Method for extracting and separating rosemary essential oil, rosemary acid, ursolic acid and carnosic acid from rosemary leaves

A technology of rosemary essential oil and rosmarinic acid, which is applied in the fields of essential oils/perfumes, chemical instruments and methods, separation/purification of carboxylic acid esters, etc., can solve the problems of high cost, poor health of operators, and poor external environment, process complex and other issues, to achieve the effects of reduced production costs, high extraction efficiency, and simple extraction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

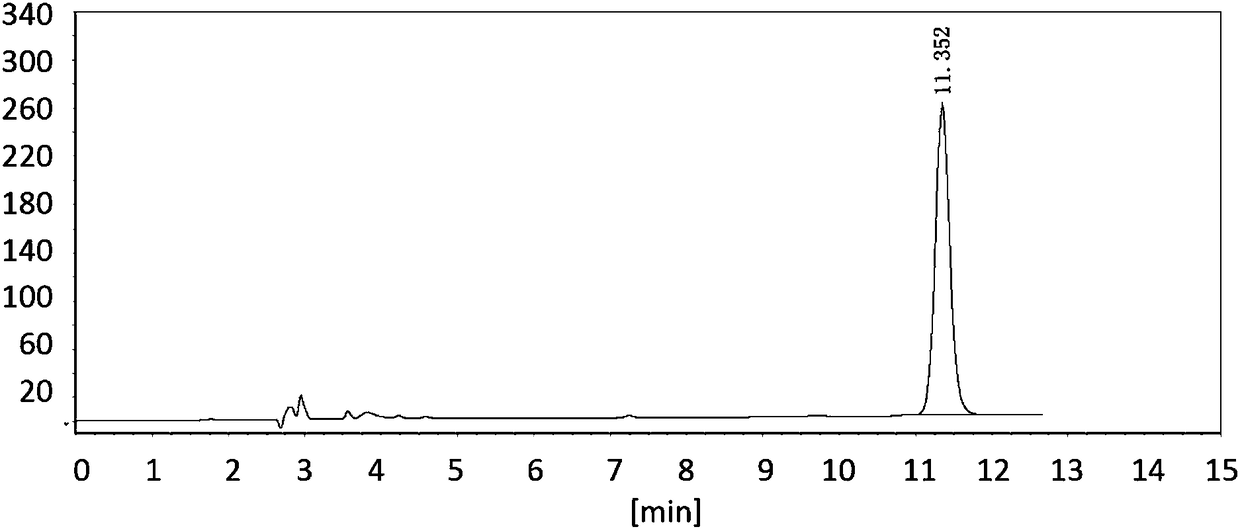

[0031]Take by weighing the dried rosemary of 100kg, pulverize, place in 1000L (V / V) water, heat up and distill for half an hour, collect distillate, obtain 0.97kg rosemary essential oil; After distillation, in the rosemary leaf residue Add 800L (V / V) 75% ethanol solution, extract at 60°C for 2 hours, filter twice with ceramic membrane to obtain filtrate A; continue to add 600L (V / V) 75% ethanol solution to the filter residue, and extract at 60°C For 1 hour, filter twice with a ceramic membrane to obtain filtrate B; combine filtrate A and filtrate B, concentrate the filtrate until there is no alcohol smell, and centrifuge at a speed of 3000r / min to obtain the water phase and the solid part, and continue to concentrate the water phase Spray to obtain dry matter rosmarinic acid 9.85kg; Add 60% ethanol solution to the solid part, after dissolving, continue to centrifuge with the same rotating speed, repeat three times, after the gained solid part is dried, obtain 7.56kg ursolic aci...

