Patents

Literature

164results about How to "Realize separation and purification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

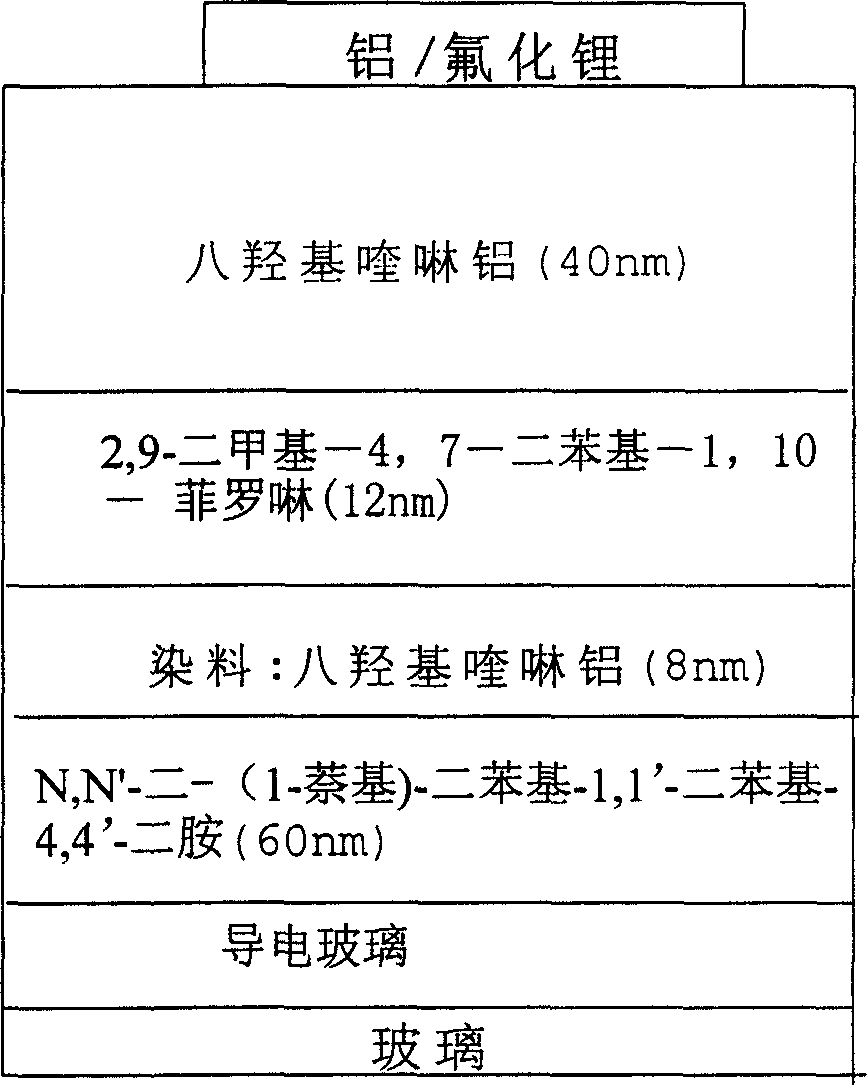

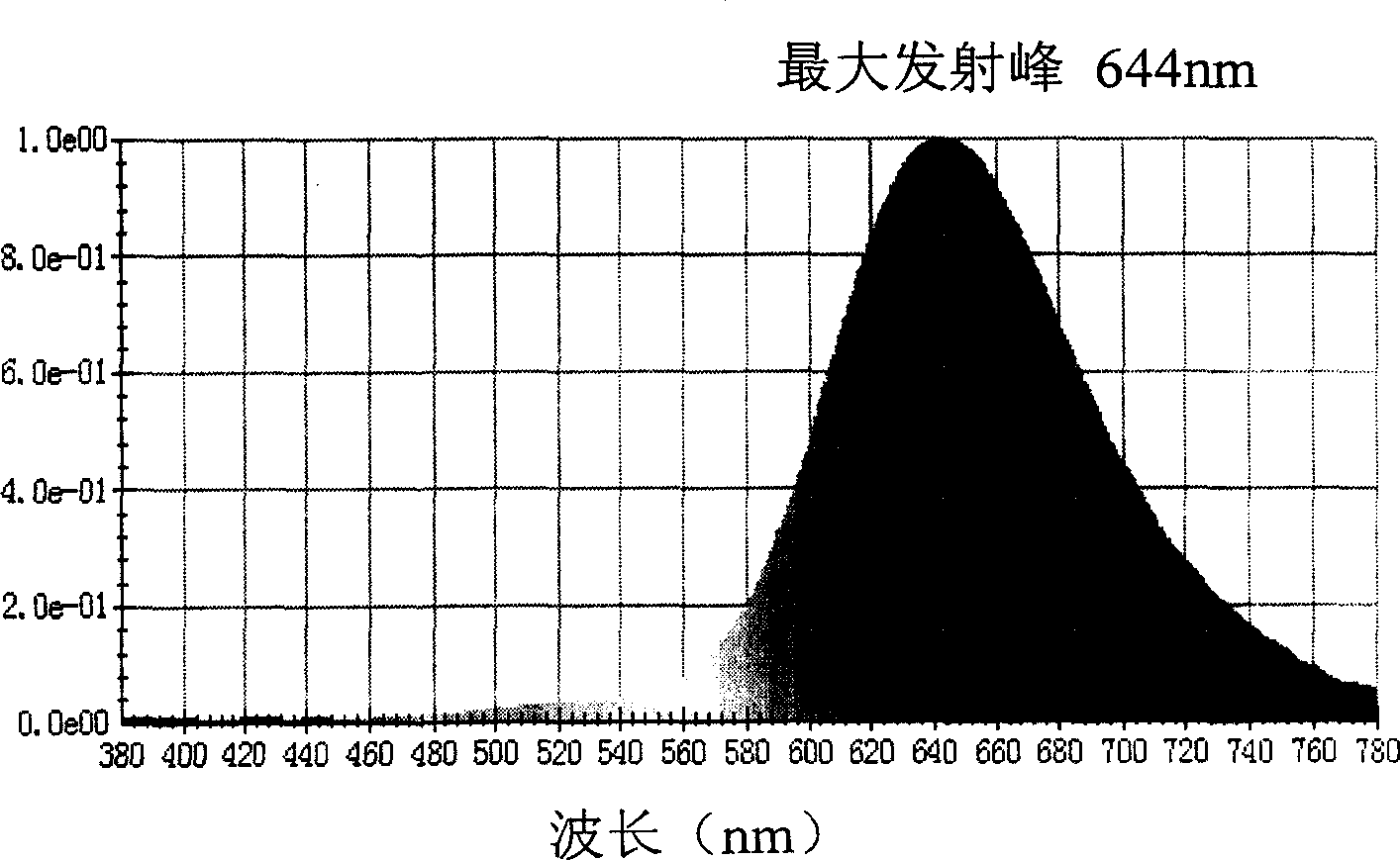

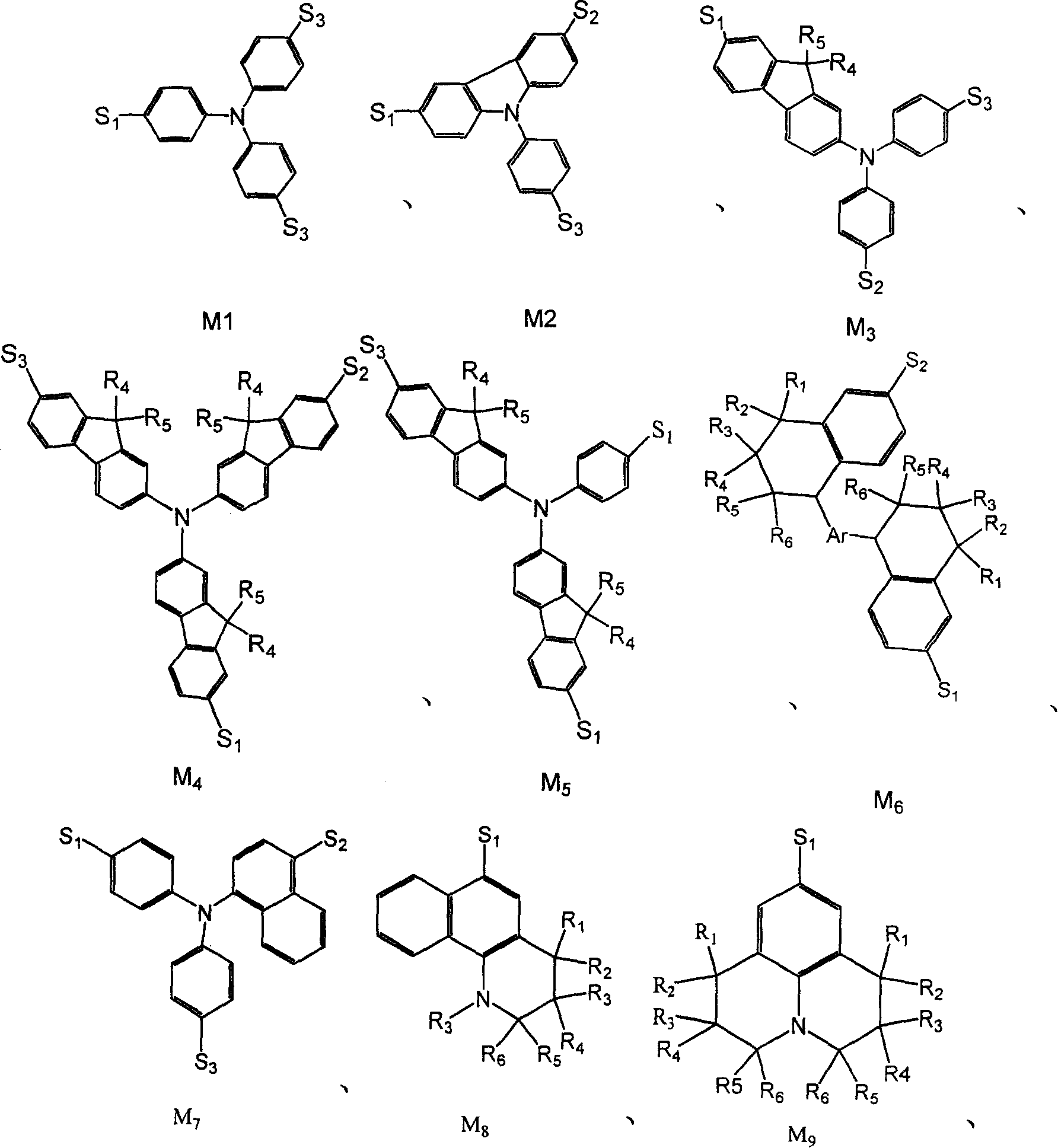

Red light emitting fluorescent dye, synthesizing process and use thereof

InactiveCN1861740ARealize separation and purificationRaw materials are easy to obtainElectrical apparatusElectroluminescent light sourcesPyroneRed light

The invention relates to the red beam luminescent dye which the receptor group is the 1, 3-indandione and the derivant 4H-pyrones. So the quenching effect of the new dyestuff has decreased efficiently and it has the saturated colour-purity. It can keep high efficient and the brightness in the high doping content. It is used for the organic photoconductor, the organic nonlinear optical material and the luminescent material of the electroluminescent cell. The emission band spectrum is in the red region of the visible spectrum and it has the high fluorescence quantum efficiency.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

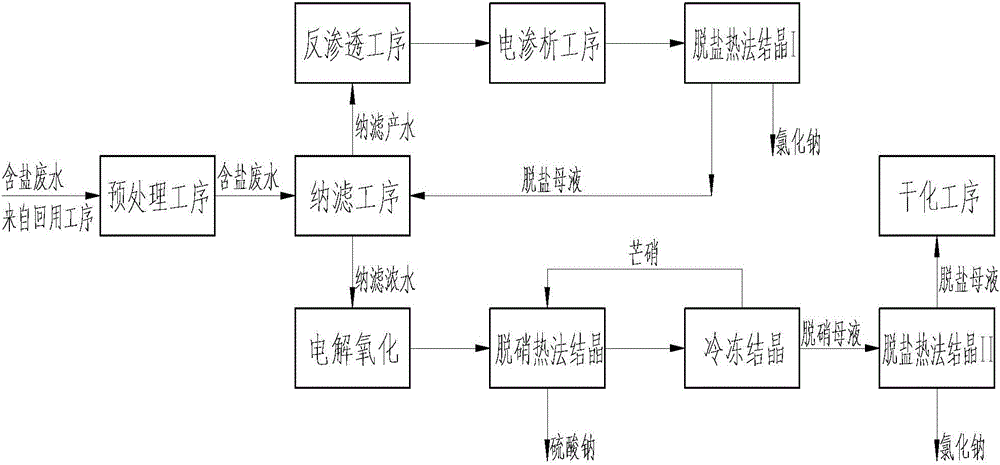

Method for extracting high-purity sodium sulfate and sodium chloride products from high-salt content wastewater in coal chemical industry

InactiveCN106116002AAchieve recyclingRealize separation and purificationWater treatment parameter controlGeneral water supply conservationElectrolysisSodium sulfate

The invention provides a method for extracting high-purity sodium sulfate and sodium chloride products from high-salt content wastewater in the coal chemical industry. The method comprises the following steps: firstly, pretreating the high-salt content wastewater in the coal chemical industry to reduce the hardness thereof and primarily concentrate the wastewater till the TDS content is about 30000mg / L, and primarily separating sodium sulfate and sodium chloride from the high-salt content wastewater in the coal chemical industry by a nanofiltration process to obtain nanofiltration concentrated water with the sodium sulfate as a main component and a nanofiltration produced water with the sodium chloride as a main component; secondly, removing a part of organic matters from the nanofiltration concentrated water to reduce the COD by an electrolytic oxidizing technology, and performing a hot crystallization technology and a freezing crystallizing technology to obtain a pure sodium sulfate product and a small amount of sodium chloride product; treating the nanofiltration produced water by a membrane concentration technology and a hot crystallizing technology to obtain a pure sodium chloride product. In the whole technical process, on the basis of achieving zero discharge of the wastewater, reuse of all water and maximized recycle of the salts in the wastewater are achieved, so that the economic efficiency is improved and the environment pollution is avoided.

Owner:EAST CHINA ENG SCI & TECH

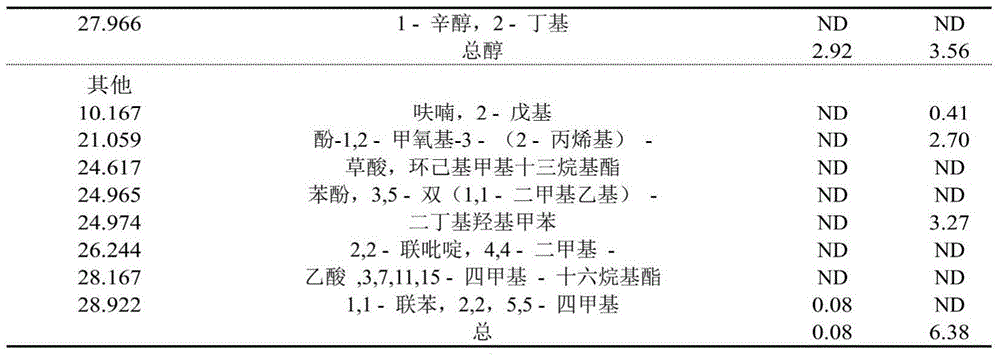

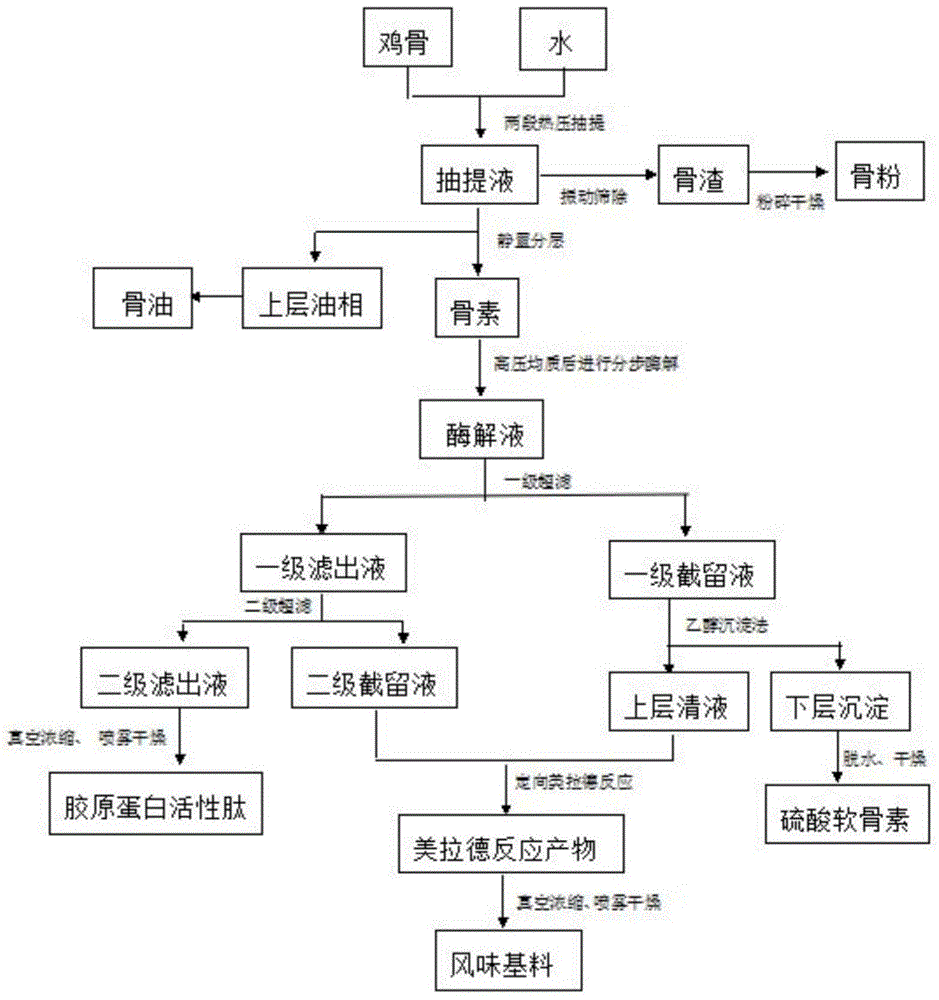

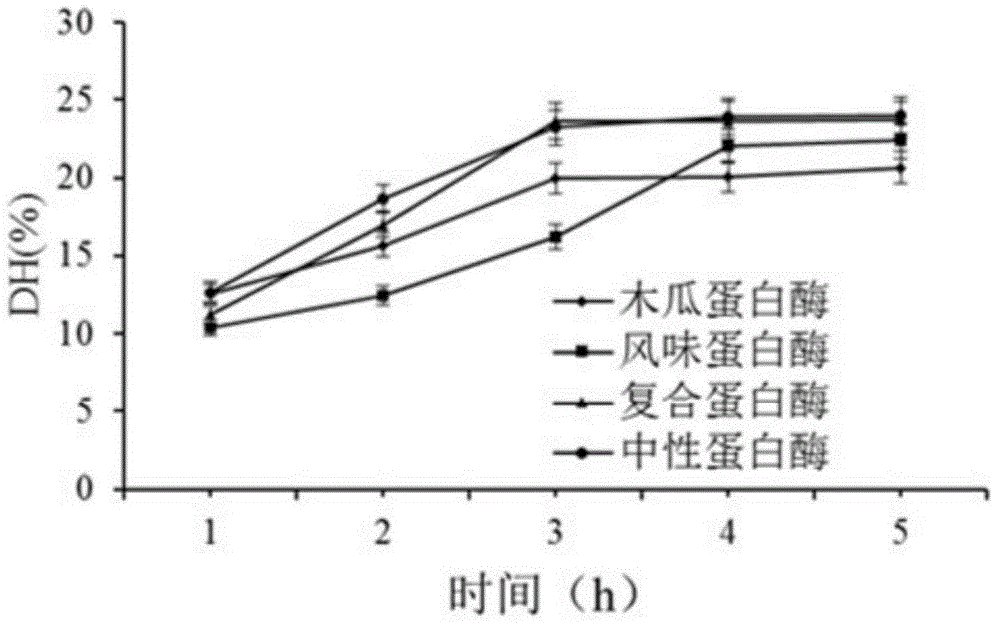

Method for coproducing collagen activity peptides and flavoured base materials with chicken bones

ActiveCN104095141AFacilitate physical disaggregationIncrease the degree of hydrolysisProtein foodstuffs working-upMaillard reactionFiltration

The invention discloses a method for coproducing collagen activity peptides and flavoured base materials with chicken bones. Through a two-step hot pressing and extracting method, and through slight pressure relief and pressure supplementation treatment, the yield of extracting the collagen activity peptides from the chicken bones is substantially increased. Through high-pressure homogenizing of osseins in extracting solutions before a step-by-step enzymolysis reaction of the osseins, the degree of hydrolysis of enzymolysis solutions is increased. In addition, two-step ultra filtration is performed on the enzymolysis solutions, and separation and purification of different products in the enzymolysis solutions are realized. Follow-up processing is performed aiming at the products of each molecule segment, different products of bone polysaccharide containing chondroitin sulfate, macromolecule polypeptide, micromolecule polypeptide and the like are obtained, making full use of ossein enzymolysis solutions is realized, and especially a Maillard reaction is performed on the macromolecule polypeptide, xylose, cysteine and thiamin to obtain the flavoured base material with a rich flavour.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

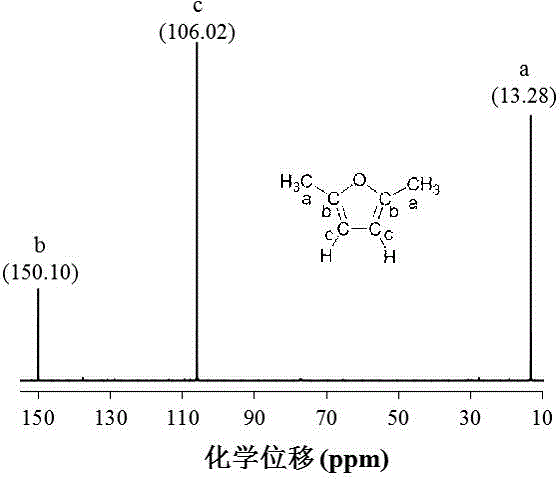

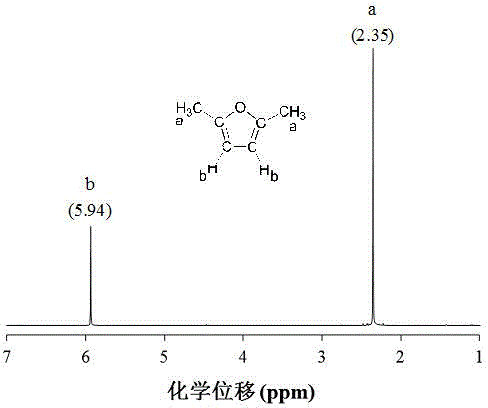

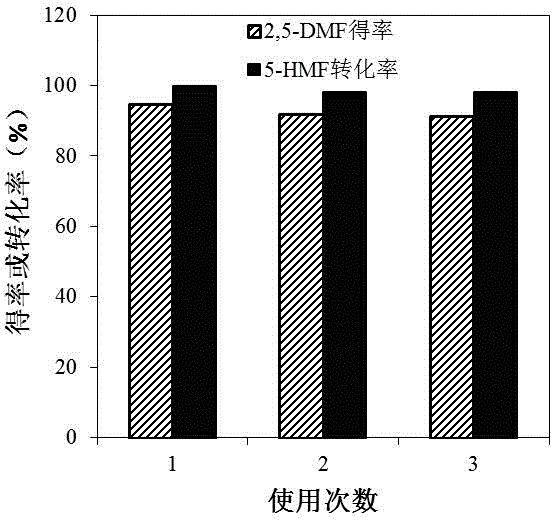

Method for preparing 2,5-dimethyl furan by catalyzing selective hydrodeoxygenation of 5-hydroxymethyl furfural

The invention discloses a method for preparing 2,5-dimethyl furan by catalyzing selective hydrodeoxygenation of 5-hydroxymethyl furfural. The method comprises the following steps: by taking a supported metal as a catalyst, taking hydrogen as a hydrogen source, taking an organic solvent as a reaction solvent, converting 5-hydroxymethyl furfural into the 2,5-dimethyl furan under the proper reaction temperature, reaction time and stirring speed. According to the method disclosed by the invention, the reaction conditions are mild, and the equipment requirement is low; the operation process is simple and easy to master; the target product yield is high and can be 94.7 percent; the target products can be separated and purified by utilizing a method for combining simple atmospheric distillation with reduced pressure distillation; and moreover, the catalyst and the reaction solvent can be recycled and can be repeatedly used, the waste emission amount is small, and the method is green and environmentally friendly and has extremely high practicality and good industrial prospects.

