Method for coproducing collagen activity peptides and flavoured base materials with chicken bones

A collagen and flavor base material technology, applied in protein food processing, protein food ingredients, food science and other directions, can solve the problems of low extraction rate, environmental pollution, low utilization rate of chicken bones, etc., to improve the flavor and improve the degree of hydrolysis , the effect of increasing the effect of enzymatic hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

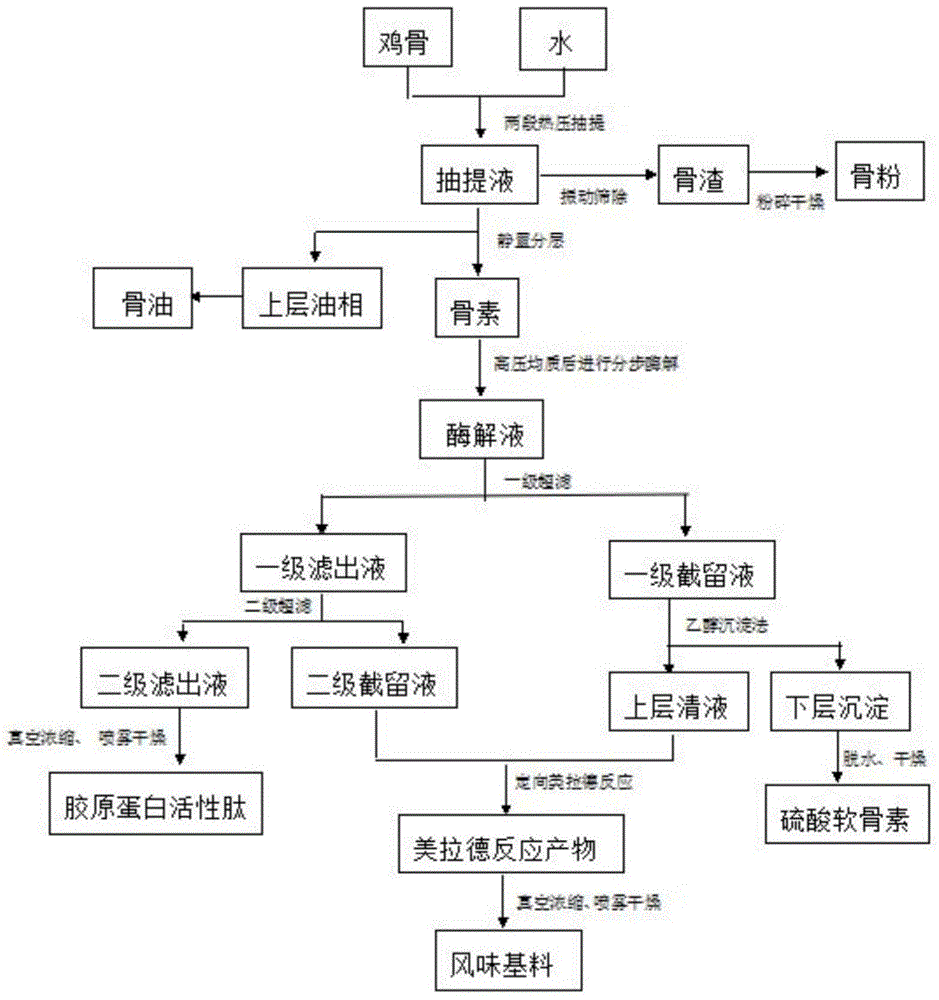

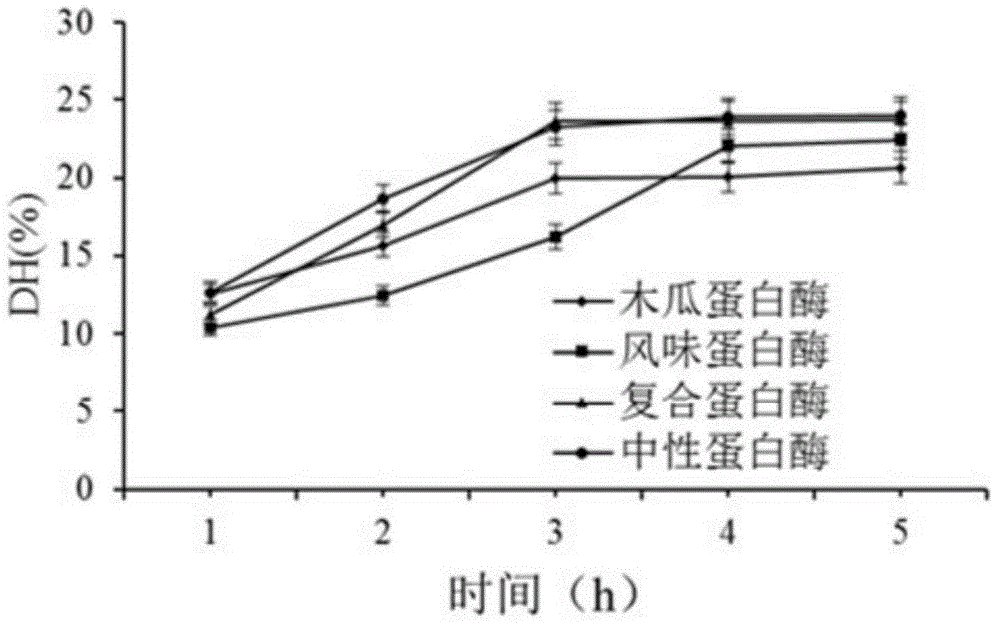

Method used

Image

Examples

preparation example Construction

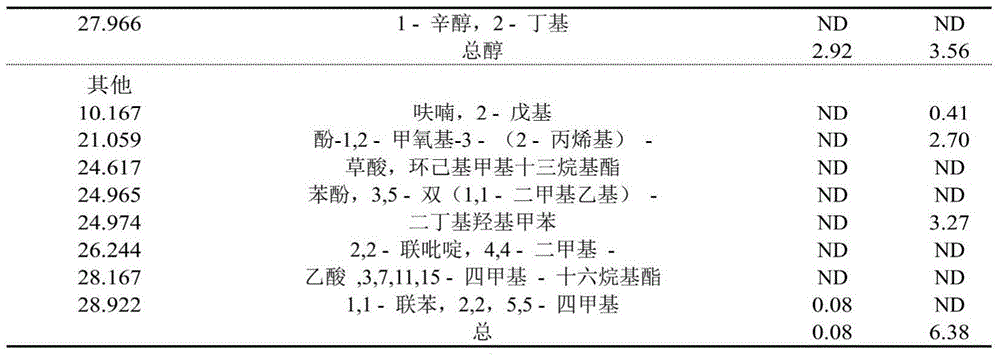

[0042] Step 3, the preparation of the flavor base material, the obtained primary entrapped liquid is processed by ethanol precipitation method, left to settle, the supernatant and the secondary entrapped liquid are mixed to form a Maillard reaction precursor, and the obtained Maillard reaction is The precursor is mixed with a certain amount of xylose, cysteine and thiamine in a hot-pressed reactor and then subjected to a hot-pressed reaction. During the reaction, low-speed stirring is started at a speed of 20-25r / min to obtain a Maillard reaction The product; the resulting Maillard reaction product is cooled to 60-70°C in a sandwich water bath, then transferred to a vacuum concentration tank for vacuum concentration to Brix=40°, the vacuum degree is above 0.08MPa, and the concentrate is spray-dried with a spray dryer Finally, the flavor base material is obtained, wherein the feed temperature of the spray dryer is controlled at 180-190° C., the discharge temperature is control...

Embodiment 1

[0054] Step 1. Rinse 300kg chicken bones with clean water to remove surface blood stain impurities, divide them into three batches and put them into the autoclaved reaction tank respectively, add quantitative clean water according to the mass ratio of 1:2, carry out two-stage hot-press extraction, one-stage hot-press The extraction temperature is 120°C, the extraction time is 120min, the temperature of the second-stage hot-press extraction is 130°C, and the extraction time is 90min. During this period, the pressure is slightly relieved / replenished to improve the product yield. The method is: the end of the second-stage hot-press extraction Finally, open the pressure relief valve of the autoclave reaction tank for 10 minutes, lower the temperature in the autoclave reaction tank by 5°C, close the pressure relief valve for 10 minutes, and increase the temperature by 5°C to return to the original temperature. Repeat this step 3 times.

[0055] Step 2: Remove the bone slag from the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com