Embodiment 2

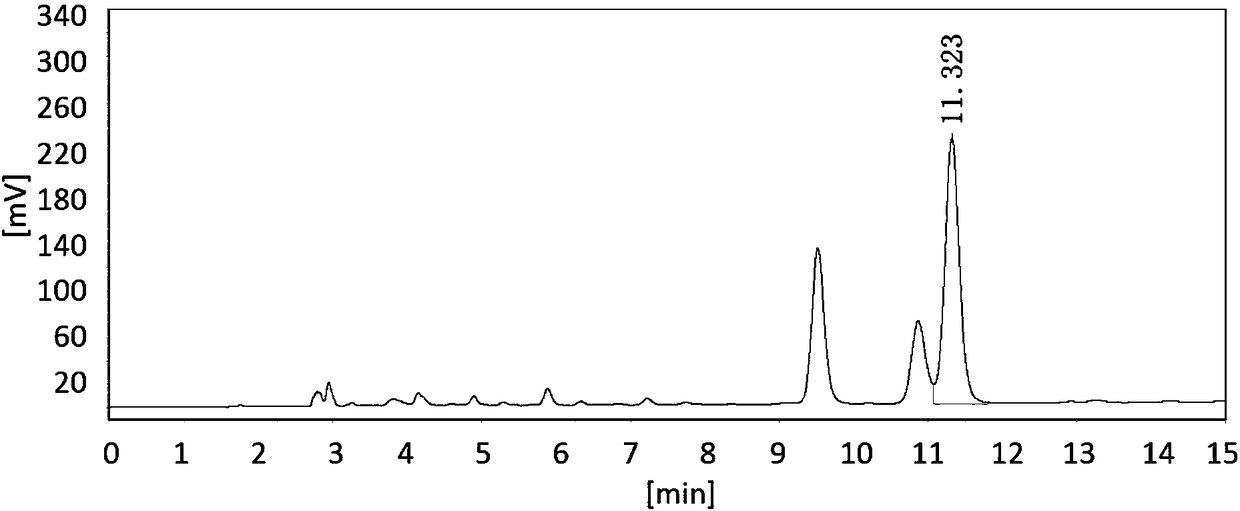

[0036] Take by weighing the dried rosemary of 150kg, pulverize, place in 1500L (V / V) water, heat up and distill for half an hour, collect distillate, obtain 1.52kg rosemary essential oil; After distillation, in the rosemary leaf residue Add 1200L (V / V) 75% ethanol solution to the mixture, extract at 60°C for 2 hours, filter twice with a ceramic membrane to obtain filtrate A; continue to add 900L (V / V) 75% ethanol solution to the filter residue, Extract under the conditions for 1 hour, filter twice with a ceramic membrane to obtain filtrate B; combine filtrate A and filtrate B, concentrate the filtrate until it has no alcohol smell, and centrifuge at a speed of 3000r / min to obtain the water phase and the solid part, and the water phase Partially continue to concentrate and spray to obtain 14.64kg of dry matter rosmarinic acid; add 60% ethanol solution to the solid part, after dissolving, continue to centrifuge at the same speed, repeat three times, after the gained solid part is...

Embodiment 3

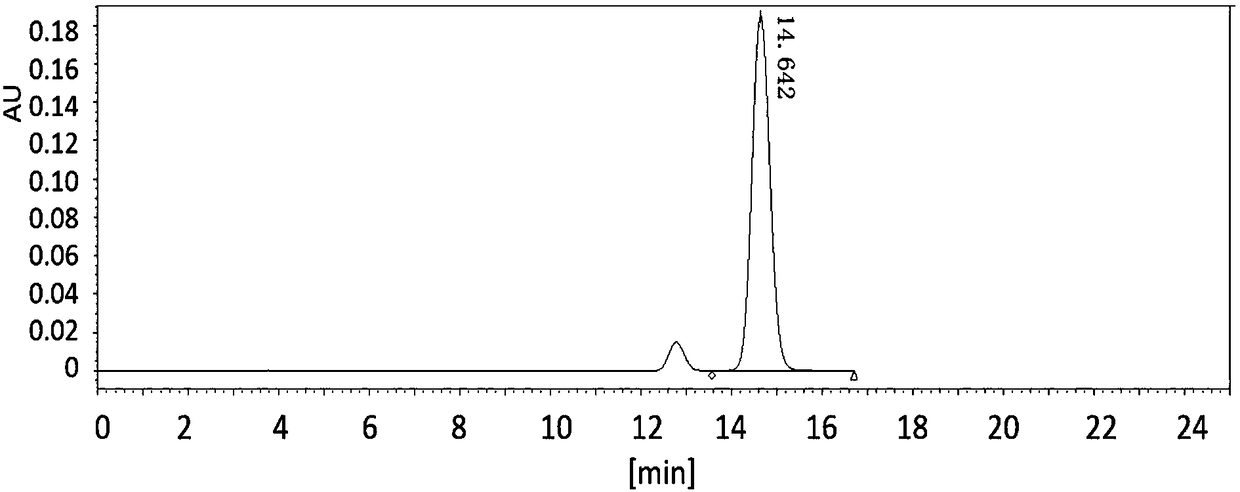

[0039] Take by weighing the dried rosemary of 200kg, pulverize, place in 2000L (V / V) water, heat up and distill for half an hour, collect distillate, obtain 1.92kg rosemary essential oil; After distillation, in the rosemary leaf residue Add 1600L (V / V) 75% ethanol solution, extract at 60°C for 2 hours, filter twice with ceramic membrane to obtain filtrate A; continue to add 1200L (V / V) 75% ethanol solution to the filter residue, extract at 60°C For 1 hour, filter twice with a ceramic membrane to obtain filtrate B; combine filtrate A and filtrate B, concentrate the filtrate until there is no alcohol smell, and centrifuge at a speed of 3000r / min to obtain the water phase and the solid part, and continue to concentrate the water phase Spray to obtain dry matter rosmarinic acid 20.11kg; Add 60% ethanol solution to the solid part, after dissolving, continue to centrifuge with the same rotating speed, repeat three times, after the gained solid part is dried, obtain 15.74kg ursolic ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com