A method of using tailings powder to improve cement workability

A technology for tailings powder and cement, applied in the field of cement processing, can solve the problems affecting the durability and corrosion resistance of concrete, unreasonable mixing ratio of mixed materials, fine cracks in concrete, etc., and achieves favorable workability and cohesion. , The effect of reducing small cracks and stable compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1. Test the compressive strength of cement with different tailings powder mixed with ordinary cement. The test results are shown in Table 1.

[0022] Table 1

[0023]

[0024] It can be seen from Table 1 that after the ordinary cement is mixed with different proportions of tailings powder, as the amount of tailings powder added increases, the 3-day strength decline trend is more obvious, especially when the tailings powder mixed with more than 5.0% , the decline increased; the 28-day intensity decreased less. When the tailings powder content is 5.0%, the 3-day strength decreases by about 2.6MPa, but it is still higher than the national standard of 4.4MPa (3-day compressive strength ≥ 21MPa), which has a good effect.

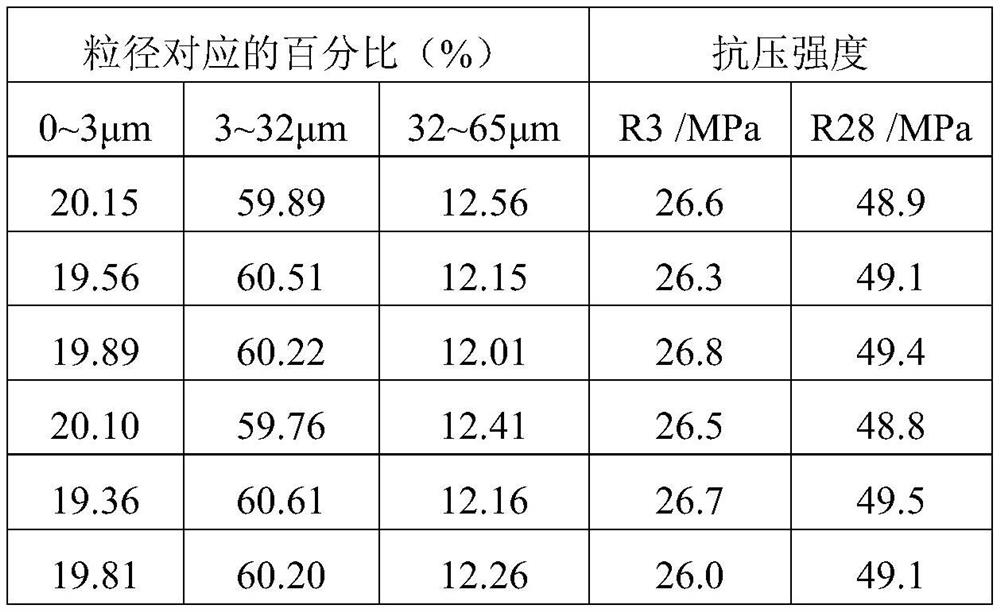

[0025] 2. Test the compressive strength of cement with different proportions of the material particle size in ordinary cement. The test results are shown in Table 2.

[0026] Table 2

[0027]

[0028] It can be seen from Table 2 that the best effe...

Embodiment 2

[0038] 1. Adjust the grinding equipment parameters:

[0039] Adjust the gradation of the mill; make the ratio of the average ball diameter of the mill to the diameter of the material entering the mill be 20:1; select the lining plate and the discharge grate plate according to the specifications of the grinding body in the fine grinding chamber, so that the gap between the grinding tail grate plate is ≤8mm; Regularly clean the granular material on the grate plate every 20 days to ensure the normal function of ventilation and feeding; optimize the process parameters of ventilation in the mill and V-selection speed, control the frequency of the V-selection speed inverter at 13Hz, and adjust the frequency conversion of the exhaust fan at the end of the mill tor frequency at 35Hz.

Embodiment 3

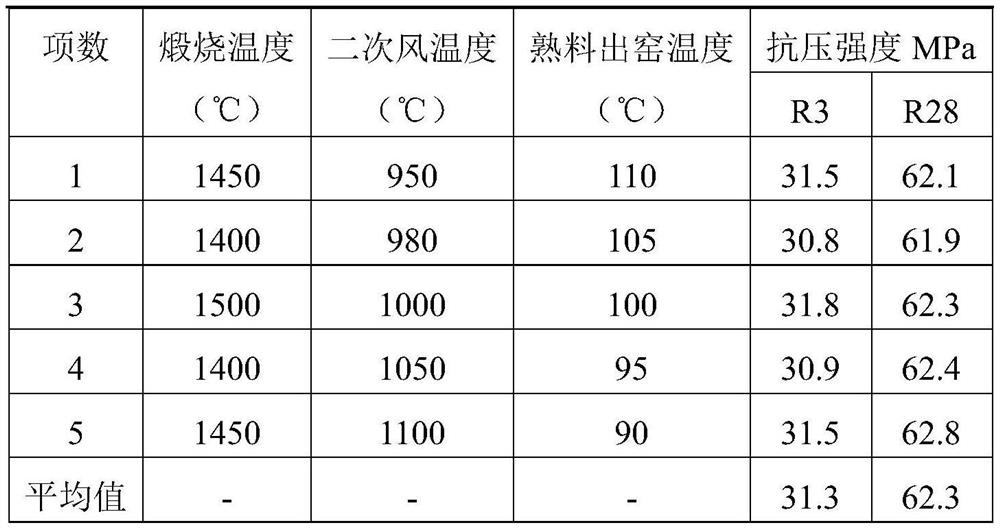

[0041] Prepare clinker and adjust the parameters of the clinker calcination process:

[0042] (1) Increase the calcination temperature: the fuel coal powder is ground to a fineness of 0.08 mm and the sieve residue is lower than 10%. %, calorific value is 25000kj / kg;

[0043] (2) Improve the stability of coal ash entering the kiln: each shift takes a sample on the coal conveyor belt every 30 minutes to check the industrial analysis of coal, grasp the situation of coal ash in time, and ensure the stability of coal ash entering the kiln;

[0044] (3) Improve the thermal system: set the secondary air temperature to 1100°C, ensure that the free calcium of the clinker is 1.1%, the vertical lift weight is not less than 1200g / L, and set the clinker temperature of the grate cooler to 90°C; The clinker calcining temperature is not lower than 1450° C., and the calcining time is 30 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com