Preparation method of rosemary extract

A rosemary extract and extract technology, applied in the field of preparation of plant extracts, can solve the problems of difficult industrialization, waste of rosemary resources, complicated preparation process, etc., achieve low equipment requirements, improve utilization rate, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

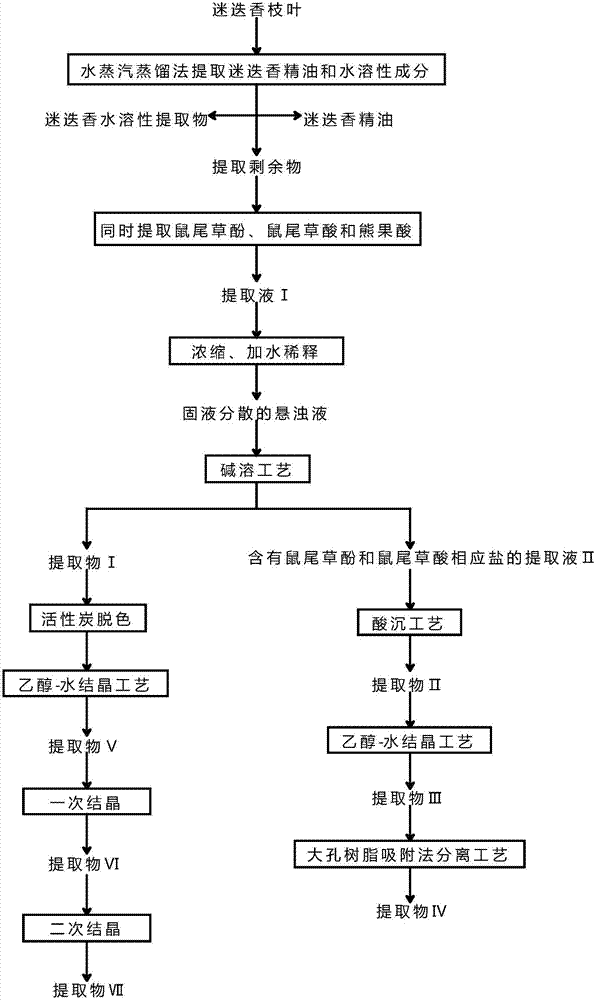

[0035] A preparation method of rosemary extract, may comprise the steps:

[0036] 100. Pretreating rosemary branches and leaves, the pretreatment includes extracting rosemary essential oil and water-soluble components.

[0037] 101. Taking rosemary branches and leaves as raw materials, simultaneously extracting carnosol, carnosic acid and ursolic acid to obtain extract Ⅰ;

[0038] 102. Concentrate the extract I to obtain a concentrate; wherein, the volume of the concentrate is concentrated to 1 / 4-3 / 4 of the extract I.

[0039] 103. Add water to the concentrated solution for dilution to obtain a suspension; wherein the volume of the water is 1-5 times the volume of the concentrated solution.

[0040] 104. The suspension is treated with an alkali-dissolving process to obtain extract II and extract I containing ursolic acid; wherein the alkali-dissolving process includes: adding the suspension to the suspension at a volume ratio of 20:1-10 : 1 Add an alkali-water solution with ...

Embodiment 1

[0049] Pretreatment of raw materials: (step 200)

[0050] Weigh 2.5kg of rosemary branches and leaves, place them in an essential oil extractor, add 50L of water, heat to boiling state, extract the essential oil and water-soluble components in rosemary branches and leaves by steam distillation, until the amount of distilled essential oil When there is no change, the heating is stopped, the rosemary essential oil and the extract containing rosemary water-soluble components are collected respectively, and the remaining solid residue is dried and pulverized to obtain the pretreated raw material.

