Base silicon wafer used for preparing cut silicon wafers and preparation method and purpose

A silicon wafer and basic technology, applied in the field of solar cell preparation, can solve problems such as cell fragmentation, and achieve the effects of reducing attenuation, reducing the generation of fine cracks, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

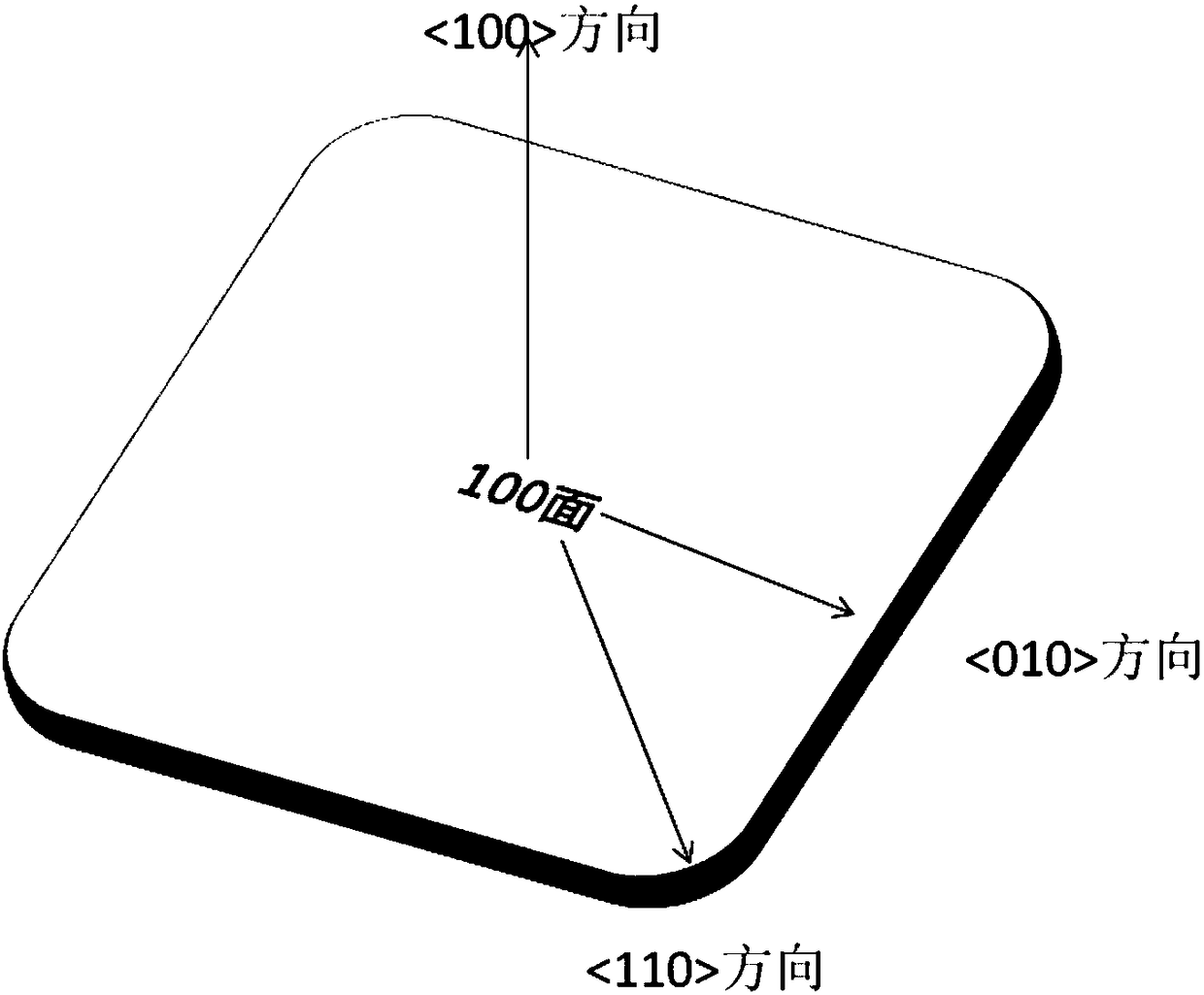

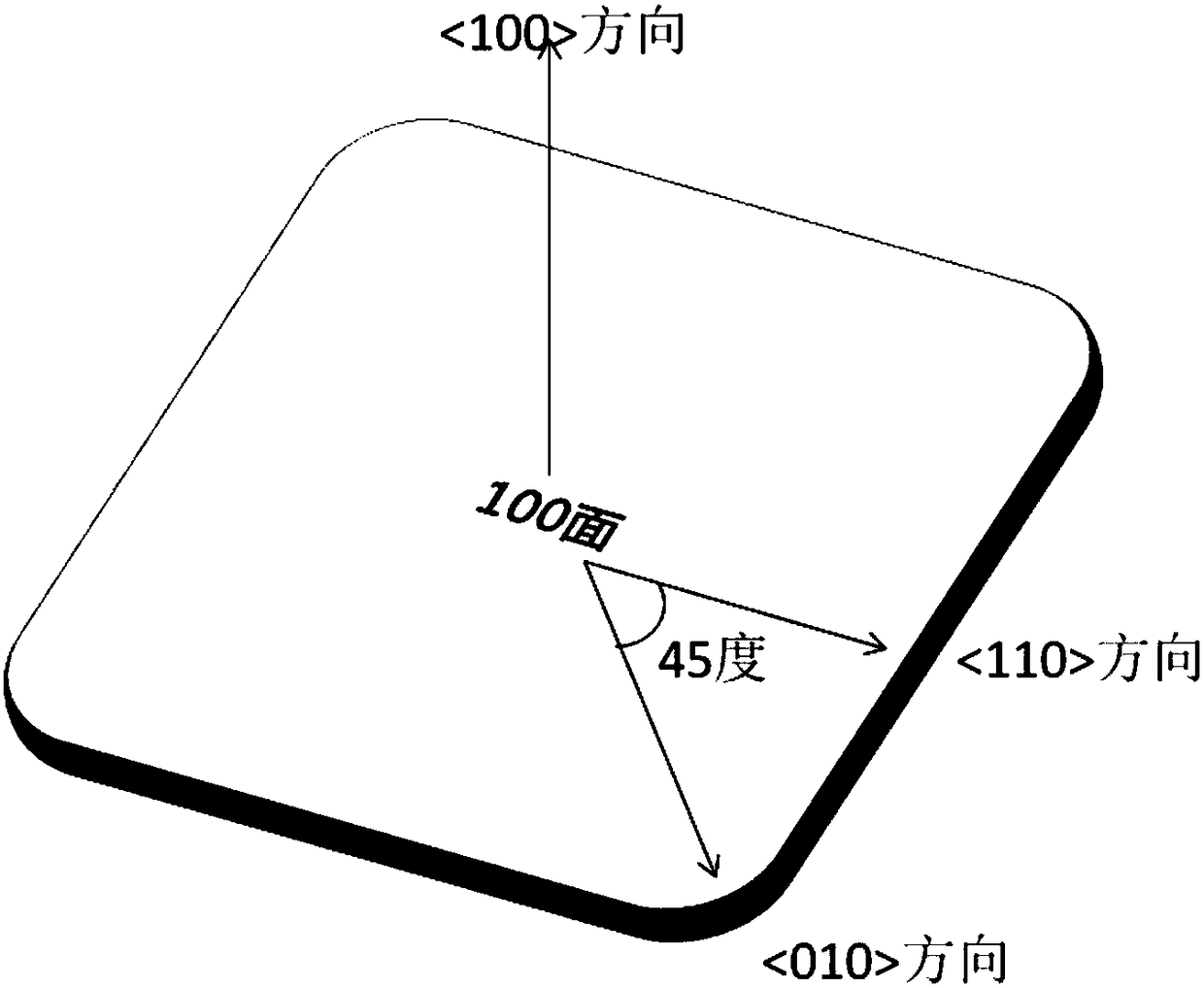

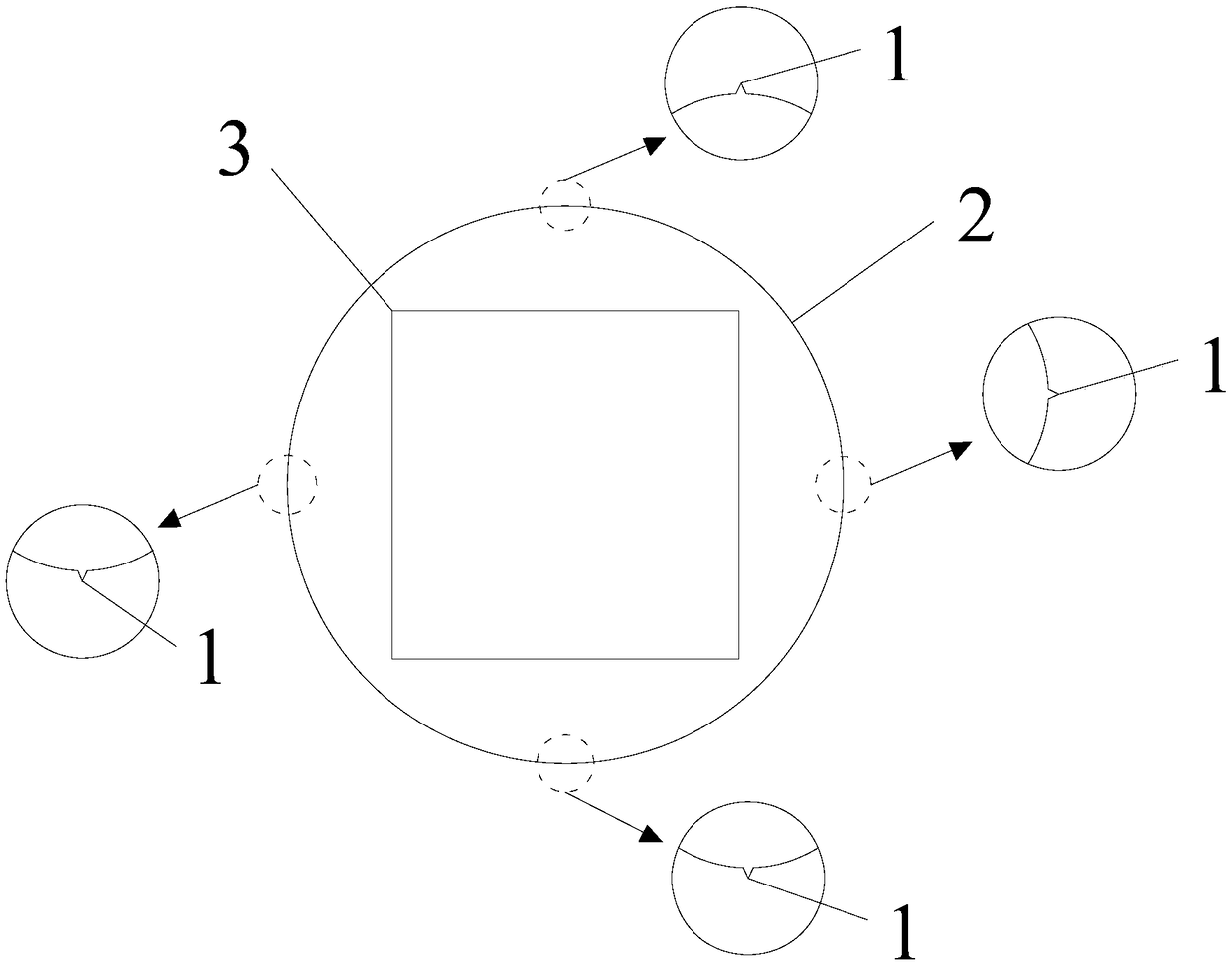

[0038] A cutting silicon wafer, prepared by the following method:

[0039] (1) Take a 0.5m long single crystal silicon rod with a diameter of 220mm and cut it into a silicon square rod with an end face side length of 156mm. The end face of the silicon square rod is parallel to the end face of the single crystal silicon rod. The extension line connecting the midpoint of the side length of the end face of the square rod and the center of the end face of the silicon square rod passes through the point on the cross section of the single crystal silicon rod through the corrugated line;

