Polyurethane synthetic leather capable of inhibiting bacteria and resisting mildew and preparation method thereof

An antibacterial, antifungal, and polyurethane technology, which is applied in fiber treatment, textiles, and papermaking, can solve the problems of sterilization, long antibacterial response time, and product discoloration, and achieve the effect of long-lasting antibacterial characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

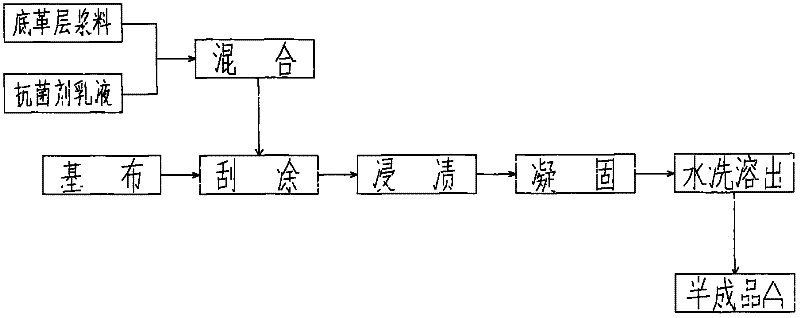

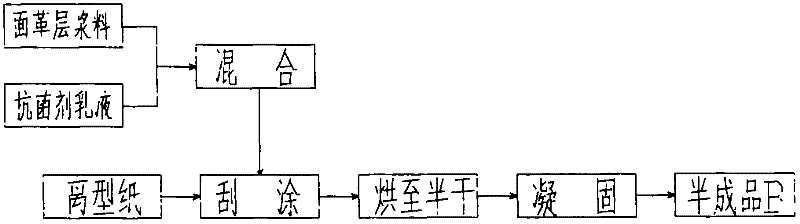

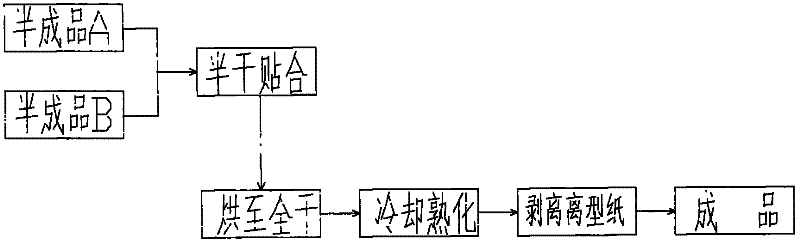

Method used

Image

Examples

Embodiment 1

[0040] The first step: preparation of inorganic / organic composite nano-antibacterial agent

[0041] First the silver-loaded montmorillonite (Andimei) with a particle size of 100nm , the silver ion content is 0.2wt% of the carrier, 10 parts of Beijing Chonggao Nano Technology Co., Ltd.), 0.05 part of sodium thiosulfate (Zibo Yiren Chemical Technology Co., Ltd.), in 100 parts of dimethylformamide (DMF solvent) Fully wet and disperse, stir and grind. Add 0.06 parts of isopropyl tri-isooctanoyl-titanate (Nanjing Nengde Chemical Co., Ltd.), and continue grinding. Add 12 parts of 2-thiocyanomethylthiobenzothiazole (Hunan Dajie Technology Co., Ltd.), and stir to form a stable suspension and emulsion mixture. spare.

[0042] The second step: the configuration of antibacterial polyurethane synthetic leather bottom leather molding slurry.

[0043] Add the selected brand of polyurethane resin into the container, slowly add dimethylformamide, stir to melt, add leveling agent, stir ev...

Embodiment 2-3

[0064] Adopt the same method as Example 1 to prepare antibacterial and antifungal polyurethane synthetic leather materials, the difference is that the addition of inorganic / organic composite antibacterial agent replaces 1% with 3% and 5% respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com