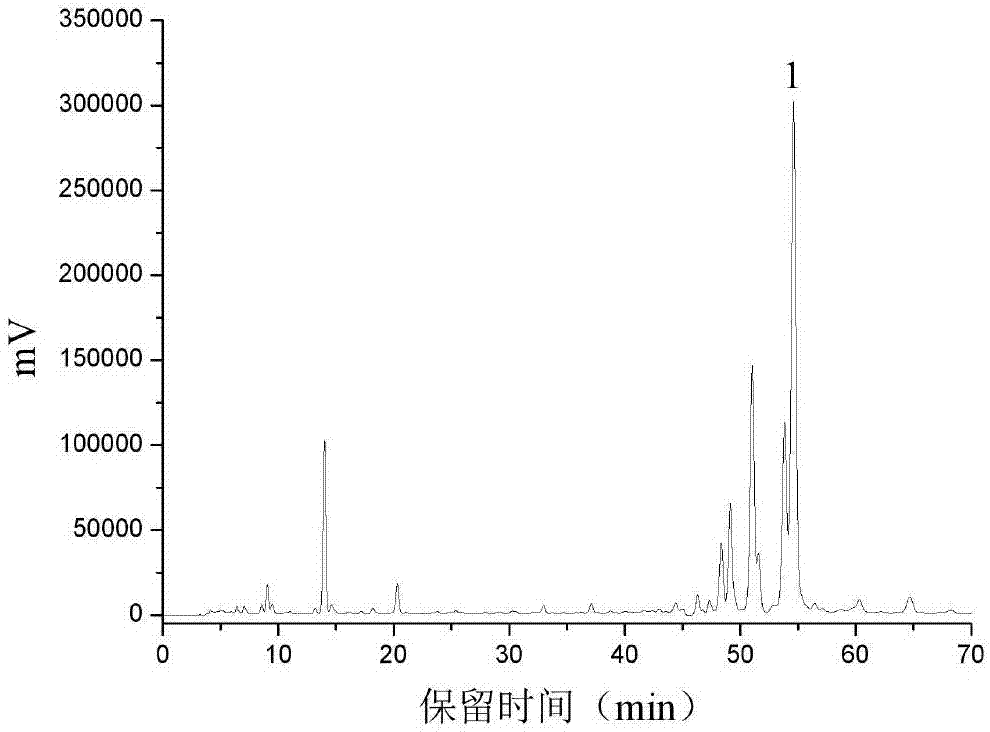

[0051] Simultaneous extraction of carnosol, carnosic acid and ursolic acid: (step 201)

[0052] Weigh 1kg of the above-mentioned pretreated raw material, put it in a 50L extraction tank, add 6L of ethanol-water solution with a volume fraction of ethanol of 80% according to the ratio of solid to liquid 1:6 (kg / L), stir, and put it at 80°C Extract at constant temperature for 90 minutes, ...

Embodiment 2

[0080] Pretreatment of raw materials: (step 300)

[0081] Weigh 2.5kg of rosemary branches and leaves, place them in an essential oil extractor, add 50L of water, heat to boiling state, extract the essential oil and water-soluble components in rosemary branches and leaves by steam distillation, until the amount of distilled essential oil When there is no change, the heating is stopped, the rosemary essential oil and the extract containing rosemary water-soluble components are collected respectively, and the remaining solid residue is dried and pulverized to obtain the pretreated raw material.

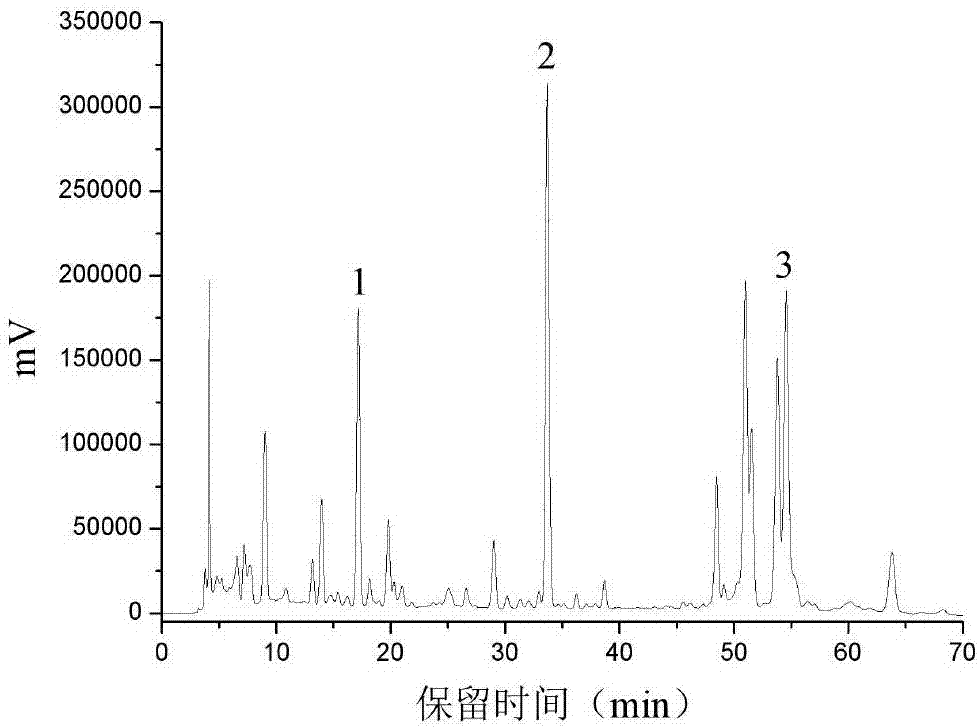

[0082] Simultaneous extraction of carnosol, carnosic acid and ursolic acid: (step 301)

[0083] Weigh 1kg of the above-mentioned pretreated raw material, put it in a 50L extraction tank, add 12L of ethanol-water solution with a volume fraction of ethanol of 60% according to the solid-liquid ratio of 1:12 (kg / L), stir, and put it at 90°C Extract at a constant temperature for 150 minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com