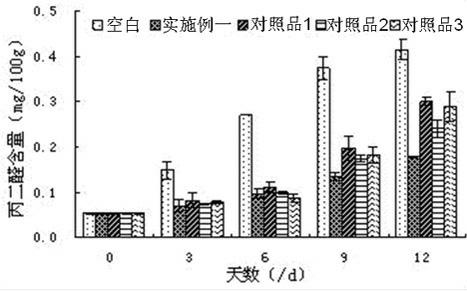

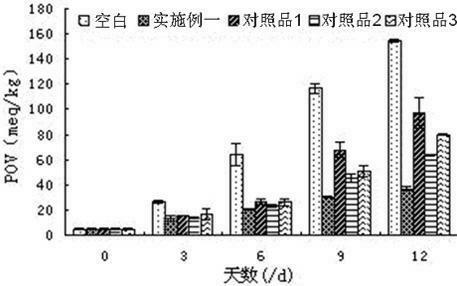

The invention relates to a compound antioxidant, which is prepared from vitamin E, tea polyphenol-palmitate, ascorbyl palmitate and a rosemary extract. According to the compound antioxidant, the content of the vitamin E is smaller than or equal to 3,000ppm and greater than or equal to 5ppm, the content of the tea polyphenol-palmitate is smaller than or equal to 600ppm and greater than or equal to 5ppm, the content of the ascorbyl palmitate is smaller than or equal to 200ppm and greater than or equal to 5ppm and the content of the rosemary extract is smaller than or equal to 700ppm and greater than or equal to 5ppm; the content of the vitamin E is calculated according to the total content of mixed tocopherol; and the content of the rosemary extract is calculated according to the content of carnosic acid in the rosemary extract. The compound antioxidant is high in stability and high in antioxidant activity, and can be applied to vegetable fat, animal fat, margarine, oleomargarine or shortening.

Owner:天津融信蓝海生物科技有限公司

Algal oil DHA (Docosahexaenoic Acid) microcapsule and preparation method thereof

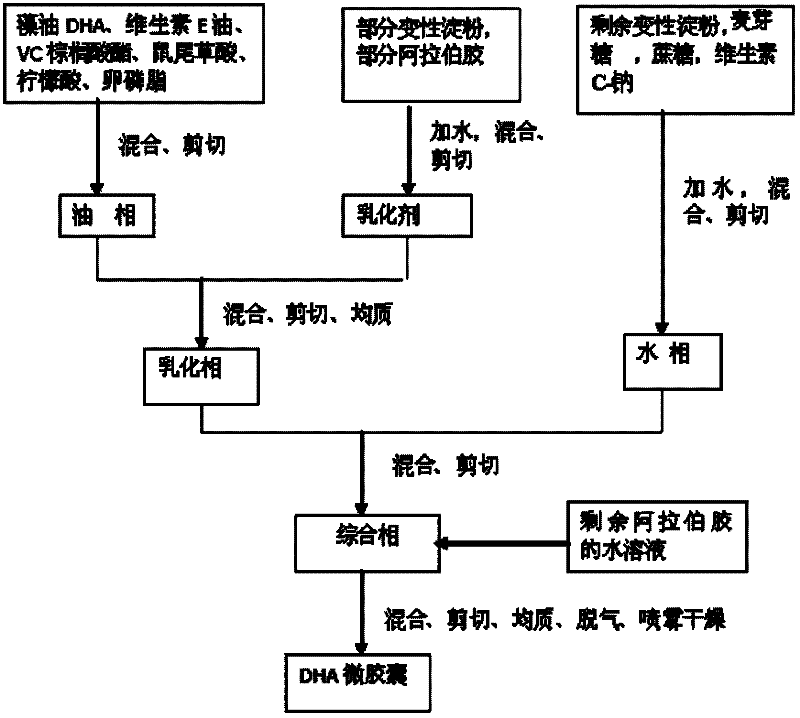

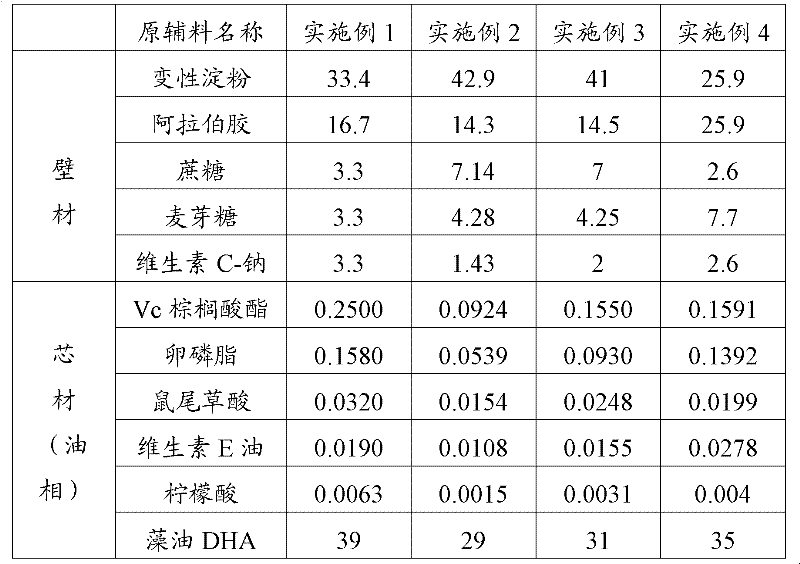

InactiveCN102228257AEffective protectionPrevent oxidationFood shapingFood preparationDocosahexaenoic acidVitamin C

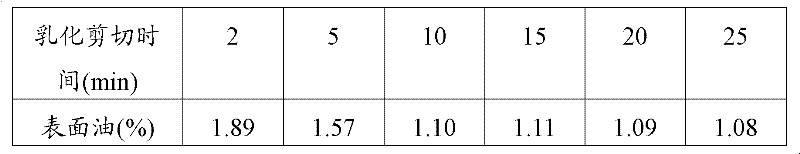

The invention relates to an algal oil DHA (Docosahexaenoic Acid) microcapsule, which consists of algal oil DHA, an antioxidant and a shell material. The antioxidant is prepared from VC (Vitamin C) palmitate, lecithin, carnosic acid, VE (Vitamin E) grease and citric acid based on the mass ratio of (40-60):(25-35):(5-10):(3-7):1 sequentially, and the dose of the antioxidant is 0.6-1.2% of the mass of the algal oil DHA; the shell material is prepared from modified starch, Arabic gum, cane sugar, maltose and vitamin C-sodium based on the mass ratio of (10-30):(5-10):(1-5):(1-3):1 sequentially, and the dose of the shell material is 60-70% of the mass of the algal oil DHA. The invention further discloses a preparation method of the algal oil DHA. According to the invention, the oxidation of the algal oil DHA is effectively slowed down, odor smell is covered, the stability of products is increased and the effect duration is prolonged.

Owner:湖北福星生物科技有限公司

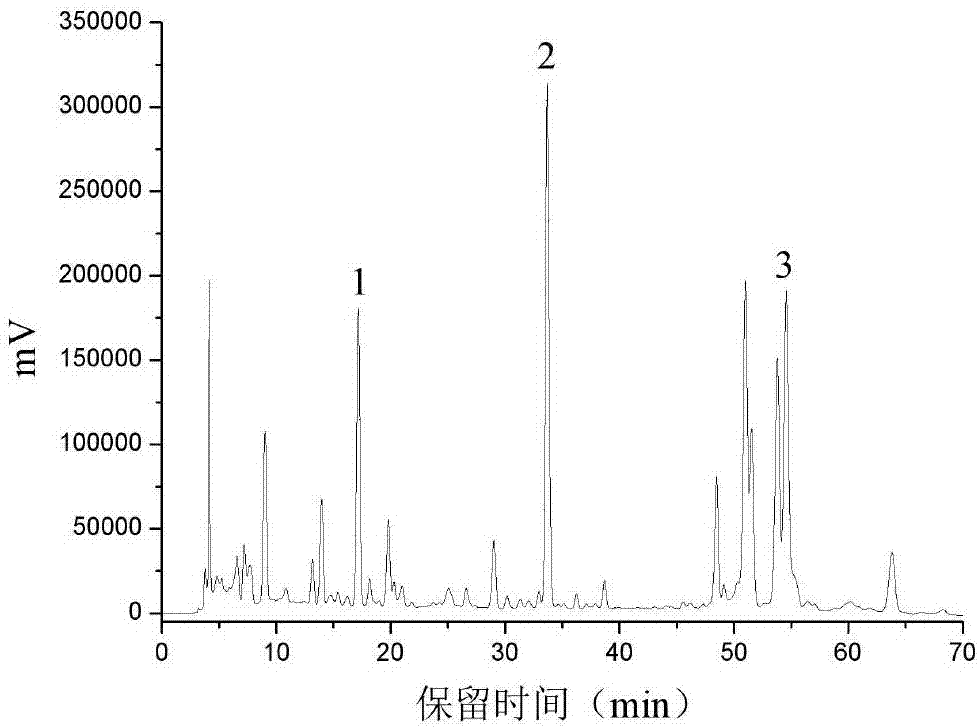

Method for extracting ursolic acid, carnosic acid and rosmarinic acid from rosemary

InactiveCN102286059AIncrease profitEasy to operateOrganic compound preparationCarboxylic acid esters preparationAlcoholRosmarinus

The present invention discloses a method for extracting ursolic acid, carnosic acid and rosmarinic acid from rosemary. Reflux extraction with 95% ethanol solution for 1-2 hours, extract 2-3 times, concentrate the extract under reduced pressure to an alcohol concentration of 30-70%, let stand for crystallization for 3-7 hours, filter out the crystals and dry to obtain ursolic acid; 2) The crystallized mother liquor was concentrated under reduced pressure to no alcohol, centrifuged to obtain the solid and dried to obtain carnosic acid, and the liquid was further concentrated under reduced pressure to obtain rosmarinic acid. The method of the invention has the advantages of simple operation, high raw material utilization rate, low production cost and easy industrial production.

Owner:NANJING ZELANG MEDICAL TECH

Method for comprehensively extracting rosmarinus officinalis and preparing fat-soluble instant antioxidant

ActiveCN102604640AAchieve complete dissolutionIncrease production costEssential-oils/perfumesSolid solvent extractionBiotechnologyRosmarinus

The invention relates to the extraction and utilization of rosmarinus officinalis, and discloses a method for comprehensively extracting the rosmarinus officinalis and preparing a fat-soluble instant antioxidant. The method comprises the following steps of: mincing raw materials rosmarinus officinalis tender stems or leaves which are dried in shade, and distilling the minced rosmarinus officinalis tender stems or leaves by using water vapor to obtain rosmarinus officinalis essential oil and distillation residues; and performing percolation extraction on the distillation residues by using ethanol, performing ethanol recovery treatment on extracting solution, obtaining a water-soluble antioxidant from a water phase, dissolving precipitates by using a low-boiling solvent, and decreaming a carnosic acid into cooking oil after decoloring; and performing concentration, and recovering the solvent to obtain a fat-soluble instant antioxidant product with the carnosic acid content of 5 to 20 percent. The method has the advantages of high yield, full raw material utilization, low production cost and the like; and in addition, the application performance of a rosmarinus officinalis antioxidant product is greatly improved, and the rosmarinus officinalis antioxidant can be more conveniently and efficiently used.

Owner:GUANGZHOU HONSEA SUNSHINE BIOTECH CO LTD

Stabilized chewing gum base

Styrene butadiene rubber (SBR) is widely used as a chewing gum base in lieu of natural gums. It is necessary to protect chewing gum SBR with a food grade antioxidant stabilizer system. This invention discloses a chewing gum rubber composition (gum base) that utilizes carnosic acid from a Libiatae plant, such as rosemary or sage, as an antioxidant stabilizer. In the practice of this invention the chewing gum base also containg lecithin that can be used as an emulsifier for the carnosic acid. This invention more specifically discloses a chewing gum base comprising: (1) about 5 weight percent to about 95 weight percent of a rubbery elastomer; (2) about 0 weight percent to about 75 weight percent of an elastomer plasticizer selected from the group consisting of natural rosin esters and synthetic terpene resins; (3) about 1 weight percent to about 65 weight percent of a filler material; (4) carnosic acid, and (5) lecithin, wherein said chewing gum base is void of sweeteners. The subject invention also reveals a chewing gum base comprising: (1) about 5 weight percent to about 95 weight percent of a rubbery elastomer; (2) about 0 weight percent to about 75 weight percent of an elastomer plasticizer selected from the group consisting of natural rosin esters and synthetic terpene resins; (3) about 1 weight percent to about 65 weight percent of a filler material; (4) carnosic acid, and (5) lecithin, wherein said chewing gum base is void of flavoring agents. The present invention further discloses a chewing gum base comprising: (1) about 5 weight percent to about 95 weight percent of a rubbery elastomer; (2) about 0 weight percent to about 75 weight percent of an elastomer plasticizer selected from the group consisting of natural rosin esters and synthetic terpene resins; (3) about 1 weight percent to about 65 weight percent of a filler material; (4) carnosic acid, and lecithin, wherein said chewing gum base is void of colorants.

