Method for preparing carnosic acid-rich liquid extract

A carnosic acid and extract technology, applied in the field of food chemical industry, can solve problems such as borate residues, unfavorable large-scale production, food safety hazards, etc., to reduce the content of impurities, ensure storage stability, and avoid precipitation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Take 200g of rosemary dry powder, add 1.6L of 70% by volume ethanol aqueous solution (add hydrochloric acid to adjust pH=3), stir and extract at room temperature for 3 hours, obtain 1.45L of filtrate after filtration, add 48g of soybean oil, after fully stirring Transfer to a rotary evaporator and concentrate under reduced pressure at 40°C until all the ethanol is evaporated. After filtration, about 58g of brown extract is obtained, add 480mL of water, mix well, transfer to a refrigerated centrifuge, and adjust the temperature to 1.5 Centrifuge at 8000rpm for 30min, separate the oil layer and continue to add 480mL of water, separate the oil layer after centrifugation, repeat the above operation once, add 0.5g of anhydrous sodium sulfate to the separated oil layer, mix well, and siphon the upper layer The oily layer obtained 55 g of light brown oily extract, wherein the content of carnosic acid was 15%.

Embodiment 2

[0034] Take 200g of rosemary dry powder, add 1.6L of 60% by volume ethanol aqueous solution (add acetic acid to adjust pH=5), stir and extract at room temperature for 2 hours, obtain 1.52L of filtrate after filtration, add 64g of sunflower oil, and stir thoroughly Then transfer to a rotary evaporator and concentrate under reduced pressure at 65°C to evaporate ethanol, obtain about 72g of light brown extract after filtration, add 640mL of water, mix well and transfer to a refrigerated centrifuge, adjust the temperature to 5°C, Centrifuge at 10,000rpm for 10min, separate the oil layer and continue to add 640mL of water, centrifuge to separate the oil layer, repeat the above operation once, add 0.5g anhydrous magnesium sulfate after separating the oil layer, mix well, and siphon the upper oil layer, Obtained 68g of light yellow oily extract, wherein the content of carnosic acid was 12.5%.

Embodiment 3

[0036] Take 50g of rosemary dry powder, add 500mL of 50% by volume ethanol aqueous solution (add acetic acid to adjust pH = 3), stand at room temperature for extraction for 3 hours, filter to obtain 475mL of filtrate, add 25g of soybean oil, stir well and transfer Concentrate under reduced pressure in a rotary evaporator at 50°C to remove ethanol, filter to obtain about 31g of a light brown extract, add 250mL of water, mix well, transfer to a refrigerated centrifuge, adjust the temperature to 3°C, and set at 9000rpm Centrifuge for 20 minutes, separate the oil layer and continue to add 250mL of water, centrifuge to separate the oil layer, repeat the above operation once, separate the oil layer, add 0.3g of anhydrous sodium sulfate, mix well, and siphon the upper oil layer to obtain light yellow 29g of oily extract, wherein the content of carnosic acid is 13%.

[0037] Determination and application of carnosic acid content in the second part of the extract