Owner:HUAIYIN TEACHERS COLLEGE

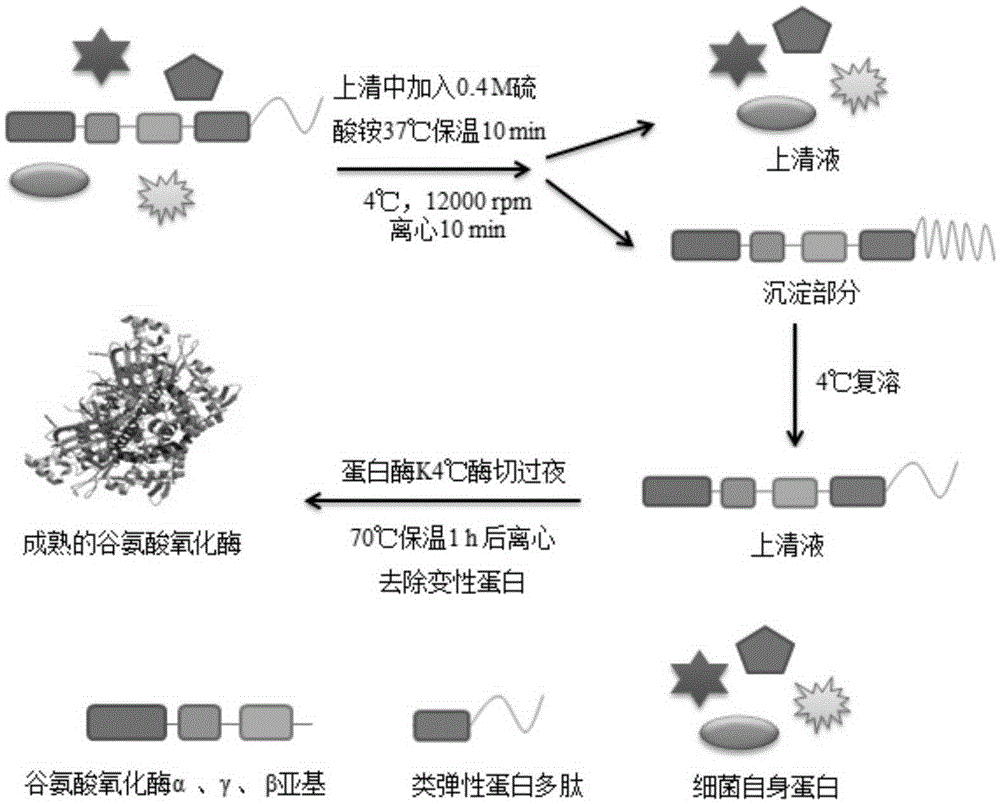

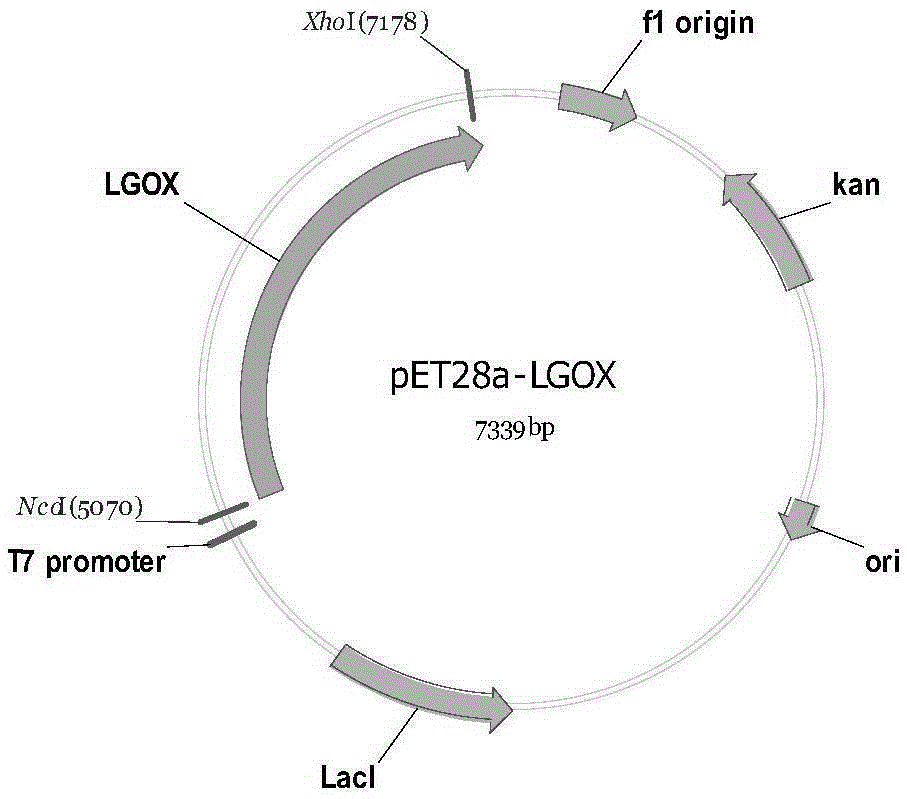

Method for producing alpha-oxoglutarate under catalysis of L-glutamate oxidase

InactiveCN105331642AReduce production cost and use costSatisfy large-scale productionEnzymesFermentationL-glutamate oxidaseKetoglutaric Acid

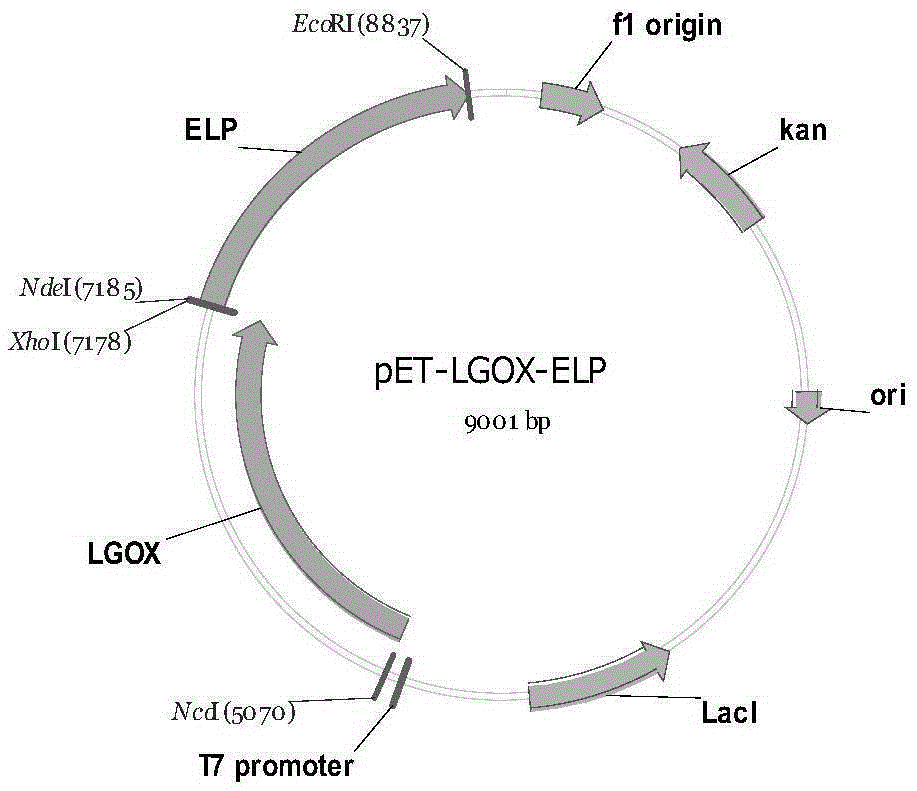

The invention discloses a method for producing alpha-oxoglutarate under catalysis of L-glutamate oxidase. The method comprises the following steps: performing optimal design and synthesis on codon of an L-glutamate oxidase (L-GOX) gene; constructing a fusion expression vector pET-28a-LGOX-ELP of the L-GOX and Elastin-Like Proteins (ELP), transferring the vector into escherichia coli Rosetta (DE3), selecting a converter for cultivation, adding an inducer for expression, and obtaining recombined L-glutamate oxidase fusion protein crude enzyme fluid; performing purification by an ITC method, thus obtaining recombined L-glutamate oxidase fusion proteins, performing enzyme digestion on the recombined L-glutamate oxidase fusion proteins by protease, and obtaining mature L-glutamate oxidase; producing oxoglutarate under the catalysis of the mature L-glutamate oxidase. The method is simple, quick and efficient, can be used for large-scale separation and purification of L-glutamate oxidase, and is higher in actual application value in the enzyme production of oxoglutarate.

Owner:ZHEJIANG DEQING HUINING BIOTECH

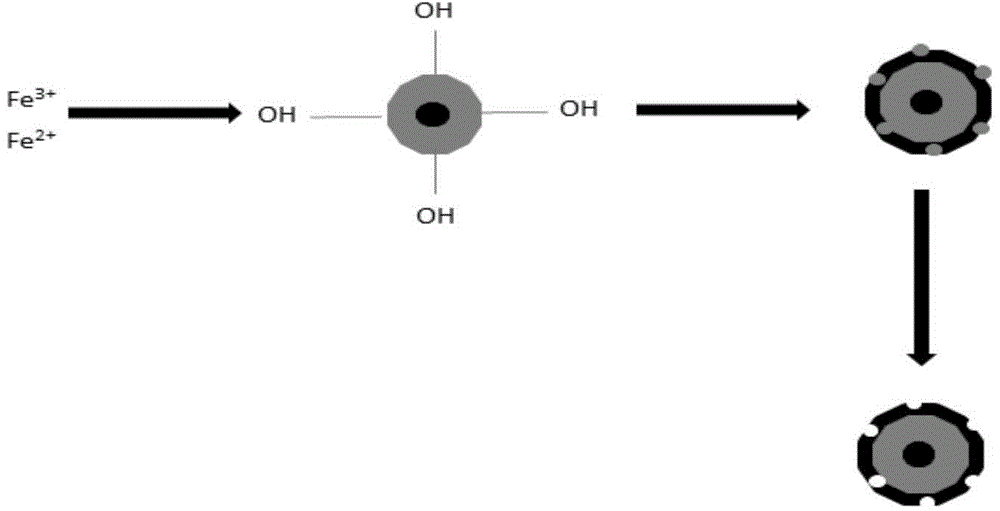

Method for preparing material containing amorphous iron oxide hydroxide and methods for regenerating the same

ActiveCN101767830AHigh sulfur capacityGood desulfurization effectIron oxides/hydroxidesIron oxideHydroxide

The invention relates to a method for preparing a material containing amorphous iron oxide hydroxide and two methods for regenerating the same after being used as desulfurizer. The content of the amorphous iron oxide hydroxide in the material prepared by the invention is as high as 65% to 100%, so the sulfur capacity of the material is high; and the desulfurizer in the prior art is non-regenerative or costly for regeneration, so that the desulfurizer in a large amount cannot but be dumped as waste liquid in landfills, while the amorphous iron oxide hydroxide in the material of the invention can be repeatedly regenerated and reused after the material is used as the desulfurizer, thereby solving the problems of the waste of effective resources in the original desulfurizer and the severe environmental pollution.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