[0040] (2) According to the predetermined silicon wafer thickness of 180 μm, the silicon square rod is cut to obtain the basic silicon wafer; the surface of the basic silicon wafer is parallel to the end surface of the silicon square rod;

[0041] (3) The basic silicon wafer of step (2) is cut into 2 pieces in a direction parallel to the length of either side, and a total of 20,000 cut silicon wafers are ...

Embodiment 2

[0043] A cutting silicon wafer, prepared by the following method:

[0044] (1) Take a 0.3m long single crystal silicon rod with a diameter of 225mm and cut it into a silicon square rod with an end face side length of 156mm. The end face of the silicon square rod is parallel to the end face of the single crystal silicon rod. The extension line connecting the midpoint of the side length of the end face of the square rod and the center of the end face of the silicon square rod passes through the point on the cross section of the single crystal silicon rod through the corrugated line;

[0045] (2) According to a predetermined silicon wafer thickness of 120 μm, the silicon square rod is cut to obtain a basic silicon wafer; the surface of the basic silicon wafer is parallel to the end surface of the silicon square rod;

[0046] (3) Cut the basic silicon wafer of step (2) into 4 pieces in a direction parallel to the length of any side, and cut a total of 40,000 cut silicon wafers, which hav...

Embodiment 3

[0049] A cutting silicon wafer, prepared by the following method:

[0050] (1) Take a 0.6m long single crystal silicon rod with a diameter of 220mm and cut it into a silicon square rod with an end face side length of 156mm. The end face of the silicon square rod is parallel to the end face of the single crystal silicon rod. The extension line connecting the midpoint of the side length of the end face of the square rod and the center of the end face of the silicon square rod passes through the point on the cross section of the single crystal silicon rod through the corrugated line;

[0051] (2) According to the predetermined silicon wafer thickness of 220 μm, the silicon square rod is cut to obtain the basic silicon wafer; the surface of the basic silicon wafer is parallel to the end surface of the silicon square rod;

[0052] (3) Cut the basic silicon wafer of step (2) into 2 pieces in a direction parallel to the length of any side, and cut a total of 20,000 pieces of cut silicon waf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com