Pneumatically controlled angle seat valve

An angle seat valve, air control technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of environmental pollution, unstable size, long casting cycle, etc., to reduce friction, compact structure, cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

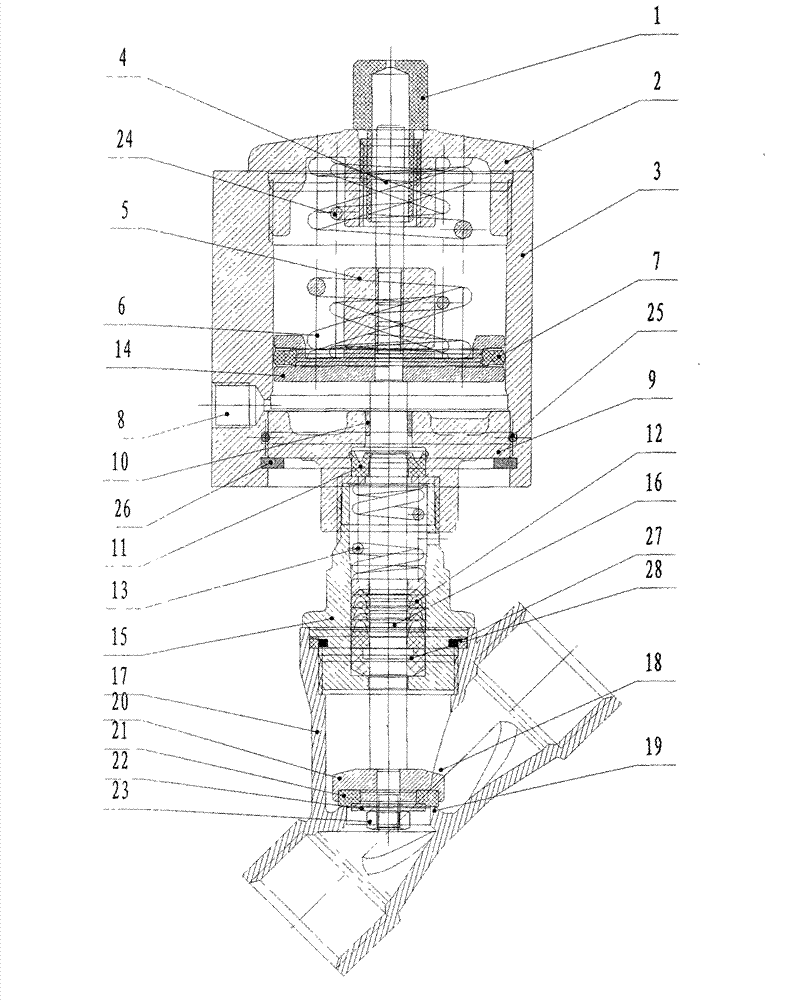

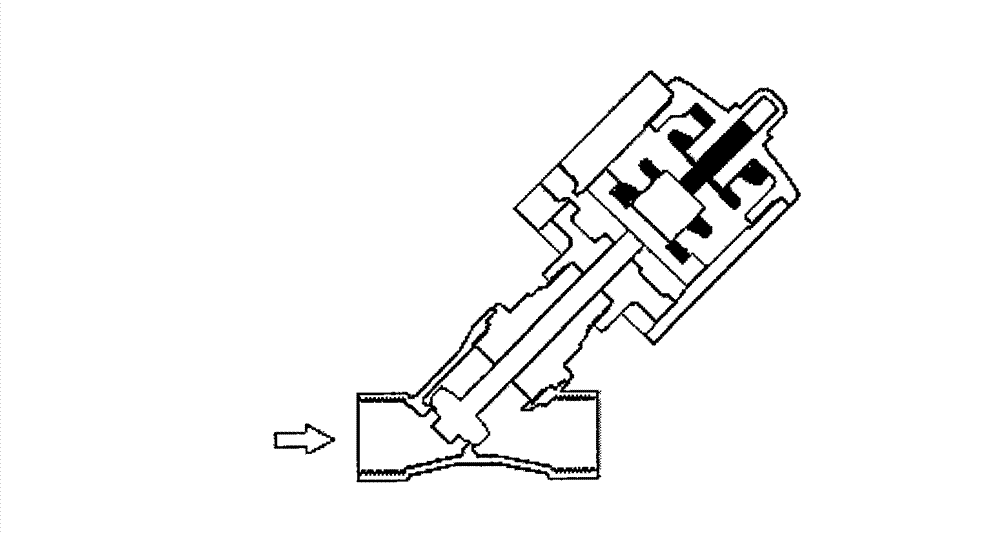

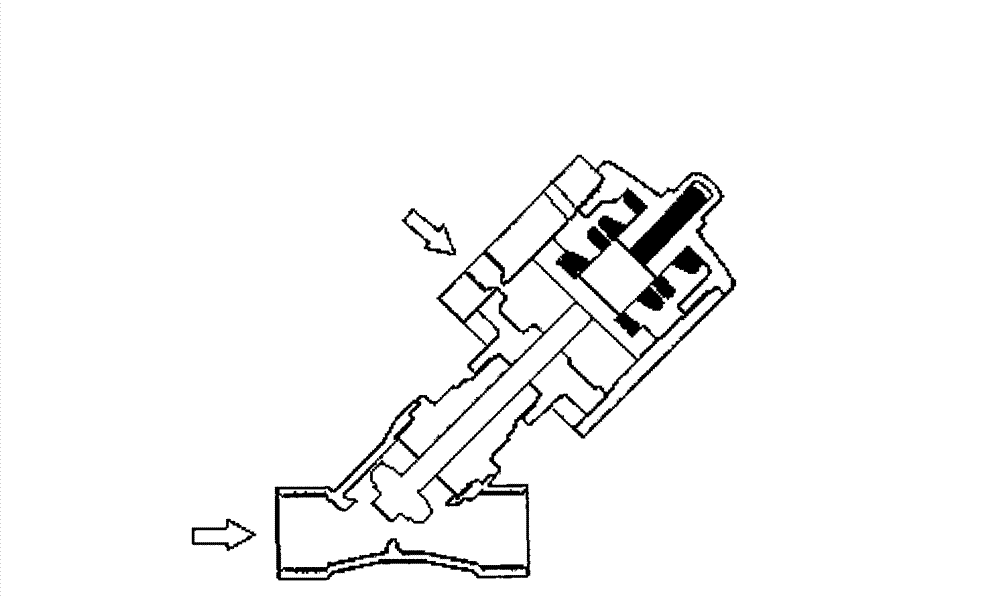

[0053] see Figure 1-Figure 3 , an air control angle seat valve of the present invention is composed of an observation window 1, an aluminum alloy upper end cover 2, an aluminum alloy cylinder barrel 3, an indicator rod 4, a lock nut 5, a spring 6, a piston ring 7, an air inlet 8, Aluminum alloy lower end cover 9, oil-impregnated bearing 10, Y-ring 11, polymer sealing assembly 12, sealing spring 13, piston 14, connection 15, valve stem 16, valve body 17, valve core 18, and valve port 19, among which, The aluminum alloy upper end cover is connected with the aluminum alloy cylinder through the sealing ring, the observation window is fixed in the center of the aluminum alloy upper end cover, one end of the indicator rod is located in the observation window, the other end is connected with the lock nut, the lock nut is connected with the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com