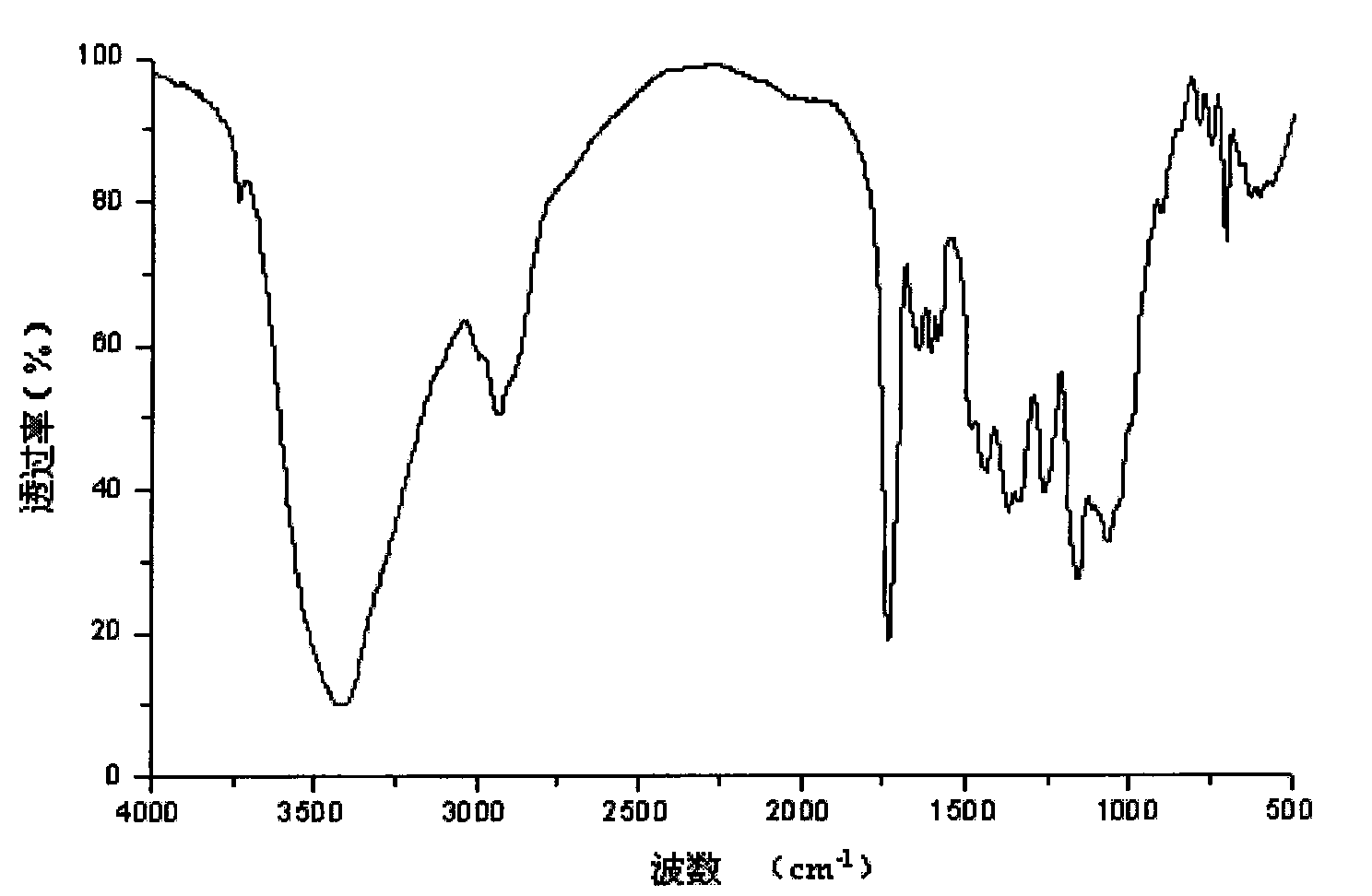

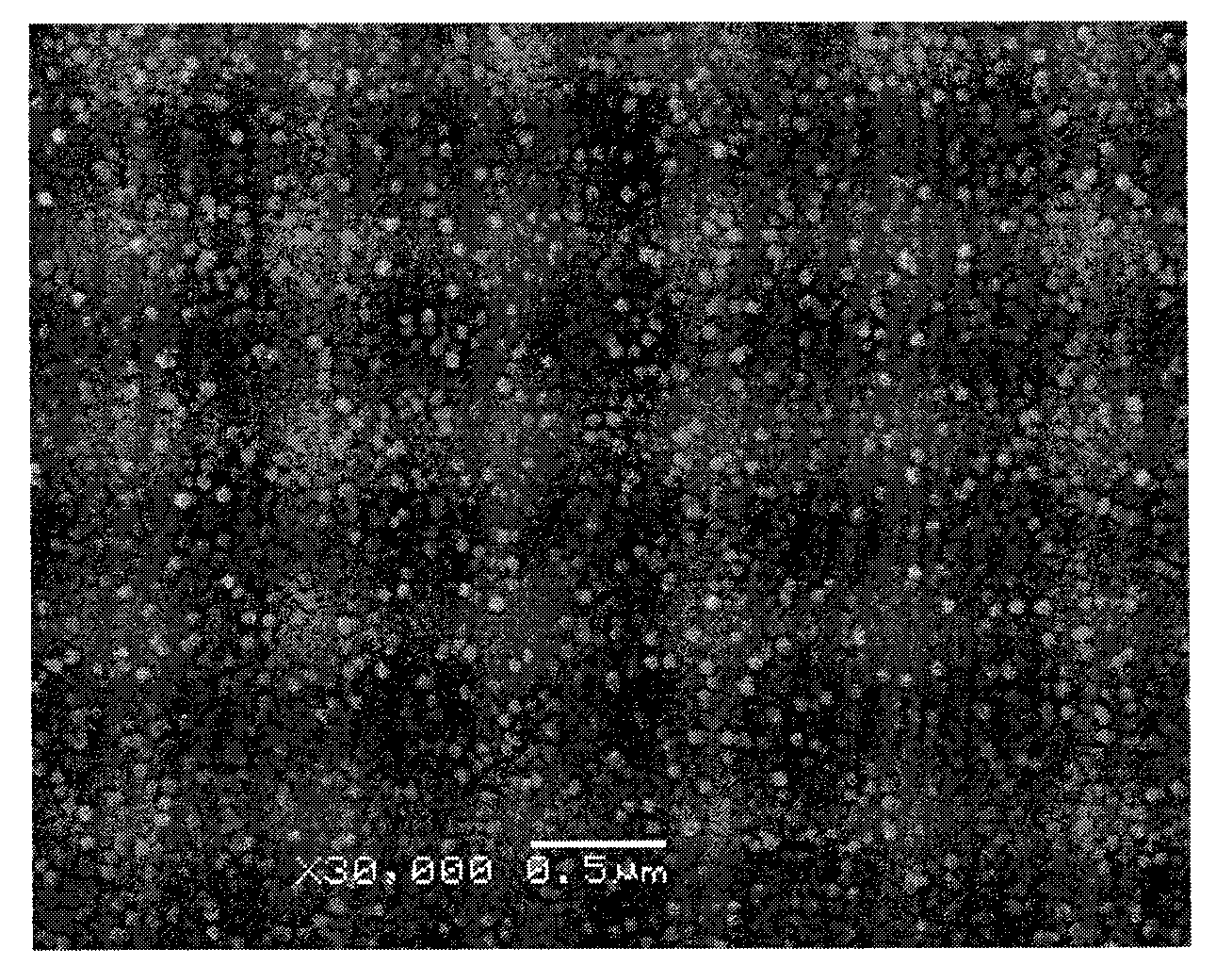

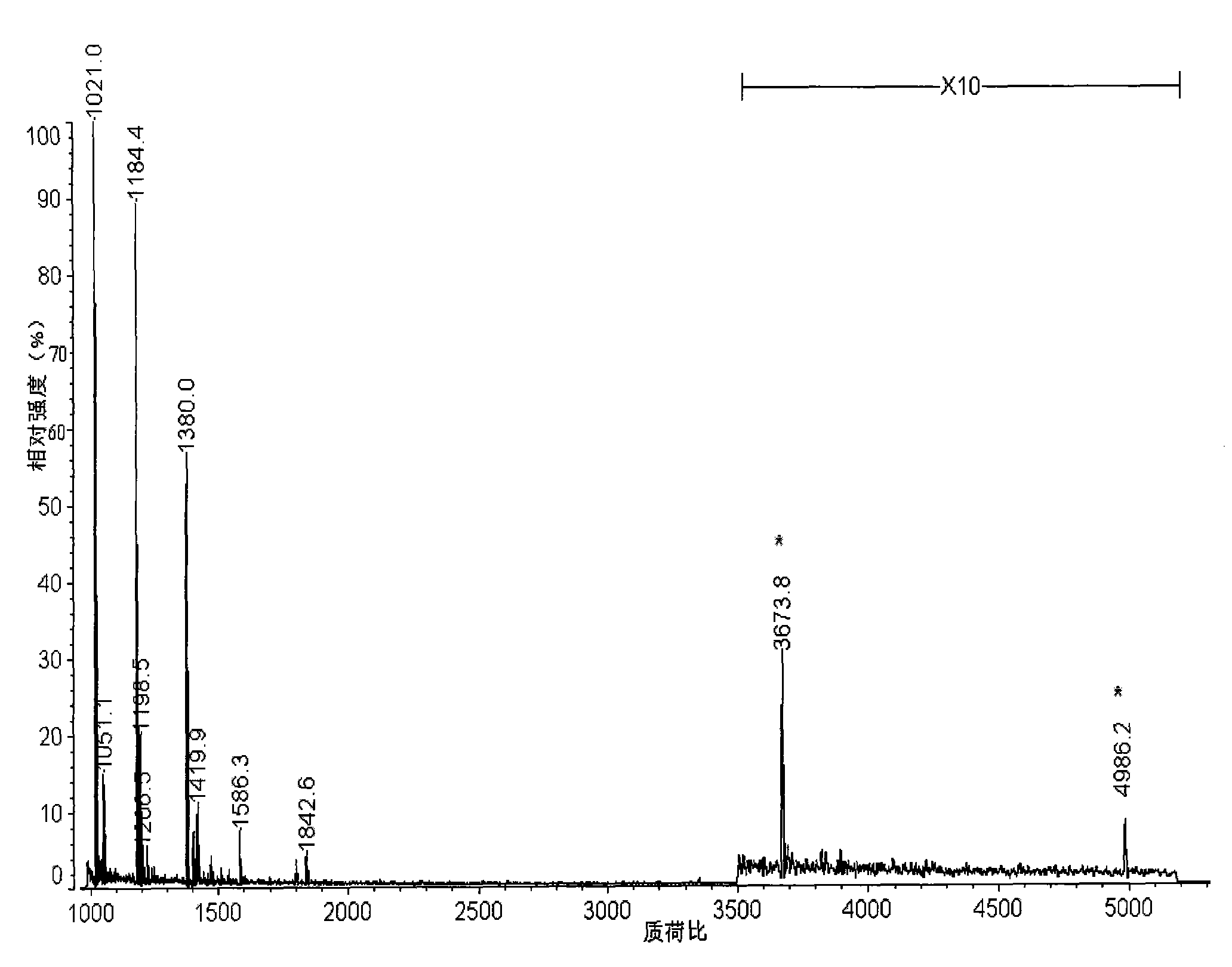

Nano chitosan derivative and preparation method and application thereof

InactiveCN101575384ARealize separation and purificationEasy to optimizePeptide preparation methodsEpoxyCycloaddition

The invention discloses a nano chitosan derivative and a preparation method thereof, belonging to the technical field of biomedical nano materials. The preparation method of the derivative comprises the following steps of: dissolving the chitosan in dilute acid and then mixing the chitosan with methacrylic acid epoxy propyl ester or acrylic acid epoxy propyl ester so as to conduct self-polymerization grafting reaction, thereby obtaining an intermediate with an active epoxy group, then leading the intermediate and an amino group to replace phenylboronic acid to carry out ring-opening addition reaction for finally obtaining the nano chitosan derivative with a boric acid active functional group, with the particle size of 1nm to 300nm. The invention also discloses the application of the chitosan derivative in the aspect of enriching and purifying glycosylated polypeptide / protein. The chitosan derivative has very high specificity, can be used for the enrichment and purification of low-abundance glycosylated polypeptide / protein in biological samples, and can also be used in the biological and medical fields, including clinical diagnosis.

Owner:PEKING UNIV

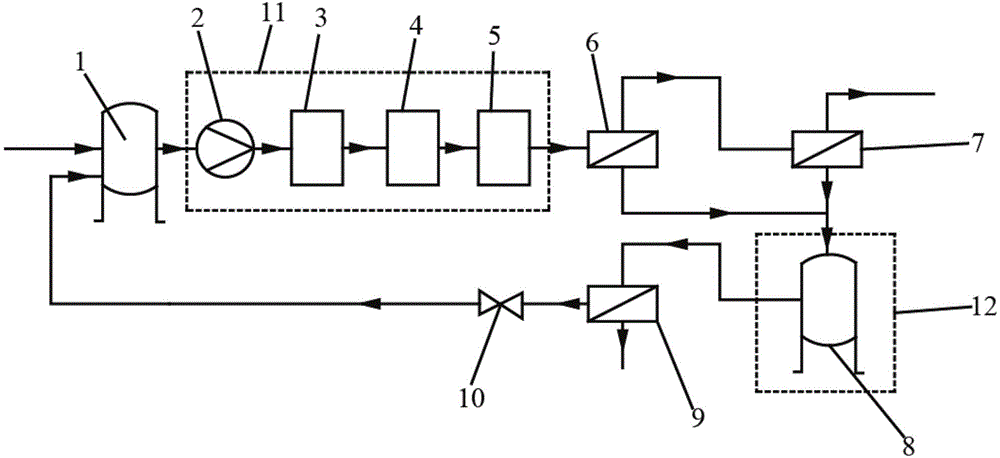

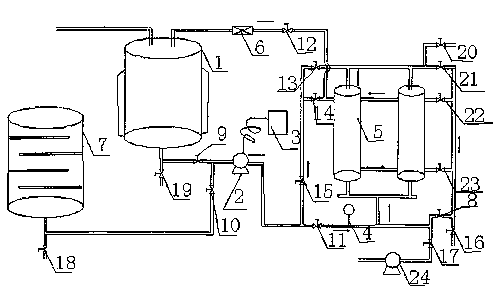

Device system for purifying by utilizing gas separation membrane

ActiveCN104587804AFully purifiedHigh recovery rateDispersed particle separationNoble gas compoundsHydrogenProduct gas

The invention discloses a device system for purifying by utilizing a gas separation membrane. The device system comprises a mixing device, a pretreatment unit and three gas separation membrane units, wherein two ends of the mixing device are respectively communicated with a raw material gas and the pretreatment unit; a gas passes through the pretreatment unit and enters a gas inlet of the first gas separation membrane unit; an impermeable gas of the first gas separation membrane unit is communicated with a gas inlet of the second separation membrane unit; impermeable gases of the first and second gas separation membrane units pass through a mixed flow tank, and are communicated with a gas inlet of the third separation membrane unit; an impermeable gas outlet of the third separation membrane unit is provided with a backpressure control valve, and is communicated with a gas inlet of the mixing device for cyclic purification; the impermeable gas of the second separation membrane unit is a tail gas; the permeable gas of the third separation membrane unit is a product gas. According to the invention, three membrane units are used for purifying independently so as to completely purify gases, such as helium, hydrogen, carbon dioxide, and the recycling rate is relatively high; the device system is simple and compact in structure, and is applied to industrial production.

Owner:甘泳

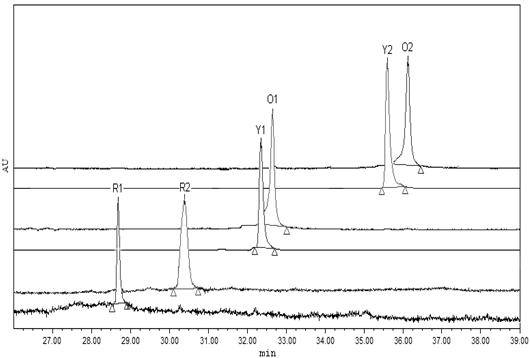

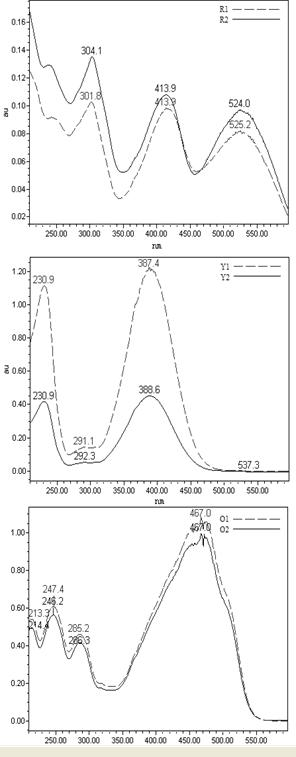

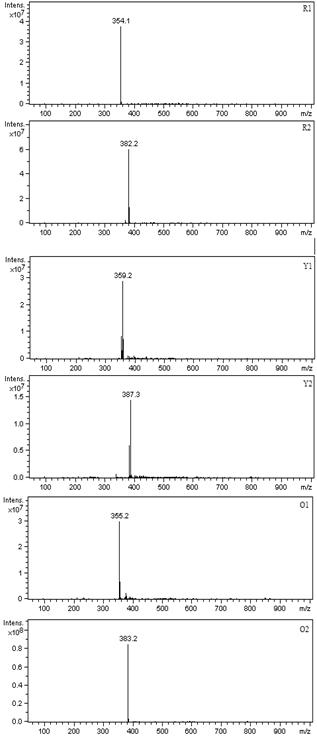

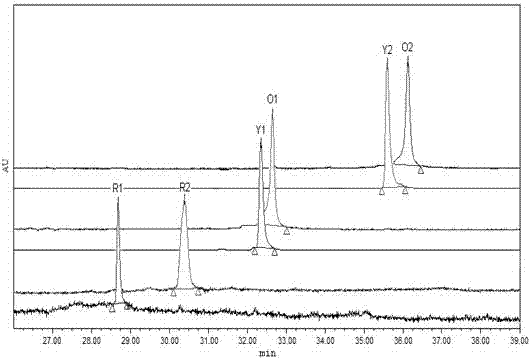

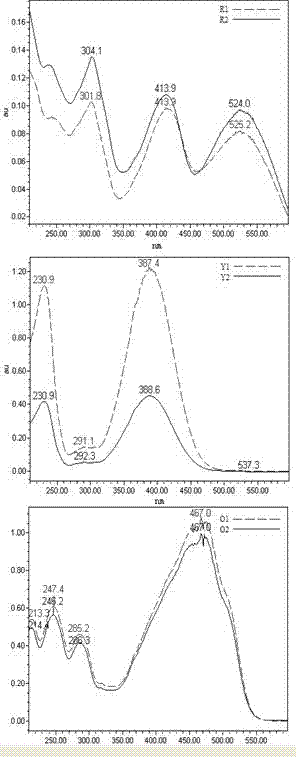

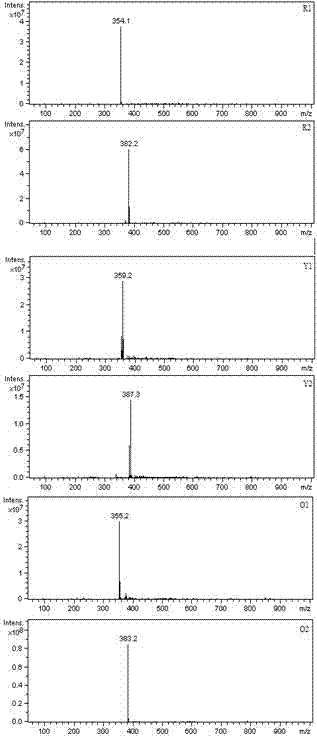

Preparation method of high-purity monascus pigment component

InactiveCN101864191ASave on separation material consumptionSimplify operation stepsNatural dyesThin-layer chromatographyCountercurrent chromatography

The invention provides a novel process for preparing high-purity monascus pigment. The process comprises the following steps of: crushing red yeast rice as a raw material; and separating and purifying to obtain 6 kinds of monascus pigment components by adopting a composite technology of extraction liquid extraction and high-speed countercurrent chromatography separation and crystallization, wherein the six monascus pigment components comprise rubropunctamine, monascorubramine, monascin, ankaflavin, rubropunctatin and monascorubin, and the purities of all the pigments are higher than 95 percent and can be used for preparing foods, cosmetic colorants and health products. The invention adopts easily-recovered organic solvent for separation to save the consumption of separation materials andovercome the problems of small treatment amount and inefficient single pigment component separation and purification of a TLC (Thin Layer Chromatography), an HPLC (High Performance Liquid Chromatography), a resin method and a silica gel column chromatography. The invention adopts the composite technology of the extraction liquid extraction and the high-speed countercurrent chromatography separation and the crystallization to prepare six kinds of high-purity monascus pigment crystals and has the advantages of simple steps and high yield.

Owner:FUZHOU UNIVERSITY

Arsenic fixing method for preparing scorodite through stabilization treatment of arsenic-alkali residue

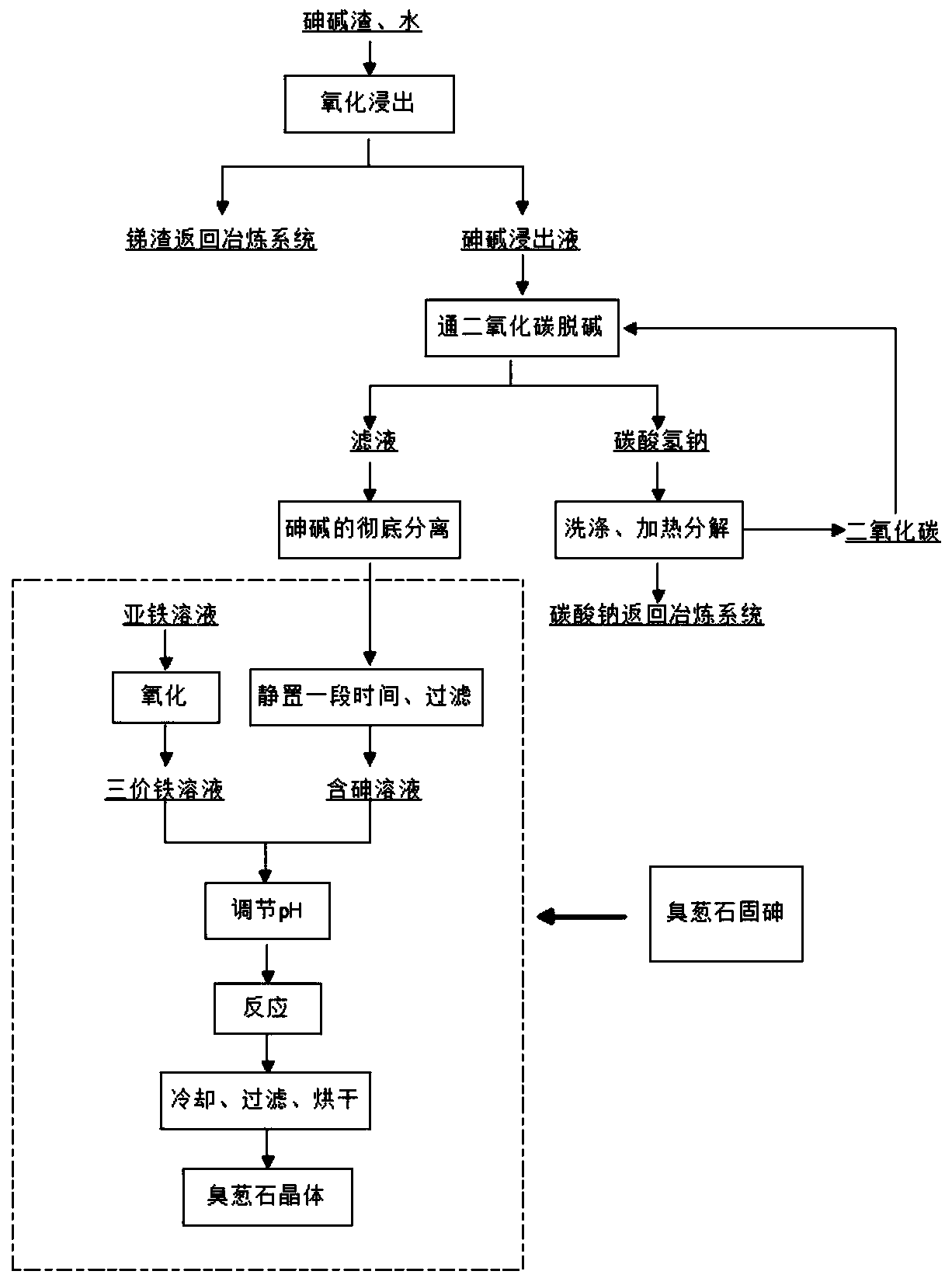

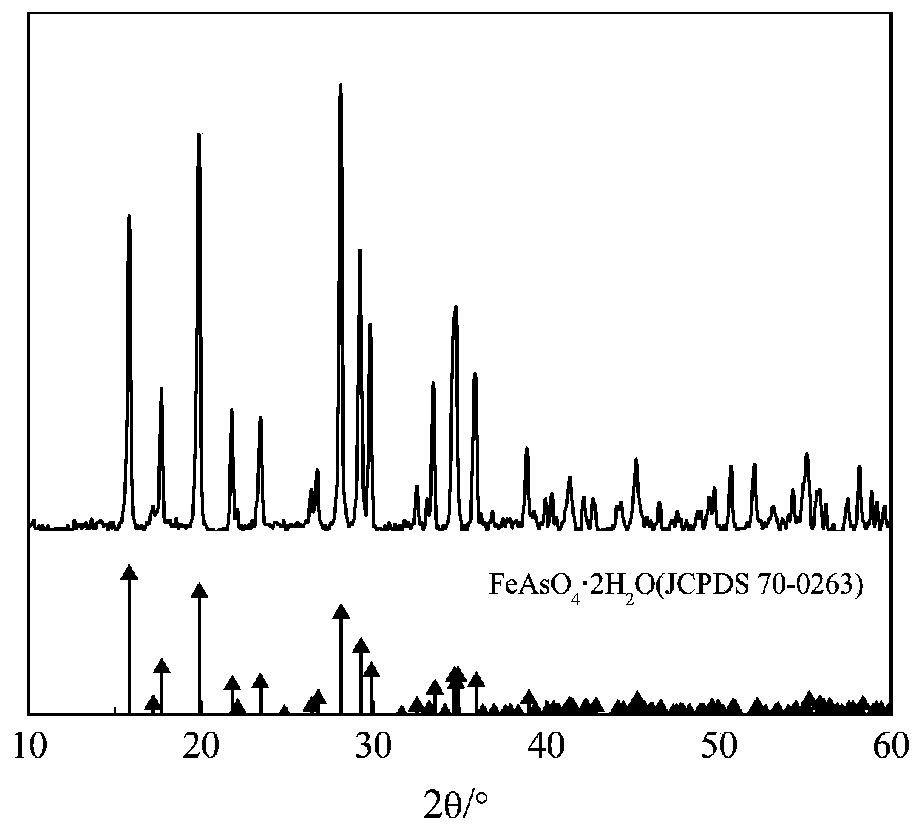

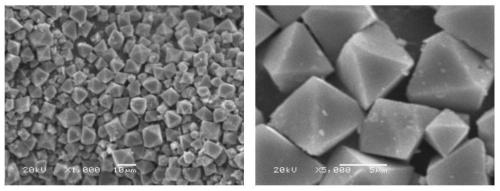

ActiveCN109809494ASimple operationSimple installation and energy savingIron compoundsAlkali metal carbonatesChemistrySodium arsenate

The invention discloses an arsenic fixing method for preparing scorodite through stabilization treatment of arsenic-alkali residue. The arsenic fixing method comprises the following steps: (1) the arsenic-alkali residue is subjected to oxidation leaching, filtering is conducted to obtain leachate containing sodium carbonate and sodium arsenate, and sodium antimonite precipitation, after the leachate is concentrated, CO2 is introduced for dealkalization, and filtering is conducted to obtain dealkalized leachate and sodium bicarbonate crystals; (2) acid is added into the dealkalized leachate obtained in the step (1) to control the pH of the dealkalized leachate to be 1.0-2.5, and an arsenic-rich solution is obtained; and (3) a mixed solution of ferrous salt and H2O2 is added into the arsenic-rich solution obtained in the step (2) according to the iron-arsenic molar ratio of 1.0-3.0, the pH of the mixture is controlled to be 1.2-2.0, the mixture reacts at 75-95 DEG C, and scorodite crystals are obtained. The arsenic-alkali residue is treated to obtain the scorodite crystals with the double-cone octahedron shape and uniform particles, the arsenic leaching concentration is lower than the concentration stipulated by the GB5085.3-2007 'hazardous waste identification standard-leaching toxicity identification', and the scorodite crystals can be safely stored for a long term.

