Back-contact solar cell module

A solar cell and back contact technology, applied in the field of solar cells, can solve the problems affecting the uniformity of the carrier transmission path, the uneven distribution of the hole metal electrodes, and the inability to realize the automation of component welding, so as to facilitate industrial application and save String welding steps, the effect of reducing welding workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

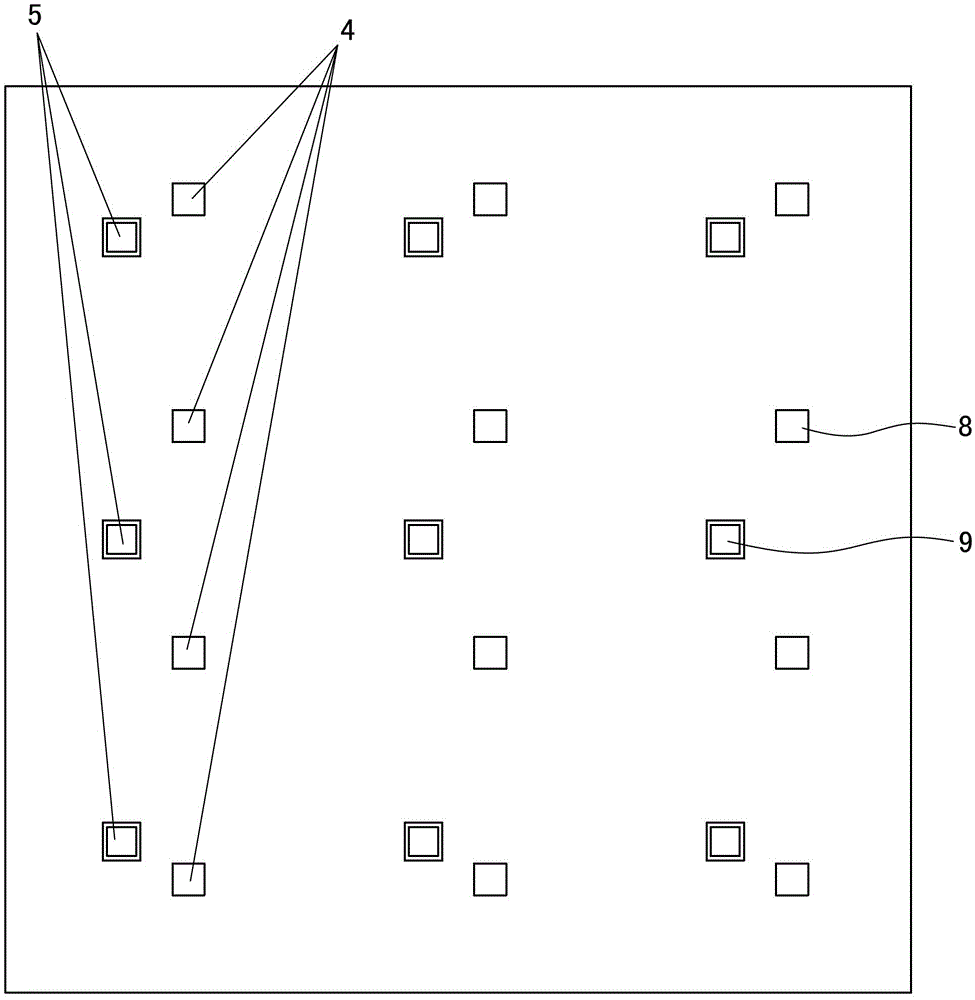

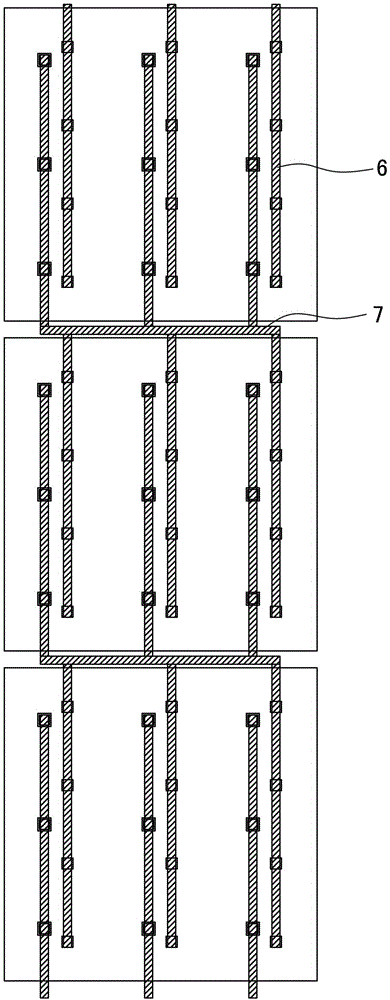

[0042] see figure 1 , 3 As shown, a back-contact solar cell module includes a series and adjacent first battery sheet 1, second battery sheet 2 and third battery sheet 3, and each battery sheet is provided with 3 sets of back electrode columns 4 and 3 sets of holes 5 metal electrode columns; the number of back electrode columns on each battery sheet is the same as the number of hole metal electrode columns; and the electrode arrangement structure on adjacent battery sheets is the same, that is, the electrode arrangement structure of each battery sheet in the assembly is Are the same;

[0043] The hole metal electrode row of the first battery sheet is directly connected with the back electrode row on the adjacent second battery sheet in the form of a zigzag line through the flow guide 6;

[0044] The hole metal electrode row of the second battery sheet is directly connected with the back electrode row on the adjacent third battery sheet in the form of a zigzag line through t...

Embodiment 2

[0052] see Figure 4 As shown, a back-contact solar cell assembly includes a series and adjacent first cell, a second cell and a third cell, the structure of which is the same as that of Embodiment 1;