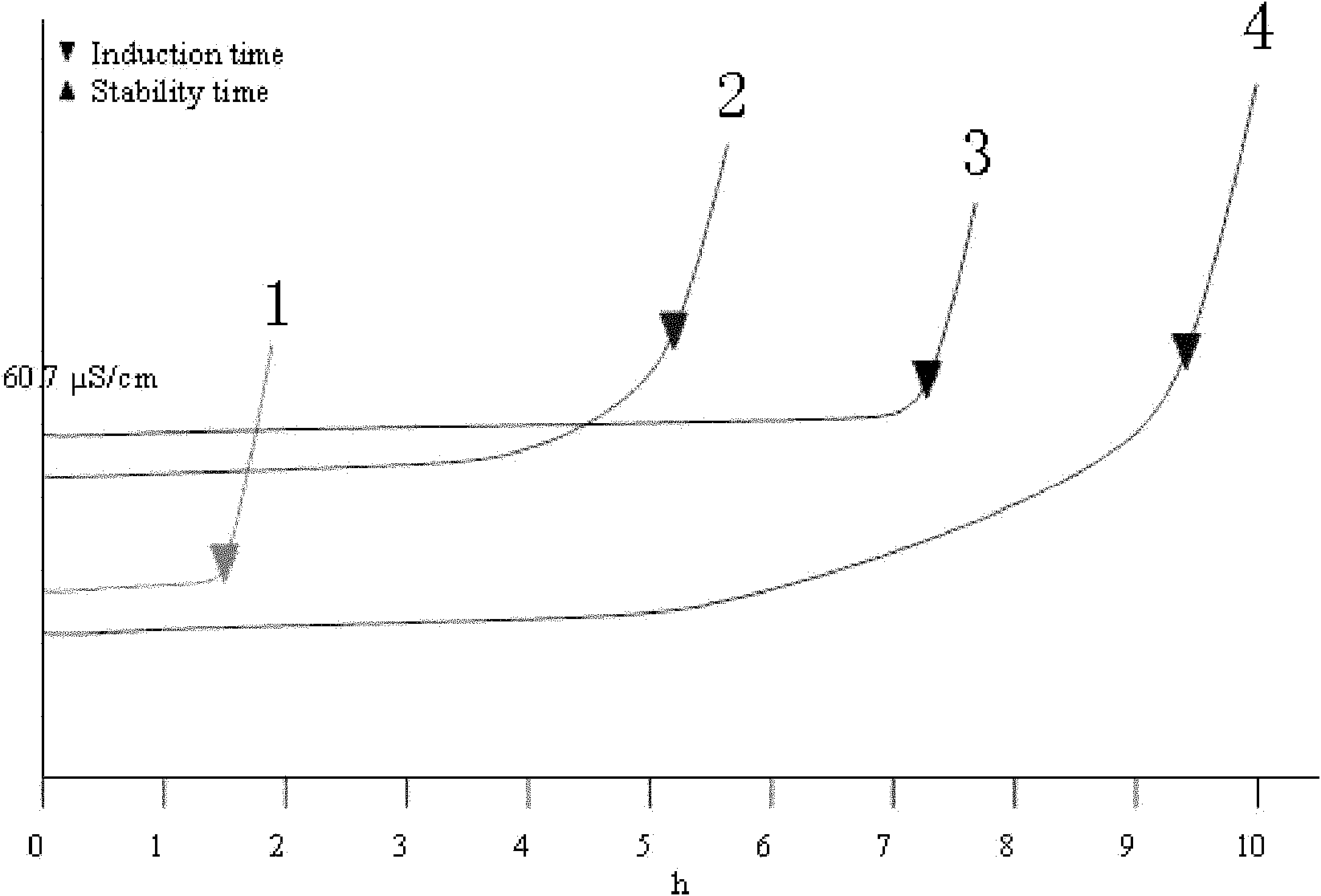

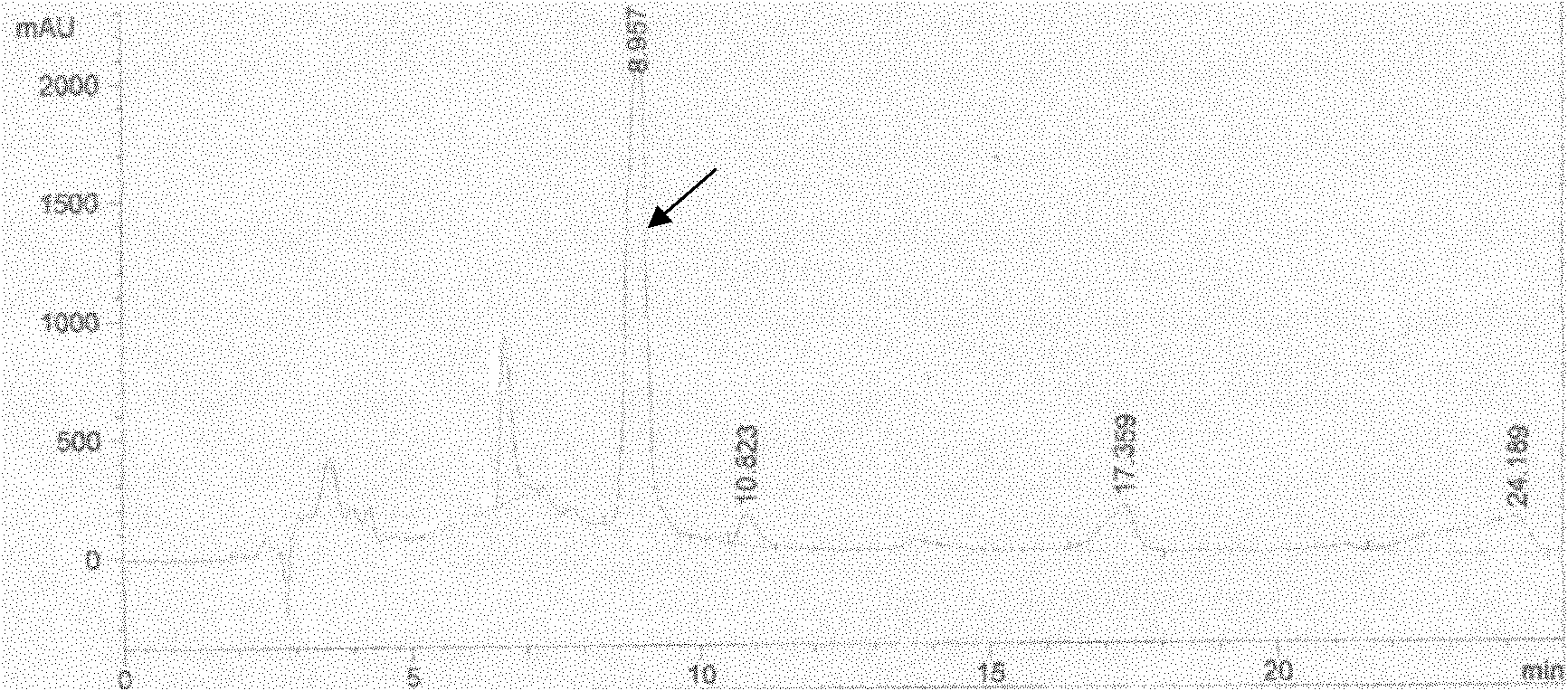