Owner:THE GOODYEAR TIRE & RUBBER CO

Comprehensive extraction technology of rosmarinic acid, ursolic acid, oleanolic acid and carnosic acid

InactiveCN104447334ASimple processEasy to operateOrganic compound preparationSteroidsAlcoholUrsolic acid

The invention discloses a comprehensive extraction technology of rosmarinic acid, ursolic acid, oleanolic acid and carnosic acid. The comprehensive extraction technology comprises the steps of (1) preprocessing raw materials; (2) performing reflux alcohol-extraction; (3) carrying out primary separation; (4) separating out rosmarinic acid; (5) separating out ursolic acid; (6) separating out oleanolic acid. According to the comprehensive extraction technology, the process is simple, the operation is convenient, industrial production can be easily carried out, and meanwhile, the purpose of synchronously extracting rosmarinic acid of rosemary, ursolic acid, oleanolic acid and carnosic acid is achieved, and the active ingredients of rosemary can be extracted to the maximum; the rosmarinic acid, ursolic acid, oleanolic acid and carnosic acid respectively have the purity exceeding 30%, 25%, 20% and 25%.

Owner:付大亮

Method for enhancing oxidation resistance of edible vegetable oil or fish oil by using natural antioxidant

InactiveCN104911027AImprove stabilityImprove antioxidant capacityFatty substance preservation using additivesOil and greaseVegetable oil

The invention discloses a method for enhancing oxidation resistance of edible vegetable oil or fish oil by using a natural antioxidant, which comprises the following step: dissolving the natural antioxidant powder (polyphenol compounds, such as tea polyphenols and carnosic acid) in high-polarity oil (propanediol octanoate) while assisting dissolution with an ultrasonic vortex instrument, wherein the dissolution required lime is directly proportional to the dissolved amount. The natural antioxidant high-load grease has favorable mutual solubility with edible vegetable oil and fish oil, and the addition amount is 10-4000 ppm, thereby obtaining favorable oxidation resistance effect.

Owner:JIANGSU FUSHENG BIOTECH CO LTD

Method for extracting high-purity ursolic acid from rosemary

ActiveCN103102384AIncrease production capacityHigh ursolic acid contentSteroidsUrsolic acidDissolution

The invention discloses a method for extracting high-purity ursolic acid from rosemary, which is characterized by comprising the following steps of: A, adding ethanol into the leftovers obtained after grinding rosemary leaves and extracting carnosic acid for extraction; filtering and obtaining the filtrate; adding active carbon into the filtrate for decoloration; filtering and concentrating; adding 2-5 times water by volume while stirring to separate out precipitate; filtering to obtain a crude extract of ursolic acid; B, adding an organic solvent into the crude extract of ursolic acid in the step A for dissolution; adding diethylamine or triethylamine for backflow reaction to generate salt; and cooling to room temperature and filtering to obtain amine salt; C, adding water into the amine salt in the step B to dissolve the amine salt; adding isopropyl ether; adjusting the pH value to 2-5 by dilute acid; keeping the temperature at 20-40 DEG C for 1 hour; filtering; and drying the filter cake; and D, adding methanol into the dried filter cake in the step C for dissolution; adding neutral alumina for decoloration; filtering and concentrating the filtrate; cooling to minus10-20 DEG C for crystallization; and centrifuging, washing and drying to obtain the finished product of ursolic acid.

Owner:ZHONGSHAN BAILING BIOTECHNOLOGY CO LTD

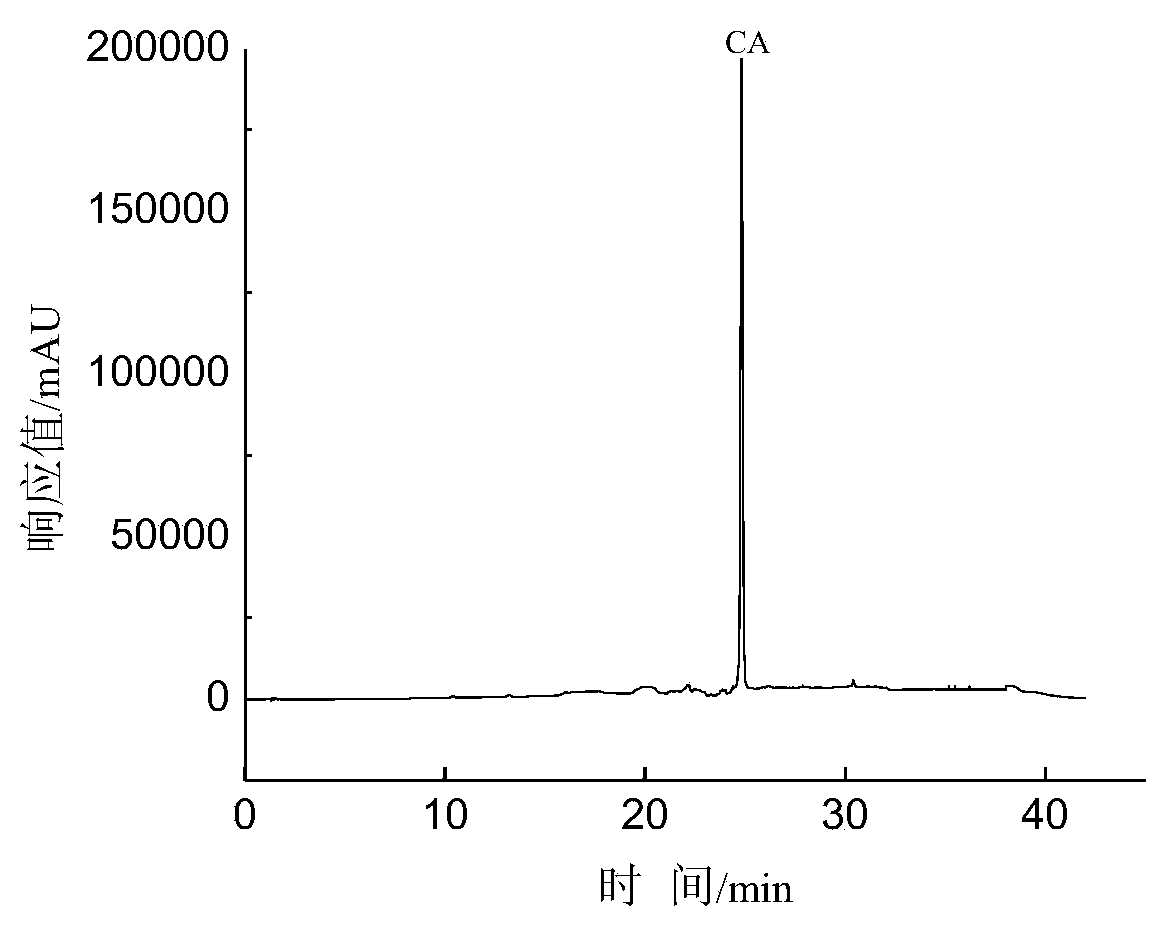

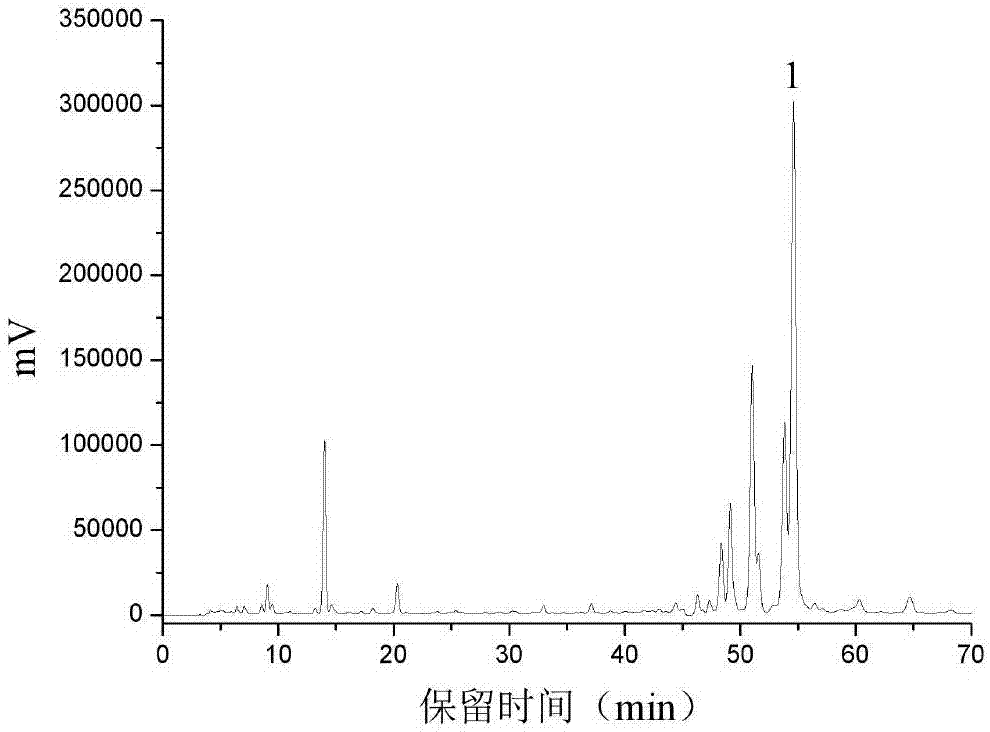

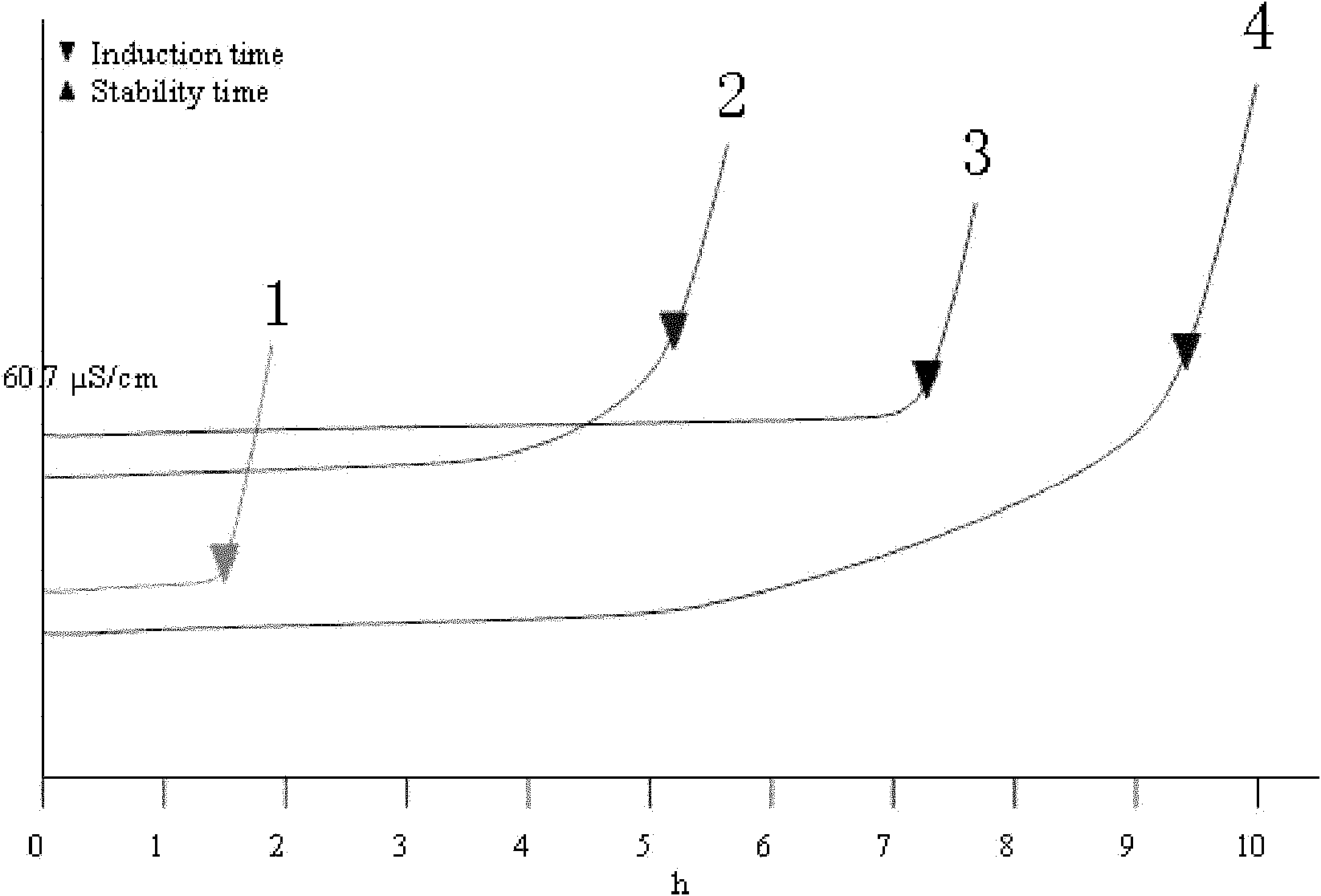

Method for preparing high-purity carnosic acid by continuous medium pressure column chromatography