[0053] The hole metal electrode row of the first battery sheet is directly connected with the back electrode row on the adjacent second battery sheet in the form of a zigzag line through the flow guide 6;

[0054] The hole metal electrode row of the second battery sheet is directly connected with the back electrode row on the adjacent third battery sheet in the form of a zigzag line through the flow guide.

[0055] In this embodiment, the flow guides on each electrode column and the flow guides between battery sheets are connected with the shortest distance.

Embodiment 3

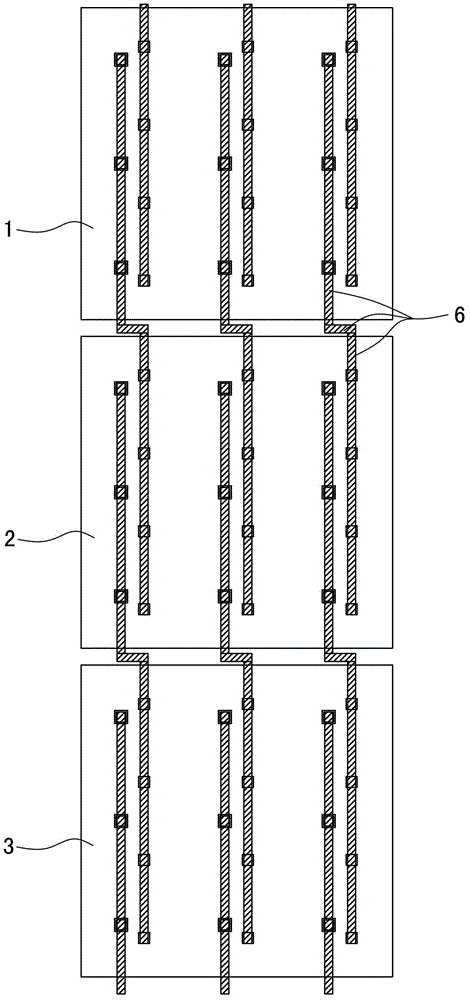

[0057] see Figure 5~6 As shown, a back-contact solar cell module includes a series of adjacent first cells, a second cell and a third cell, and each cell is provided with 4 rows of back electrode rows and 4 rows of hole metal electrode rows ; The number of back electrode columns on each battery sheet is the same as the number of hole metal electrode columns; and the electrode arrangement structure on adjacent battery sheets is the same, that is, the electrode arrangement structure of each battery sheet in the module is the same;

[0058] The back electrode row of the first battery sheet and the hole metal electrode row on the adjacent second battery sheet are directly connected in a broken line through the guide 6;

[0059] The back electrode row of the second battery sheet is directly connected with the hole metal electrode row on the adjacent third battery sheet in the form of a zigzag line through the flow guide.

[0060] The porous metal electrodes on the battery sheet a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com