Owner:CENT SOUTH UNIV

Method for preparing urokinase and freeze-dried powder of urokinase

ActiveCN110894495ARealize separation and purificationHigh levels of urokinasePeptidasesPhysical chemistryIon exchange

The invention relates to a method for preparing high-purity macromolecular urokinase and freeze-dried powder of the urokinase and belongs to the technical field of biochemical engineering. The methodspecifically comprises the steps: (1) preparing a urokinase crude product; (2) preparing a urokinase fine product; and (3) carrying out purifying, wherein in the step (3), the urokinase fine product obtained in the step (2) is dissolved, and then, the urokinase fine product solution is added into a cation exchange chromatography column for purification; and the purified urokinase is subjected to freeze-drying, thereby obtaining the freeze-dried powder of the urokinase. Fillers filled in the cation exchange chromatography column comprise one of Capto S impAct, SP sepharose HP and source 30S. According to the method for preparing the urokinase and the freeze-dried powder of the urokinase, high-resolution ion-exchange chromatography is selected, so that on the premise of guaranteeing purity,activity and yield, the production cost is reduced greatly, and large-scale production of high-purity high-molecular-weight urokinase becomes possible.

Owner:JIANGSU YOULIKA BIOTECHNOLOYG CO LTD

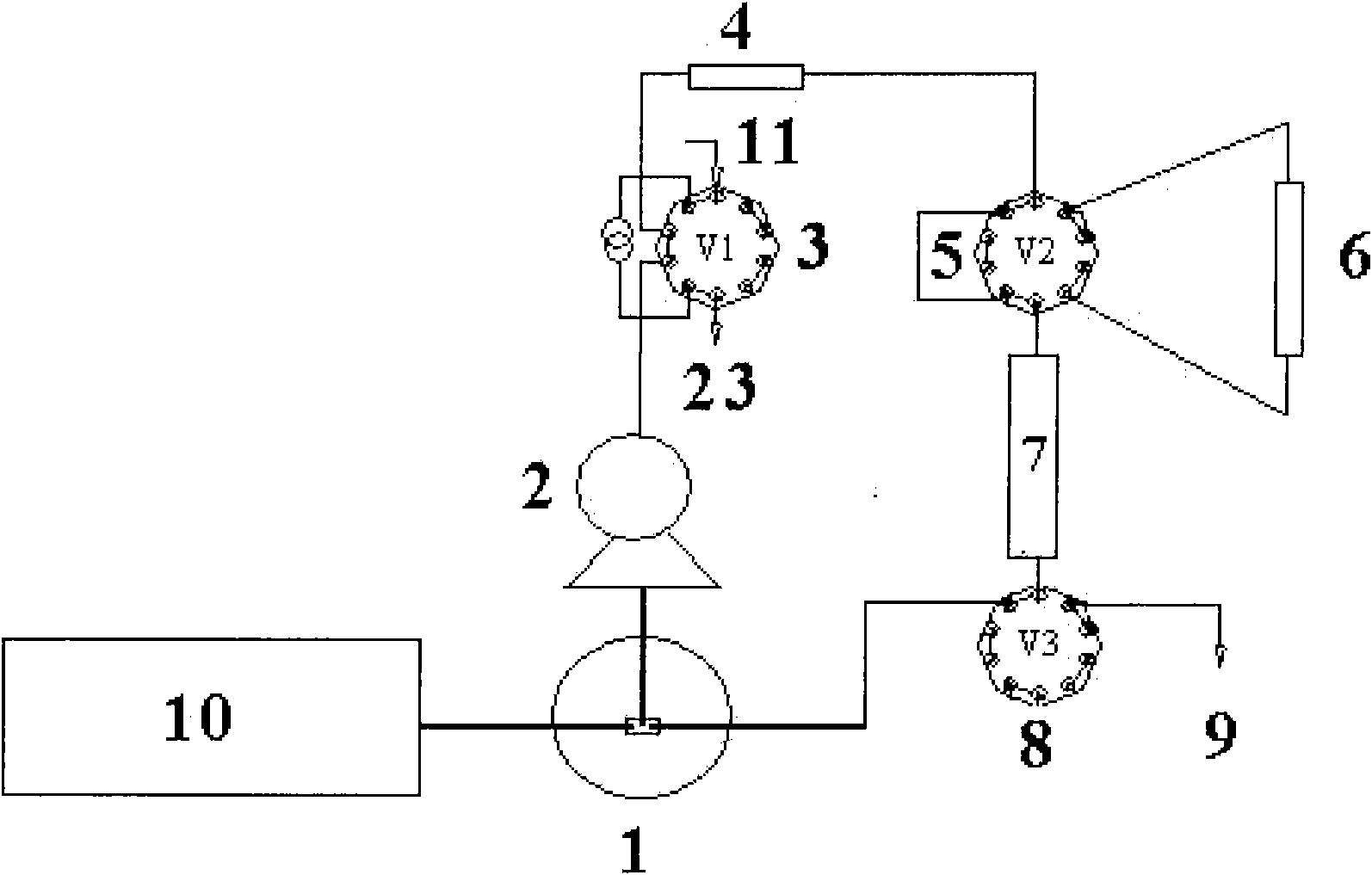

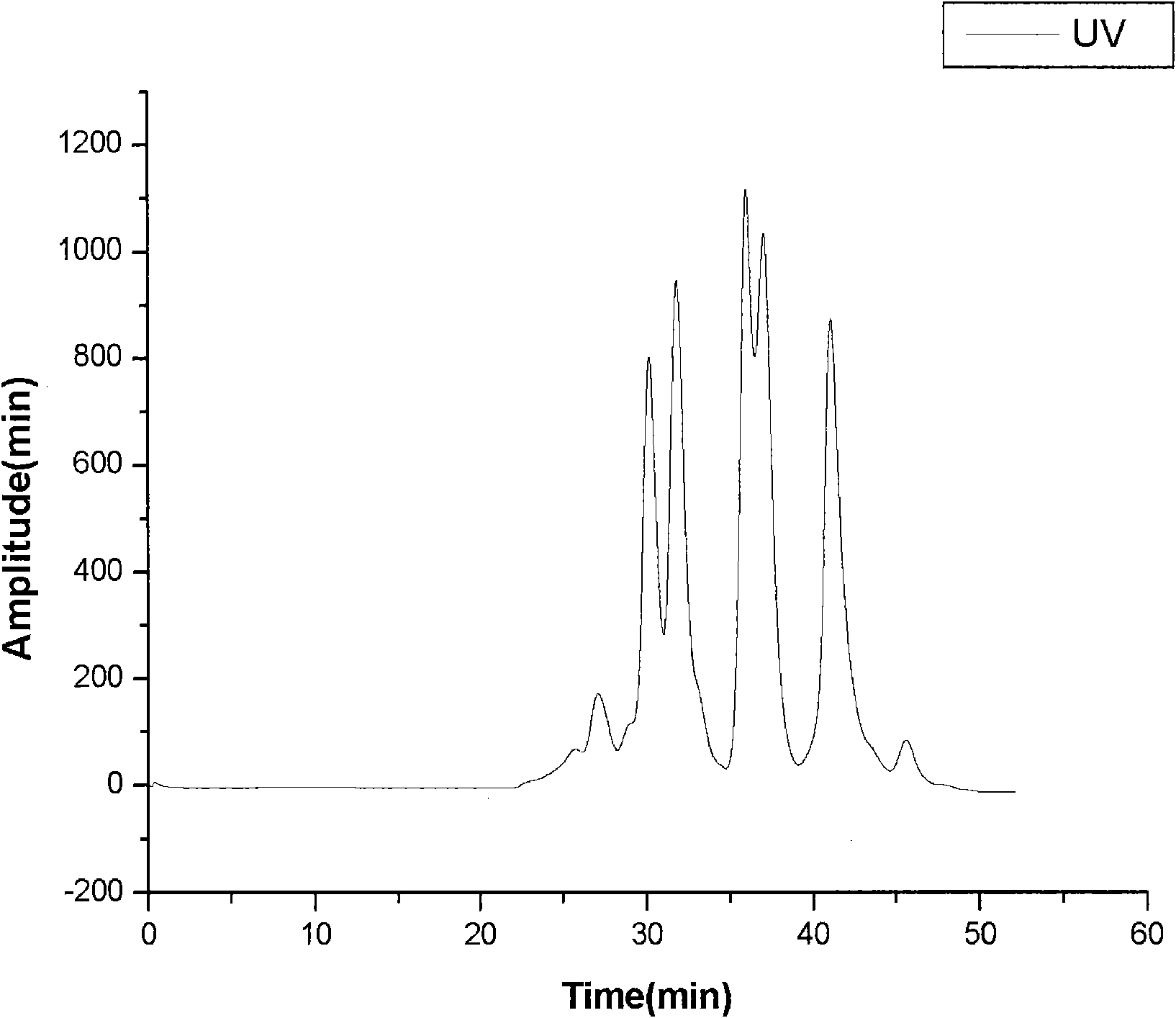

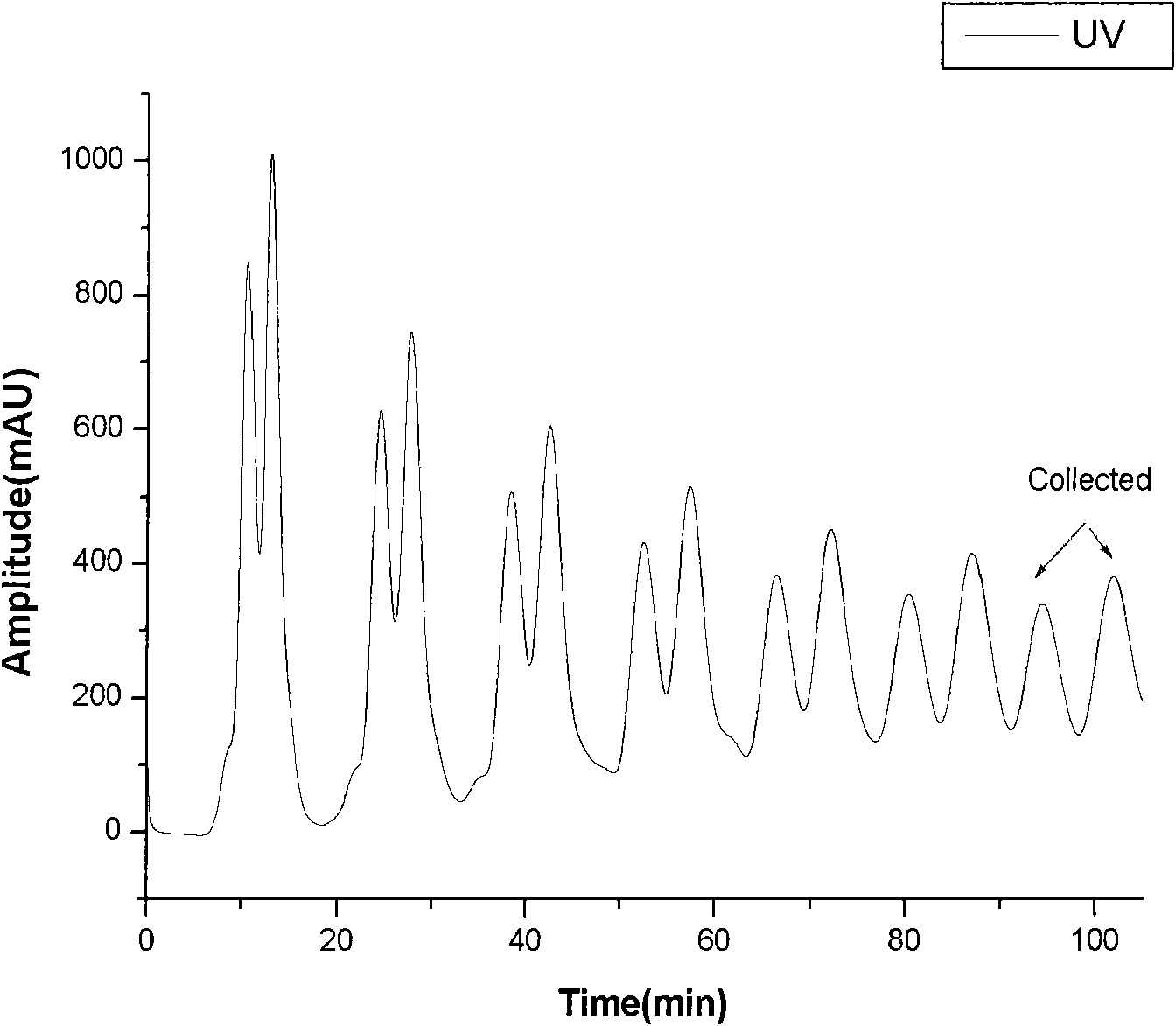

Column-switching circulating volume exclusion chromatography system for biomacromolecule separation and purification

InactiveCN101619090AHigh-resolutionEasy to separateSugar derivativesSolid sorbent liquid separationImage resolutionColumn switching

The invention relates to a column-switching circulating volume exclusion chromatography system for biomacromolecule separation and purification, which comprises a liquid chromatography pump, a sampling valve, a three-way or four-way connector, a switching valve A, a switching valve B, a volume exclusion column A, a volume exclusion column B and a detector. The pump, the sampling valve, the volume exclusion column A, the switching valve A, the volume exclusion column B, the detector, the switching valve B and the three-way or four-way connector are connected with one another in turn through pipelines, the number of the biomacromolecules getting into a circulation and separation system can be controlled by adjusting the switching frequency or mode of the valve A, and the separation and the collection of the biomacromolecule components can be controlled by adjusting the switching of the valve B. Compared with the conventional volume exclusion chromatography, the system has the characteristics of strong separating power, high resolution and the like, and can be applied to the separation and the purification of biomacromolecule samples. Simultaneously, the system also has good utility value in constructing a continuous biomacromolecule multi-dimensional separation platform.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

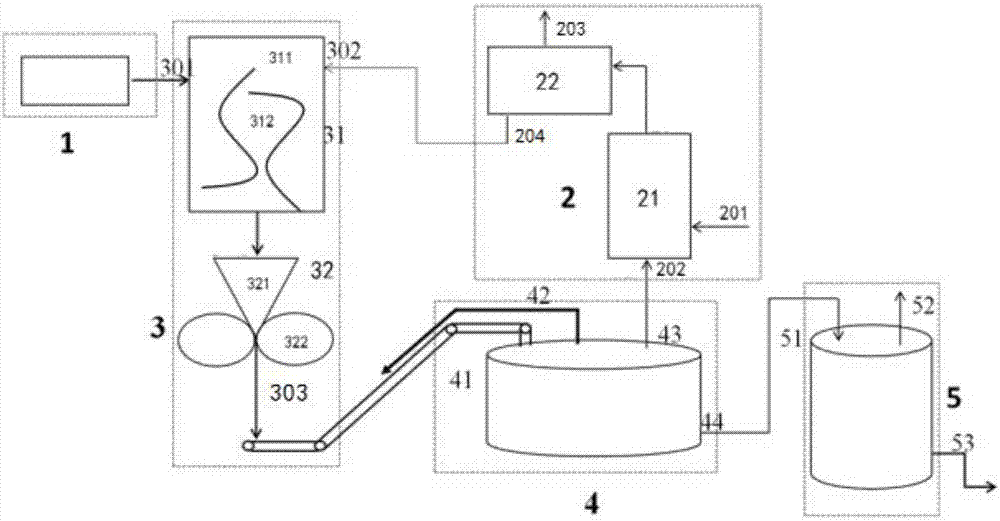

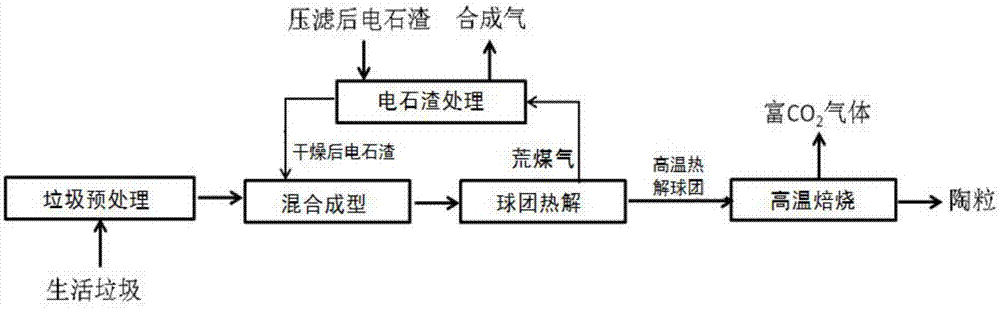

System and method for comprehensive treatment of garbage and carbide slag

PendingCN107541223ARealize resourcesHarmlessHydrogen productionSpecial form destructive distillationSyngasSlag

The invention relates to a system and method for comprehensive treatment of garbage and carbide slag. The system comprises a carbide slag treatment unit, a mixed forming unit, a pellet pyrolysis unitand a high-temperature roasting unit; the carbide slag treatment unit comprises a carbide slag inlet, a raw coke-oven gas inlet, a syngas outlet and a dried carbide slag outlet; the mixed forming unitcomprises a dried carbide slag inlet, a garbage inlet and a mixed pellet outlet; the pellet pyrolysis unit comprises a mixed pellet inlet, a flue gas outlet, a raw coke-oven gas outlet and a high-temperature pyrolysis pellet outlet; the high-temperature roasting unit comprises a high-temperature pyrolysis pellet inlet, a CO2-rich gas outlet and a roasted ceramsite outlet. The system and method ofthe comprehensive treatment of the garbage and carbide slag disclosed by the invention use an anaerobic pyrolysis furnace to carry out co-pyrolysis on the garbage and the carbide slag, and an obtained product is in direct contact with the carbide slag, so that the high-quality syngas is obtained while the carbide slag is dried; furthermore, the solidification effect of calcium oxide in the carbide slag on garbage heavy metals is fully utilized to prepare safe and high-performance building ceramsite.

Owner:SHENWU TECH GRP CO LTD

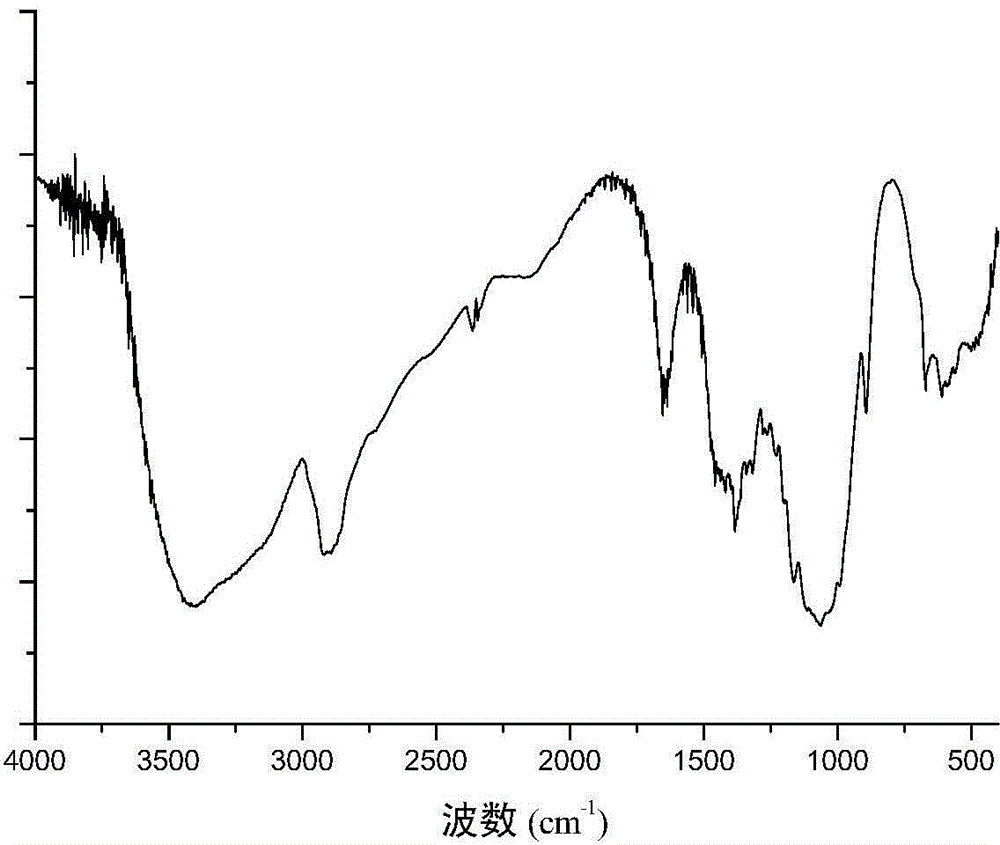

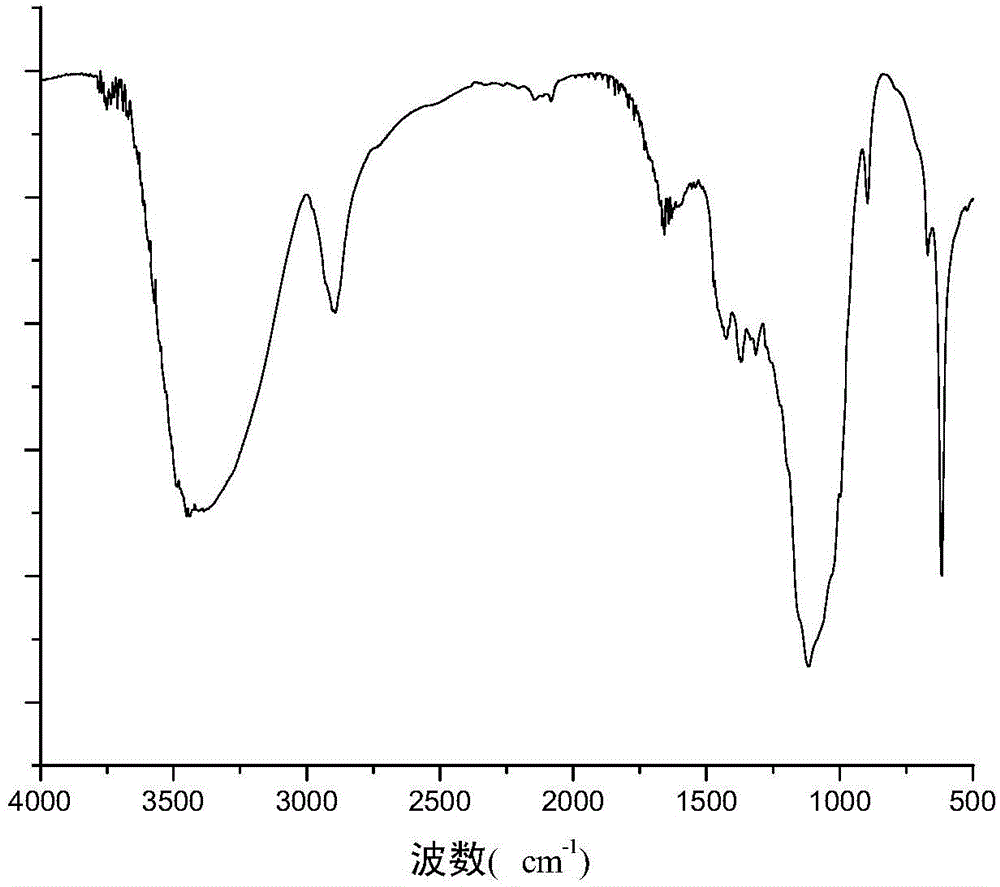

Artesunate surface molecular imprint porous magnetic cellulose microsphere as well as preparation method and application thereof

ActiveCN104693363ARealize separation and purificationThe separation process is simple and convenientOther chemical processesFerroso-ferric oxidesCellulosePolymer science

The invention relates to an artesunate surface molecular imprint porous magnetic cellulose microsphere, which is prepared from artesunate, acrylamide, methacrylic acid, a magnetic cellulose microsphere, an initiator and water. The cellulose is dissolved through an alkalinuria system, so as to prepare a fluid of Fe3O4 and the porous magnetic cellulose microsphere, so that the artesunate surface molecular imprint porous magnetic cellulose microsphere is prepared. The artesunate surface molecular imprint porous magnetic cellulose microsphere is used for selectively identifying and adsorbing artesunate as an adsorbent, is capable of quantitatively detecting the artesunate, and separating and purifying the substance. The microsphere can be recycled and repeatedly utilized.

