Method for extracting silk protein

A technology of silk protein and extraction method, applied in the field of silk protein processing technology, can solve the problems of easy degradation of silk protein, severe degradation of degumming solution, complicated extraction process, etc., and achieves wide application range, high extraction efficiency and simple extraction process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The method for extracting silk protein in this embodiment includes the following steps in sequence.

[0025] (1) Weighing 0.5g of cocoon layer of silkworm cocoon, peeling off the cocoon layer of silkworm cocoon into thin cocoon layer to obtain silk protein raw material. The present invention can peel off the cocoon layer of silkworm cocoon into thin layers or cut the cocoon layer of silkworm cocoon into pieces or cut the cocoon silk of silkworm cocoon into short fibers to obtain the silk protein raw material, wherein the used cocoon silk includes cocoon layer silk, cocoon silk Cloth and chrysalis lining.

[0026] (2) Put the silk protein raw material prepared in step (1) in CaCl with a mass concentration of 50% (w / w) at a temperature of 98°C 2 dissolved in aqueous solution, CaCl 2 The aqueous solution is kept in a slightly boiling state, the bath ratio is 1:25, and the dissolving treatment is carried out for about 5 minutes until the undissolved part of the fibroin be...

Embodiment 2

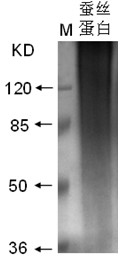

[0031] see figure 1 , the method for extracting silk protein in this embodiment includes the following steps in turn.

[0032] (1) Weighing 0.5g of cocoon layer of silkworm cocoon, peeling off the cocoon layer of silkworm cocoon into thin layers to obtain silk protein raw material.

[0033] (2) Put the silk protein raw material prepared in step (1) in CaCl at a temperature of 96°C 2 Dissolve in an aqueous solution, the mass concentration of calcium chloride is 50% (w / w), the bath ratio is 1:25, and the dissolving treatment is carried out for about 5 minutes until the undissolved part of the silk protein raw material becomes jelly, thereby obtaining the dissolving treatment liquid .

[0034] (3) Filter the solution prepared in step (2) with filter paper, rinse with a small amount of pure water, and separate by filtration to obtain silk protein / CaCl 2 Mix the aqueous solution and unsoled gel.

[0035] (4), the silk protein / CaCl in step (3) 2 The mixed aqueous solution is pl...

Embodiment 3

[0038] The method for extracting silk protein in this embodiment includes the following steps in sequence.

[0039] (1) Weighing 1g of cocoon layer of silkworm cocoon, peeling the cocoon layer of silkworm cocoon into thin layers to obtain silk protein raw material.

[0040] (2) Put the silk protein raw material prepared in step (1) in CaCl at a temperature of 100°C 2 Dissolve in an aqueous solution for about 5 minutes until the undissolved part of the silk protein raw material becomes jelly, thereby obtaining a solution for dissolving. The mass concentration of calcium chloride used in this example is 50% (w / w), and the bath ratio is 1:25.

[0041] (3) Filter the solution prepared in step (2) with filter paper, rinse with a small amount of pure water, and separate by filtration to obtain silk protein / CaCl 2 Mix the aqueous solution and unsoled gel.

[0042] (4) Washing the unsolvated substance in step (3) with water for several times to remove the adhered calcium chloride m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com