Method for improving antioxidant activity of corn peptides by aid of irradiation aided enzymolysis technology

A technology for anti-oxidative activity and auxiliary enzymatic hydrolysis is applied in the field of improving the anti-oxidative activity of corn peptides by means of irradiation-assisted enzymatic hydrolysis technology, which can solve the problems of rough taste, less application, complex composition and the like, and achieves convenient processing and production. The process is simple and the effect of improving the comprehensive utilization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

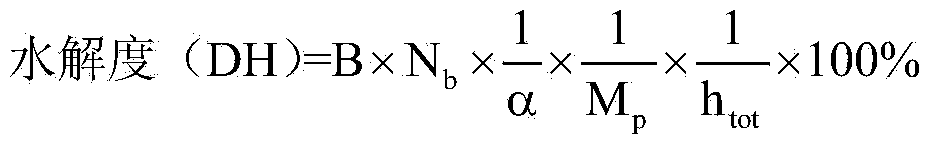

Method used

Image

Examples

Embodiment 1

[0027] Corn gluten powder with a protein content of 45% and a particle size of 160 meshes is used as raw material, packed in ziplock bags according to the weight of each bag of 100g, placed on a conveyor belt with a speed of 5m / h, and transported into the fast neutron electron beam Irradiate in an irradiation room, so that the radiation dose absorbed by the material is 5K, and obtain zein irradiated powder; use zein irradiated powder with a protein content of 45% as the substrate, and prepare the substrate concentration with 20°C purified water according to the weight ratio It is a 4% protein solution system; then use a magnetic stirrer to process the protein solution system, the stirring temperature is controlled at 60°C, and the stirring time is 10min; then it is placed in a water bath at 90°C for 20min, and then cooled to alkaline protease The suitable enzymatic hydrolysis temperature is 50°C, adjust the pH value to 9, add alkaline protease according to the [E] / [S] ratio of ...

Embodiment 2

[0029]Corn gluten powder with a protein content of 48% and a particle size of 150 mesh is used as raw material, packed in ziplock bags according to the weight of each bag of 200g, placed on a conveyor belt with a speed of 2m / h, and transported into the fast neutron electron beam The irradiation room is irradiated circularly, so that the radiation dose absorbed by the material is 36.8K, and the corn gluten irradiation powder is obtained; the corn gluten irradiation powder with a protein content of 48% is used as the substrate, and the bottom is prepared with 25°C deionized water according to the weight ratio. The protein solution system with a concentration of 2%; the protein solution system was processed with a magnetic stirrer, the stirring temperature was controlled at 55 ° C, and the stirring time was 15 min; then placed in a water bath at 92 ° C for 15 min, and cooled to alkali The suitable enzymolysis temperature for protease is 45°C, adjust the pH value to 10, add alkalin...

Embodiment 3

[0031] Corn gluten powder with a protein content of 50% and a particle size of 170 mesh is used as raw material, packed in ziplock bags according to the weight of each bag of 300g, placed on a conveyor belt with a speed of 10m / h, and transported into the fast neutron electron beam The irradiation room was irradiated circularly, so that the radiation dose absorbed by the material was 65K, and the corn gluten irradiation powder was obtained; the corn gluten irradiation powder with a protein content of 50% was used as the substrate, and the substrate concentration was prepared with 30°C distilled water according to the weight ratio. 3% protein solution system; then process the protein solution system with a magnetic stirrer, the stirring temperature is controlled at 50°C, and the stirring time is 25min; then it is placed in a water bath at 88°C for 30min, and cooled to the concentration of alkaline protease. The suitable temperature for enzymatic hydrolysis is 50°C, adjust the pH ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com