Owner:EAST CHINA NORMAL UNIV

Biological enzyme purification separating device

InactiveCN103131630AStay activeKeep activeApparatus sterilizationMicroorganism fixing/supporting apparatusHollow fibreTraffic volume

The invention provides a biological enzyme purification separating device. The biological enzyme purification separating device comprises a raw material storage tank, a Graef pump, a micro-filter tube, a rejection liquid collection pump, a wash tank, a flow adjusting device, a valve, a pressure gage, a flow gauge, and a material tube. The biological enzyme purification separating device can achieve continuous filtering and separating of high turbidity liquid under the fully sealed condition and maintaining of high activity of zymin. Due to the fact that the micro-filter tube, with the pore diameter of 0.1-0.2 microns and high-strength, acid-base resistance and corrosion resistance, of a hollow fiber organic membrane or ceramic or acstainless steel component is adopted, the biological enzyme purification separating device can efficiently conduct edulcoration and degerming and achieve separation and purification effect, at the same time, cannot damage an original ingredient, an original structure, an original special flavor, and original energy activity, improves sanitary quality of products. The biological enzyme purification separating device is widely applied for filtering and separation of variousbiological enzymes with strict demands for microorganismsanitation and enzyme activity and at the same time is further suitable for filtering and separation of certain simple liquid state drinks and condiments.

Owner:XIAN REJE BIOLOGICAL TECH

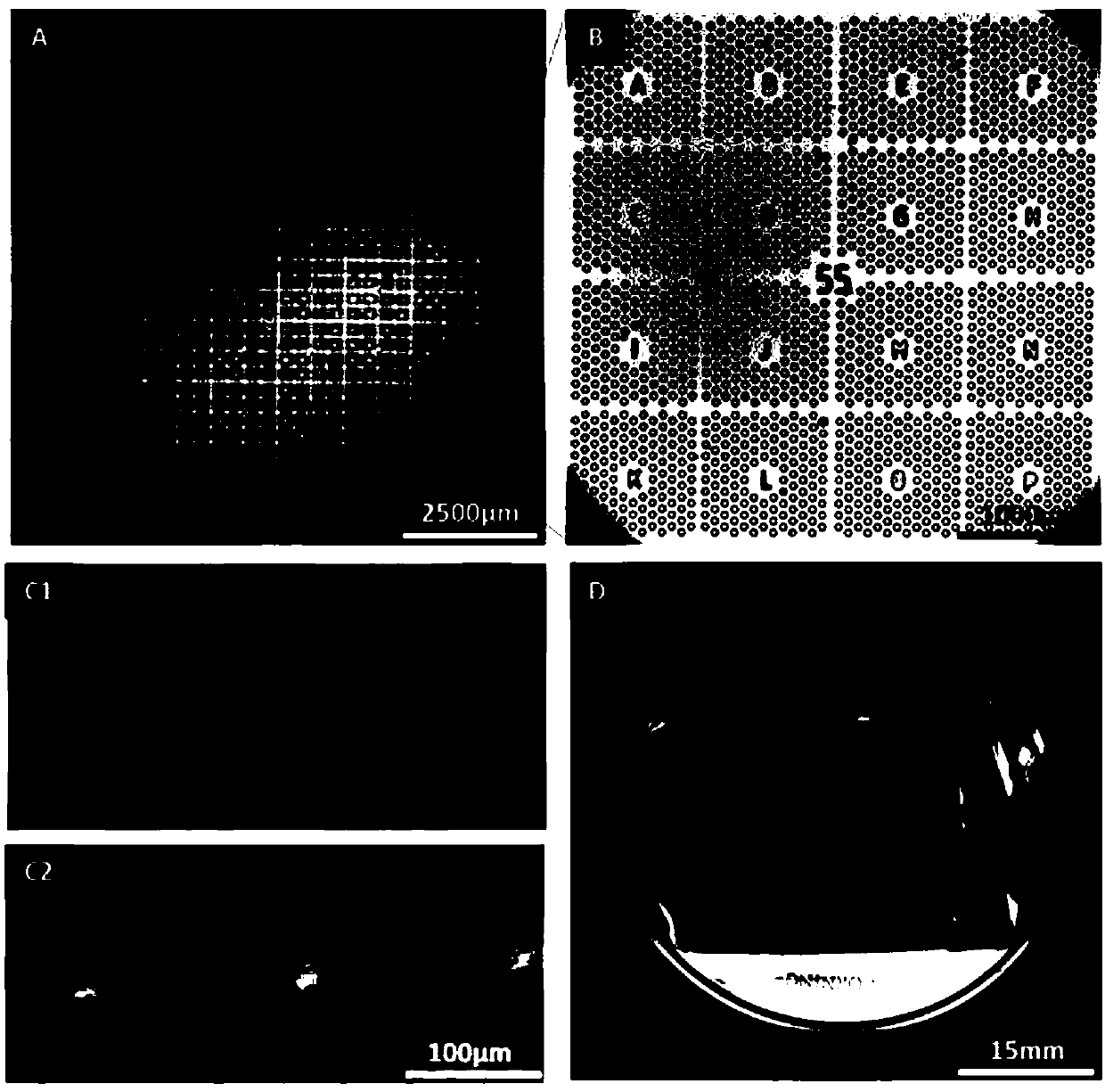

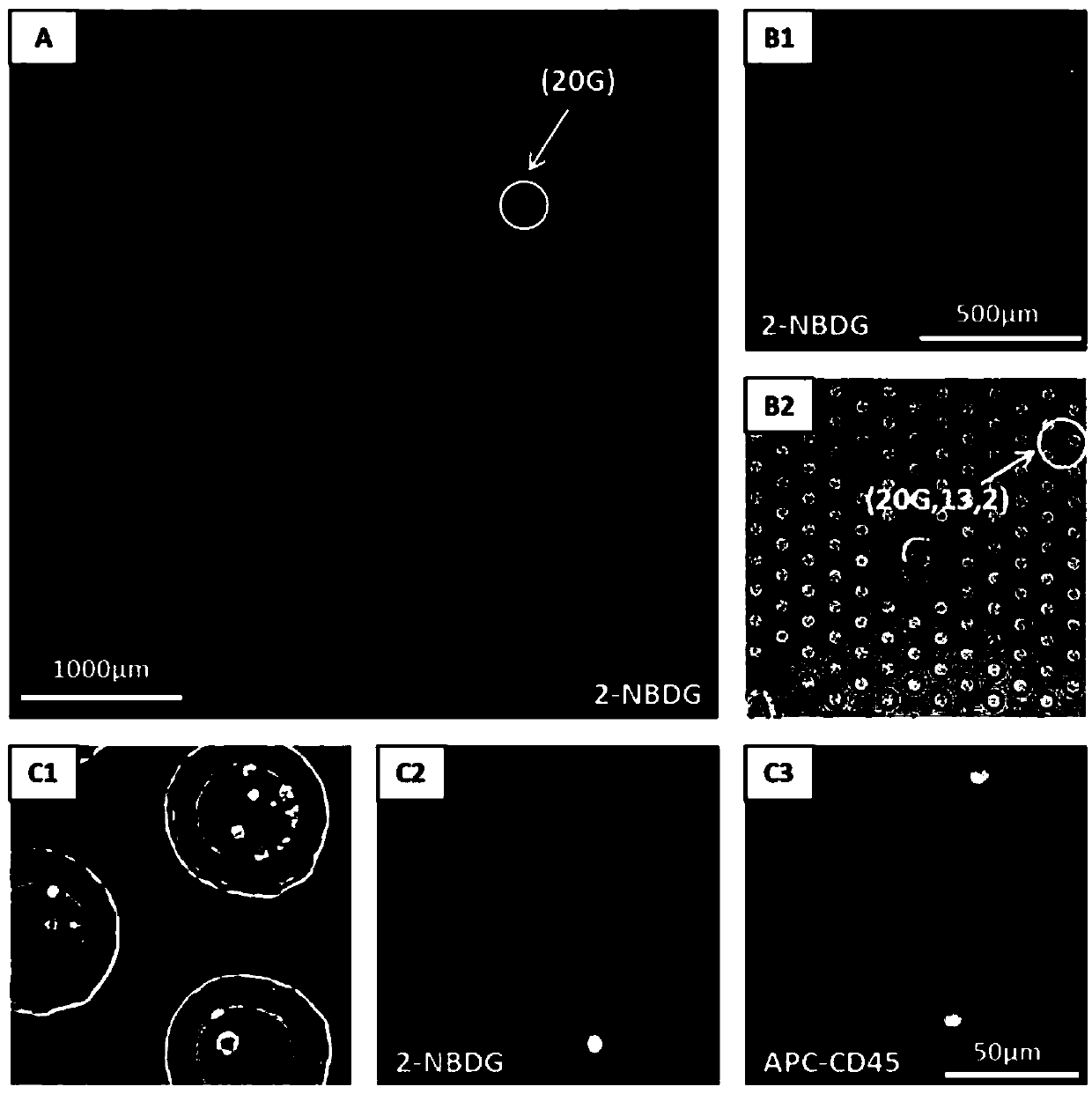

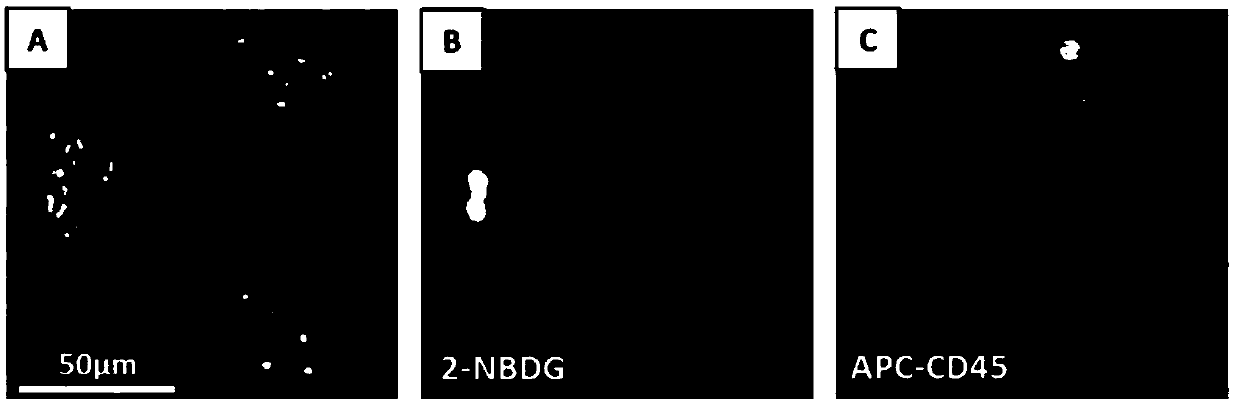

Micro-fluidic device and method for negative separation of circulating tumor cells and clusters

InactiveCN108671971AAchieving simultaneous negative separationRealize separation and purificationLaboratory glasswaresFluid controllersCirculating cancer cellCell separation

The invention provides a micro-fluidic device for negative separation of circulating tumor cells and clusters. The micro-fluidic device is made by assembling a sample storage chamber and a micro-fluidic chip by virtue of thermal bonding, the micro-fluidic device has the diameter of 60mm and is the same as a cell-culture dish having the diameter of 60mm, and the micro-fluidic device can be just putinto the culture dish to centrifuge. A micro-cavity array chip is capable of synchronously capturing CTCs (Circulating Tumor Cells) and CTCs-Clusters, and on the base of the micro-fluidic device, synchronous negative separation of the CTCs and CTCs-Clusters can be realized; the whole micro-cavity array chip is divided into 64 regions by numbers from 1 to 64, and each region is divided into 16 cells by letters from A to P, so that each micro cavity can be accurately located, accurate localization and single-cell isolation purification of the enriched CTCs / CTCs-Clusters can be realized, and convenience is provided for performing single-cell analysis on subsequent target cells.

Owner:UNIV OF SCI & TECH BEIJING

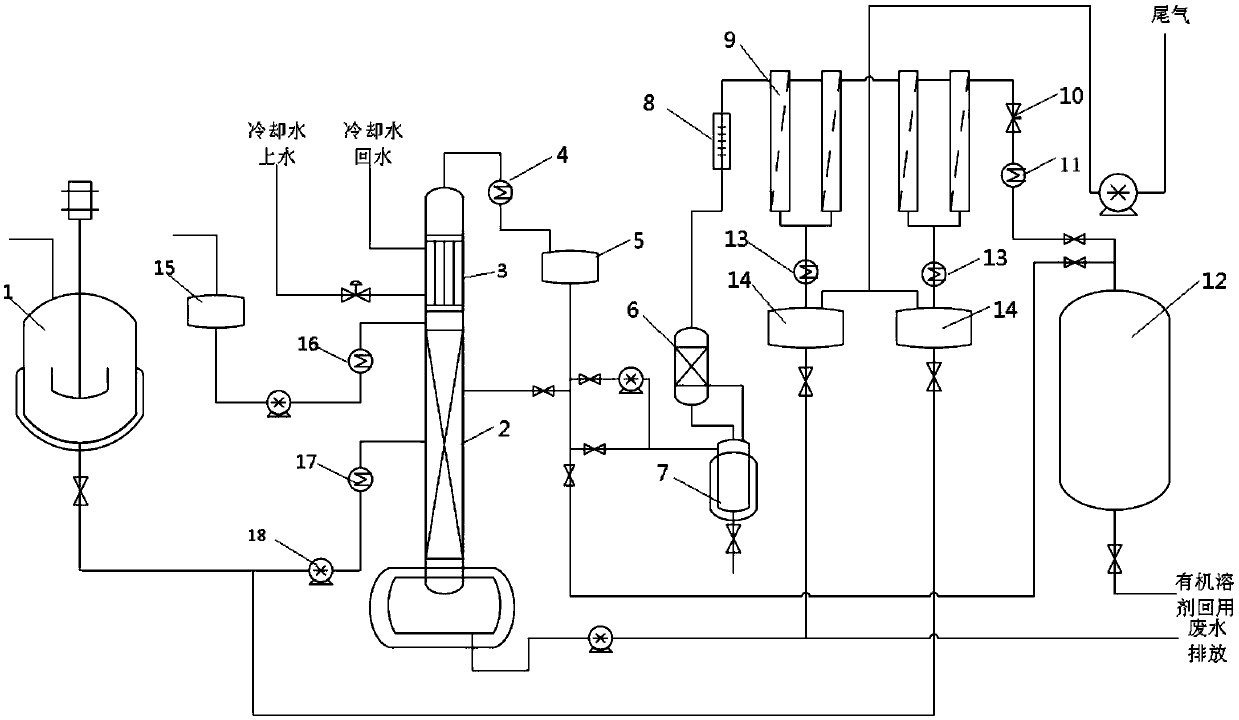

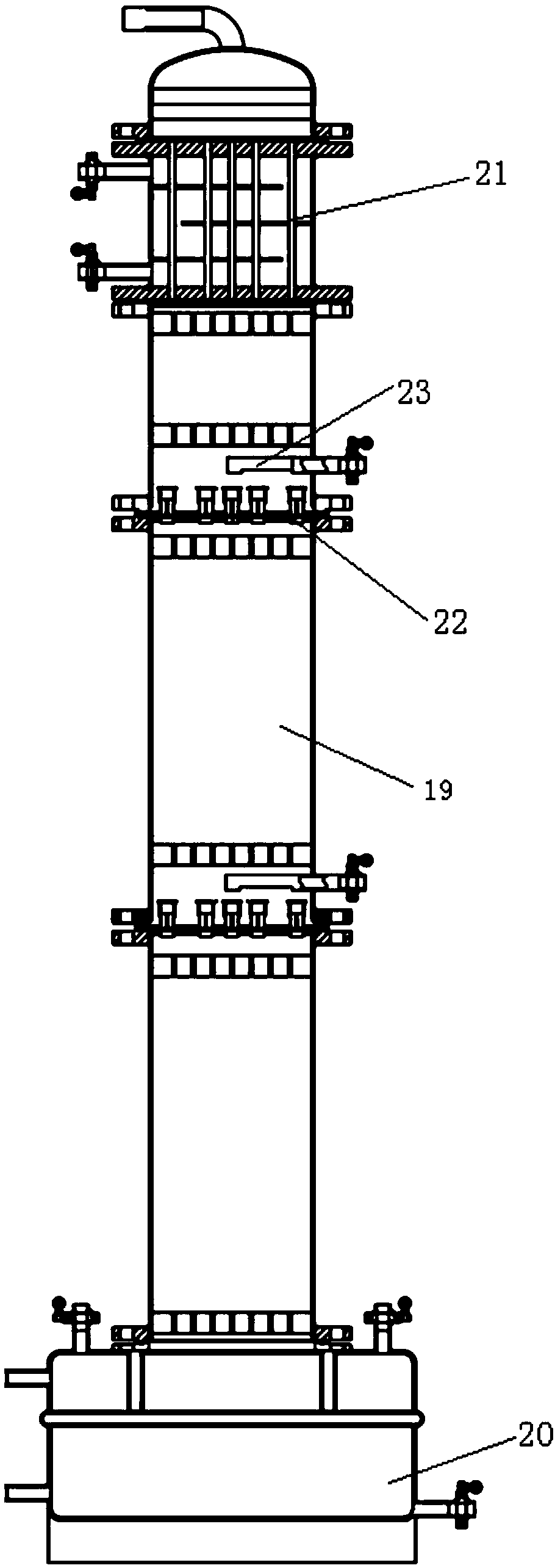

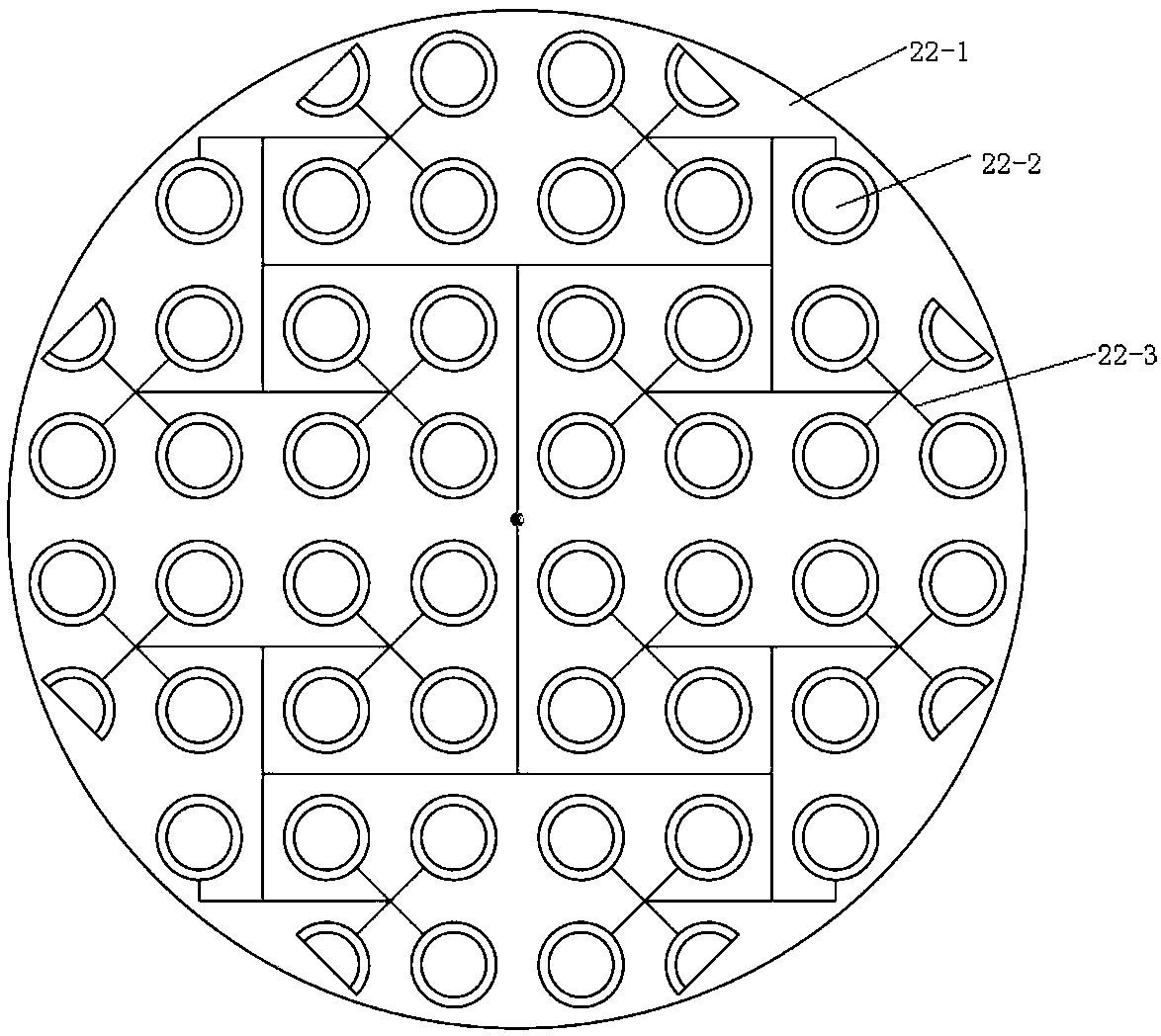

Separation and recycle system for water-containing organic waste liquid and organic solvents as well as recycle method

PendingCN109663376AAvoid accumulationEasy to separateLiquid distribution in distillationDistillationLiquid wasteRecovery method

The invention provides a separation and recycle system for water-containing organic waste liquid and organic solvents as well as a recycle method, wherein the separation and recycle system consists ofa distillation system and a pervaporation membrane separation system through process pipeline connection. A packed tower is adopted as a rectifying tower, and the material inlet of the packed tower is arranged in the center of a packed tower liquid distributor. A damping structure is arranged in the pervaporation membrane unit of the pervaporation membrane separation system. The separation and recycle system provided by the invention is suitable for online dehydration and recycle of multiple kinds of water-containing and two or more than two azeotropic or non-azeotropic organic solvents as well as for separation and reuse of the organic solvents.

