Method for separating and purifying carnosic acid from rosemary extract through atmospheric pressure column chromatography

A technology of rosemary extract and carnosic acid, which is applied in the field of separation and purification of carnosic acid, can solve the problems of insufficient purity of carnosic acid, long purification time, and high purification cost, so as to improve the utilization rate of raw materials and equipment, Inexpensive, less residue effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Preparation method of rosemary extract powder (Li Dawei. Ultrasonic-assisted extraction and separation of active components of rosemary leaves [D]. Beijing: Chinese Academy of Forestry Master's degree thesis, 2012): 100g rosemary leaves (crushing), add 75% ethanol 1600mL according to solid-liquid ratio 1:16 (g / mL), add 3% acid stabilizer (relative to ethanol), ultrasonic frequency 28kHz, ultrasonic power 200W, ultrasonic extraction time 40min, ultrasonic temperature 35°C. The extract is filtered to obtain a filtrate, and the filtrate is distilled under reduced pressure to obtain a rosemary extract extract, which is dried in a vacuum oven at 40°C and ground in a mortar to obtain 16.93 g of rosemary extract powder (the carnosic acid content is 20%wt).

Embodiment 2

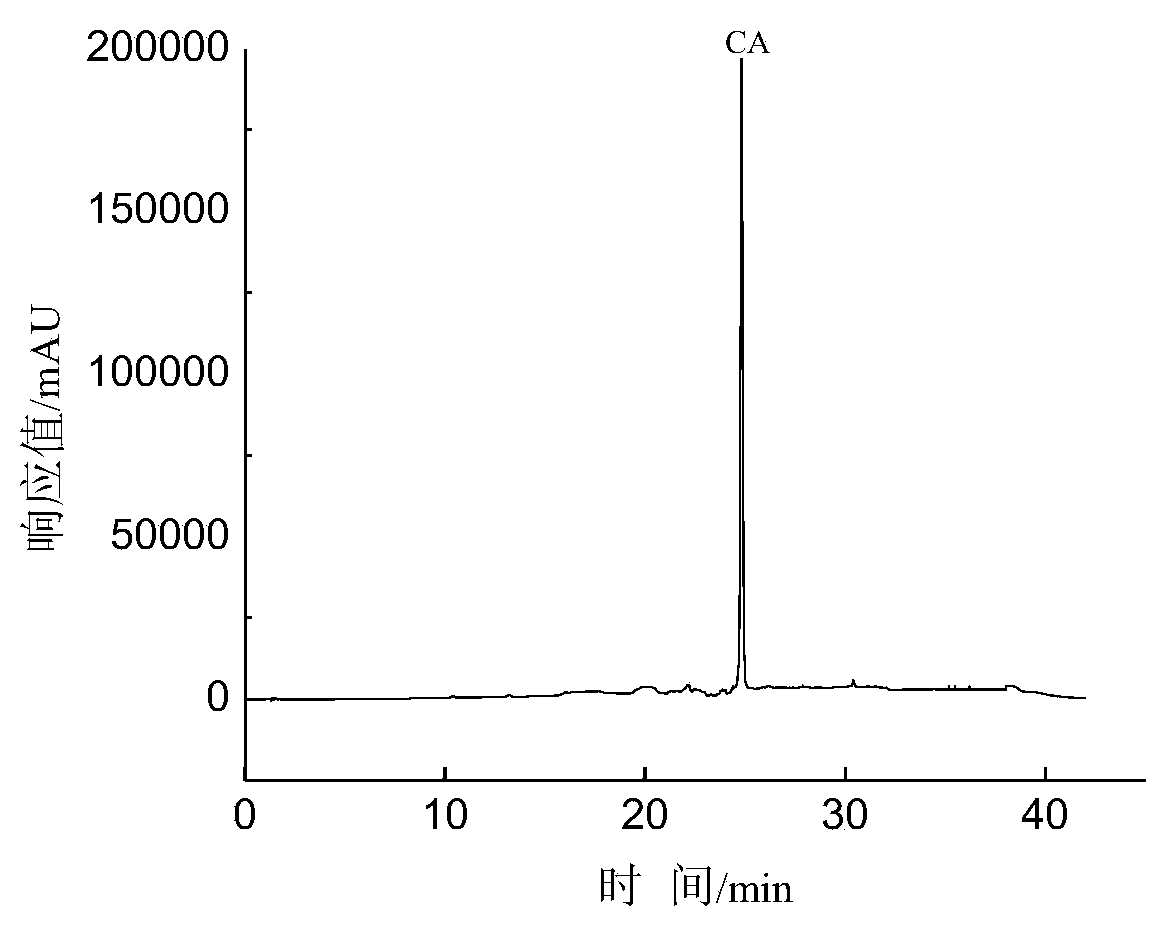

[0020] Rosemary extract powder (prepared according to the method of Example 1, carnosic acid content is 20%wt, the same below.) 0.5g, dissolved with 1-2mL butyl acetate, to get the column sample. Weigh 40 g of 200-300 mesh silica gel, disperse it with an equal volume of petroleum ether (60-90° C.), and then homogenate it for wet packing. Put half a column of petroleum ether (60-90°C) into the chromatography column, and slowly add silica gel. Rinse with petroleum ether (60-90°C) to fully settle the packing, and tap the side wall of the chromatography column to make the packing compact and uniform. The eluent is butyl acetate: petroleum ether (60-90°C) at a ratio of 4:10 (v / v), the flow rate is 6mL / min, and the sampling volume is 5mL / tube. It is separated by column chromatography and identified by thin-layer chromatography. Several fractions with higher carnosic acid content were collected and combined, concentrated to dryness under reduced pressure to obtain 0.0642 g of a puri...

Embodiment 3

[0022] 0.5 g of rosemary extract powder was dissolved in 1-2 mL of butyl acetate to obtain a column sample. Weigh 40 g of 200-300 mesh silica gel, disperse it with an equal volume of petroleum ether (60-90° C.), and then homogenate it for wet packing. Put half a column of petroleum ether (60-90°C) into the chromatography column, and slowly add silica gel. Rinse with petroleum ether (60-90°C) to fully settle the packing, and tap the side wall of the chromatography column to make the packing compact and uniform. The eluent is butyl acetate:petroleum ether (60-90°C) at a ratio of 4:11 (v / v), the flow rate is 6mL / min, the sample volume is 5mL / tube, separated by column chromatography, and identified by thin-layer chromatography Several fractions with higher carnosic acid content were collected and combined, concentrated to dryness under reduced pressure to obtain 0.0726 g of a purified product of carnosic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com