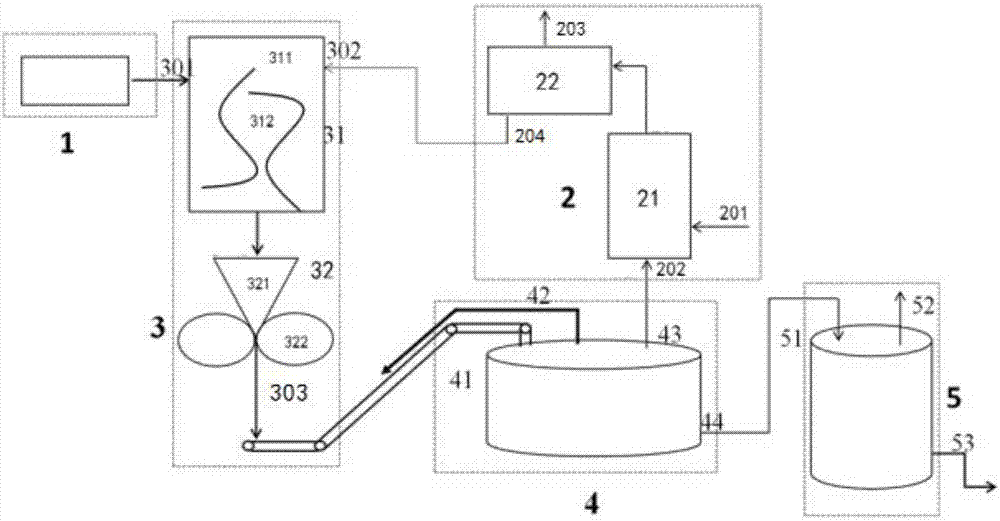

System and method for comprehensive treatment of garbage and carbide slag

A comprehensive treatment, calcium carbide slag technology, applied in the chemical industry, can solve the problems of high heavy metal content, low pyrolysis efficiency, high ash content, etc., to achieve the effect of reducing heavy metal content, increasing surface area, and reducing ceramsite bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

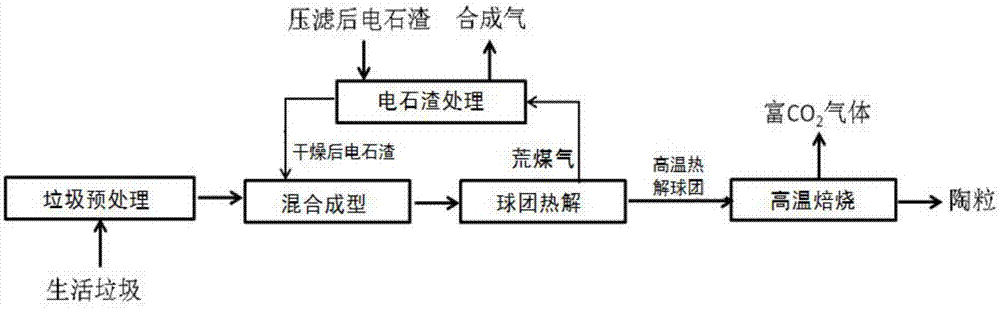

Method used

Image

Examples

Embodiment 1

[0064] The air-dry garbage (10t / h) is sequentially processed through bag breaking, roller screening, and then sorted and crushed so that the particle size of the garbage is ≤15mm and the water content is 40%. The obtained powdery calcium carbide slag (5t / h) is mixed according to the mass ratio of 1:0.5, and pressed into a high-pressure briquetting machine; the obtained pellets are transported to the material plate of the anaerobic pyrolysis device, and the material thickness is 80mm ; The pellets pass through the preheating zone, pyrolysis zone 1 and pyrolysis zone 2 in order to complete anaerobic pyrolysis, and obtain high value-added raw coal gas and high-temperature pyrolysis pellets. The temperature in the preheating zone is 400°C. The temperature of the pyrolysis zone 1 is 750°C, the temperature of the pyrolysis zone 2 is 800°C, and the pyrolysis time is 90 minutes; the high-temperature pyrolysis pellets are directly transported to the high-temperature calciner for calcina...

Embodiment 2

[0066] The process of comprehensive treatment of garbage and calcium carbide slag in this embodiment is the same as in Example 1, but the process parameters are different, as follows:

[0067] The air-dried garbage is processed in turn by bag breaking, roller sieving, and then sorted and crushed so that the particle size of the garbage is ≤15mm and the water content is 40%. The slag is mixed according to the mass ratio of 1.2:1, and pressed into a high-pressure briquetting machine; the obtained pellets are transported to the material plate of the anaerobic pyrolysis device, and the material thickness is 80 mm; the pellets are preheated in turn in the furnace Zone, Pyrolysis Zone 1 and Pyrolysis Zone 2 complete anaerobic pyrolysis to obtain high value-added raw coal gas and high-temperature pyrolysis pellets. The temperature in the preheating zone is 400°C, the temperature in the The temperature in the second pyrolysis zone is 800°C, and the pyrolysis time is 60 minutes; the hi...

Embodiment 3

[0069] The process of comprehensive treatment of garbage and calcium carbide slag in this embodiment is the same as in Example 1, but the process parameters are different, as follows:

[0070] The air-dried garbage is processed by bag breaking, roller sieving, and then sorted and crushed, so that the particle size of the garbage is ≤15mm and the water content is 45%. The slag is mixed according to the mass ratio of 0.8:1, and pressed into a high-pressure briquetting machine; the obtained pellets are transported to the material plate of the anaerobic pyrolysis device, and the material thickness is 70 mm; the pellets are preheated in turn in the furnace zone, pyrolysis zone 1 and pyrolysis zone 2 complete anaerobic pyrolysis to obtain high value-added raw coal gas and high-temperature pyrolysis pellets. The temperature in the preheating zone is 500°C, the temperature in the The temperature in the second pyrolysis zone is 850°C, and the pyrolysis time is 30 minutes; the high-temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com