Owner:CHENGDU GELAI HIGH TECH CO LTD

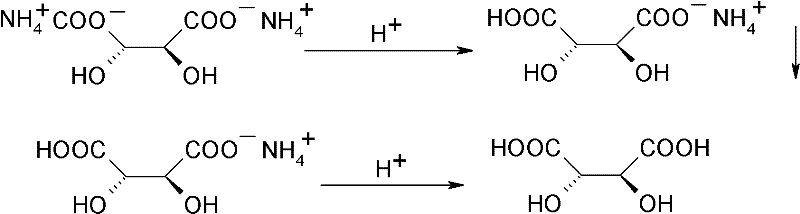

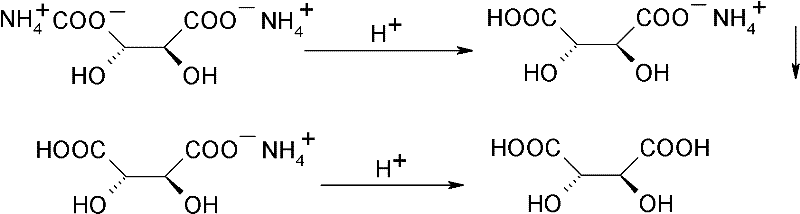

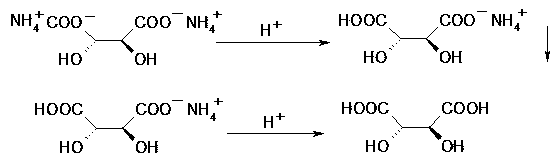

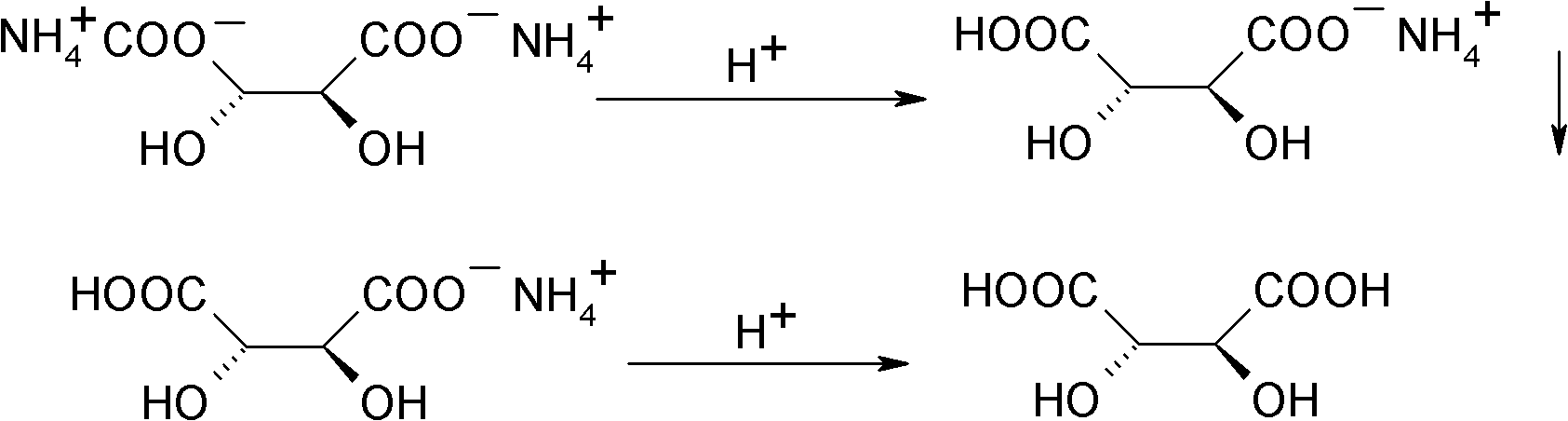

Method for recovering and recycling L-tartaric acid

ActiveCN102503810ARealize separation and purificationReduce generationPreparation from carboxylic acid saltsOrganic compound preparationHydrogenWastewater

The invention provides a method for recovering and recycling L-tartaric acid. The method comprises the following steps of: performing acidification and precipitation specific to waste water containing tartaric acid diammonium generated in a process for splitting racemic 4-methylsulfonylphenyl serine ethyl ester to form and separate a tartaric acid hydrogen ammonium salt; and acidizing and desalting to obtain a methanol solution of the L-tartaric acid. The method can be directly applied to the splitting process of racemic 4-methylsulfonylphenyl serine ethyl ester, and the recovery and recycling of the L-tartaric acid are realized. The method provided by the invention has mild reaction conditions and simple process operation, and the production cost of the splitting process can be greatly lowered.

Owner:京山瑞生制药有限公司

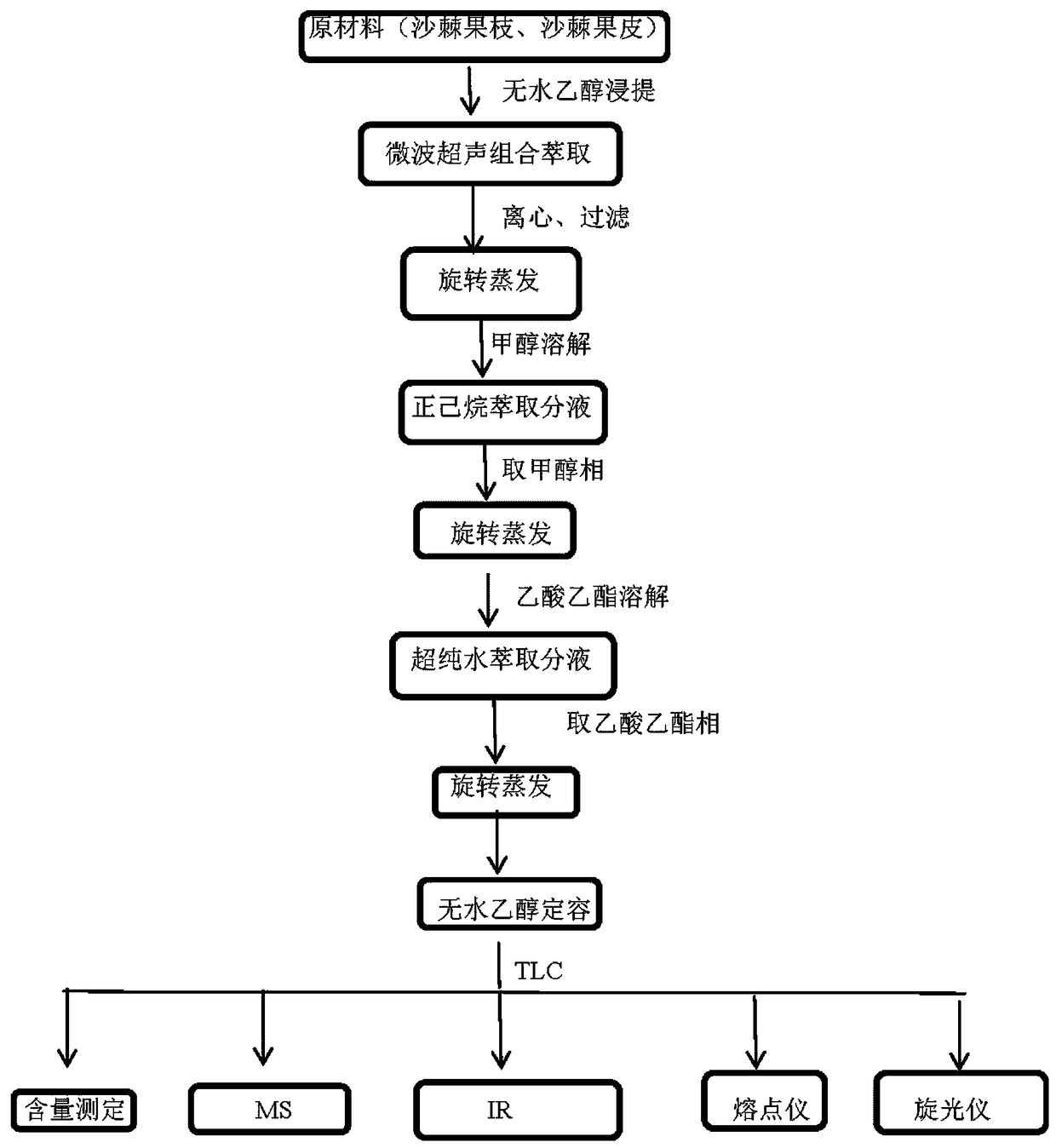

Method for carrying out extraction, inspection and content determination on 5-hydroxytryptamine in sea buckthorn

ActiveCN109187842ARealize separation and purificationEasy accessComponent separationPolarimeterEvaporation

The invention discloses a method for carrying out extraction, inspection and content determination on 5-hydroxytryptamine in sea buckthorn and relates to the field of extraction, inspection and content determination of indole derivatives in the sea buckthorn. Sea buckthorn fruit peels and fruit branches are taken as a raw material; the raw material is smashed and screened; absolute ethyl alcohol is added; ultrasonic microwave extraction is carried out; centrifugal filtration is carried out; the raw material is concentrated to 1 / 4; methanol is added for dissolution; normal hexane is added, andmixing, extraction and concentration are carried out; ethyl acetate is added for dissolution; after sufficient dissolution is carried out, ultrapure water is added; liquid separation is carried out; ethyl acetate phase is obtained and is concentrated to dry; little absolute ethyl alcohol is added for dissolution; volume is fixed at 50mL; content is determinated through TLC reflection scanning; molecular weight information of samples is determinated through utilization of a mass spectrometer; functional groups are detected through infrared; optical rotation and specific rotation are determinated through utilization of a polarimeter; evaporation and crystallization are carried out; and a melting point is determinated. According to the method provided by the invention, time and labor are reduced; a separation effect is relatively good; purity is high; a result is accurate; and the method for carrying out the extraction, inspection and content determination is simple in operation and highin efficiency.

Owner:LULIANG UNIV

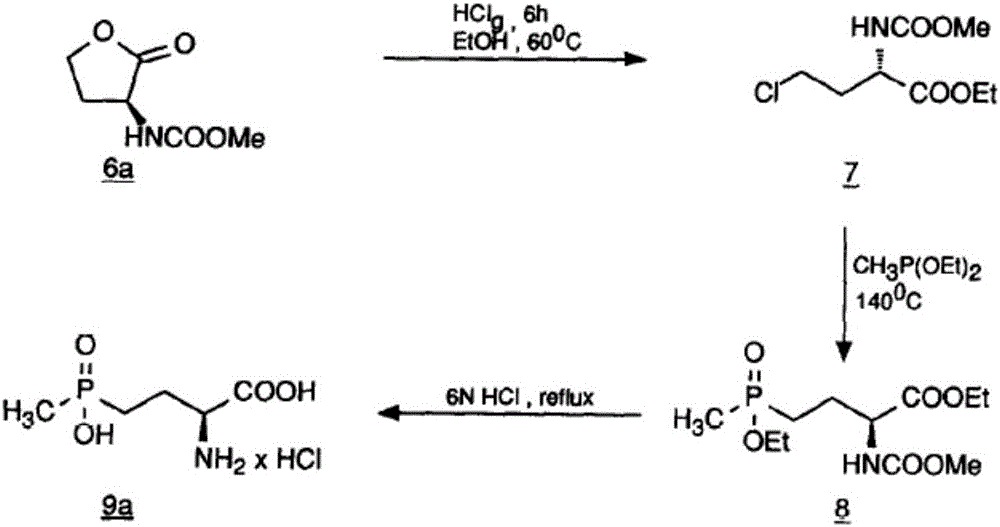

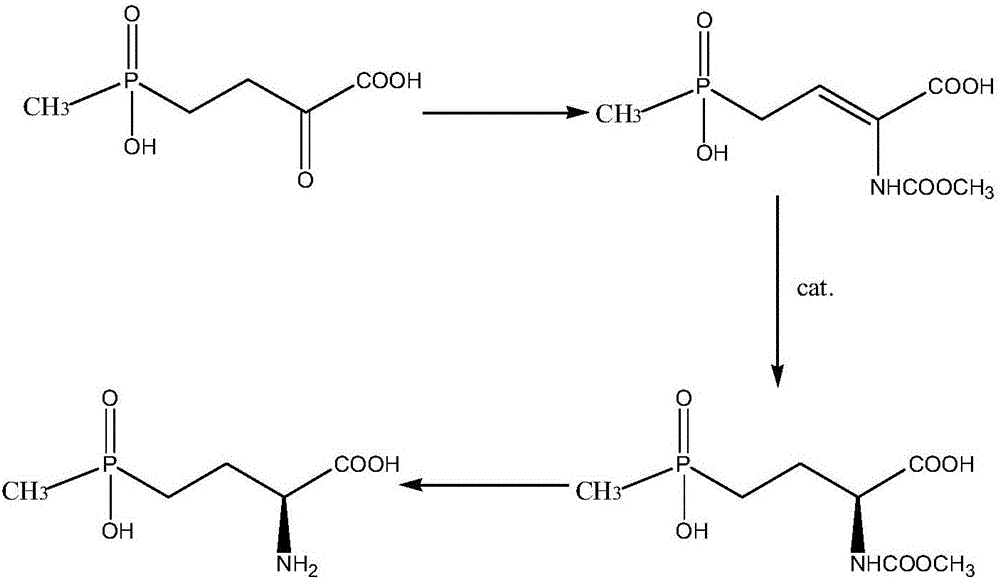

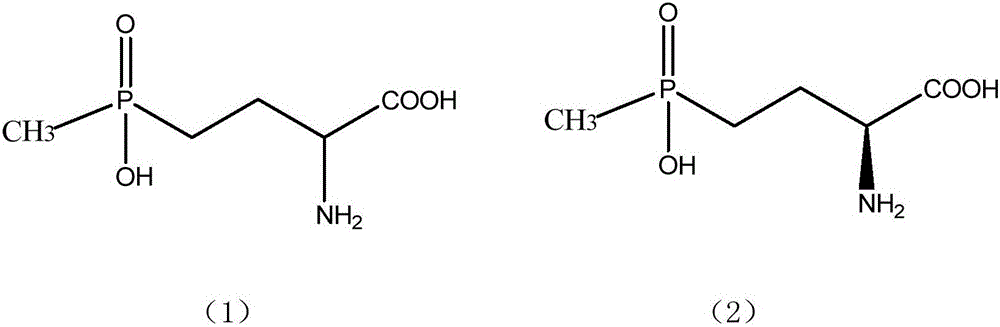

Method for separation and refining of L-glufosinate-ammonium and salts thereof

ActiveCN106188134AAchieve separationSolving Difficult-to-Purify ProblemsGroup 5/15 element organic compoundsGlufosinate-ammoniumSolubility

The invention discloses a method for separation and refining of L-glufosinate-ammonium and salts thereof. An L-glufosinate-ammonium acquisition method includes: adding crude glufosinate-ammonium into acid water solution, heating for dissolving, cooling for solid precipitation, filtering for separating solids, and subjecting filtrate to aftertreatment to obtain refined L-glufosinate-ammonium, wherein the content of L-glufosinate-ammonium in the crude glufosinate-ammonium is larger than 52%, and the pH value of the acid water solution is 1.2-4.0. According to different solubility of different glufosinate-ammonium isomers in specific-acidity water solution, purification and separation of free amino acids or hydrochlorides of L-glufosinate-ammonium are realized, chiral isomer separation is realized by low cost, high-content biological activity is obtained, and the problem of difficulty in purification of L-glufosinate-ammonium obtained by chemical synthesis is solved.