InactiveCN101851158AFacilitate industrial continuous productionChange the production processCarboxylic compound separation/purificationSilica gelEthyl acetate

The invention discloses a method for preparing high-purity carnosic acid by continuous medium pressure column chromatography. The method prepares the carnosic acid with the purity of over 98 percent by using a carnosic acid raw material with the content of not lower than 15 percent. The method comprises the following steps of: dissolving a coarse carnosic acid product into ethyl acetate, filtering the insoluble substances to obtain a column filling sample, and filling a column by using silica gel, namely dispersing the silica gel by using the ethyl acetate and then wetly filling the silica gel into the column; after filling, feeding liquid into the column through a plunger solvent pump by using the ethyl acetate as eluent, collecting the eluted fractions section by section, concentrating the fractions under reduced pressure till the eluent is dryly reclaimed to obtain a chromatographic product, reusing the reclaimed eluent, re-crystallizing the chromatographic product by using a hydrocarbon solvent, and drying a crystallized product under reduced pressure to obtain a pure carnosic acid product with the purity of over 98 percent, wherein after the ethyl acetate is reclaimed under reduced pressure, the mother solution serving as a column chromatography raw material can be re-purified, the used chromatographic column is regenerated by using a mixed solvent containing ethyl acetate and ethanol, the ethyl acetate is balanced by a balancing agent, and the balanced chromatographic column can be reused for over 30 times. The method has the main characteristics that the purification process has no pollution, all solvents can be recycled and the method is convenient for industrial continuous production.

Owner:NORTHEAST FORESTRY UNIVERSITY +1

Method for comprehensive extraction of carnosic acid, carnosol and ursolic acid

ActiveCN105669432AIncrease contentLight colorSteroidsCarboxylic compound separation/purificationOxalateAlcohol

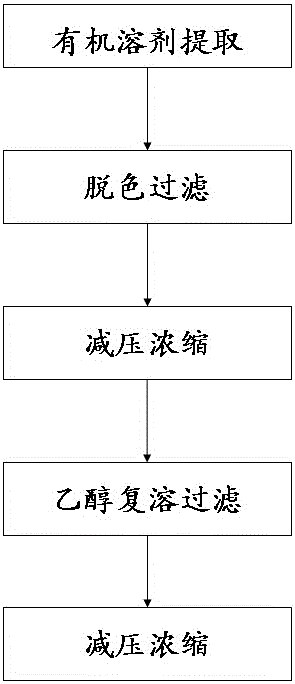

The invention discloses a method for comprehensive extraction of carnosic acid, carnosol and ursolic acid.According to the method, rosemary flowers or leaves are used as raw materials, an organic solvent is adopted for extraction, the content of obtained rosemary extract is 40-45%, and the ratio of the content of carnosic acid to the content of carnosol in the rosemary extract is 4:1 to 6:1.The method comprises the steps of extraction with the organic solvent, decoloration and filtration, vacuum concentration, ethyl alcohol redissolution and filtration and vacuum concentration.By means of the method, the yield of the rosemary extract can be greatly increased, the ratio of the content of carnosic acid to the content of carnosol in the extract is increased, the content of carnosol in the extract is reduced, and the overall oxidation resistance of the extract is enhanced.

Owner:HENAN ZHONGDA HENGYUAN BIOTECH CO LTD

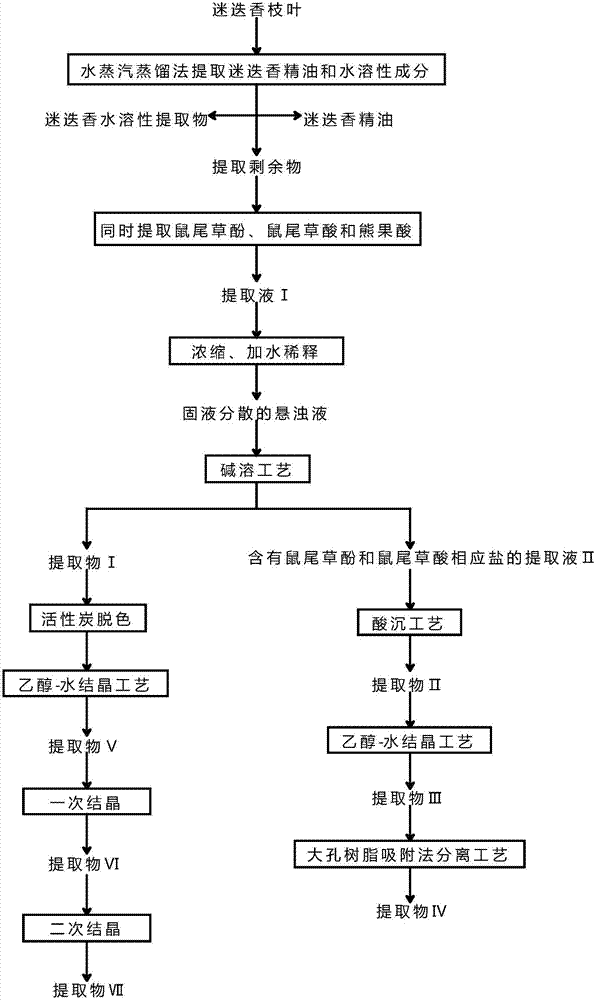

Method for extracting and separating rosemary essential oil, rosemary acid, ursolic acid and carnosic acid from rosemary leaves

InactiveCN108070453ASimple extraction processSuitable for industrial productionOrganic compound preparationEssential-oils/perfumesSlagDistillation

The invention relates to a method for extracting and separating rosemary essential oil, rosemary acid, ursolic acid and carnosic acid from rosemary leaves. The method mainly comprises the following steps that rosemary dry leaves are crushed and are then put into a water solution; temperature rise distillation is performed for 0.5h; distillates are collected to obtain the rosemary essential oil; after the distillation is completed, eight times of volume of 75-percent ethanol solution is added; extraction is performed for 2h at 60 DEG C; filtering is performed to obtain filtering liquid A; six times of volume of 75-percent ethanol solution is added into filtering slag; extraction is performed for 1h at 60 DEG C; filtering is performed to obtain filtering liquid B; the filtering liquid A andthe filtering liquid B are merged; concentration and centrifugation are performed to obtain a solid part and a water phase part; the water phase part is subjected to concentration spray treatment to obtain the rosemary acid; 60-percent ethanol solution is added into the solid part; after the dissolution, centrifugation is continuously performed and is repeated for three times to obtain the ursolicacid; the liquid part is subjected to concentration drying treatment to obtain the carnosic acid. The extracting method has the advantages that the process is simple; green and environment-friendly effects are achieved; the operation is convenient; the cost is low; the yield is high; the method is suitable for industrial production.

Owner:长沙卫一生物科技有限公司

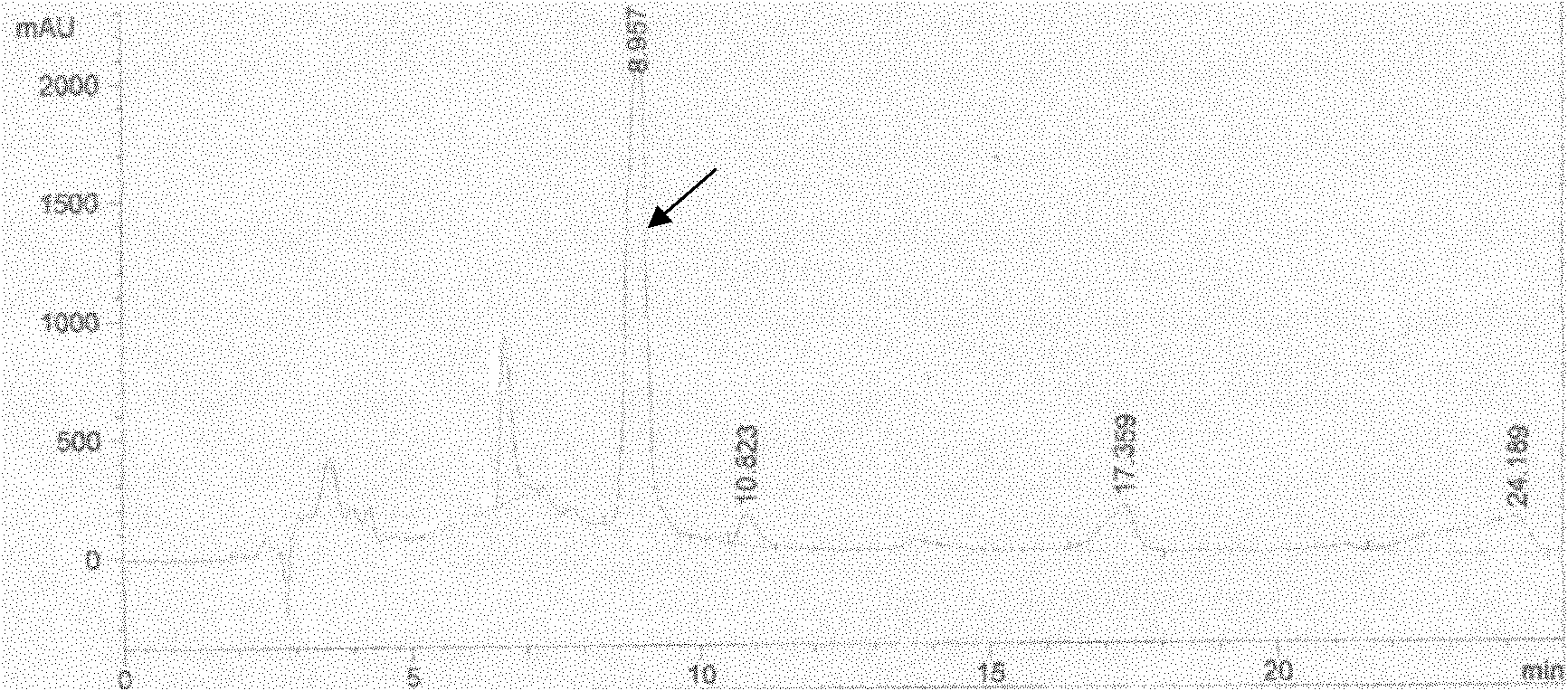

Method for separating carnosic acid from rosemary leaf extract

ActiveCN102115442AGuaranteed stabilityHigh purityCarboxylic compound separation/purificationPhosphoric acidEthyl acetate

The invention discloses a method for separating carnosic acid from a rosemary leaf extract. The method comprises the following steps of: dispersing column chromatography silica gel in a phosphoric acid-ethanol solution, vacuumizing, ultrasonically soaking, recycling ethanol and drying to obtain a phosphoric acid-silica gel stationary phase; filling the phosphoric acid-silica gel stationary phase into a chromatography column tube, imported with high-purity nitrogen for protection, to obtain a phosphoric acid-silica gel chromatography column; and dissolving the rosemary leaf extract in ethyl acetate, adding the phosphoric acid-silica gel stationary phase into the mixture, fully stirring to recycle the ethyl acetate to obtain a stationary phase adsorbing the rosemary leaf extract, adding thestationary phase adsorbing the rosemary leaf extract into the phosphoric acid-silica gel chromatography column, eluting, collecting fractions and performing vacuum drying to obtain carnosic acid. By adopting the method, the carnosic acid is separated independently only by once column chromatography, the column chromatography time is short, the purity is up to 92 percent, and the application of a product in the market is promoted.