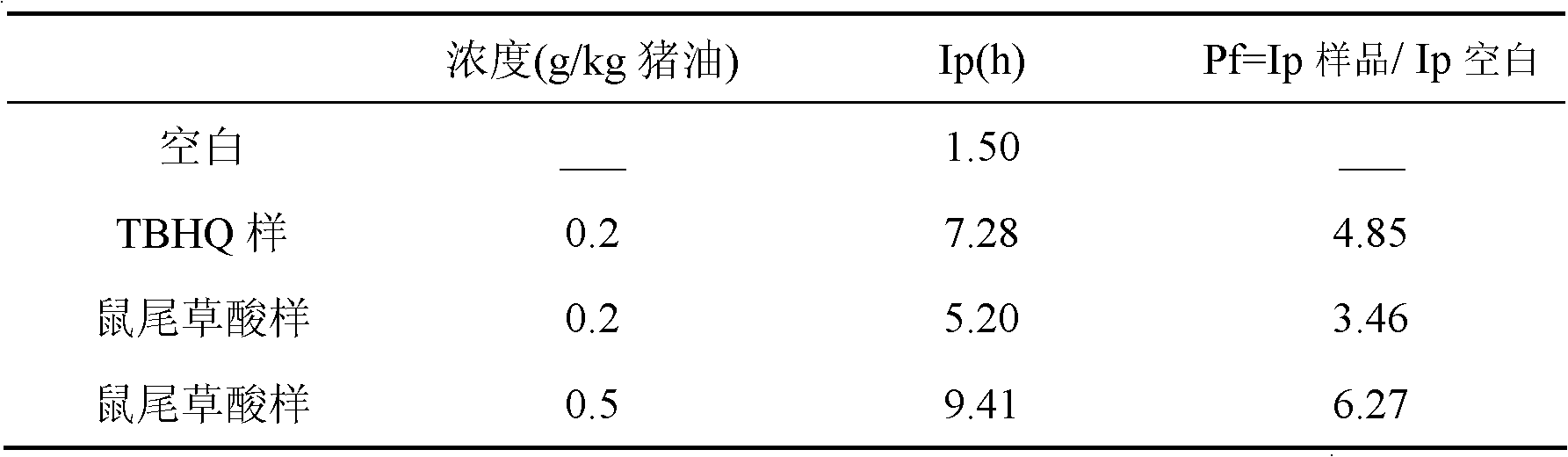

[0038] 2.1 Determin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com