Owner:YONGNONG BIOSCI

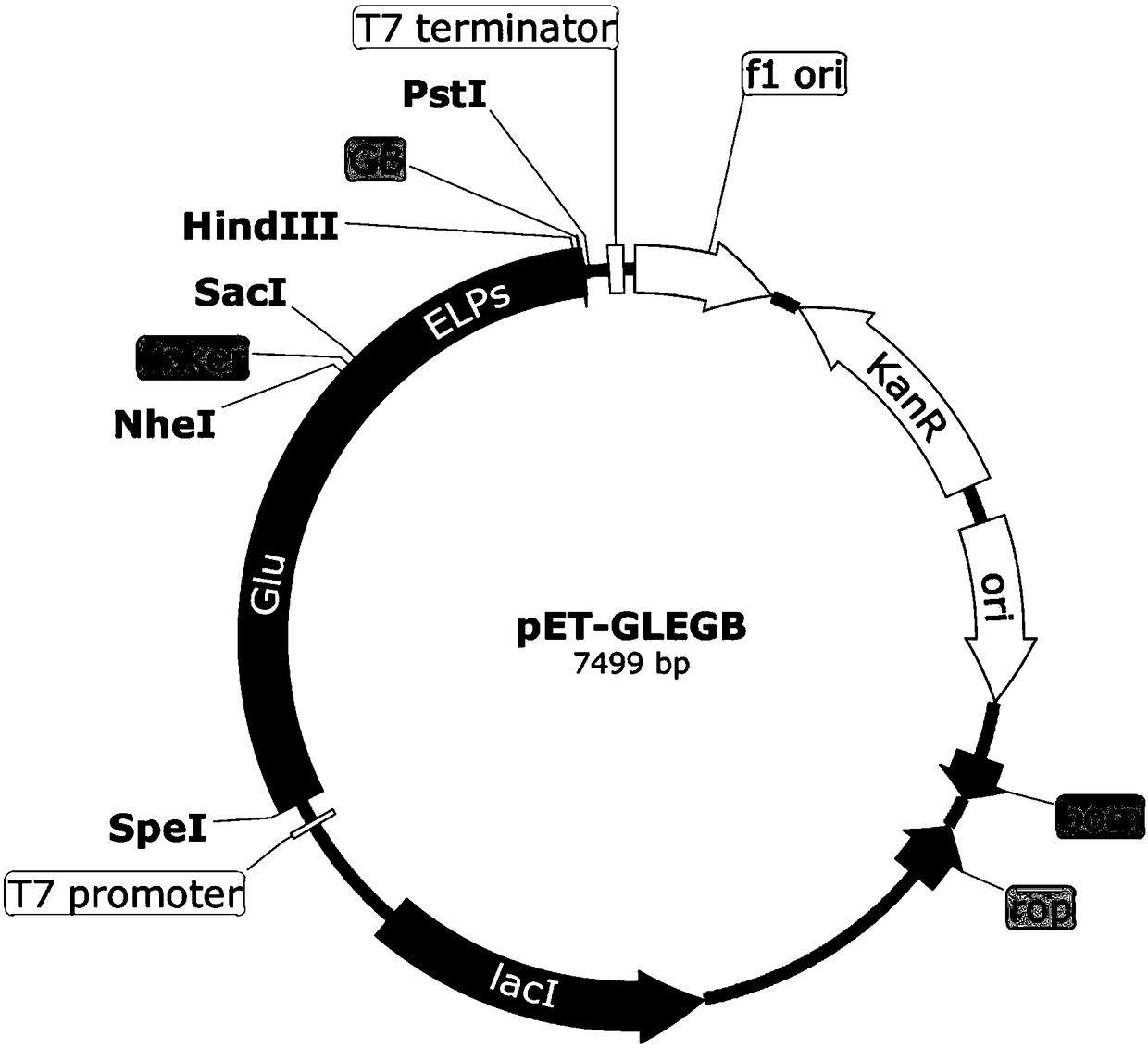

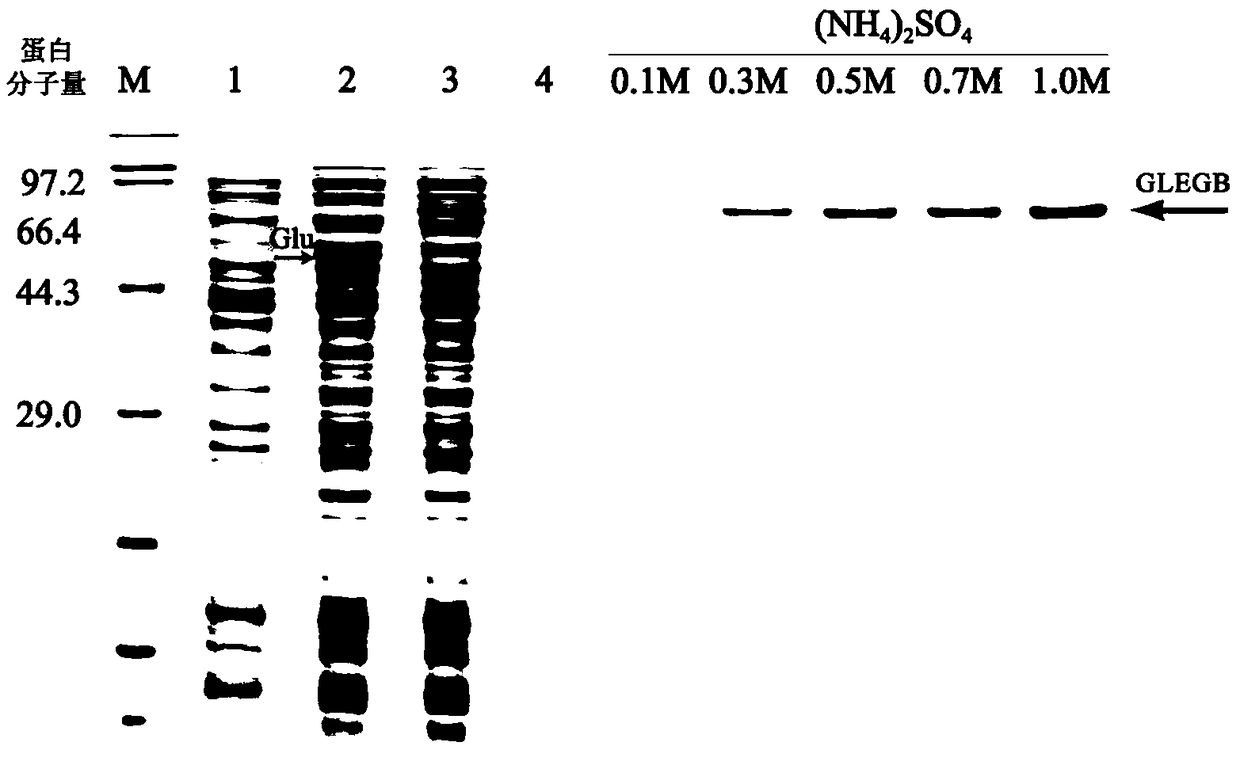

Recombinant beta-glucosidase and expression and purification method and immobilization application thereof

ActiveCN108752479AAchieve productionUnaffected structureAntibody mimetics/scaffoldsHybrid peptidesTemperature responseAlglucerase

The invention relates to a recombinant beta-glucosidase and an expression and purification method and the immobilization application thereof, and belongs to the technical field of biological enzyme engineering. The recombinant beta-glucosidase is recombinant beta-glucosidase Glu-linker-ELP-GB (GLEGB) obtained by linking binary labels ELP and GB with beta-glucosidase (Glu) through a universal linking peptide linker, wherein the sequence of GB polypeptide is linked to the 3' end of an ELP gene. By virtue of a reversible phase change property of an ELP label on recombinant enzyme, separation andpurification of the enzyme can be achieved; the recombinant enzyme containing the ELP label can be precipitated only by adding a certain amount of (HN4)2SO4 for incubation for a period of time; by virtue of a temperature response behavior of the ELP label, one-step rapid separation and purification of a target enzyme molecule is achieved; the enzyme purifying effect of the expression and purification method is superior to that of an ammonium sulfate precipitation method, and the purification cost of the expression and purification method is much lower than that of a chromatography method.

Owner:JIANGSU UNIV

Method of separating water soluble monascus pigment by the use of macroreticular resin and application thereof

ActiveCN106590020AAdsorption and desorption process is rapidHigh recovery rateNatural dyesBiotechnologyInorganic salts

The invention discloses a method of separating water soluble monascus pigment by the use of macroreticular resin and application thereof. The method comprises the steps of conducting solid-liquid separation on fermented monascus fungi fermentation primary liquid in a liquid fermentation medium, taking liquid to obtain extracellular water soluble monascus pigment fermentation solution, then adding the macroreticular resin after pretreatment to conduct absorbing, then using ethyl alcohol to conduct elution, removing eluent from obtained eluant and conducting frozen vacuum drying on the eluant, and finally obtaining the water soluble monascus pigment. According to the method of separating the water soluble monascus pigment by the use of the macroreticular resin and application thereof, the problems of unstable water soluble monascus pigment and massive impurities in the fermentation solution are solved by utilizing the macroreticular resin to conduct separation and purification on the monascus pigment; meanwhile efficient separation of the extracellular water soluble monascus pigment is achieved by removing impurities of polysaccharide, inorganic salt and the like in the monascus pigment fermentation solution, and a good application prospect and market value are provided.

Owner:SOUTH CHINA UNIV OF TECH

Process for separating copper in nickel-cobalt-copper system by solvent extraction method

InactiveCN102234722AHigh recovery rateRealize separation and purificationProcess efficiency improvementHigh concentrationSulfonate

The invention provides a process for separating copper in a nickel-cobalt-copper system by a solvent extraction method. The process comprises the following steps: by taking N902-sulfonated kerosene as an extracting agent, controlling the volume ratio of an organic phase to a water phase at (3:1) to (4:1); regulating the pH value of a material liquid to 2.0-2.5; extracting at room temperature; and after carrying out clearing and phase separation on raffinate, based on sulfuric acid as a reverse extraction acid for the copper-supported organic phase, controlling the volume ratio of the organic phase to the reverse extraction acid at (6:1)-(4:1), carrying out reverse extraction at room temperature, and eluting a reverse extraction liquid to obtain a copper sulfate solution. In the process, the N902-sulfonated kerosene is used as the extracting agent, sulfuric acid is used as a reverse extraction agent, copper is separated out of the high-concentration nickel-cobalt-copper system in a high selectivity and high reverse extraction property mode, and copper is output in a pure copper sulfate solution form, thereby avoiding the retreatment and recovery of copper slag with a chemical method, and the recovery of copper is high; and after nickel-cobalt raffinate with copper removed is subjected to sodium jarosite iron removal, P204 deep impurity removal and P507 separation of nickel-cobalt, nickel-cobalt salt products are produced, thereby achieving the purification and separation of copper in a nickel-cobalt-copper impure material and the comprehensive recovery of nickel-cobalt-copper.

Owner:JINCHUAN GROUP LIMITED

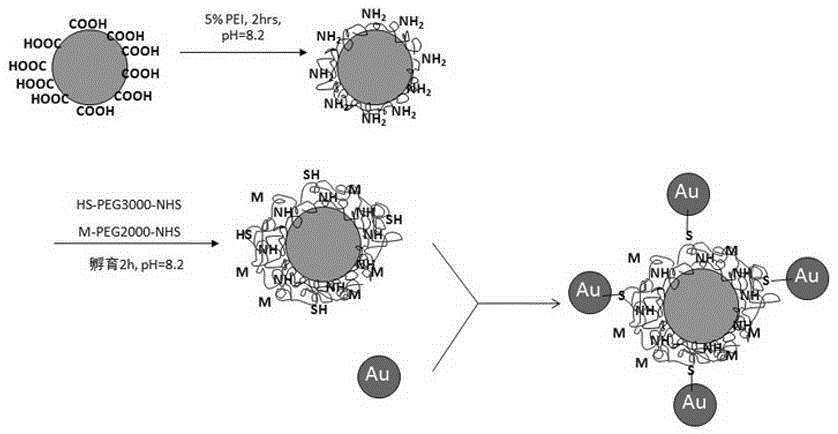

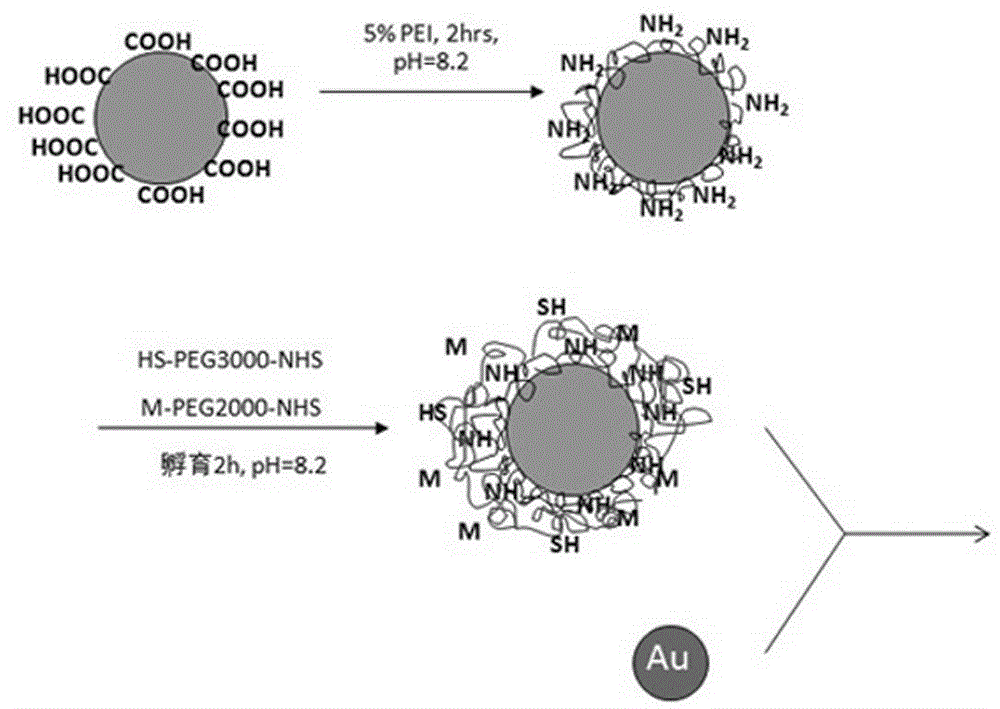

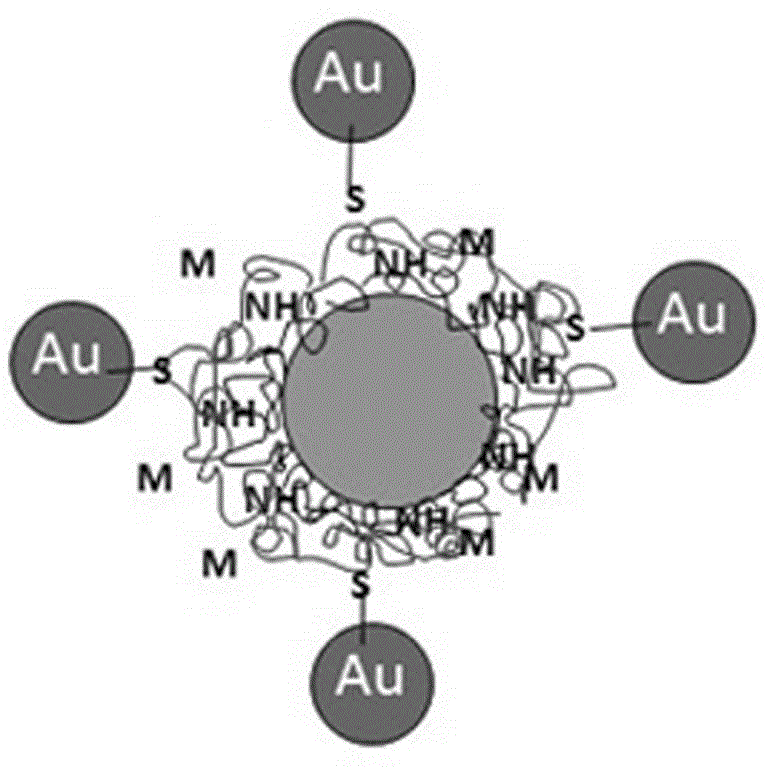

Functionalization method for modifying surfaces of magnetic particles with gold nanoparticles

InactiveCN104528636AThe method steps are simpleSimple and fast operationMaterial nanotechnologyNanostructure manufactureImidePolyetherimide

The invention provides a simple functionalization method for modifying surfaces of magnetic particles with gold nanoparticles, namely a surface carboxylation method for modifying the surfaces of the magnetic particles with the gold nanoparticles in a functionalization mode. Firstly, polyetherimide (PEI) is used for conducting amination on carboxyl functional groups on the surfaces of the magnetic nanometer or micrometer particles; then, polyethylene glycol (PEG) macromolecules are coupled to the aminated magnetic particles, wherein sulfhydryl (SH) radical groups are located at one end of each PEG macromolecule, and N-Hydroxysuccinimide is located at the other end of each PEG macromolecule; finally, the magnetic particles react with the gold nanoparticles, and therefore the magnetic nanometer or micrometer particles are modified with the gold nanoparticles. According to the method, the steps are simple, operation is simple, price is relatively low, and a nanometer-level multifunctional research platform can be built.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

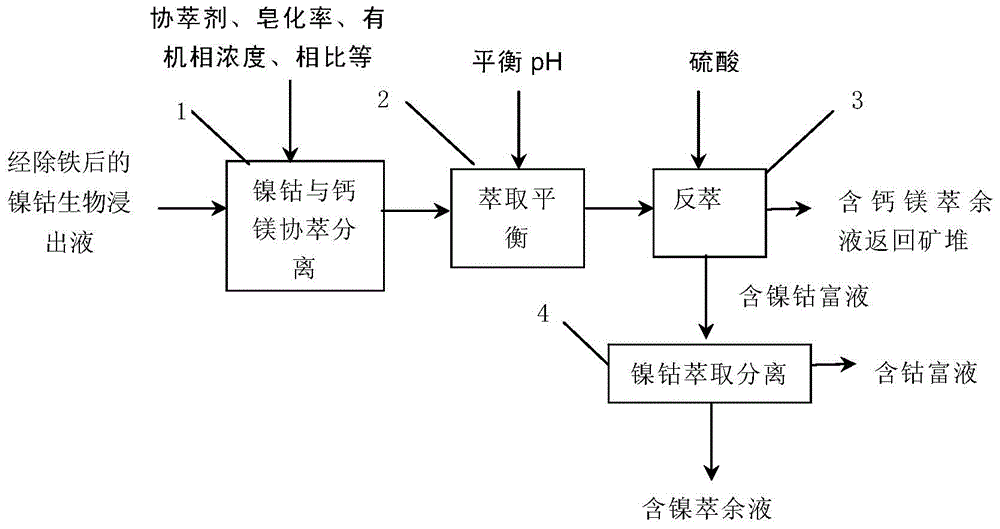

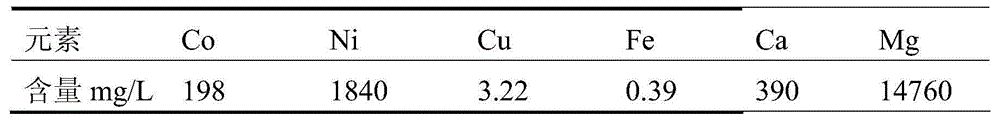

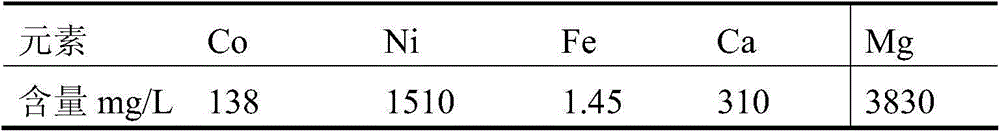

Method for removing calcium and magnesium from bioleaching solution of nickel cobalt by synergetic extraction method

ActiveCN105803197ARealize separation and purificationReduce entrainment lossProcess efficiency improvementPregnant leach solutionCobalt

The invention provides a method for removing calcium and magnesium from a bioleaching solution of nickel cobalt by a synergetic extraction method. The method comprises the following steps: homogeneous saponification is separately carried out for a nickel cobalt extractant Versatic10 and a synergic extractant Cynaex301 by using a NaOH solution, and saponification rate is 40-60%; an organic phase is composed of a combined extractant and a diluent Mextral DT100; the combined extractant comprises 20-40V% of the synergic extractant Cynaex301 and 80-60V% of the extractant Versatic; the volume of the combined extractant is 10-30% of the total volume of the organic phase; when an initial pH value is 1.5-3.0, the organic phase and the bioleaching solution of nickel cobalt are mixed with shaking, the pH value is controlled at 3.0-4.0 for balancing extraction, and after standing, the organic phase and the aqueous phase are separated; sulfuric acid is added into the organic phase for back extraction of nickel cobalt, so that effective separation between nickel cobalt as well as calcium and magnesium is realized.

Owner:有研资源环境技术研究院(北京)有限公司

Preparation method of high-purity monascus pigment component

InactiveCN101864191BRealize separation and purificationReduce consumptionNatural dyesBiotechnologyRed yeast rice

The invention provides a novel process for preparing high-purity monascus pigment. The process comprises the following steps of: crushing red yeast rice as a raw material; and separating and purifying to obtain 6 kinds of monascus pigment components by adopting a composite technology of extraction liquid extraction and high-speed countercurrent chromatography separation and crystallization, wherein the six monascus pigment components comprise rubropunctamine, monascorubramine, monascin, ankaflavin, rubropunctatin and monascorubin, and the purities of all the pigments are higher than 95 percent and can be used for preparing foods, cosmetic colorants and health products. The invention adopts easily-recovered organic solvent for separation to save the consumption of separation materials andovercome the problems of small treatment amount and inefficient single pigment component separation and purification of a TLC (Thin Layer Chromatography), an HPLC (High Performance Liquid Chromatography), a resin method and a silica gel column chromatography. The invention adopts the composite technology of the extraction liquid extraction and the high-speed countercurrent chromatography separation and the crystallization to prepare six kinds of high-purity monascus pigment crystals and has the advantages of simple steps and high yield.