Owner:湖南和广生物科技有限公司

Extract of rosmarinus officinalis l. leaves for pharmaceutical applications

ActiveUS20110091580A1Increase antioxidative statusPrevent/alleviate/treat Type diabetesBiocideAnimal repellantsAcute hyperglycaemiaRosmarinus

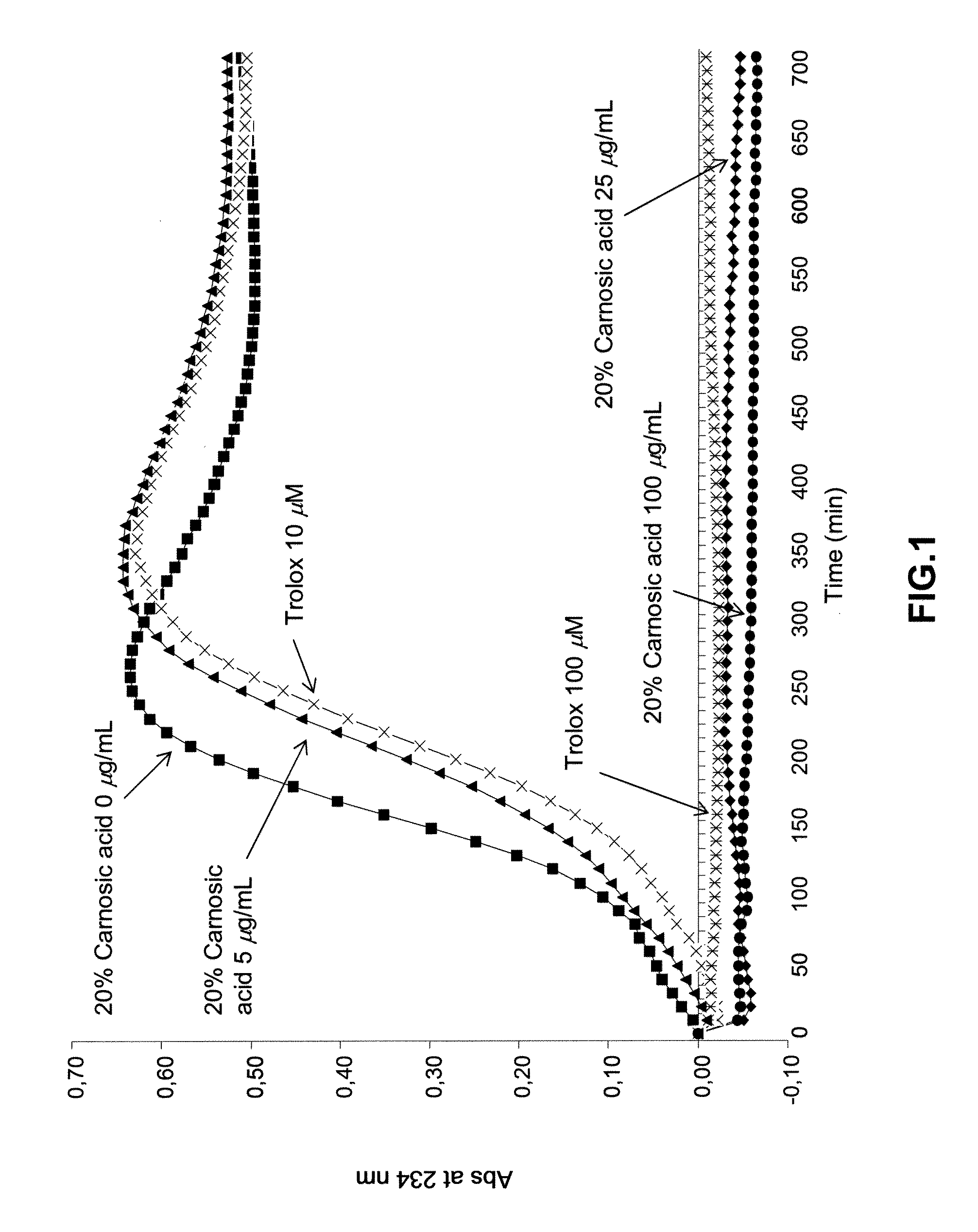

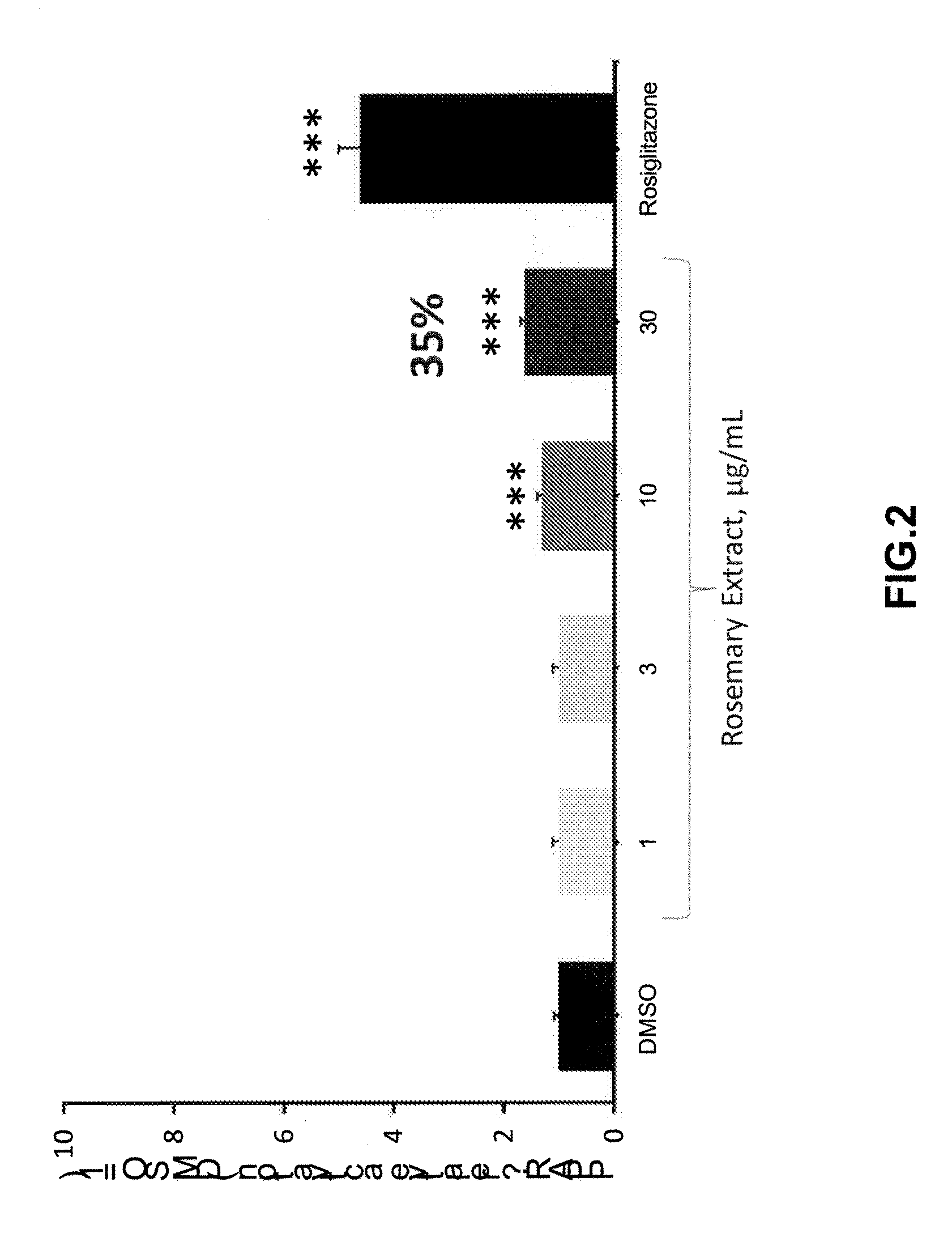

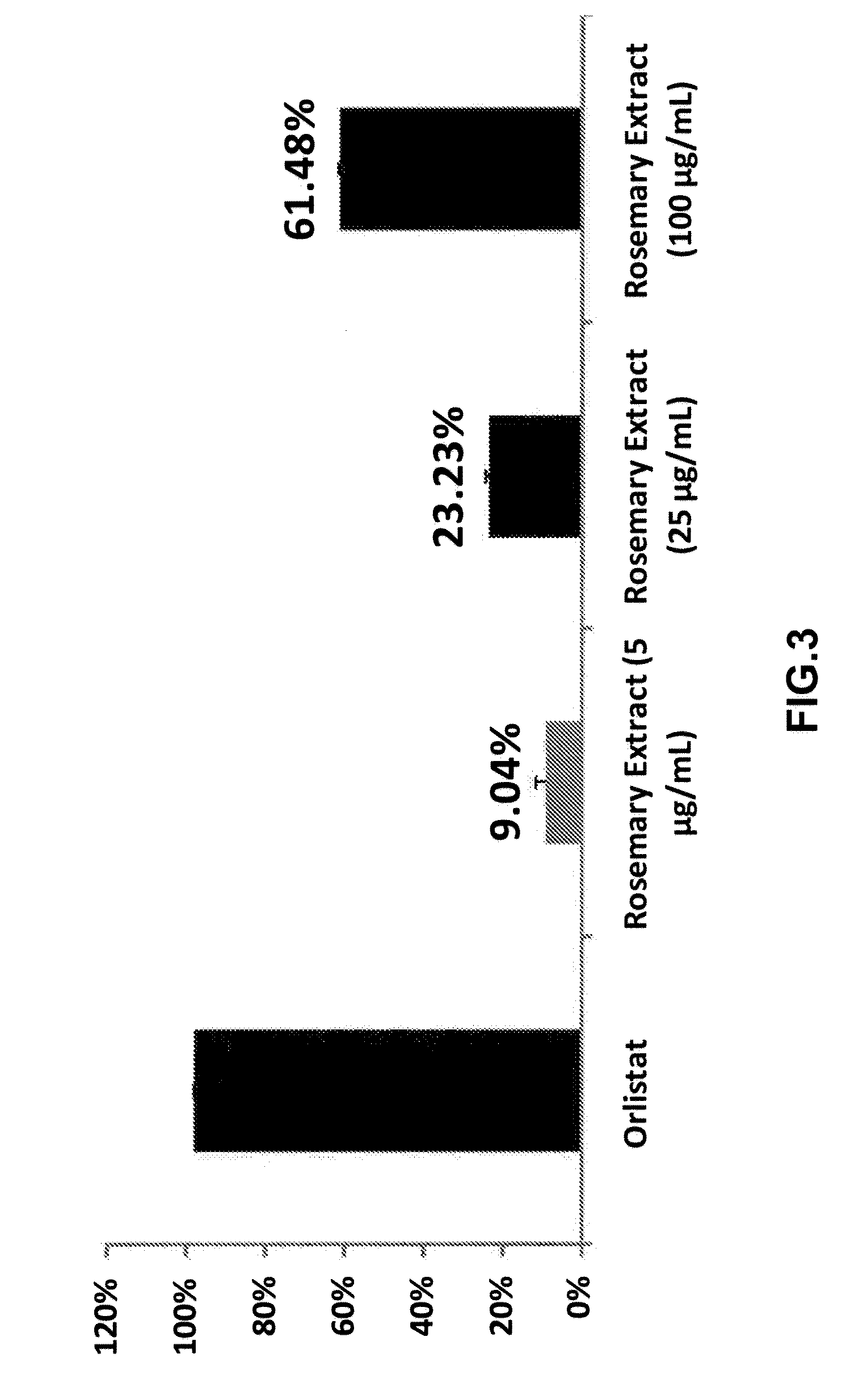

Disclosed are methods of alleviating oxidative stress, regulating blood glucose levels, and controlling pancreatic lipase activity by administering a Rosemary extract. Such methods may be useful to help body weight and body fat, prevent obesity, and treat hyperglycemia, hyperinsulinemia, cardiovascular disease and Type-2 diabetes. Preferred extracts contain 20% or 50% carnosic acid.

Owner:NATUREX INC

Method for separating and purifying carnosic acid from rosemary extract through atmospheric pressure column chromatography

InactiveCN104058955AGet quicklyGet efficientlyCarboxylic compound separation/purificationAcetic acidButyl acetate

Provided is a method for separating and purifying carnosic acid from rosemary extract through atmospheric pressure column chromatography. Silica gel is evenly dispersed though petroleum ether with the volume equal to that of the silica gel at the temperature ranging from 60 DEG C to 90 DEG C and then homogenate wet-method packing is performed, the rosemary extract is dissolved through butyl acetate and then added into a sample, butyl acetate and petroleum ether are mixed according to the volume ratio of 4:1 to 4:10 at the temperature ranging from 60 DEG C to 90 DEG C and serve as eluent, the flow speed is 2 mL / min to 8 mL / min, segmented fraction collection is performed after elution, the fractions of the same content are combined, a chromatography product is obtained through vacuum concentration, and the carnosic acid product with the purity higher than 98% can be obtained. According to the method, a convectional solvent easy to obtain is used, no special high-pressure and high-temperature devices are needed, cost is low, the purifying efficiency is high, and the residual solvent is small and can be recycled easily.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Preparation method of rosemary extracts

PendingCN109232229AIncrease profitImprove transfer rateEssential-oils/perfumesSteroidsDistillationAdditive ingredient

The invention relates to a preparation method of rosemary extracts. The method comprises the following steps of (1) putting dried rosemary raw materials into an extraction tank; performing extractionto obtain rosemary essential oil; (2) adding an ethanol solution; performing back flow extraction, concentration, separation and drying to obtain carnosic acid, ursolic acid and rosmarinic acid products; (3) performing crushing, extraction, concentration and separation on the carnosic acid products to obtain oily products containing carnosic acid; (4) performing molecular distillation separation on the oily products containing carnosic acid to obtain rosemary essential oil and smell-removed carnosic acid oily products. The raw material utilization rate is high; the effective ingredient transfer rate is high; the industrialized production can be easily realized; the carnosic acid oily products prepared by the method have high anti-oxidization active ingredient content, basically have no rosemary smell, and have good market prospects are realized in aspects in edible grease, meat product fresh keeping and corrosion prevention.

