Preparation method and use of sunflower seed polypeptide

A sunflower seed and back-up technology is applied in the field of sunflower seed polypeptide preparation, which can solve the problems of protein action site destruction, low yield of small molecular polypeptides, unsuitable for industrialized production, etc., and achieves improved polypeptide yield and strong antioxidant function. , the effect of blocking the synthesis of nitrosamines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] After the sunflower seeds are crushed and degreased, the isolated protein is extracted by alkali-soluble acid precipitation method, 20g of the isolated protein is dissolved in 250mL of water, the pH is adjusted to 9.0, 0.3g of alkaline protease is added, and the ultrasonic power density is 0.3W / cm 2 Place the sonicator in a water bath at 50 °C. It was hydrolyzed at an ultrasonic frequency of 24KHz for 2 hours, during which ultrasonic treatment was performed for 3 minutes every 12 minutes; for the next 2 hours, it was treated at an ultrasonic frequency of 36KHz, and ultrasonic treatment was performed for 1 minute every 8 minutes.

[0022] Adjust pH to 2.5-3.5, temperature 38°C, add 0.9g Aspergillus oryzae acid protease and 1.0g pepsin, mix well, first use 24KHz frequency for 3h hydrolysis, then use 36KHz frequency for ultrasonic hydrolysis for 2h, at this stage, ultrasonic treatment for 3min every 10min Finally, the enzyme was inactivated in a boiling water bath for 8 mi...

Embodiment 2

[0025] After the sunflower seeds are crushed and degreased, the isolated protein is extracted by alkali-dissolving and acid-precipitating method. Dissolve 20g of protein isolate in 300ml of water, adjust the pH to 8.5, add 0.4g of alkaline protease, and make the power density 0.2~0.47W / cm 2 In a 60°C water bath in an ultrasonic generator, hydrolyze at 20KHz ultrasonic frequency for 3 hours, during which ultrasonic treatment is performed for 3 minutes every 10 minutes, and then hydrolyzed at 28KHz ultrasonic frequency for 2 hours, during which ultrasonic treatment is performed for 2 minutes every 10 minutes;

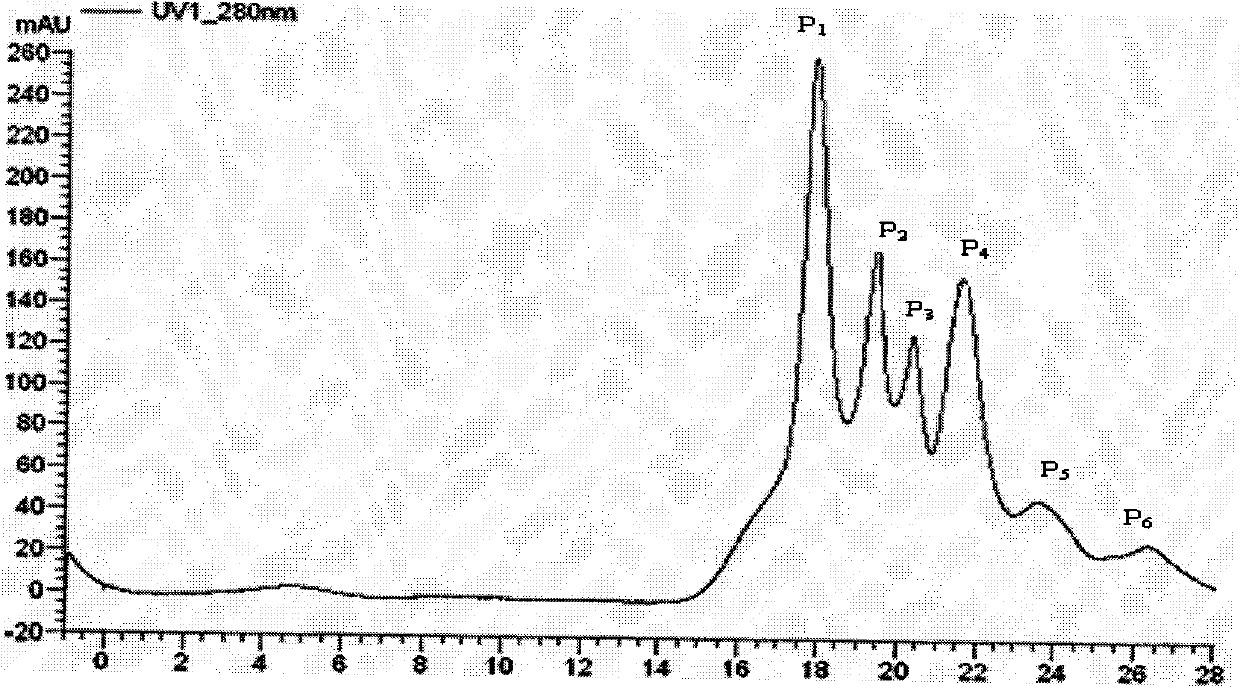

[0026] Use HCl to adjust the pH to 4.0, add 0.85g each of Aspergillus oryzae acid protease and Aspergillus niger acid protease, hydrolyze at 28KHz ultrasonic frequency for 2h; Inactivate the enzyme in the bath for 10 minutes. The degree of proteolysis after two-stage hydrolysis is 17.7%, and the yield of polypeptide is 90.44%. The enzymatic solution is separated and pur...

Embodiment 3

[0029] After the sunflower seeds are crushed and degreased, the isolated protein is extracted by alkali-dissolving and acid-precipitating method. Dissolve 20g of protein isolate in 400mL of water, adjust the pH to 8.0, add 0.5g of alkaline protease, and treat in an ultrasonic generator at 55°C at an ultrasonic frequency of 28KHz for 3 hours, during which time every 10min for 3min, and at an ultrasonic frequency of 32KHz 1h, sonicate for 1min every 8min.

[0030] Adjust the pH to 3.0, add 0.8 g each of Aspergillus oryzae acid protease, Aspergillus niger acid protease and pepsin, hydrolyze at a temperature of 36°C and an ultrasonic frequency of 24-32KHz for 5 hours, and sonicate for 2 minutes every 10 minutes during this period. After hydrolysis, the enzyme was inactivated in a boiling water bath for 10 min. The hydrolysis degree of the sample is 21%, and the peptide yield is 96.75%. The enzymolysis solution is separated and purified by a 0.22 μm microfiltration membrane and a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| control rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com