Chip for two-way voltage regulator diode DB3 and manufacturing technique thereof

A technology of two-way voltage stabilization and production process, which is applied in the photoengraving process, optics, instruments and other directions of the pattern surface, which can solve the problem of high corrosion debris rate in deep mesa grooves, insufficient high temperature rebound voltage, and insufficient breakdown voltage. and other problems, to achieve the effect of improving voltage resistance stability, reducing high temperature power consumption, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

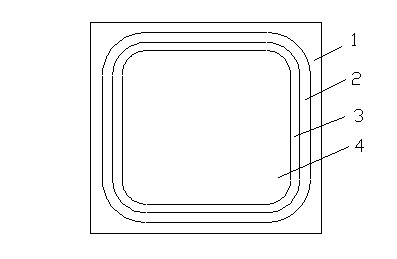

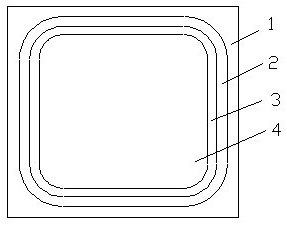

[0023] Such as figure 1 The chip structure of the bidirectional Zener diode DB3 shown is N + PN + type. The chip sections are chip 1 of DB3, mesa groove 2, glass layer 3, and metal surface 4 in sequence.

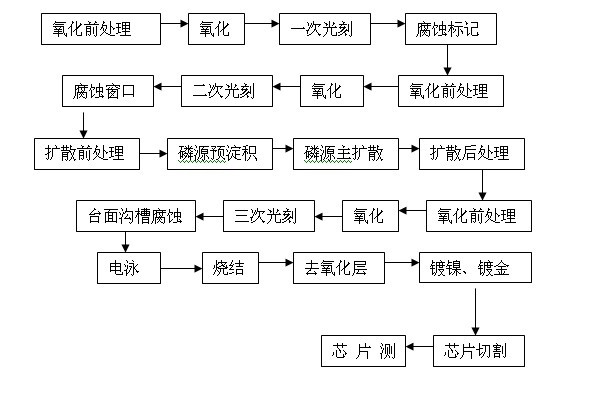

[0024] Such as figure 2 The production process of the shown bidirectional voltage regulator diode DB3 is as follows:

[0025] 1) Pre-oxidation treatment: chemically treat the surface of silicon wafers through acid, alkali, deionized water and other processes.

[0026] 2) Oxidation: Clean the original silicon wafer, grow an oxide layer in an oxidation furnace at 1100-1200 ° C as a mask, and prepare to open windows and trenches;

[0027] 3) Three photolithography: the oxidized silicon wafer is coated with glue, photolithographic mark, photolithographic window, photolithographic table top, exposure, development, deoxidation layer and other processes, and the marking, window, and table top graphics are engraved.

[0028] 4) Pre-diffusion treatment: chemically treat the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com