Owner:CHANGSHA LANGLIN BIOLOGY PROD

Method for increasing carnosic acid content in rosemary fat-soluble antioxidant

InactiveCN107739305AEasy to separateImprove separation precisionChemical inhibitorsCarboxylic compound separation/purificationOxalateRosmarinus

A method for improving the carnosic acid content in a rosemary fat-soluble antioxidant belongs to the technical field of plant extraction. The method uses rosemary leaves as a raw material, and comprises the following steps of: preparing a rosemary extract, preparing a carnosic acid crude extract, preparing a carnosic acid refined solution, preparing a carnosic acid eluent, preparing a rosemary extract refined product and preparing a regenerated D370R or D315 anion exchange resin column, thereby preparing a rosemary extract refined product with the carnosic acid content exceeding 90%. In the method provided by the invention, a ceramic membrane is used for separating macromolecular impurities in the rosemary extract, and D370R or D315 weakly basic anion exchange resin is used for separatingand purifying carnosic acid in the rosemary extract, so that the separation specificity is strong, the separation efficiency is high, and the yield is high; the rosemary waste leaves and other byproducts generated in an implementation process are subjected to deep processing treatment, thus realizing comprehensive utilization and environmental protection; and the operation condition is mild, theproduction cost is low, and the prepared product can be widely applied to the fields of food, health products, medicines and the like.

Owner:HUNAN XINLI BIOLOGICAL SCI & TECH +1

Peel-off coix seed mask and preparation method of mask

InactiveCN103356420AFade fine linesElasticityCosmetic preparationsToilet preparationsCocoyl glutamateGlycerol

The invention discloses a peel-off coix seed mask and a preparation method of the mask. The peel-off coix seed mask disclosed by the invention is prepared from the following raw materials in parts by weight according to a conventional method: 10-14 parts of polyvinyl alcohol, 8-12 parts of glycerol, 0.8-1.2 parts of disodium cocoyl glutamate, 4-6 parts of alcohol, 6-8 parts of disodium lauramido PEG-2 sulfosuccinate, 0.8-2 parts of coix seed extract, 0.03-0.08 part of a compound antiseptic and 100 parts of de-ionized water, wherein the compound antiseptic consists of 1-3 parts of carnosic acid, 3-5 parts of antioxidant of bamboo, 1-3 parts of nisin and 1-3 parts of iodopropynyl butylcarbamate. The peel-off coix seed mask disclosed by the invention can be used for removing stains, eliminating plane warts and softening skin.

Owner:汉皇印象江苏生物科技股份有限公司

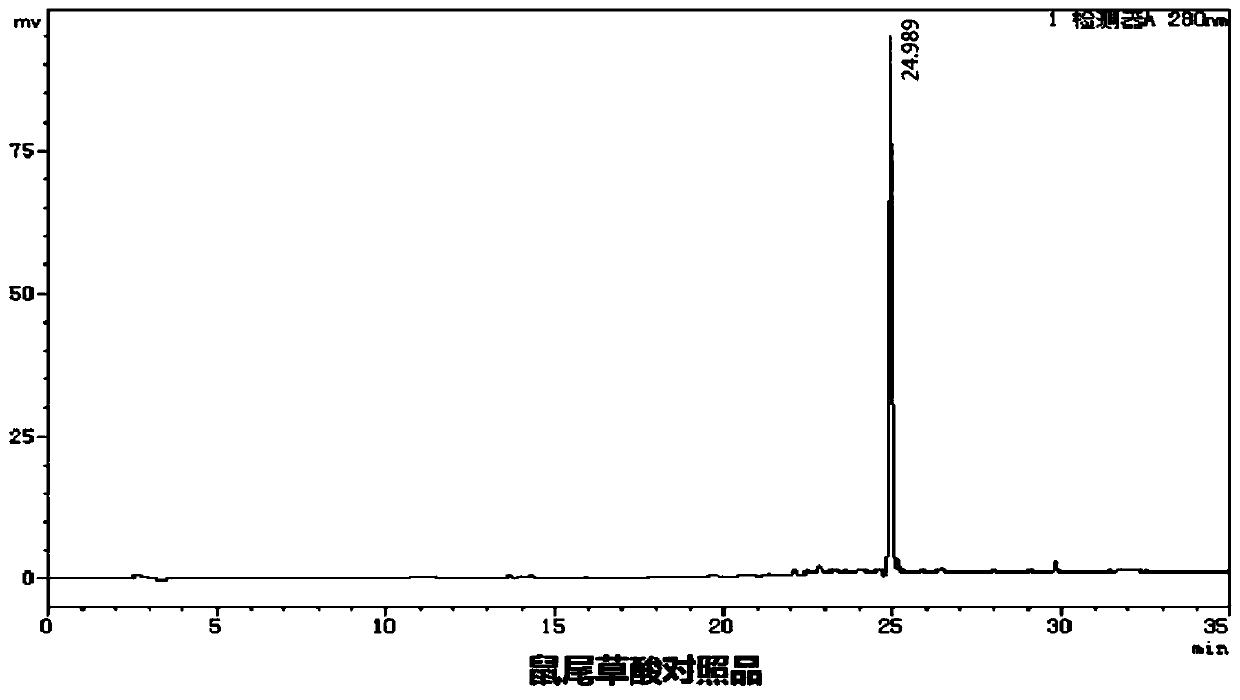

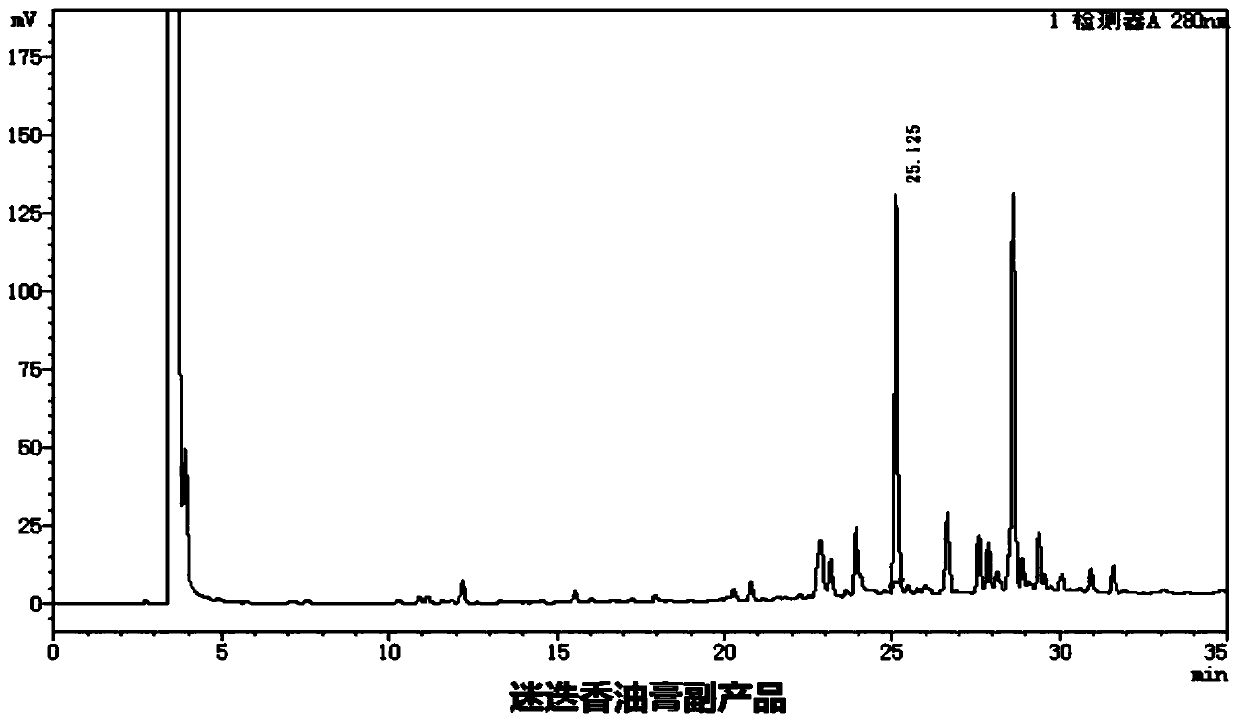

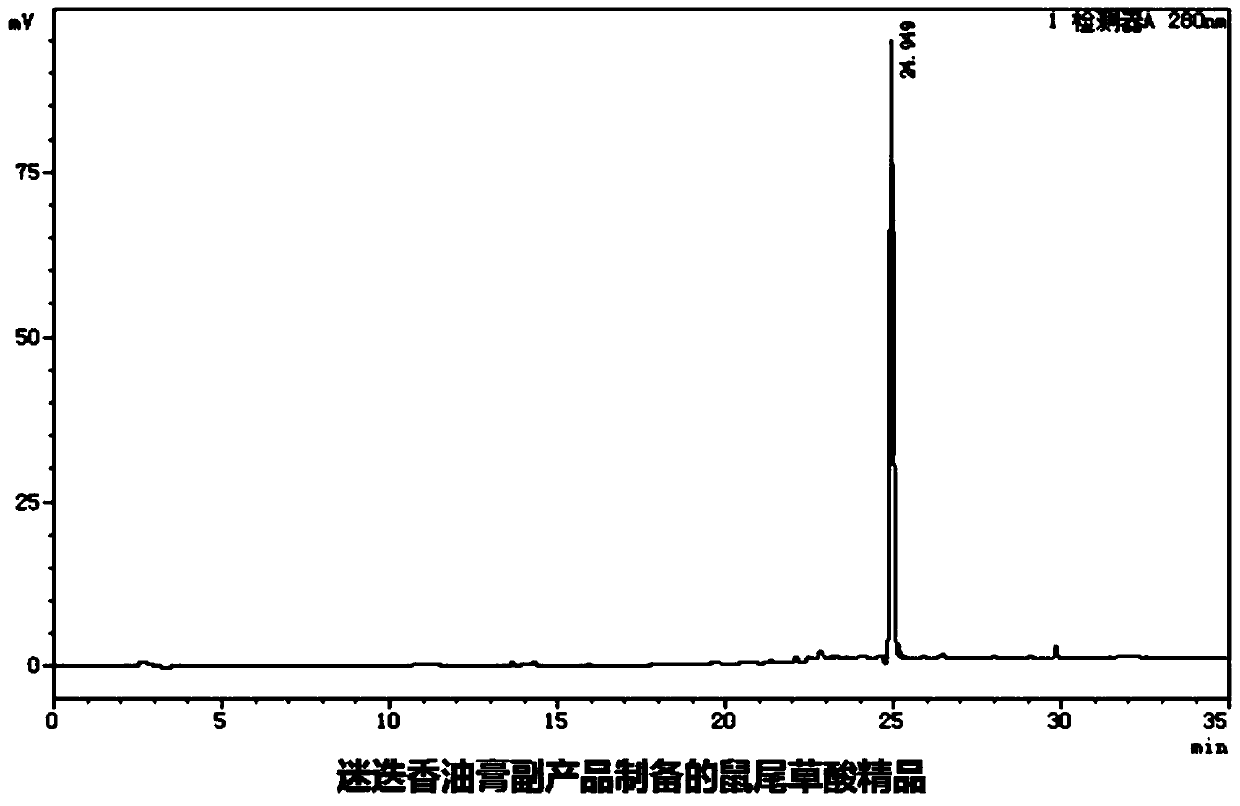

Method for preparing high-purity carnosic acid from rosemary oil paste byproduct

ActiveCN110845328AEasy to operateHigh yieldCarboxylic compound separation/purificationAgainst vector-borne diseasesActivated carbonProcess engineering

The invention discloses a method for preparing carnosic acid from a rosemary oil paste byproduct, and the method comprises the following steps: preparing an R67 extract, preparing the rosemary oil paste byproduct, preparing rosemary oil paste particle powder, carrying out solid-liquid extraction on the rosemary oil paste powder, concentrating the extract, and crystallizing to prepare crude carnosic acid dry powder, remove impurities from the crude carnosic acid product by activated carbon adsorbing, and refining carnosic acid to prepare a carnosic acid product with carnosic acid content of 95-98%. The method has the characteristics of simplicity in operation, high efficiency, recyclability of the extract, environmental friendliness, high product yield and the like.