Owner:FUZHOU UNIV

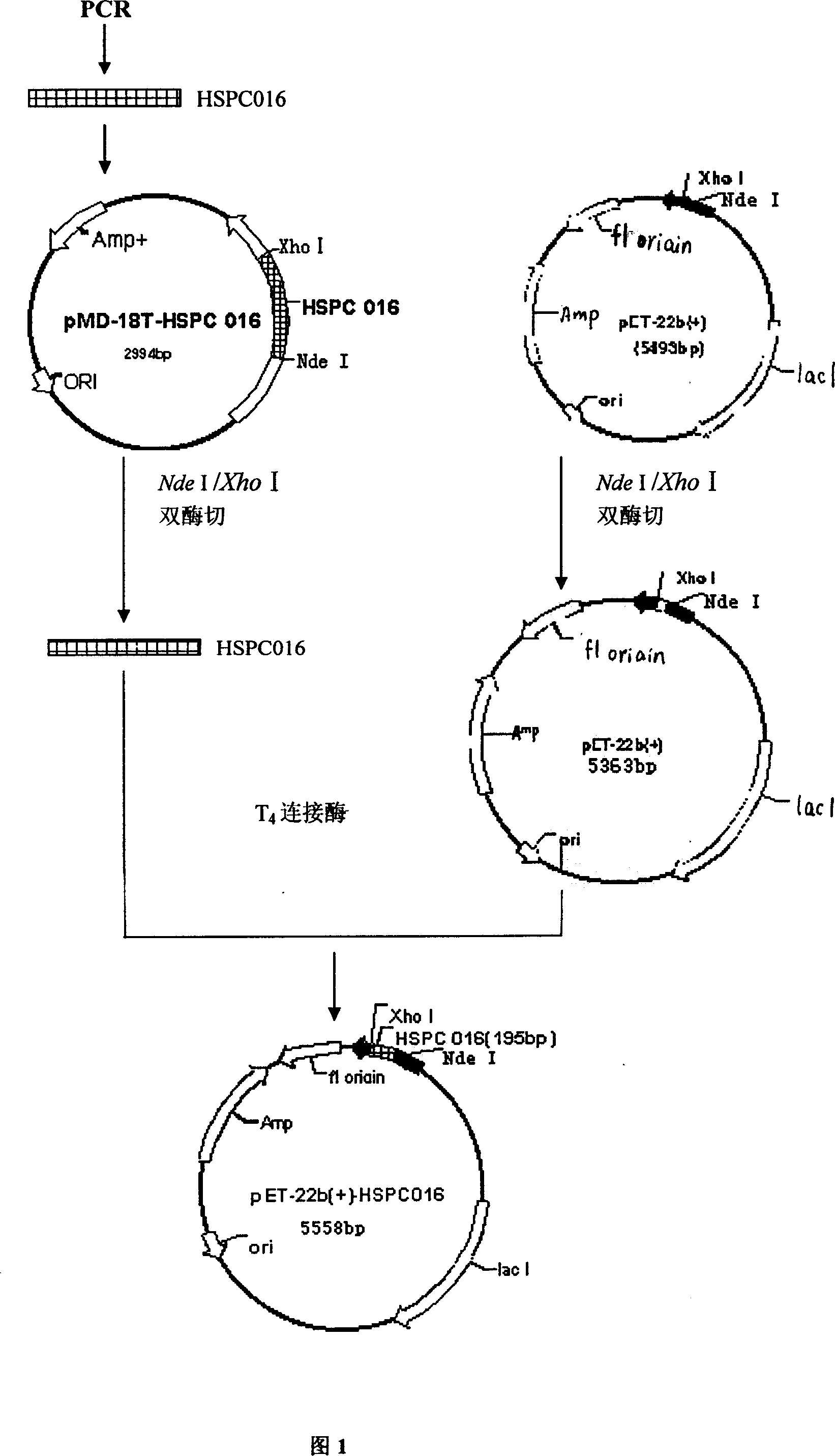

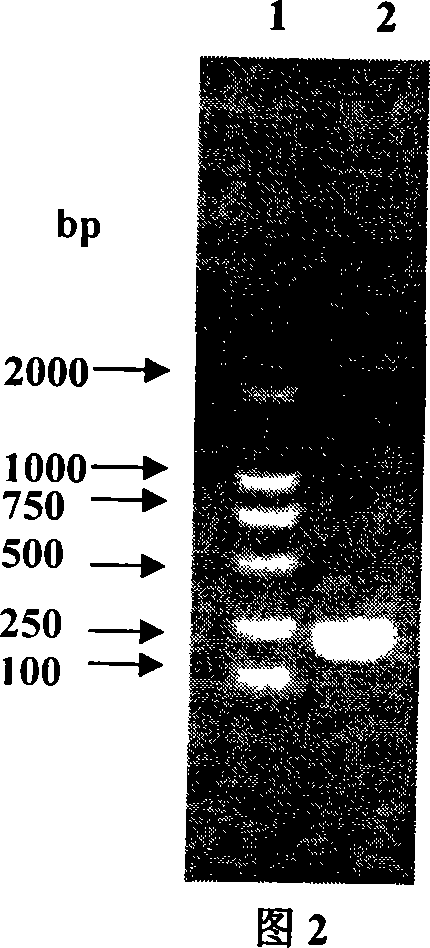

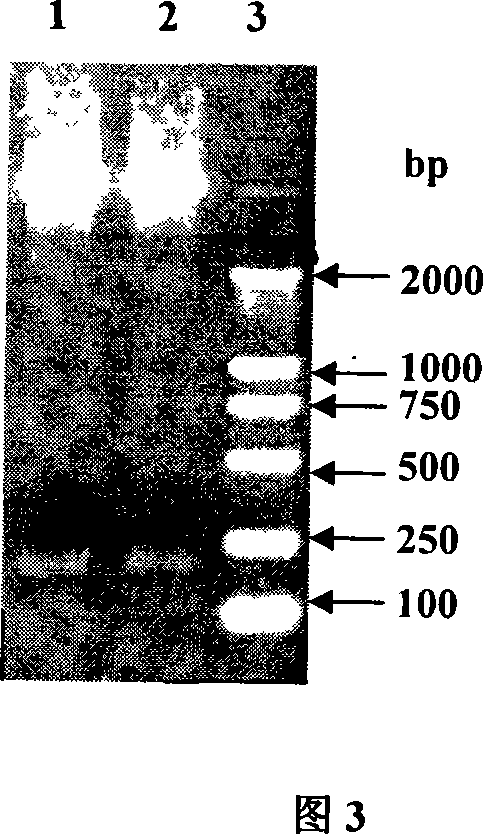

Gene engineering process of preparing human hair papilla cell protein HSPC016 and its expression vector and engineering bacterium

InactiveCN101067138AEasy to purifyRealize separation and purificationBacteriaMicroorganism based processesProtein targetGene engineering

The present invention relates to gene engineering, and is one kind of expression vector of human hair papilla cell HSPC016 gene. The vector is plasmid pET-22b(+) containing the functional sequence of HSPC016 gene, and the HSPC016 coded sequence is located between Nde I and Xho I cleavage site of pET-22b(+) vector. The present invention also relates to one kind of gene engineering bacterium transformed with the said vector and provides process of preparing human hair papilla cell HSPC016 target protein. The HSPC016 target protein is expressed through inducing colibacillus pET-22b(+) / HSPC016 / BL21 with IPTG. The present invention has the advantages of high target protein expressing amount, expression rate over 28 %, addition of 6xHis purification label for easy protein purification, high bioactivity of the target protein, etc.

Owner:THE FIRST AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIVERSITY OF PLA

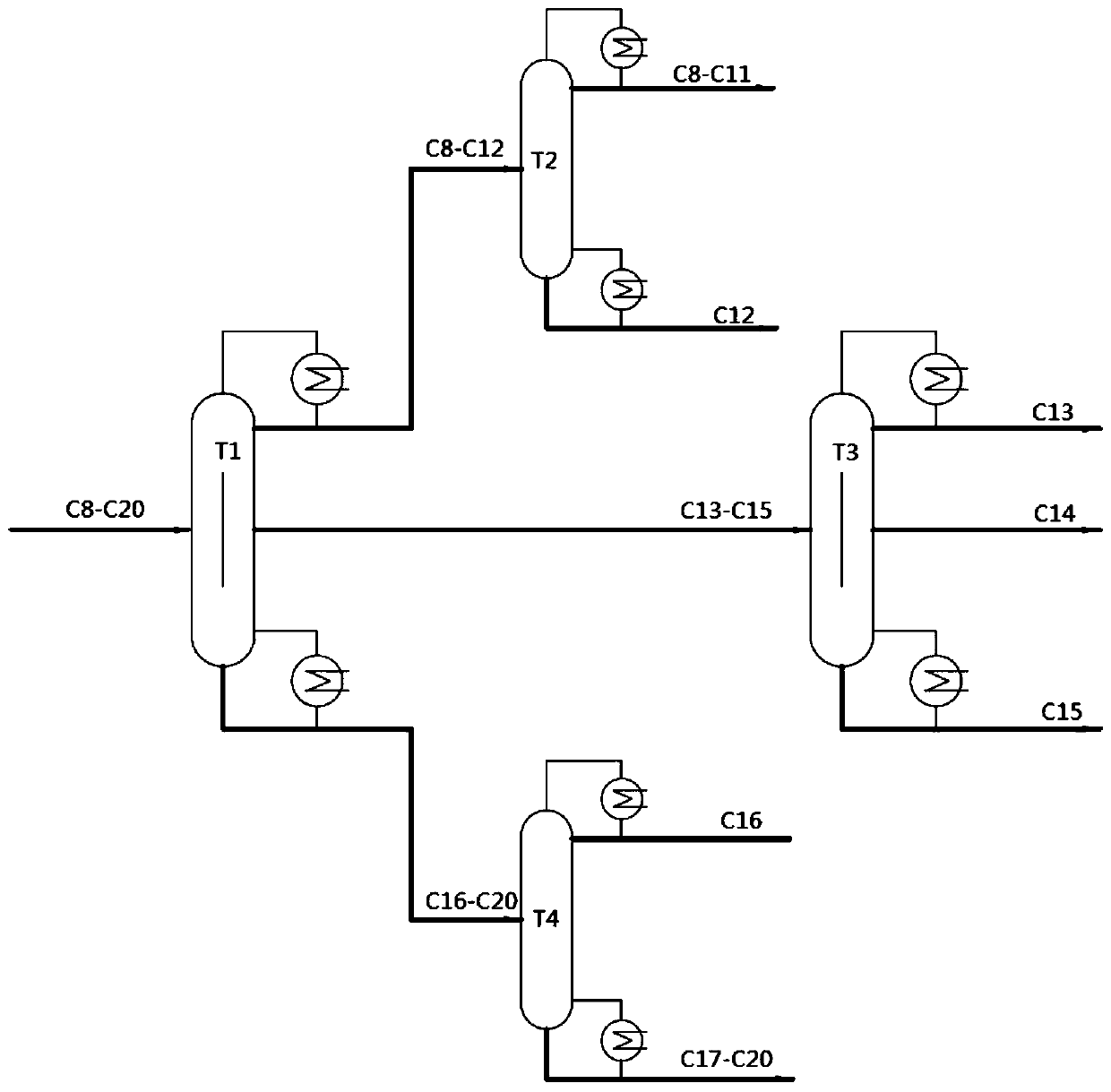

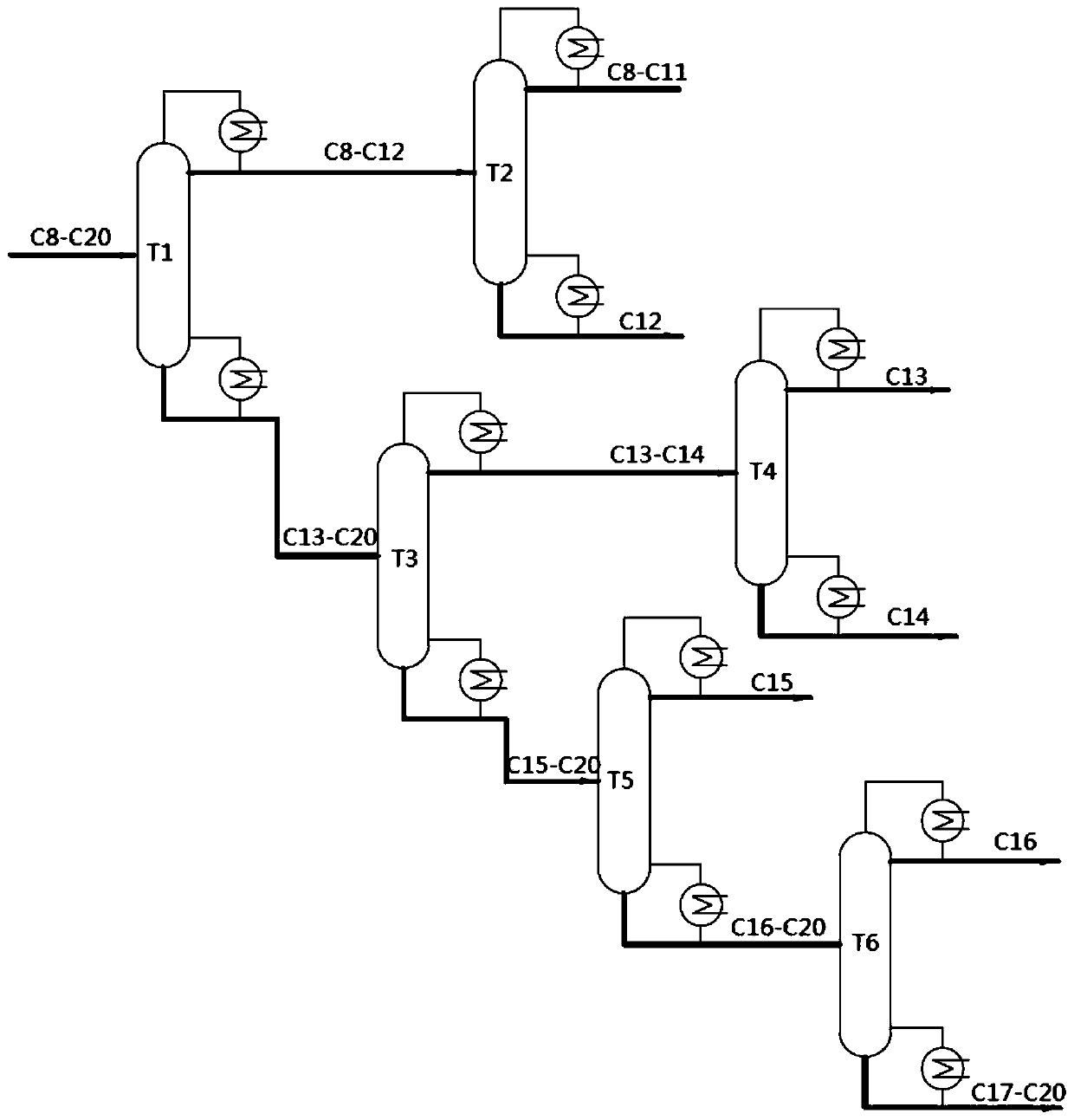

Separation and purification device for C8-C20 n-alkane mixed fractions and separation and purification process thereof

InactiveCN111073677ARealize separation and purificationTandem process simplificationHydrocarbon distillationDistillation purification/separationAlkaneProcess engineering

The invention discloses a separation and purification device for C8-C20 n-alkane mixed fractions and a separation and purification process thereof, the separation and purification device combines a partition plate rectifying tower and a conventional rectifying tower, the traditional multi-tower series process is simplified, a side extraction stream is added, and the separation of a target productis realized. The separation and purification are carried out on the target product C8-C20 n-alkane mixed fraction; according to the method, the seven products, namely the lightest C8-C11 mixture, theheaviest C17-C20 mixture and the high-purity C12, C13, C14, C15 and C16 single-component products, are obtained, so that the traditional process flow is greatly simplified, the energy consumption of the whole process is remarkably reduced, and the method has remarkable practicability and economical efficiency.

Owner:CHINA PETROLEUM & CHEM CORP +2

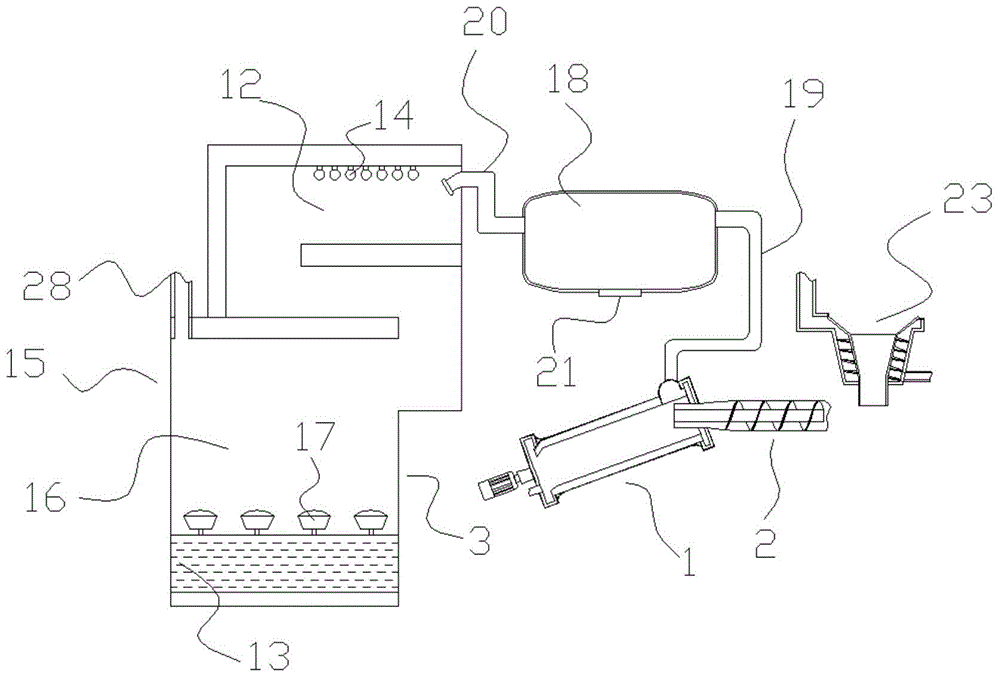

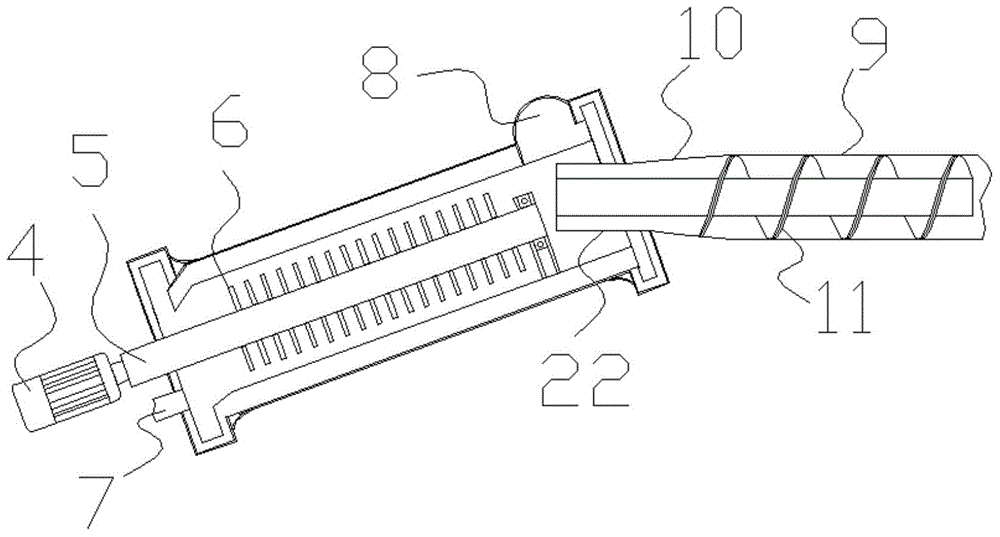

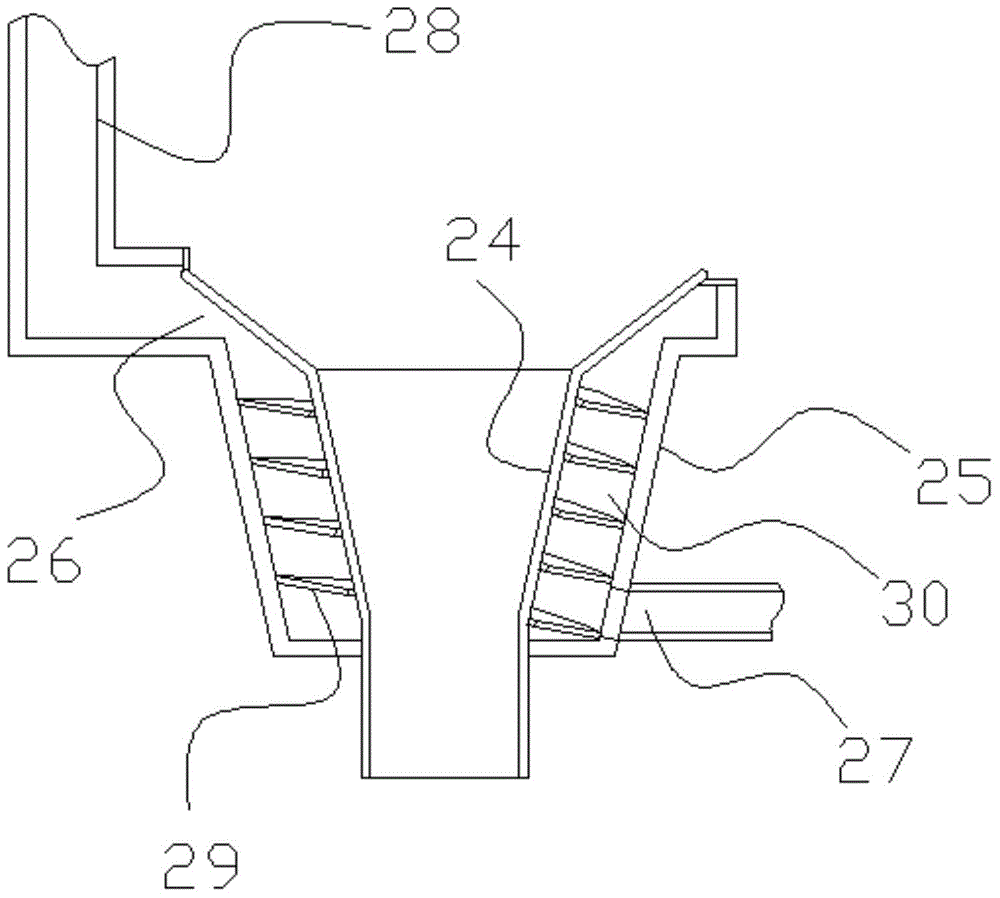

Ash fertilizer firing device

InactiveCN104595913ARealize separation and purificationHas clearedUsing liquid separation agentEnergy inputParticulatesEngineering

The invention discloses an ash fertilizer firing device which can effectively carry out firing on wheat straw in a concentrating mode, a firing process is stable and efficient, full firing can be guaranteed, prepared ash fertilizer is high in purity, generated smoke can be effectively processed, and smoke pollution can be avoided. The ash fertilizer firing device comprises an incineration kiln, a feeding device and a smoke purifying device. An incineration inner cavity is arranged at the incineration kiln. The incineration kiln is oblique, and the angle between the incineration kiln and the horizontal plane is 10-60 degrees. A transmission shaft driven by a main motor is arranged in the incineration inner cavity. A plurality of material dispersing bodies for stirring materials are arranged on the transmission main shaft. An air inlet, a smoke outlet, a feeding opening and a material clearing opening-closing door are arranged on the incineration kiln. The ash fertilizer firing device has the advantages that separating effect is good, removing of solid particles and dust in smoke can be achieved, raw materials are subjected to drying through smoke waste heat, following firing effect is improved, a preheating structure is arranged, and following incineration can be well and fully guaranteed.

Owner:ZHEJIANG SCI-TECH UNIV

Method for recovering and recycling L-tartaric acid

ActiveCN102503810BRealize separation and purificationReduce generationPreparation from carboxylic acid saltsOrganic compound preparationHydrogenWastewater

The invention provides a method for recovering and recycling L-tartaric acid. The method comprises the following steps of: performing acidification and precipitation specific to waste water containing tartaric acid diammonium generated in a process for splitting racemic 4-methylsulfonylphenyl serine ethyl ester to form and separate a tartaric acid hydrogen ammonium salt; and acidizing and desalting to obtain a methanol solution of the L-tartaric acid. The method can be directly applied to the splitting process of racemic 4-methylsulfonylphenyl serine ethyl ester, and the recovery and recycling of the L-tartaric acid are realized. The method provided by the invention has mild reaction conditions and simple process operation, and the production cost of the splitting process can be greatly lowered.

Owner:京山瑞生制药有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com