Owner:湖南德诺贝莱健康产业有限公司

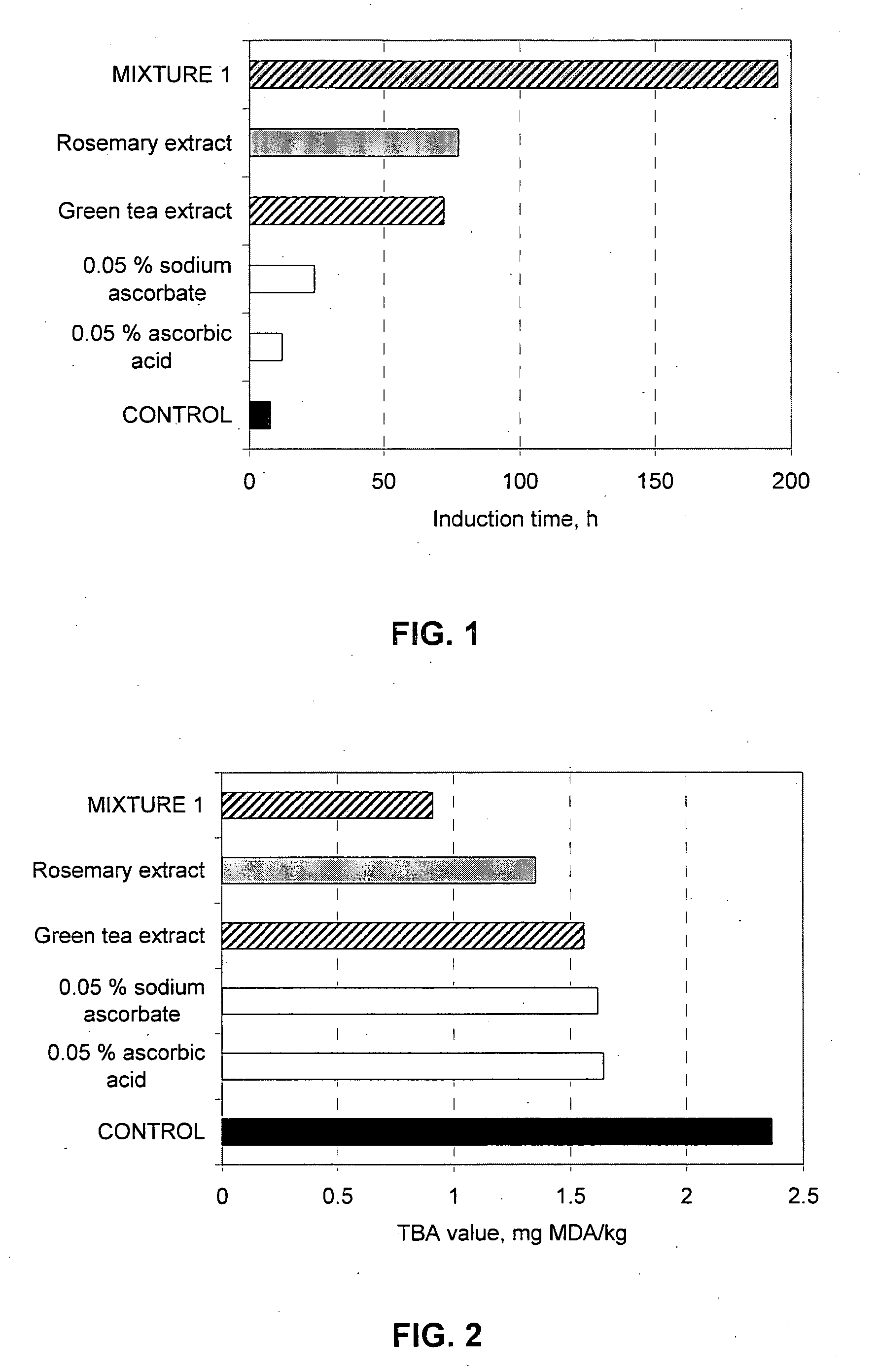

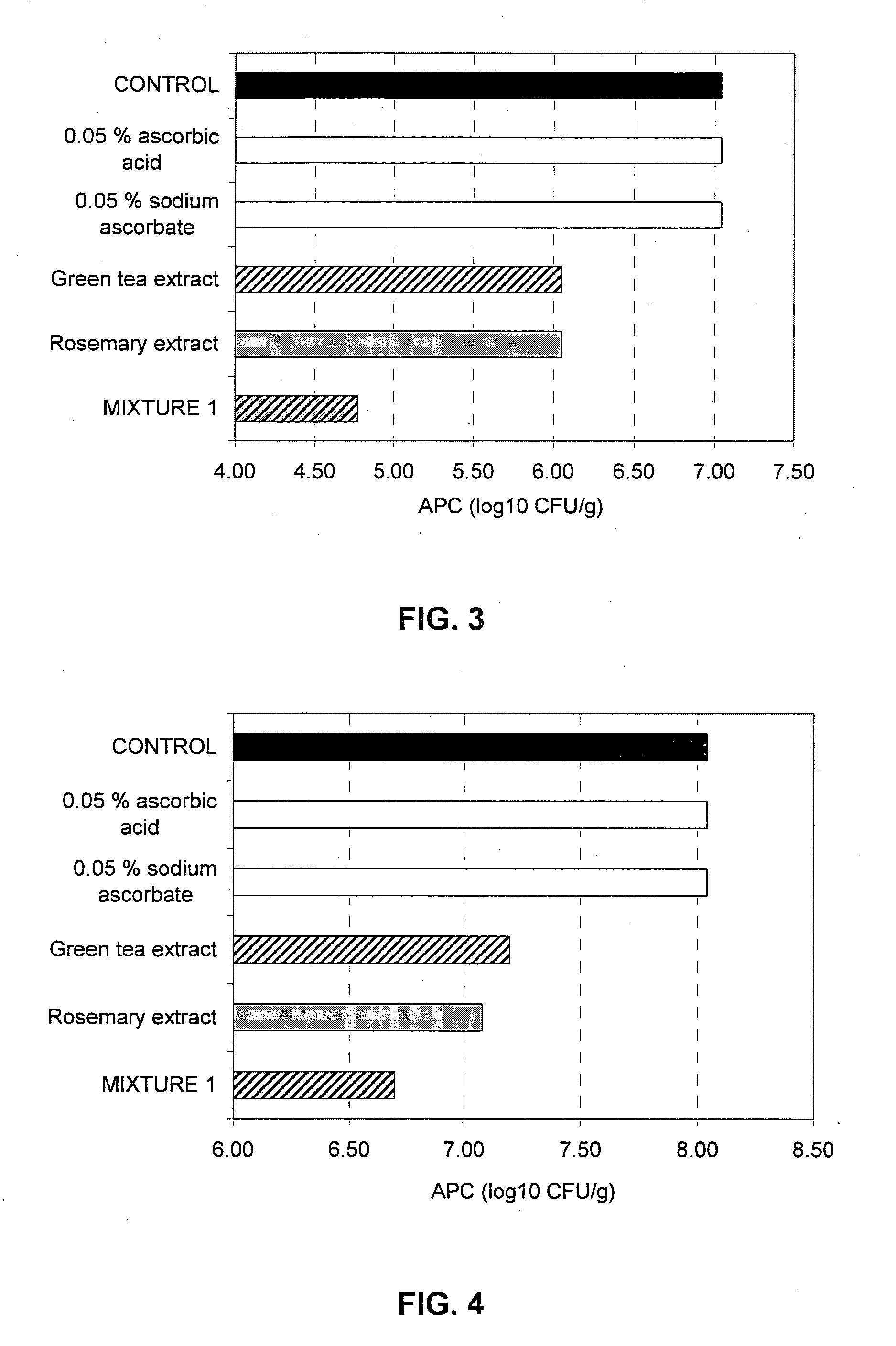

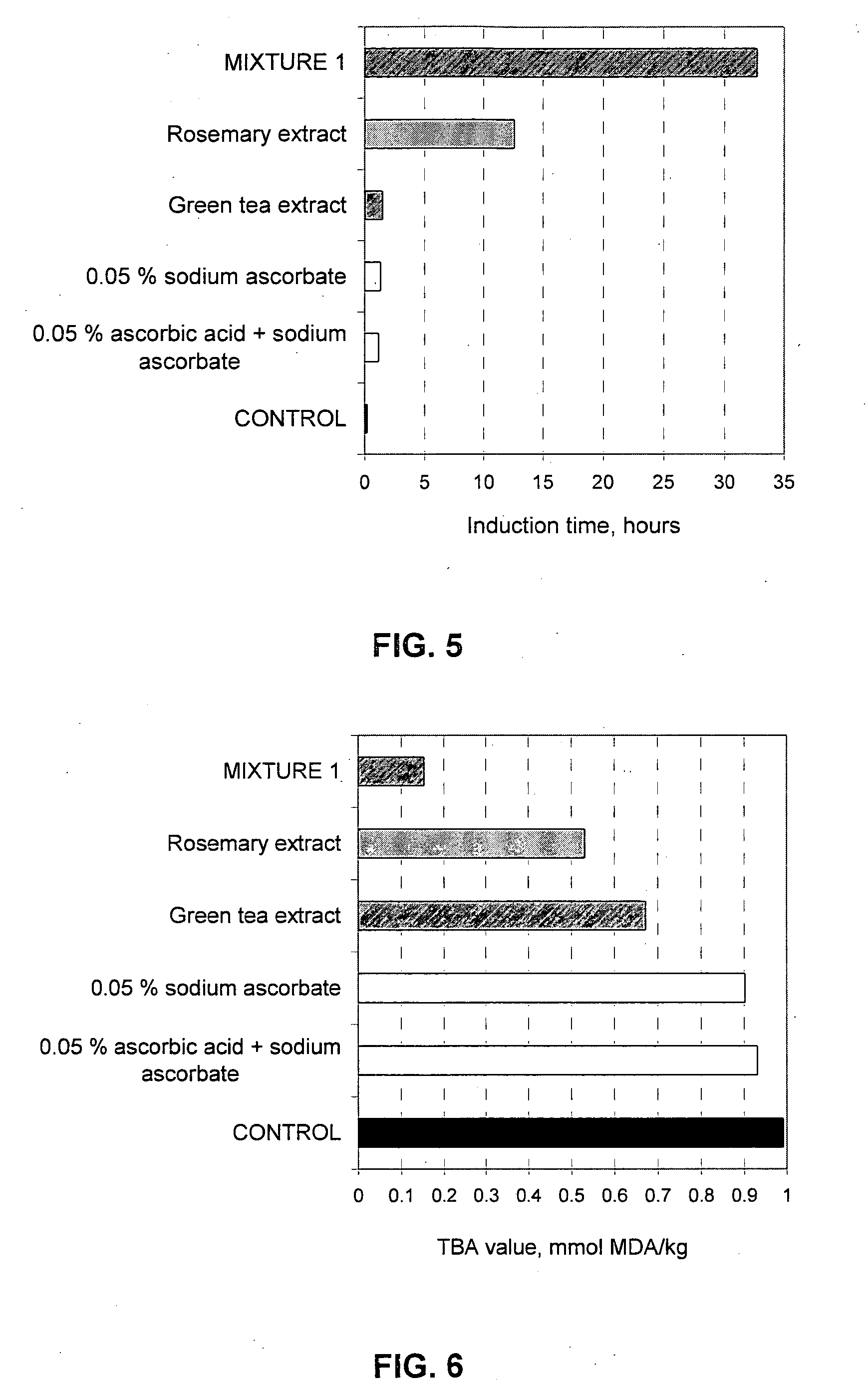

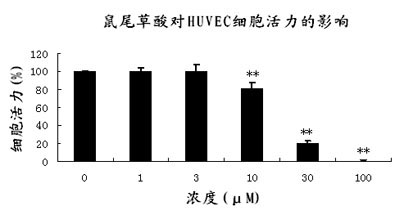

Antioxidative and antimicrobiological protection of fats and foodstuffs containing fats with a mixture of labiatae and green tea extracts

InactiveUS20100203213A1Fatty substance preservation using additivesEdible oils/fatsMicroorganismGreen tea extract

The antioxidative and microbialogical protection of fats and foodstuff comprising fats, such as, meat, meat products, fish and fish products, is achieved by the addition of a mixture, based on the extract of at least one plant from the Labiatae family and green tea extract, wherein the mixture has synergistic effect to the fats / foodstuff comprising fats. The active substances in the mixture may be carnosic acid, rosmarinic acid and epigallocatechin-gallate. The mixture may comprise 0 to 50% of each of those substances, wherein the amount of the existing substances in the final product is at least 1 ppm.

Owner:VITIVA D D

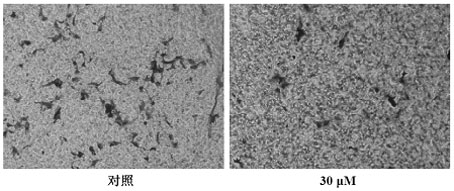

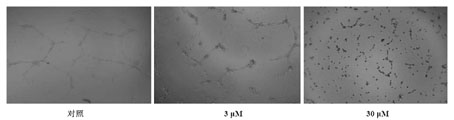

Application of carnosic acid in preparing medicament for suppressing angiogenesis

InactiveCN102058570AHas anti-angiogenic activityPrevent proliferationOrganic active ingredientsSenses disorderDiseaseArthritis

The invention relates to application of carnosic acid in preparing a medicament for suppressing angiogenesis. The invention has the advantages that: the novel application of the carnosic acid discovers the effect of the carnosic acid in resisting angiogenesis for the first time, and the carnosic acid can effectively suppress proliferation, migration and canaliculization of vascular endothelial cells for the first time, which proves that the carnosic acid has the activity of resisting the angiogenesis, can be used as an angiogenesis suppressant, and can be applied to preparation of angiogenesis medicaments as the angiogenesis suppressant to treat neovascularization dependent and neovascularization related diseases, such as tumors, arthritis, psoriasis, ocular diseases, atherosclerosis, and the like.

Owner:SHANGHAI JIAOTONG UNIV SCHOOL OF MEDICINE

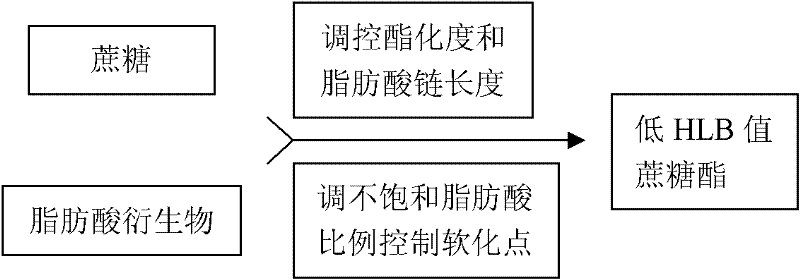

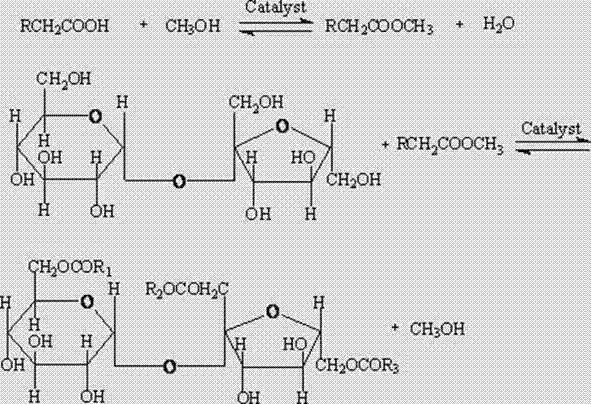

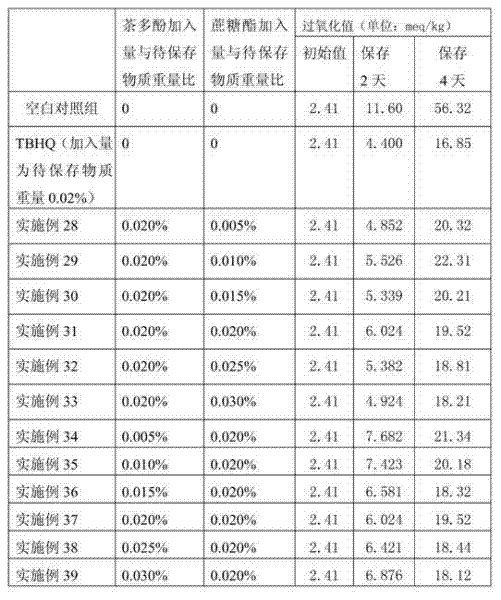

Production method of sucrose ester and use thereof in preparation of special antioxidant for oil

ActiveCN102533454AOptimize and simplify the purification processShort processFatty acid esterificationEdible oils/fatsChemical synthesisSucrose

The invention relates to a production method of sucrose ester with low HLB (Hydrophile-Lipophile Balance) and use thereof in preparation of a special antioxidant for oil. The production method of the invention comprises the following steps: (1) adding tea seed oil, methanol and concentrated sulfuric acid to synthesize tea seed oil fatty acid methyl ester; (2) adding KOH solution, stearic acid, cane sugar, a catalyst and methyl palmitate and mixing with the tea seed oil fatty acid methyl ester, and preparing sucrose fatty acid ester with high degree of substitution by an ester exchange method;adding absolute ethyl alcohol to reflow so as to separate and purify the sucrose fatty acid ester, completely removing the catalyst and the un-reacted raw materials by petroleum ether, and removing the petroleum ether to obtain the available sucrose ester. The sucrose ester with low HLB value prepared by the invention is compounded with vitamin E, carnosic acid or tea polyphenol, and can be used for producing a natural oil antioxidant with excellent production property and replacing a chemical synthesis oil antioxidant to be forbidden.

Owner:LIUZHOU GAOTONG FOOD CHEM

Method for extracting antioxidant components from rosmarinus officinalis

ActiveCN110283226AIncrease profitHigh content of active ingredientsSteroidsCarboxylic acid esters separation/purificationRosmarinusUrsolic acid

The invention belongs to the field of rosmarinus officinalis extraction, in particular to a method for extracting antioxidant components from rosmarinus officinalis. The method for extracting the antioxidant components from the rosmarinus officinalis comprises the following steps: using a solvent to extract the rosmarinus officinalis, concentrating an extracting solution, centrifuging and collecting a centrifuged supernatant and centrifuged precipitate respectively, and performing macroporous resin purification, concentration and drying on the centrifuged supernatant to separate out rosmarinic acid; dissolving the centrifuged precipitate, using trapped fluid obtained by organic nanofiltration to separate out ursolic acid and oleanolic acid, and using membrane passing liquid obtained by the organic nanofiltration to separate out carnosic acid and carnosol. According to the method provided by the invention, water-soluble and fat-soluble antioxidant components such as the rosmarinic acid, the ursolic acid, the oleanolic acid, the carnosic acid, and the carnosol can be extracted simultaneously, so that the utilization rate of the rosmarinus officinalis is improved.

Owner:GUILIN NATURAL INGREDIENTS CORP

Preparation process for rosemary extract

ActiveCN105949057AAvoid compromising qualityEfficient extractionEssential-oils/perfumesSteroidsUrsolic acidImpurity

The invention provides a preparation process for rosemary extract. The preparation process comprises the following steps: drying and crushing a rosemary plant; adding the obtained rosemary powder into an extraction tank for extraction of rosemary essential oil; then adding an ethanol solution with a concentration of 65% into the extraction tank for further extraction, delivering extracted material liquid into a concentrator for concentration, recovering ethanol, then carrying out centrifugation, transferring extracted liquid to a resin column, carrying out elution by using an ethanol solution with a concentration of 70%, collecting rosemary material liquid, delivering the rosemary material liquid to the concentrator for concentration, and then carrying out drying so as to obtain 20 to 40% of rosmarinic acid crystal; subjecting residues obtained after centrifugation to elution with petroleum ether so as to remove fat-soluble impurities and carrying out extraction so as to obtain 50 to 95% of dry ursolic acid powder; and successively carrying out separation, extraction and transferring to the resin column so as to obtain 20 to 60% of dry carnosic acid powder. The preparation process can produce a plurality of products like the rosemary essential oil, the rosmarinic acid crystal, the dry ursolic acid powder and the dry carnosic acid powder at the same time.

Owner:张星增

Long-acting water-based antirust agent and preparation method thereof

The invention discloses a long-acting water-based antirust agent. The long-acting water-based antirust agent is characterized in that the long-acting water-based antirust agent is prepared from the following raw materials in parts by weight: 8 to 12 parts of beta-cyclodextrin, 3 to 5 parts of hydroxypropyl methyl cellulose, 2 to 4 parts of rosin, 0.5 to 1 part of methyl salicylate, 1 to 2 parts of xanthan gum, 0.5 to 1 part of sodium lignin sulfonate, 0.5 to 1 part of sodium methylene bis-m-naphthalene sulfonate, 0.5 to 1 part of rosin-polythylene oxide ester, 6 to 8 parts of a performance additive, 0.05 to 0.1 part of carnosic acid, 0.1 to 0.2 part of sodium benzoate, and 40 to 50 parts of water. The antirust agent provided by the invention has the characteristics of safety and environment friendliness, has certain slow-release effect, and can protect metal products for a long time; a formed film is highly stable, and has a certain tolerance for salt-spray environments and hygrothermal environments.

Owner:HEFEI DAAN PRINTING

Peel-off ginseng mask and preparation method of mask

InactiveCN103356425AReduce dosageExtended shelf lifeCosmetic preparationsToilet preparationsGlycerolGINSENG EXTRACT

The invention discloses a peel-off ginseng mask and a preparation method of the mask. The peel-off ginseng mask is prepared from the following raw materials in parts by weight according to a conventional method: 10-14 parts of polyvinyl alcohol, 8-12 parts of glycerol, 0.8-1.2 parts of polysorbate-60, 4-6 parts of alcohol, 6-8 parts of lauryl glucoside, 0.8-2 parts of ginseng extract, 0.03-0.08 part of a compound antiseptic and 100 parts of de-ionized water, wherein the compound antiseptic consists of 1-3 parts of carnosic acid, 3-5 parts of antioxidant of bamboo, 1-3 parts of nisin and 1-3 parts of iodopropynyl butylcarbamate. The peel-off ginseng mask disclosed by the invention can be used for deeply nourishing skin, promoting the blood circulation of skin, improving roughness and lackluster of skin, activating and brightening skin, so that the skin is ruddy and lustrous.

Owner:汉皇印象江苏生物科技股份有限公司

Preparation method of rosemary extract

ActiveCN107513095AImprove dissolution efficiencyEase subsequent separationOrganic compound preparationSteroidsUrsolic acidRosmarinus

The invention discloses a preparation method of a rosemary extract. The method comprises the steps of S1, taking rosemary branches and leaves as raw materials and extracting carnosol, carnosic acid and ursolic acid at the same time to obtain an extracting solution I; S2, concentrating the extracting solution I to obtain a concentrated solution; S3, adding water into the concentrated solution for dilution to obtain turbid liquid; S4, treating the turbid liquid by an alkali dissolution process to obtain an extracting solution II and an extract I containing the ursolic acid; S5, treating the extracting solution II by adopting an acid sediment process to obtain an extract II containing the carnosol and the carnosic acid, thus realizing the synchronous extraction and separation of the extract containing the carnosol and the carnosic acid and the extract containing the ursolic acid.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

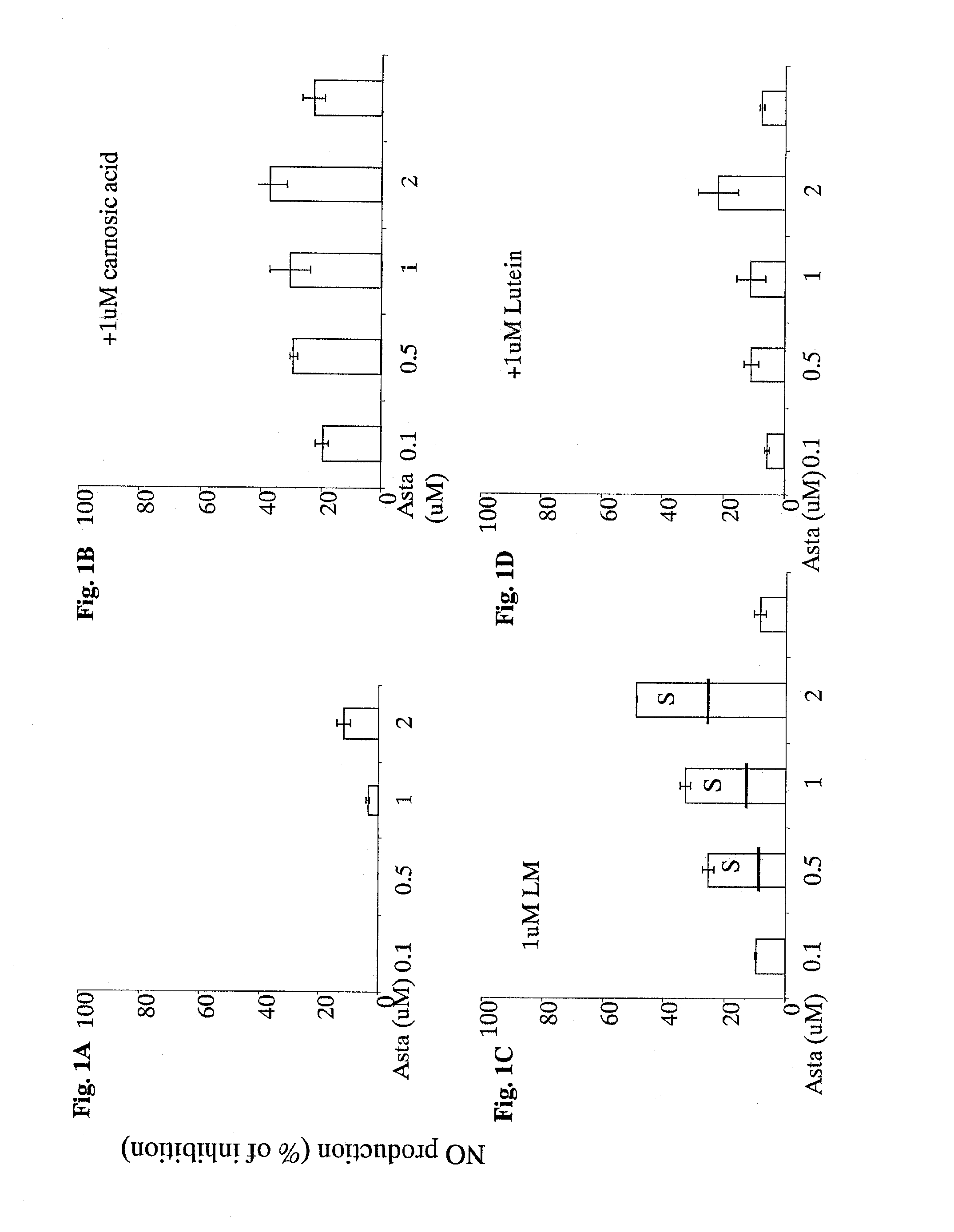

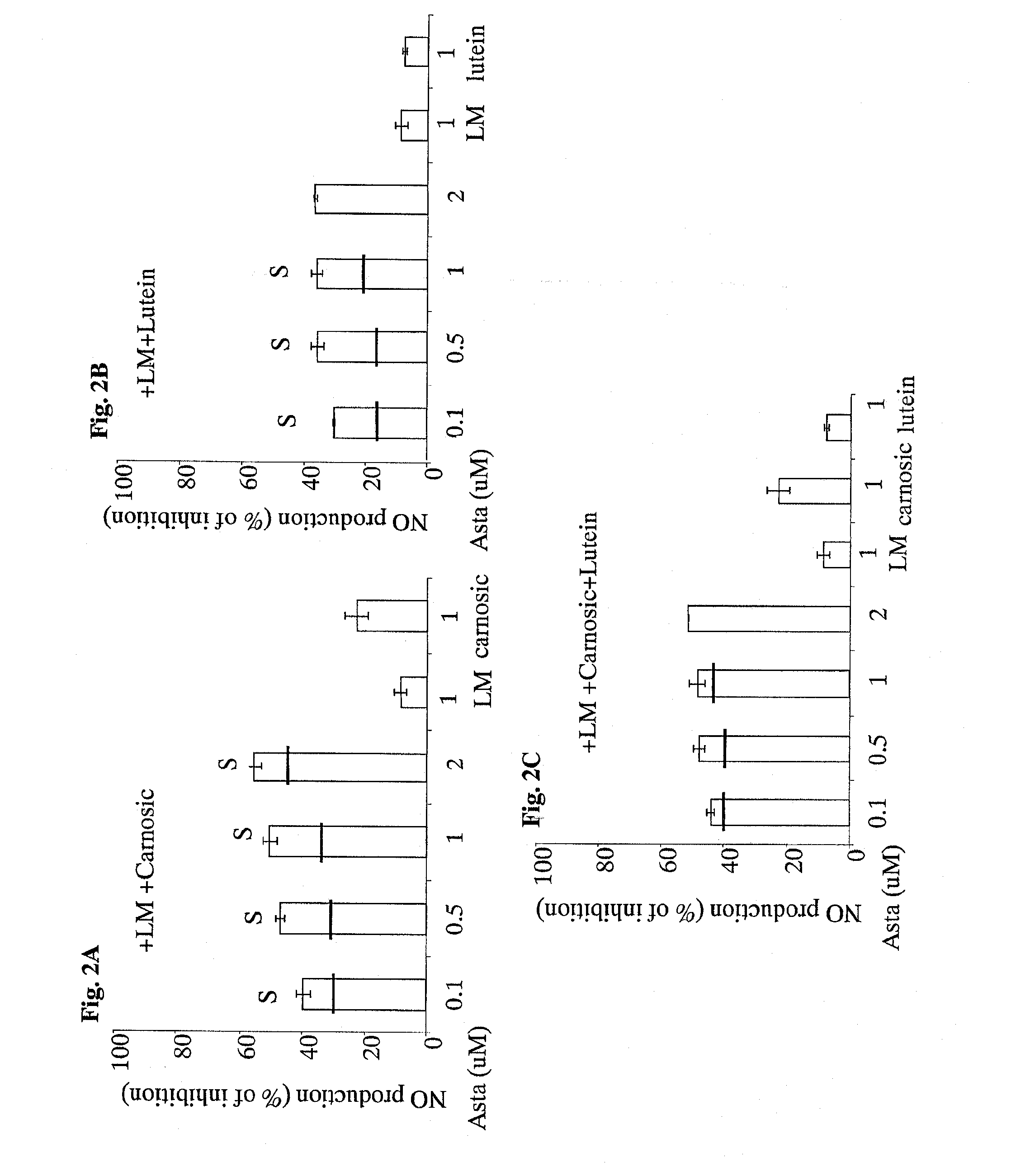

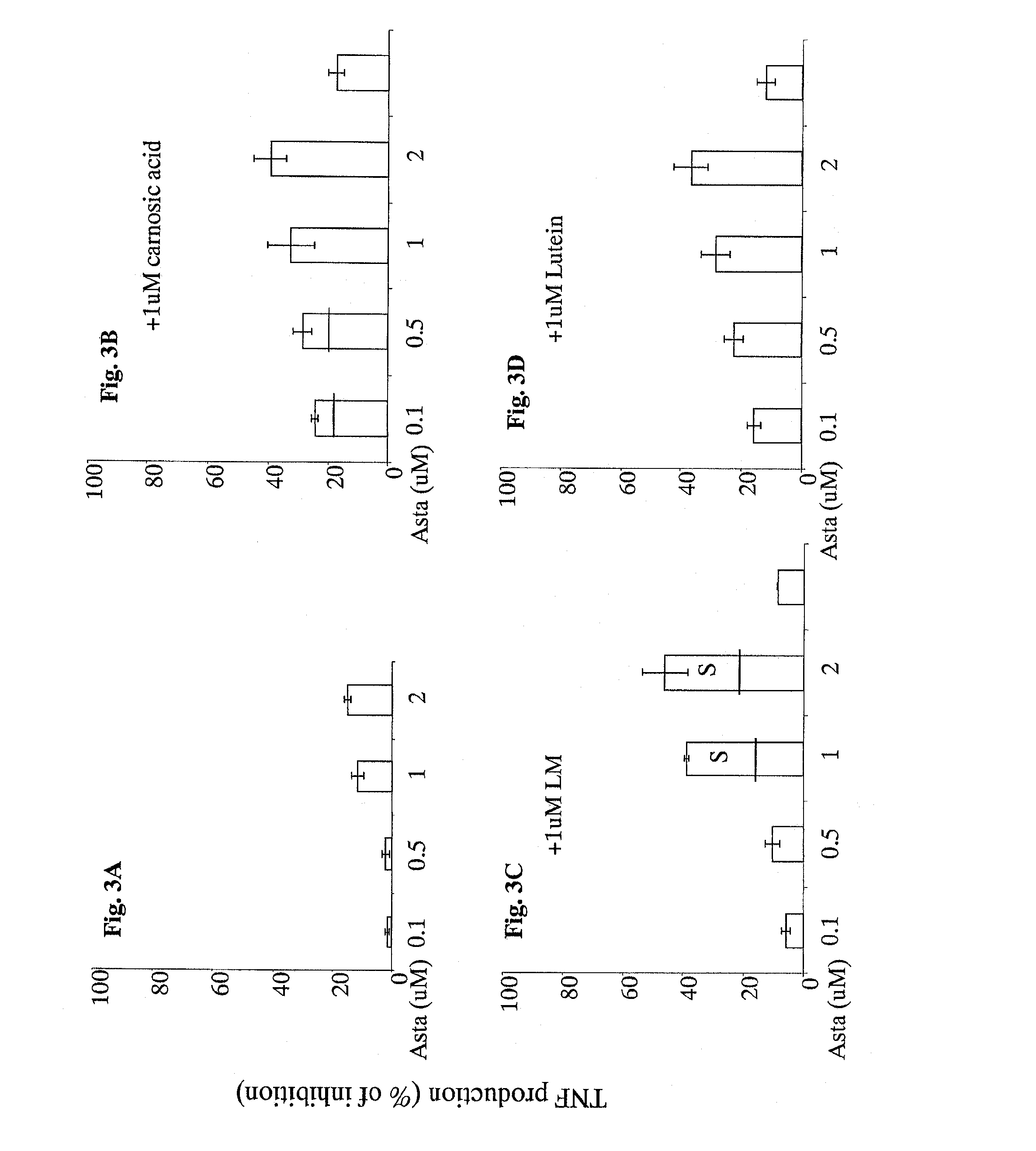

Astaxanthin anti-inflammatory synergistic combinations

ActiveUS9468609B2Synergistic effectHydrocarbon active ingredientsHydroxy compound active ingredientsInflammation mediatorsLutein

This invention is directed to compositions having synergistic combinations of astaxanthin with a tomato extract lycopene, and optionally with carnosic acid and / or lutein. More specifically, the present invention provides compositions having synergistic combinations of the aforementioned compounds, which may be used, inter alia, to inhibit / suppress inflammation via the suppression of the expression of anti-inflammatory mediators or via the suppression of the secretion of anti-inflammatory mediators from macrophages at a site of inflammation.

Owner:LYCORED

Bletilla striata-added skin-whitening facial mask and preparation method thereof

InactiveCN105496895ALess irritatingMild performanceCosmetic preparationsToilet preparationsWrinkle skinBletilla striata

The invention discloses a bletilla striata-added skin-whitening facial mask and a preparation method thereof. The facial mask is prepared according to a conventional method from the following raw materials in parts by weight: 10-14 parts of polyvinyl alcohol, 8-12 parts of glycerinum, 0.8-1.2 parts of disodium cocoyl glutamate, 4-6 parts of ethanol, 6-8 parts of lauramido PEG-2 disodium sulfosuccinate, 0.8-2 parts of bletilla striata extract, 1-3 parts of carnosic acid, 3-5 parts of bamboo leaf antioxidant, 1-3 parts of nisin, 1-3 parts of iodopropynyl butylcarbamate and 100 parts of deionized water. The bletilla striata-added skin-whitening facial mask has mild performance and low skin irritation, and has the effects of removing couperose skin, whitening skin, removing wrinkles and tendering skin especially after the bletilla striata extract is added.

Owner:万嘉裕

Method for preparing carnosic acid-rich liquid extract

InactiveCN102070440AReduce contentAvoid destructionFood preparationCarboxylic compound separation/purificationSolubilityVegetable oil

The invention discloses a method for preparing a carnosic acid-rich liquid extract, wherein the extract can be extracted from an acidic ethanol solution; and an active substance is transferred into a vegetable oil phase, then subjected to a series of high-speed refrigerated centrifuge and then dried, thus preparing the extract. The extract prepared by the method is rich in the main anti-oxidationactive substance of rosemary, and can be added directly to various oil and fat type foods when being utilized as a food antioxidant. The extract extracted by the method provided by the invention has the characteristics of good oil solubility, light color, good storage stability and the like, and can be applied to various oil and fat products without additionally adding an emulsion stabilizer.

Owner:GUANGDONG FOOD IND INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com